Ship mooring chain manufacturing device

A chain control and mooring technology, which is applied to ships and other directions, can solve the problem that the height of the ship mooring chain control cannot be adjusted according to the needs of use, and achieve the effects of convenient adjustment, improved stability, and guaranteed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

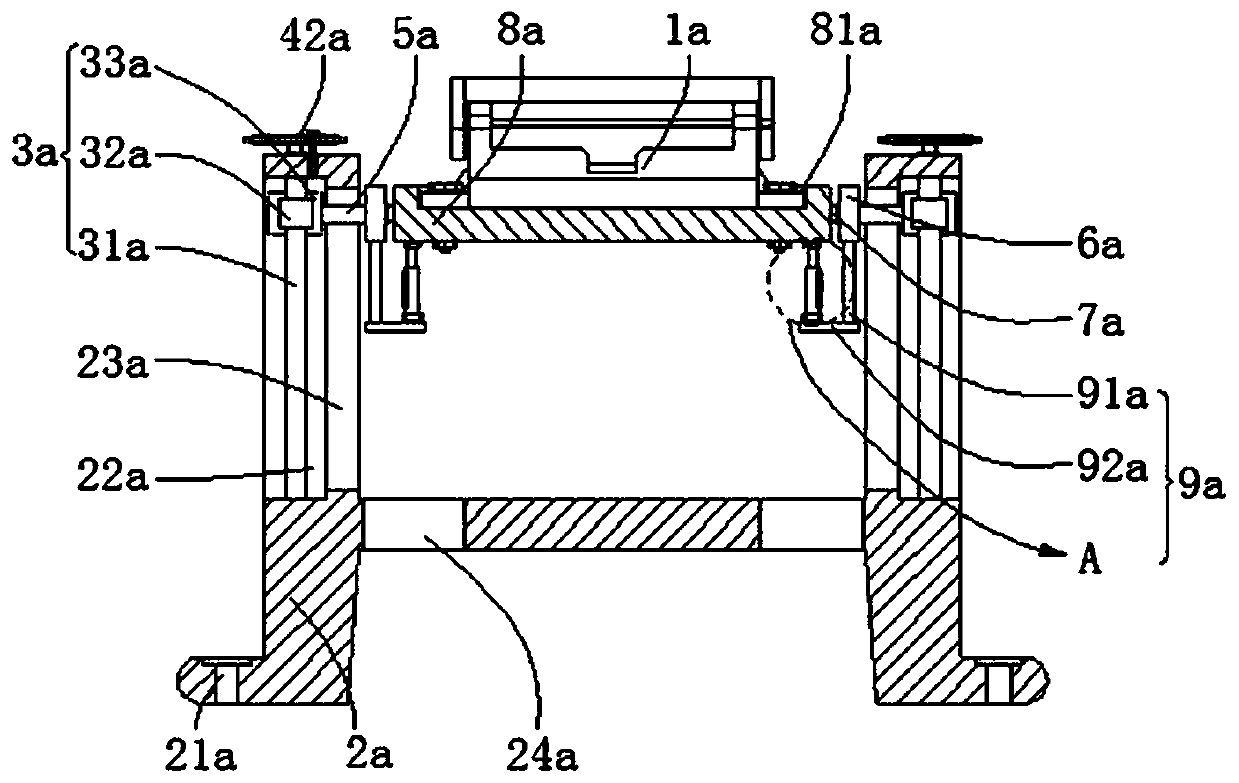

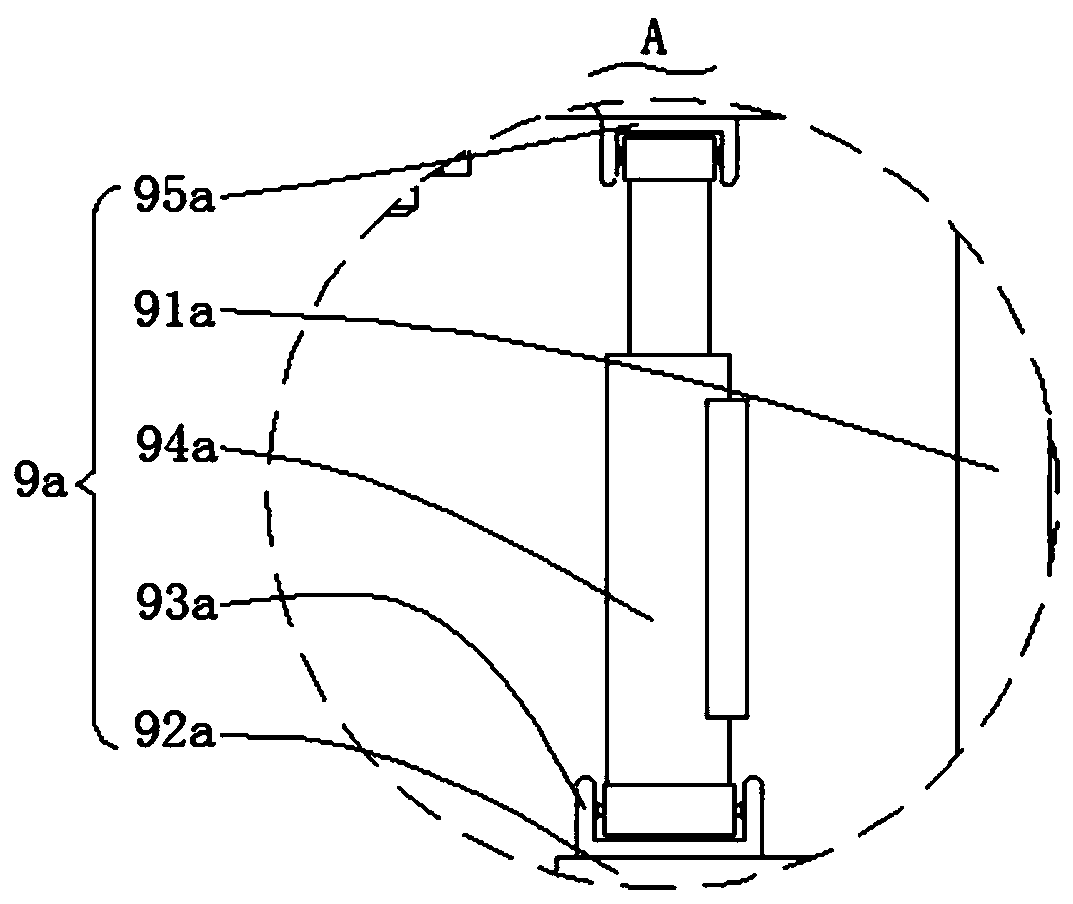

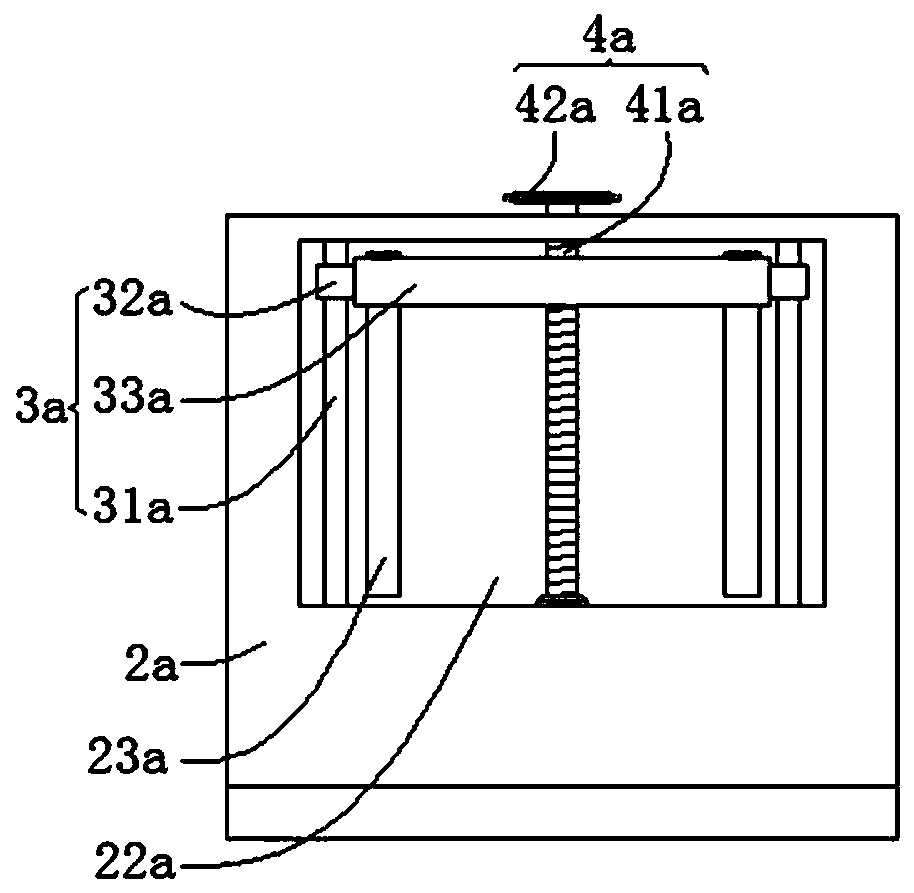

[0061] S1 by turning the adjusting disc 42a, the adjusting disc 42a drives the adjusting rod 41a to rotate synchronously. When the adjusting rod 41a rotates, it drives the movable plate 33a to move up and down synchronously. When the movable plate 33a moves upwards, the movable plate 33a drives the linkage rod 5a to move synchronously. 5a synchronously drives the linkage plate 6a to move upward, and the linkage plate 6a drives the lifting frame 8a to adjust upward through the rotating shaft 7a, so as to facilitate the adjustment of the height of the chain stopper body 1a above the lifting frame 8a;

[0062] S2 When it is necessary to lower the height of the chain brake body 1a, it is only necessary to reversely turn the adjustment dial 42a, the adjustment dial 42a drives the movable plate 33a to adjust downward through the adjustment rod 41a, and the movable plate 33a drives the linkage plate 6a through the linkage rod 5a Synchronously move downwards, the linkage plate 6a drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com