Technology for producing casting polypropylene (CPP) film laser holographic film

A technology of laser holography and production technology, which is applied in printing devices, printing, copying/marking methods, etc., can solve the problems of time-consuming nickel plate, low production efficiency, and troublesome plate mounting, and avoid short service life of nickel plate and production cost The effect of low, efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

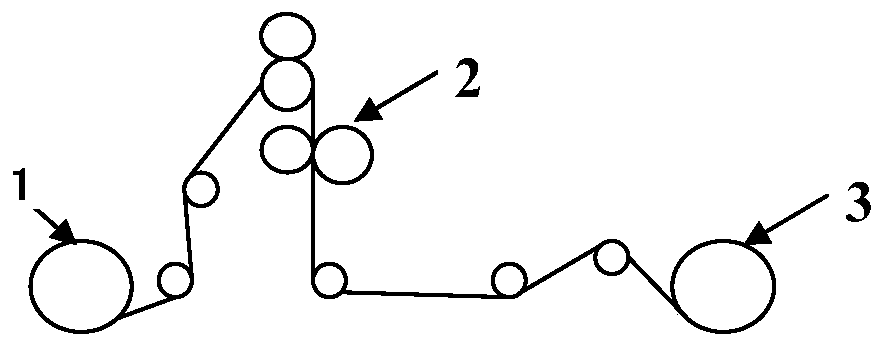

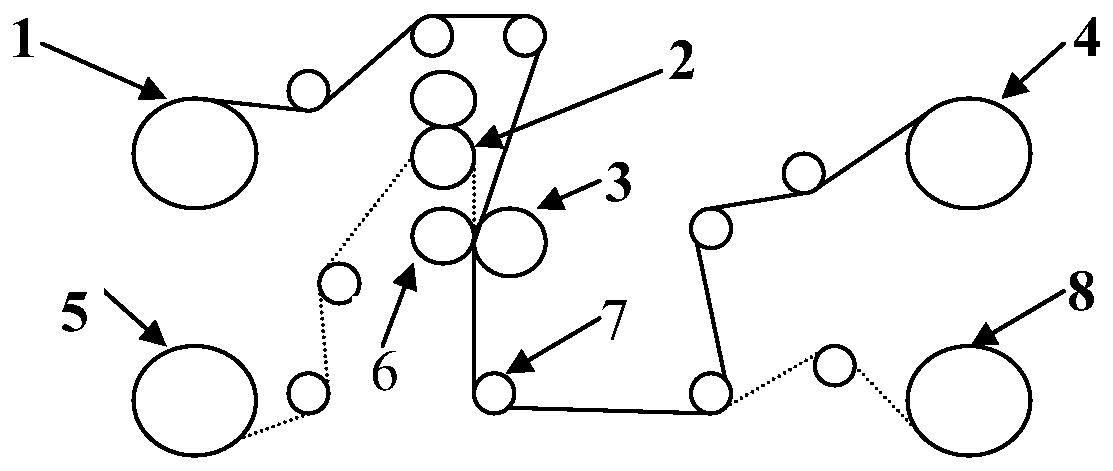

[0023] A kind of production technology of CPP film laser holographic film, it comprises the following steps, and please refer to figure 2 :

[0024] Step 1, use the holographic master film 1 to replace the holographic nickel plate, then use the preheating roller 2 to preheat the transparent sub-film 5 to 60°C, and stack the holographic master film 1 on the single-version roller 3, so that the holographic master film 1 and the transparent sub-film The film 5 is overlapped, and the rubber roller 6 is squeezed with the single-plate roller 3 to complete the laser transfer;

[0025] Step 2, pass the holographic mother film 1 to be lasered through the gap between the rubber roller 6 and the single-plate roller 3, and introduce the transparent sub-film 5 to be lasered into the tension roller 7 at the same time, the holographic mother film 4 and the transparent sub-film 5 The finished product 8 passes through the tension roller to the coupon collection output port; wherein, the tens...

Embodiment 2

[0028] A kind of production technology of CPP film laser holographic film, it comprises the following steps, and please refer to figure 2 :

[0029] Step 1: Use the holographic master film 1 to replace the holographic nickel plate, then use the preheating roller 2 to preheat the transparent sub-film 5 to 55°C, and stack the holographic master film 1 on the single-version roller 3 to make the holographic master film 1 and the transparent sub-film The film 5 is overlapped, and the rubber roller 6 is squeezed with the single-plate roller 3 to complete the laser transfer;

[0030] Step 2, pass the holographic mother film 1 to be lasered through the gap between the rubber roller 6 and the single-plate roller 3, and introduce the transparent sub-film 5 to be lasered into the tension roller 7 at the same time, the holographic mother film 4 and the transparent sub-film 5 The finished product 8 passes through the tension roller to the coupon collection output port; wherein, the tensi...

Embodiment 3

[0033] A kind of production technology of CPP film laser holographic film, it comprises the following steps, and please refer to figure 2 :

[0034] Step 1, use the holographic master film 1 to replace the holographic nickel plate, then use the preheating roller 2 to preheat the transparent sub-film 5 to 65°C, and stack the holographic master film 1 on the single-plate roller 3, so that the holographic master film 1 and the transparent sub-film The film 5 is overlapped, and the rubber roller 6 is squeezed with the single-plate roller 3 to complete the laser transfer;

[0035] Step 2, pass the holographic mother film 1 to be lasered through the gap between the rubber roller 6 and the single-plate roller 3, and introduce the transparent sub-film 5 to be lasered into the tension roller 7 at the same time, the holographic mother film 4 and the transparent sub-film 5 The finished product 8 passes through the tension roller to the coupon collection output port; wherein, the tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com