Double-sided composite progressive resin lens and manufacturing technology thereof

A resin lens, double-sided technology, applied in the field of double-sided composite progressive resin lens and its manufacturing process, can solve the problems of life obstacles, reduced eye muscle adjustment ability and zoom ability, blurring, etc., and achieves improved adaptability and deformation. The effect of reducing and alleviating visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

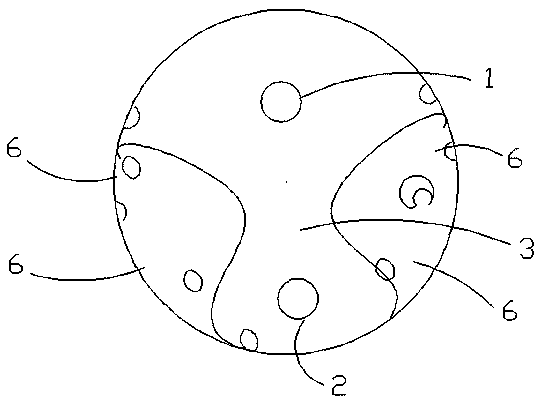

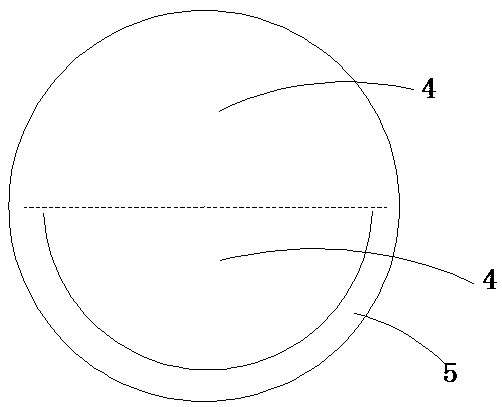

[0019] Such as Figure 1-2 As shown, this embodiment provides a double-sided composite progressive resin lens, including a far vision zone 1, a near vision zone 2 is arranged in front of the far vision zone 1, and a progressive channel 3 is arranged between the far vision zone 1 and the near vision zone 2, The far vision zone 1, the near vision zone 2 and the progressive channel 3 form the rear surface of the resin lens, the front surface of the resin lens includes a photometric zone 4 and a peripheral defocus zone 5, and the peripheral defocus zone 5 is located at the periphery of the photometric zone 4, so A peripheral astigmatism zone 6 is provided on the rear surface of the resin lens.

[0020] Choose a semi-finished resin blank with a refractive index of 1.60, design the luminosity of the front surface through the optical system to be -1.00D, the peripheral luminosity 10 to be -0.50D, and design the free-form surface of the back surface to see the luminosity of the far zo...

Embodiment 2

[0023] This embodiment provides a double-sided compound progressive resin lens, including a far vision zone 1, a near vision zone 2 is arranged in front of the far vision zone 1, a progressive channel 3 is arranged between the far vision zone 1 and the near vision zone 2, and the The far vision zone 1, the near vision zone 2 and the progressive channel 3 form the back surface of the resin lens, the front surface of the resin lens includes a photometric zone 4 and a peripheral defocus zone 5, the peripheral defocus zone 5 is located at the periphery of the photometric zone 4, and the resin lens A peripheral astigmatism zone 6 is provided on the rear surface of the lens.

[0024] Select a semi-finished resin blank with a refractive index of 1.60, design the front surface luminosity to -1.50D, the peripheral luminosity to -0.50D through the optical system design, and design the rear surface free-form surface to see the far zone luminosity -1.00D, progressive middle channel, and ne...

Embodiment 3

[0027] This embodiment provides a double-sided compound progressive resin lens, including a far vision zone 1, a near vision zone 2 is arranged in front of the far vision zone 1, a progressive channel 3 is arranged between the far vision zone 1 and the near vision zone 2, and the The far vision zone 1, the near vision zone 2 and the progressive channel 3 form the back surface of the resin lens, the front surface of the resin lens includes a photometric zone 4 and a peripheral defocus zone 5, the peripheral defocus zone 5 is located at the periphery of the photometric zone 4, and the resin lens A peripheral astigmatism zone 6 is provided on the rear surface of the lens.

[0028] Select a semi-finished resin blank with a refractive index of 1.67, design the front surface luminosity to -1.50D, peripheral luminosity to -0.50D through the optical system design, design the back surface free-form surface to see the far zone luminosity -5.00D, progressive middle channel, near vision T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap