Motor rotor, motor and compressor

A motor rotor and rotor core technology, which is applied in the fields of compressors, motor rotors, and motors, can solve the problems of high manufacturing cost, low utilization rate, and high permanent magnet consumption of rotors and even motors, so as to improve utilization rate, reduce consumption, and reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

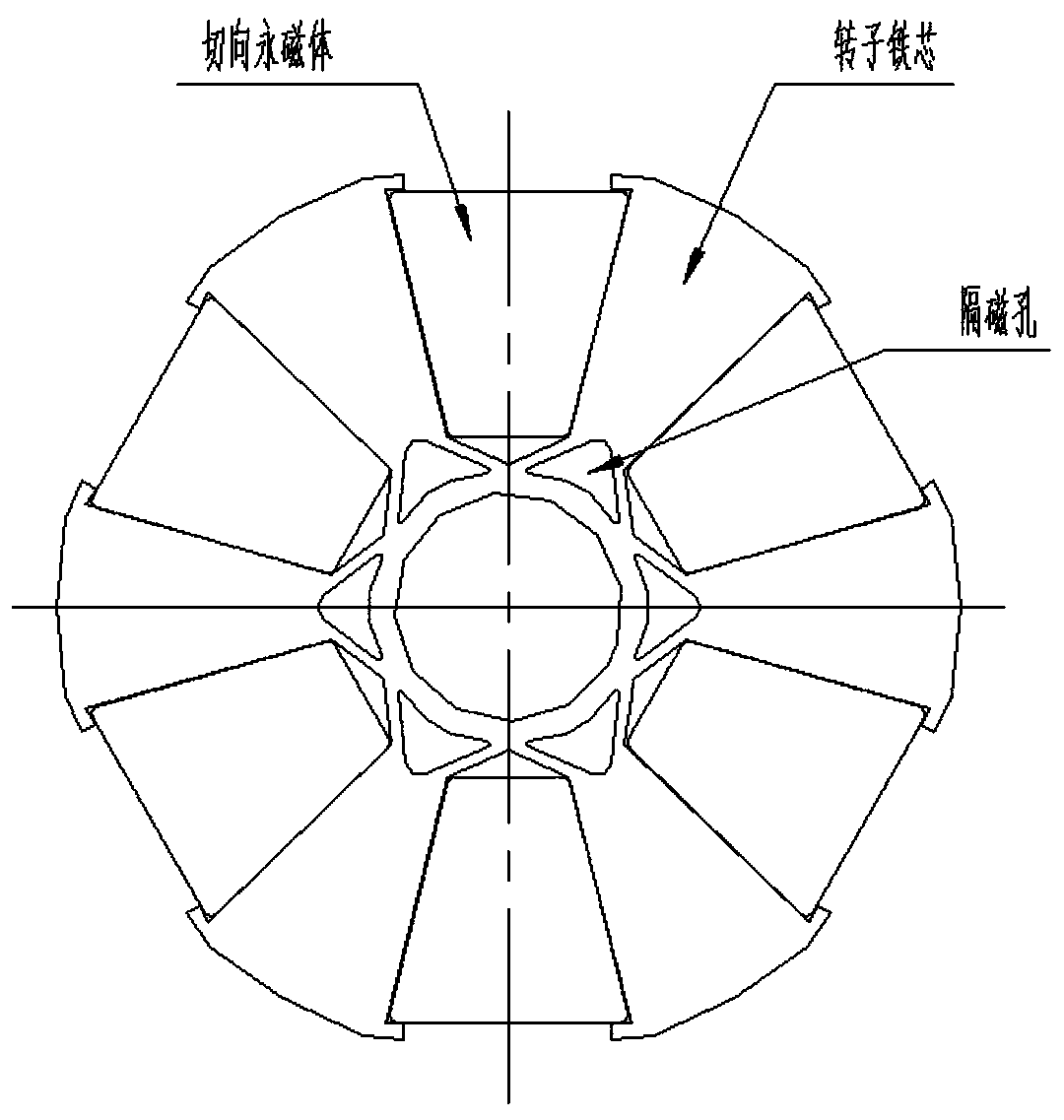

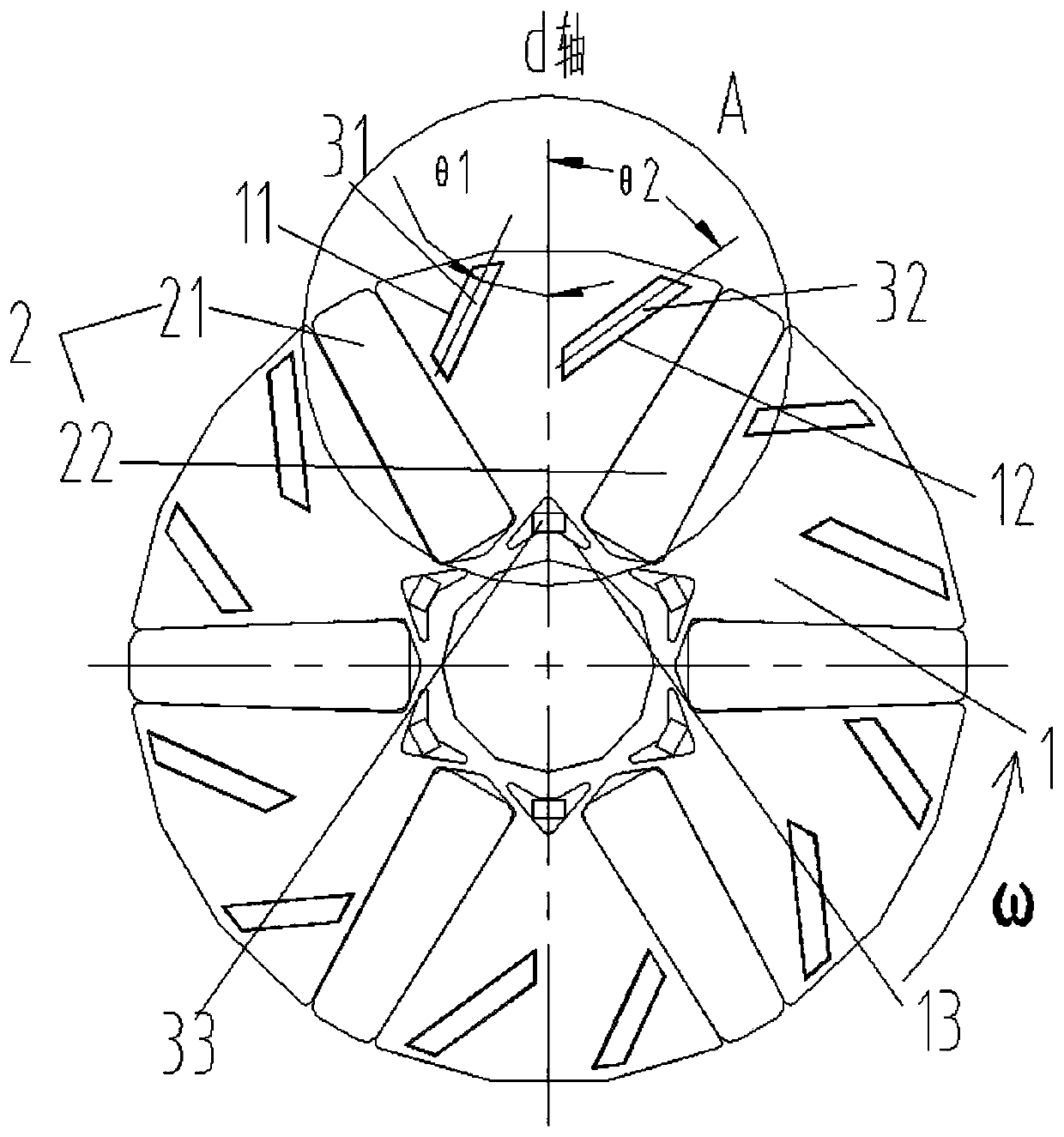

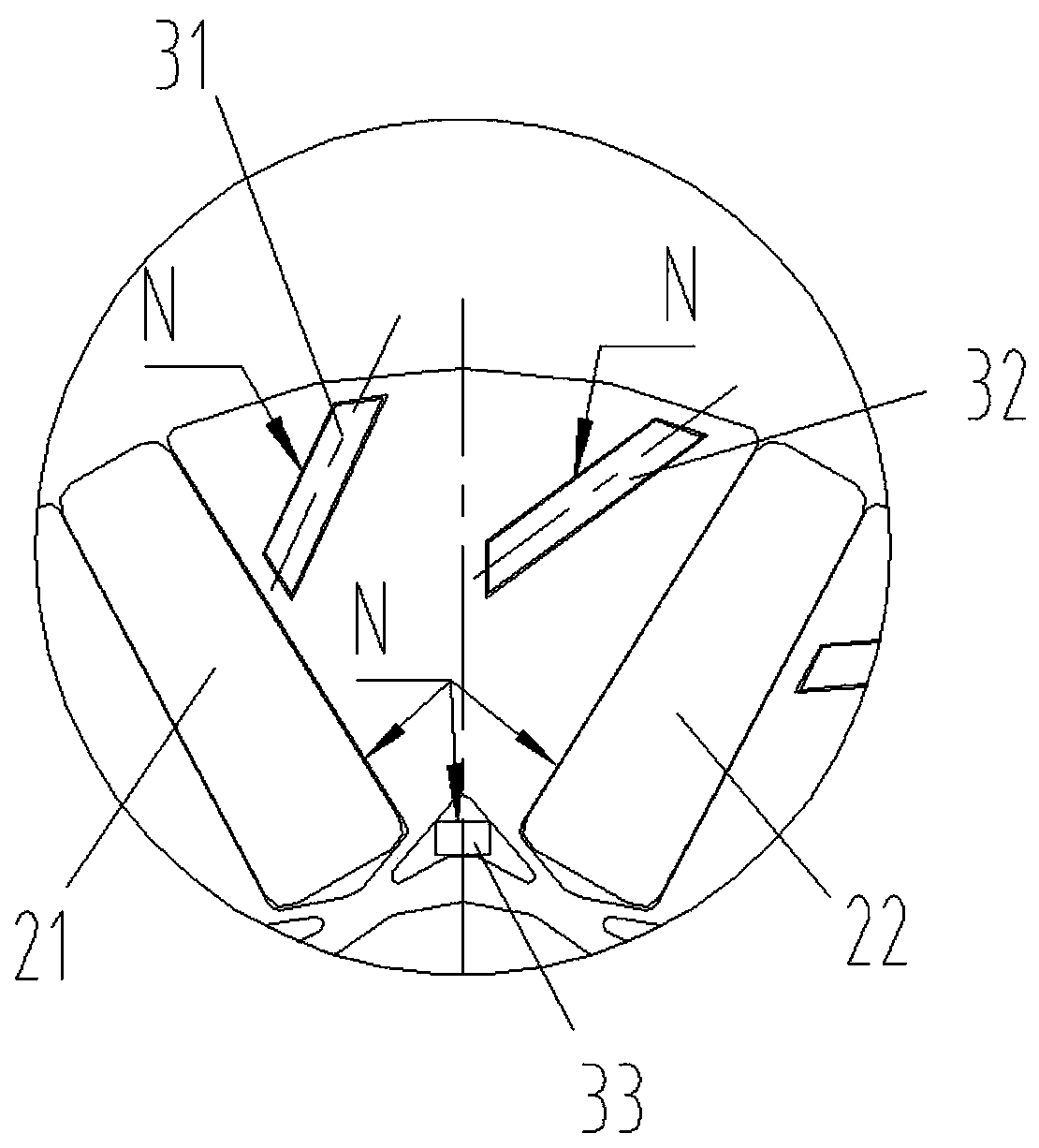

[0025] see in conjunction Figure 2 to Figure 5 As shown, according to an embodiment of the present invention, a motor rotor is provided, including a rotor core 1, M tangential permanent magnets 2 arranged at intervals along the circumference of the rotor core 1, and the tangential permanent magnets 2 are arranged along the The radial direction of the rotor core 1 extends, and the rotor core 1 between any two adjacent tangential permanent magnets 2 is configured with a first magnetic isolation slot 11, which is perpendicular to the rotor core. On any section of the axis of 1, the extension direction of the first magnetic isolation slot 11 forms an angle θ1 with the d-axis, 0°<θ1<90°, any two adjacent tangential permanent magnets 2 The opposite side has the same polarity, and the first magnetic isolation slot 11 has a first end close to the axis of the rotor core 1 and a second end far away from the axis of the rotor core 1, along the In the direction of rotation of the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com