Prefabricated steel sleeve connecting joint of assembly-type concrete frame

A technology of steel sleeve and concrete, which is applied in the direction of construction and building construction, etc. It can solve the problems of inaccurate hoisting points of prefabricated components, difficulty in ensuring the quality of on-site welding, and long curing time of post-cast concrete, so as to improve labor production efficiency and quality and safety level, promote wide application, and reduce the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

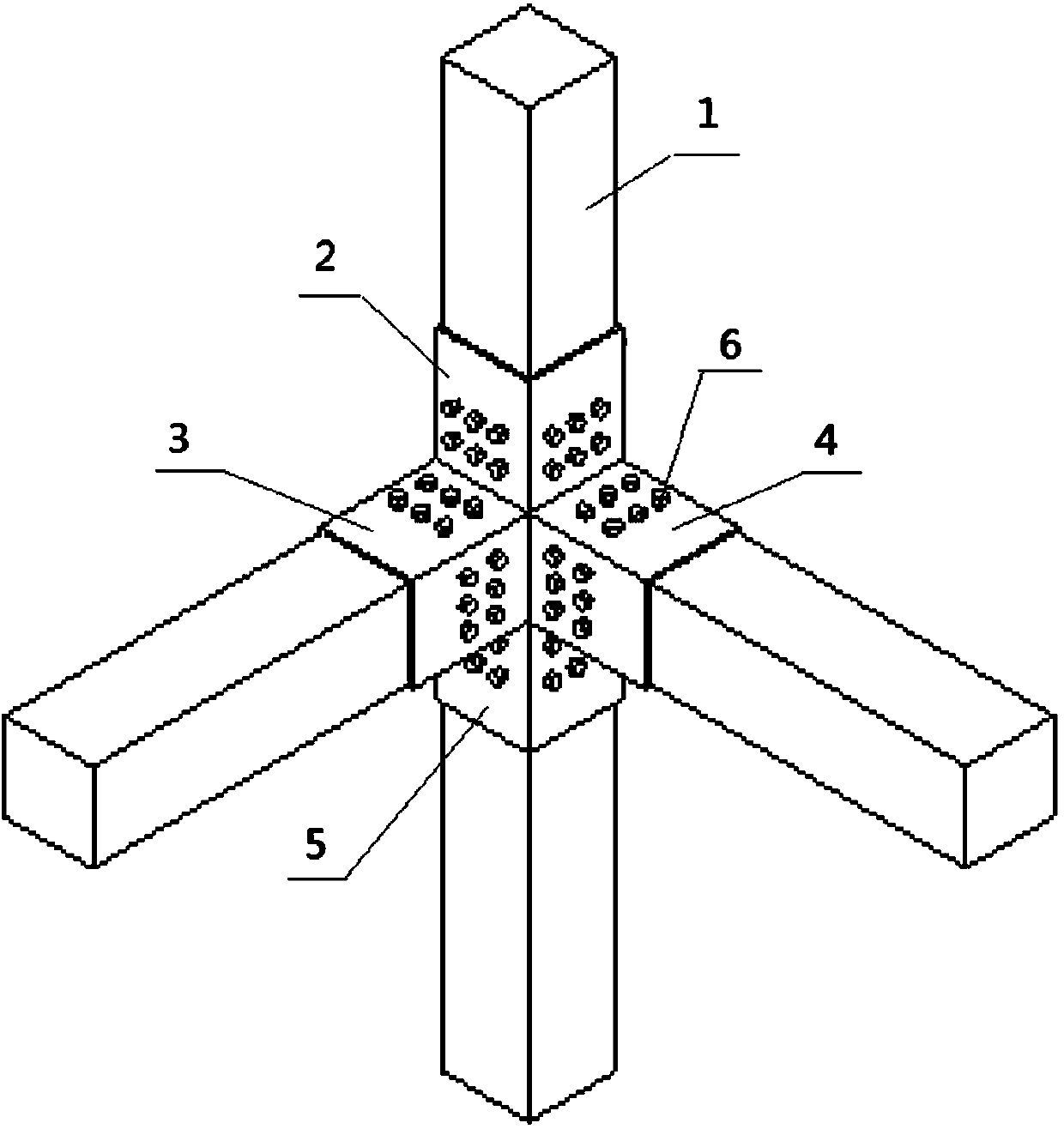

[0021] A prefabricated concrete frame prefabricated steel sleeve connection node, which consists of: a prefabricated concrete column body 1, the prefabricated concrete column body is inserted into a prefabricated steel sleeve, and the prefabricated steel sleeve includes No. 1 prefabricated steel sleeve 2. The No. 1 prefabricated steel sleeve is connected to the No. 2 prefabricated steel sleeve 3 and the No. 3 prefabricated steel sleeve 4, and the No. 2 prefabricated steel sleeve is connected to the No. 3 prefabricated steel sleeve. No. 1 prefabricated steel sleeve 5, said No. 1 prefabricated steel sleeve is perpendicular to said No. 2 prefabricated steel sleeve, said No. 1 prefabricated steel sleeve is perpendicular to said No. 3 prefabricated steel sleeve , the No. 4 prefabricated steel sleeve is perpendicular to the No. 2 prefabricated steel sleeve, the No. 4 prefabricated steel sleeve is perpendicular to the No. 3 prefabricated steel sleeve, and the No. 2 prefabricated steel...

Embodiment 2

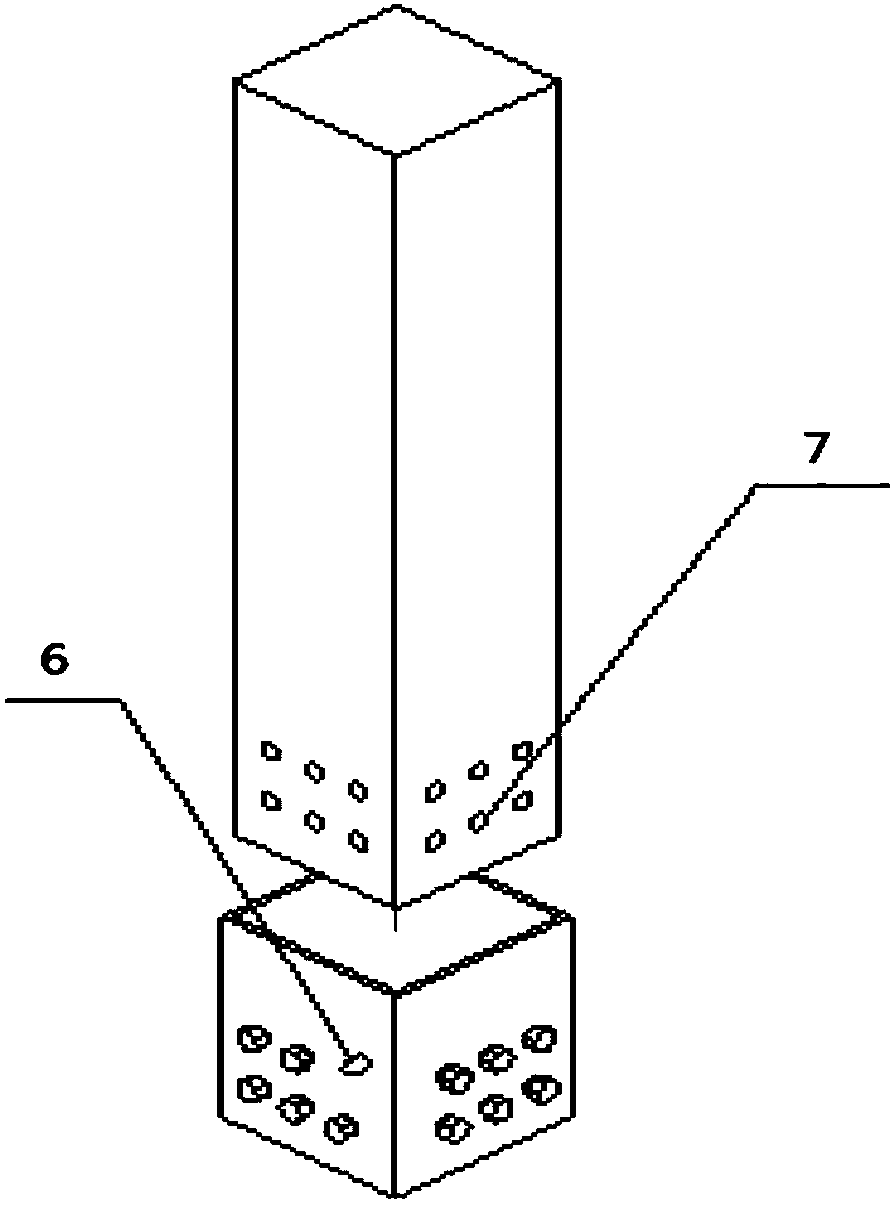

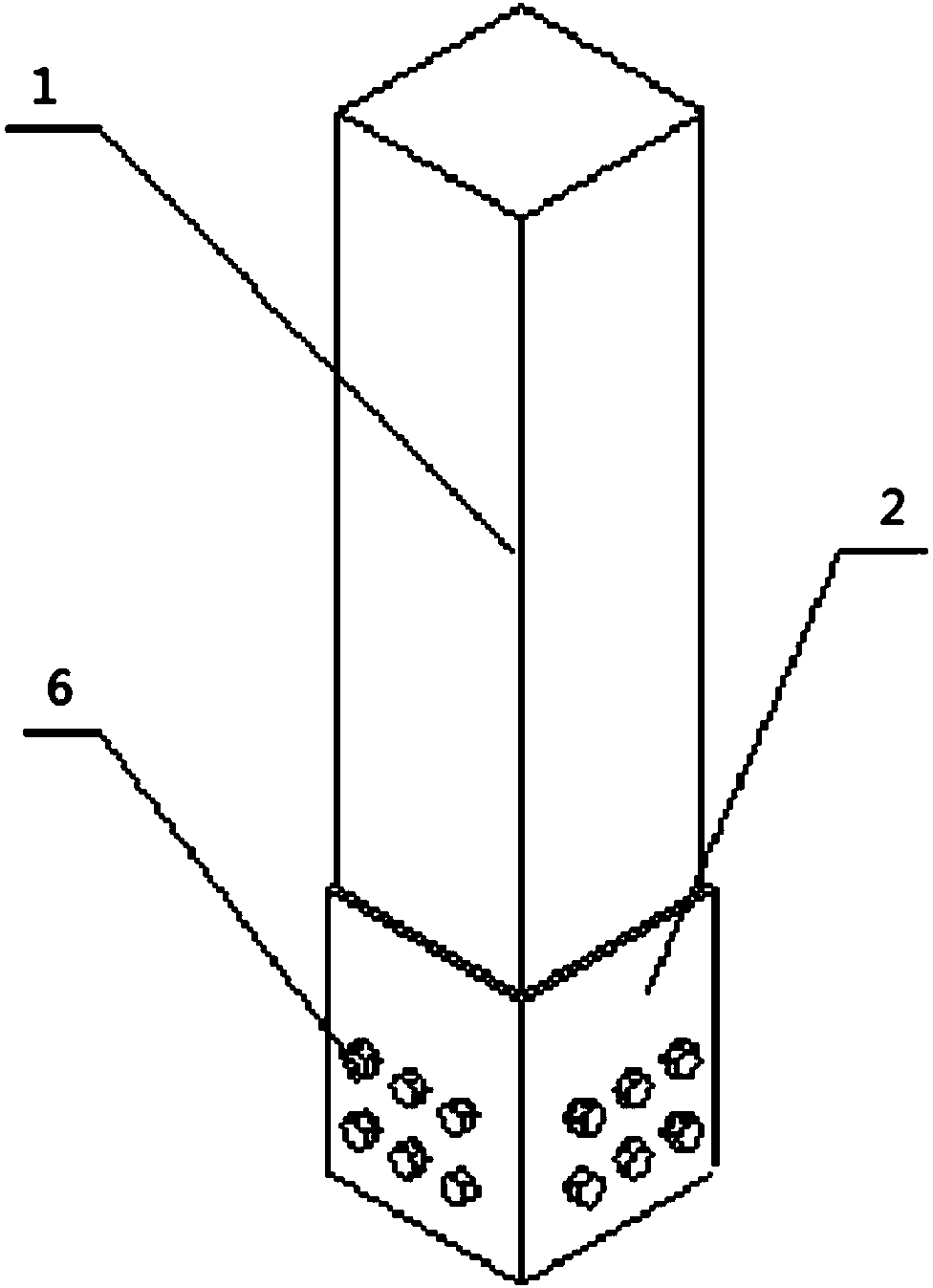

[0023] An assembled concrete frame prefabricated steel sleeve connection node described in Example 1, the No. 1 prefabricated steel sleeve, the No. 2 prefabricated steel sleeve, the No. 3 prefabricated steel sleeve, the The No. 4 prefabricated steel sleeves are all provided with bolt holes 6 reserved for the prefabricated steel sleeves, and the prefabricated concrete column body has reserved bolt holes 7 for the prefabricated concrete columns, and the reserved bolt holes for the prefabricated steel sleeves are The bolt holes reserved for the prefabricated concrete column coincide and are fixed by bolts 8 .

Embodiment 3

[0025] An assembled concrete frame prefabricated steel sleeve connection node described in Example 2, the bolt holes reserved for the prefabricated concrete columns are arranged horizontally and vertically, and the bolt holes reserved for the prefabricated concrete columns are arranged horizontally, in vertical arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com