Railway sleeper bolt rust removal protection device

A protective device and sleeper technology, which is applied in the field of railway sleeper bolt rust removal and protection devices, can solve the problems of low rust removal efficiency and poor rust removal quality of sleeper bolts, and achieve the effects of good adaptability, comprehensive rust removal, and improved fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

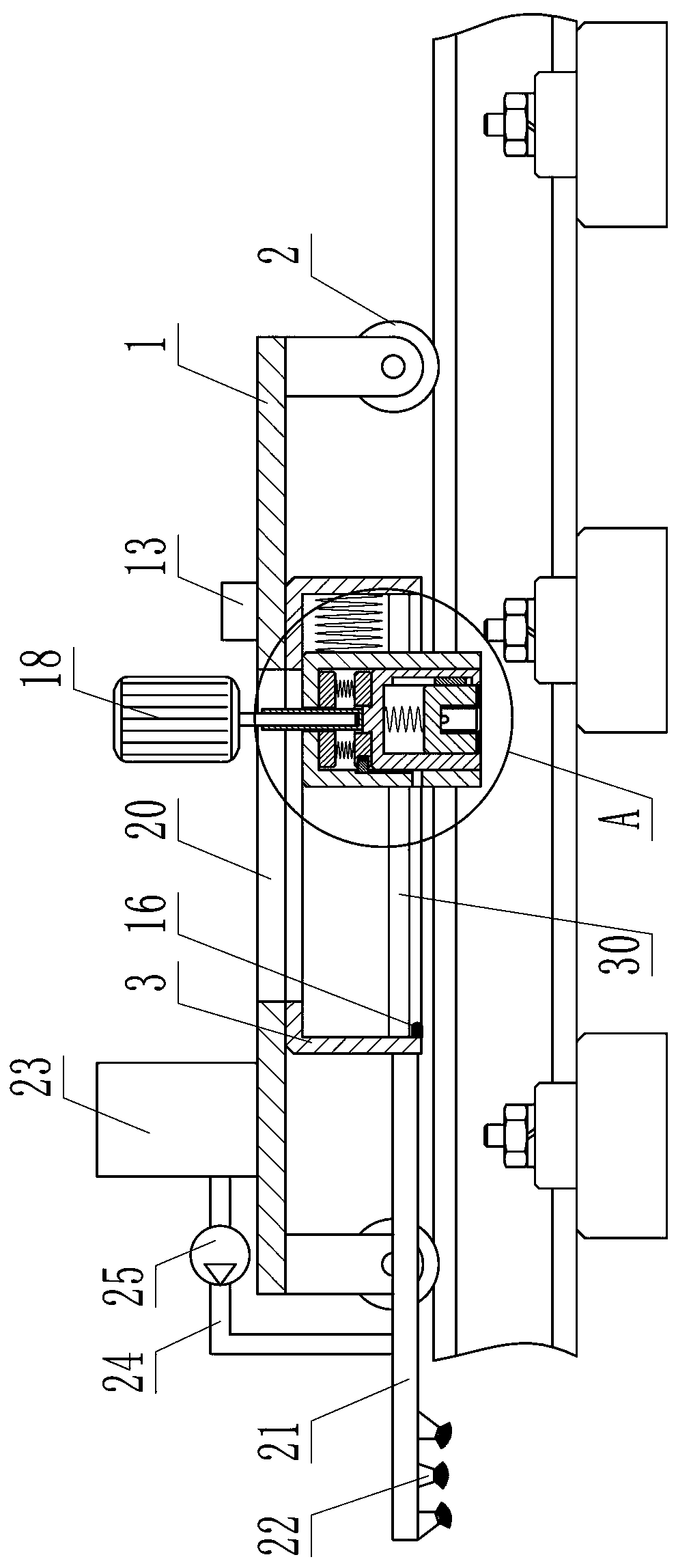

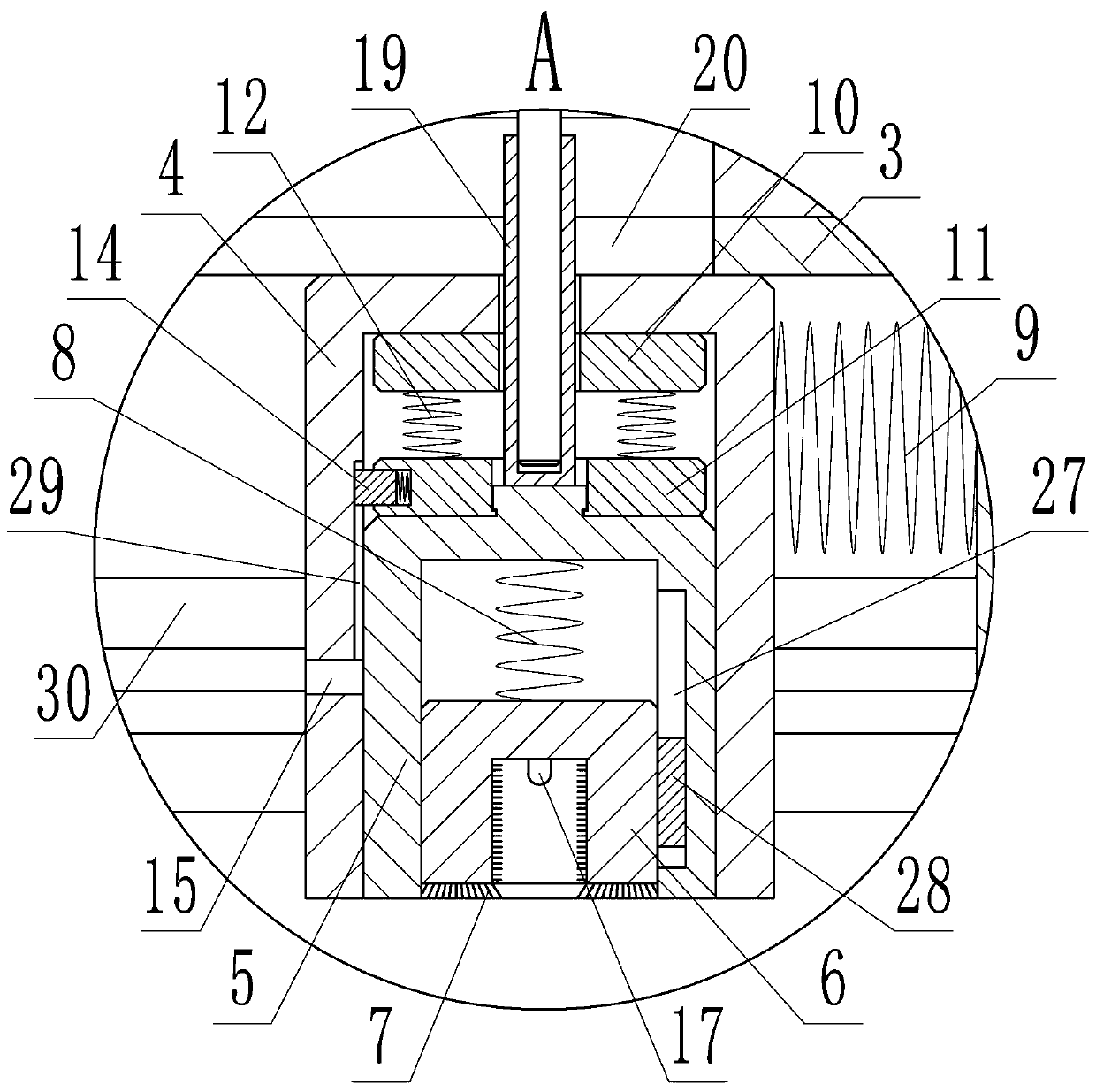

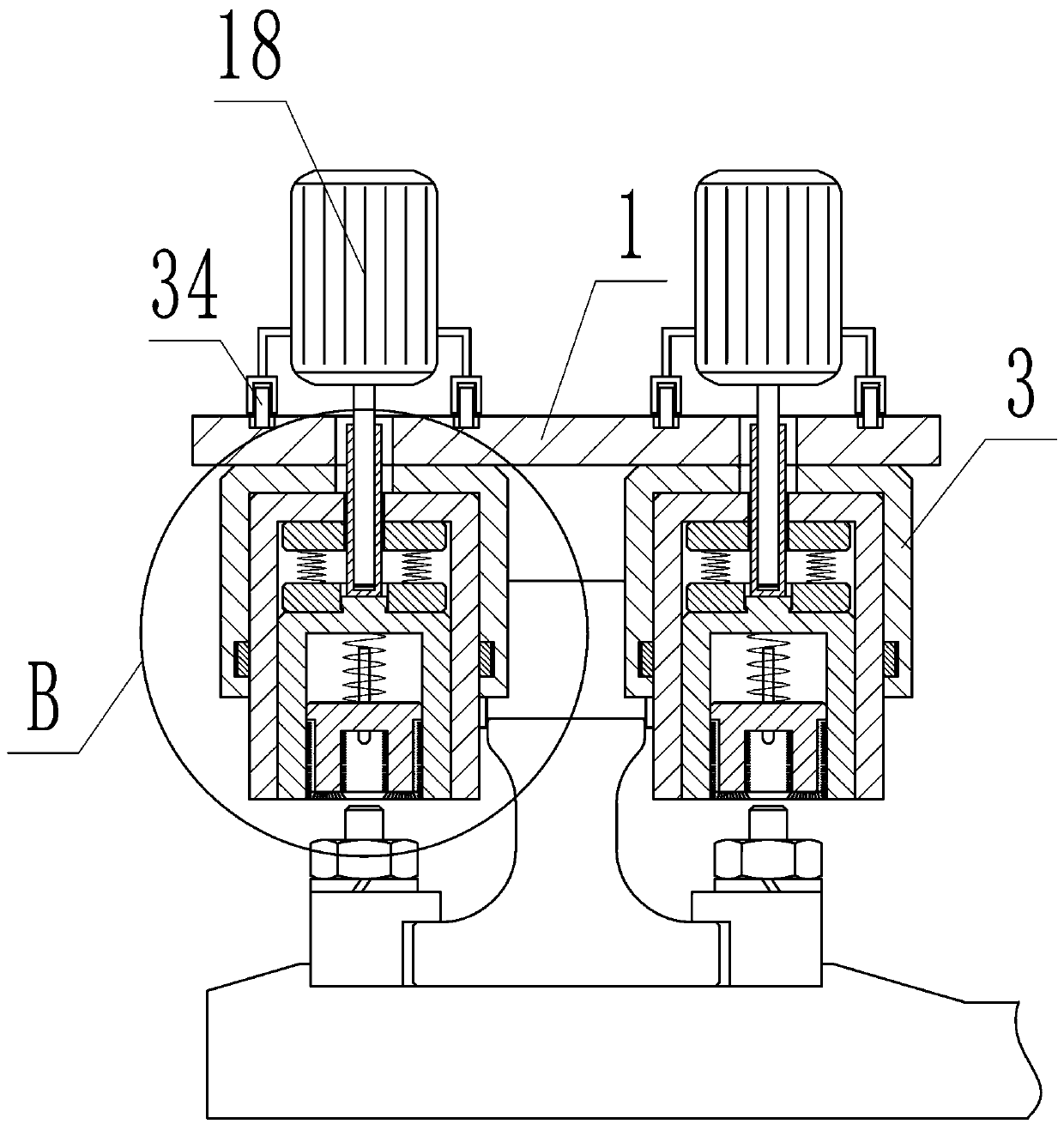

[0019] Depend on Figure 1 to Figure 12 Provided, the present invention comprises a working vehicle composed of a vehicle board 1 and a rail wheel 2, two groups of derusting units are installed symmetrically front and back on the lower surface of the vehicle board 1, and each group of derusting units includes an opening facing downwards and arranged along the left and right directions A tank body 3, a first housing 4 that can slide left and right is installed in the tank body 3, and a second housing 5 that can slide up and down and rotate inside the first housing 4, the second housing A third housing 6 that can slide up and down inside the body 5 is installed. The three housings are all cylindrical and open at the lower ends. The inner walls of the second housing 5, the third housing 6 and the lower end surfaces are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com