Thrust reverser cascade and method of manufacture

A thrust reverser, cascading technology, applied in the aircraft field, can solve the problems of labor-intensive, time-consuming and expensive cascading of composite thrust reversers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

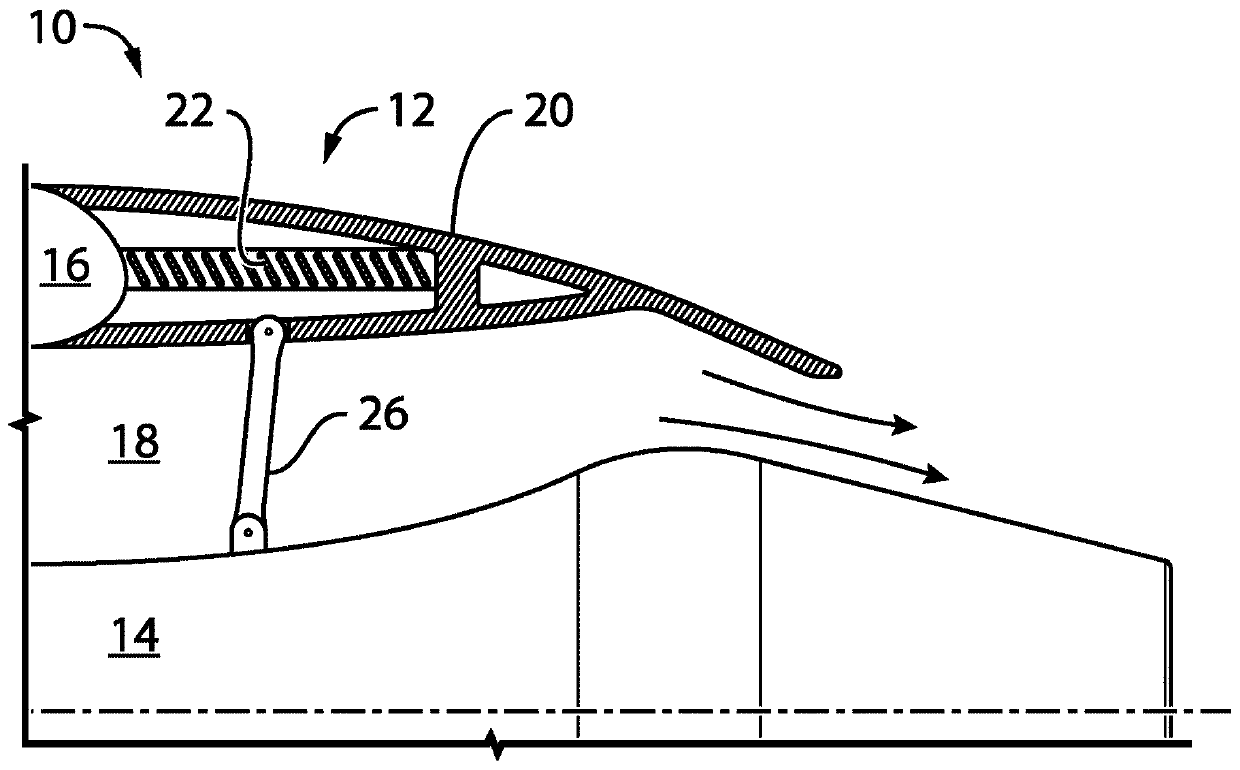

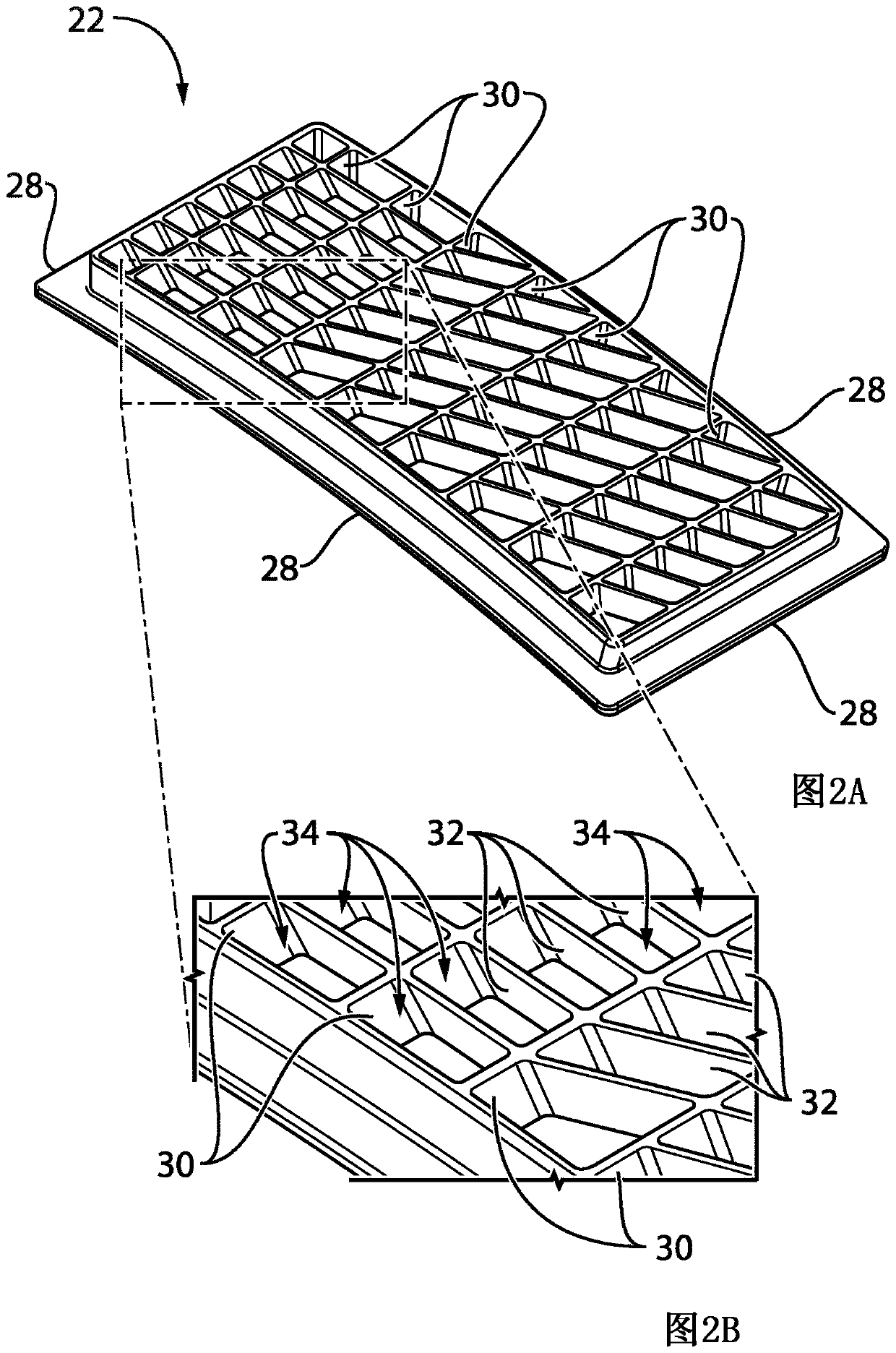

[0088] The following disclosure relates to thrust reverser cascades made of (eg, thermoplastic) composite materials and methods for manufacturing such cascades. It should be understood that the methods disclosed herein can also be used to fabricate parts other than thrust reverser cascades. For example, the methods disclosed herein can be used to fabricate composite (eg, aircraft or aircraft engine) parts having one or more aerodynamic surfaces intended to interact with fluid (eg, air) flows. In various embodiments, methods disclosed herein may use overmolding to form a portion of a part that defines an aerodynamic surface, such as one or more blades of a thrust reverser cascade. In some embodiments, the methods disclosed herein may be of reduced complexity, less time consuming, and thus less expensive than some existing methods of fabricating composite thrust reverser cascades (eg, thermoset methods) Low. In some embodiments, the methods disclosed herein may also exhibit be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com