Air bag cleaning machine and application method thereof

A cleaning machine and air bag technology, used in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problem of ineffective cleaning of air bags in batches, save manpower, reduce cleaning time, and ensure cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

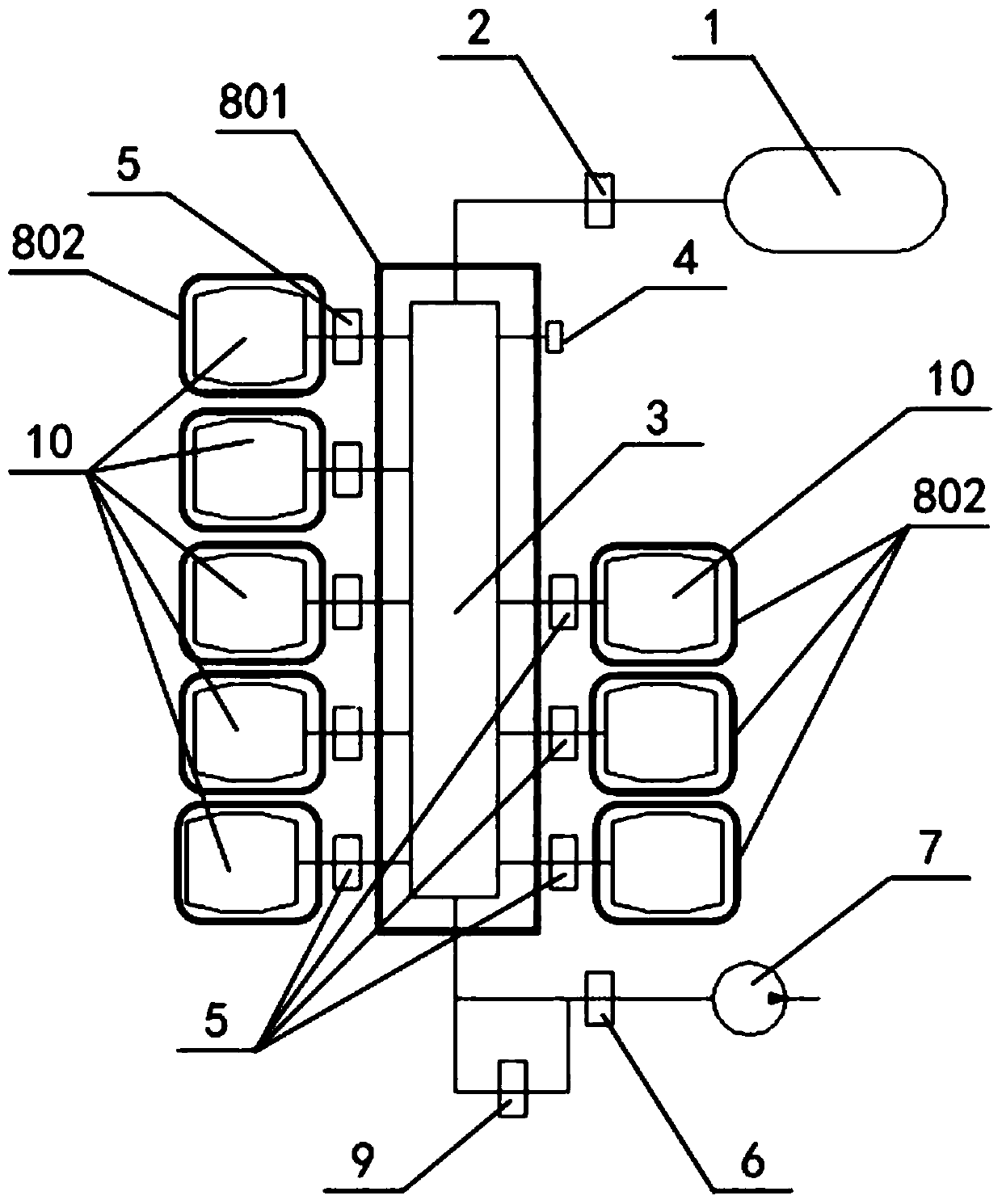

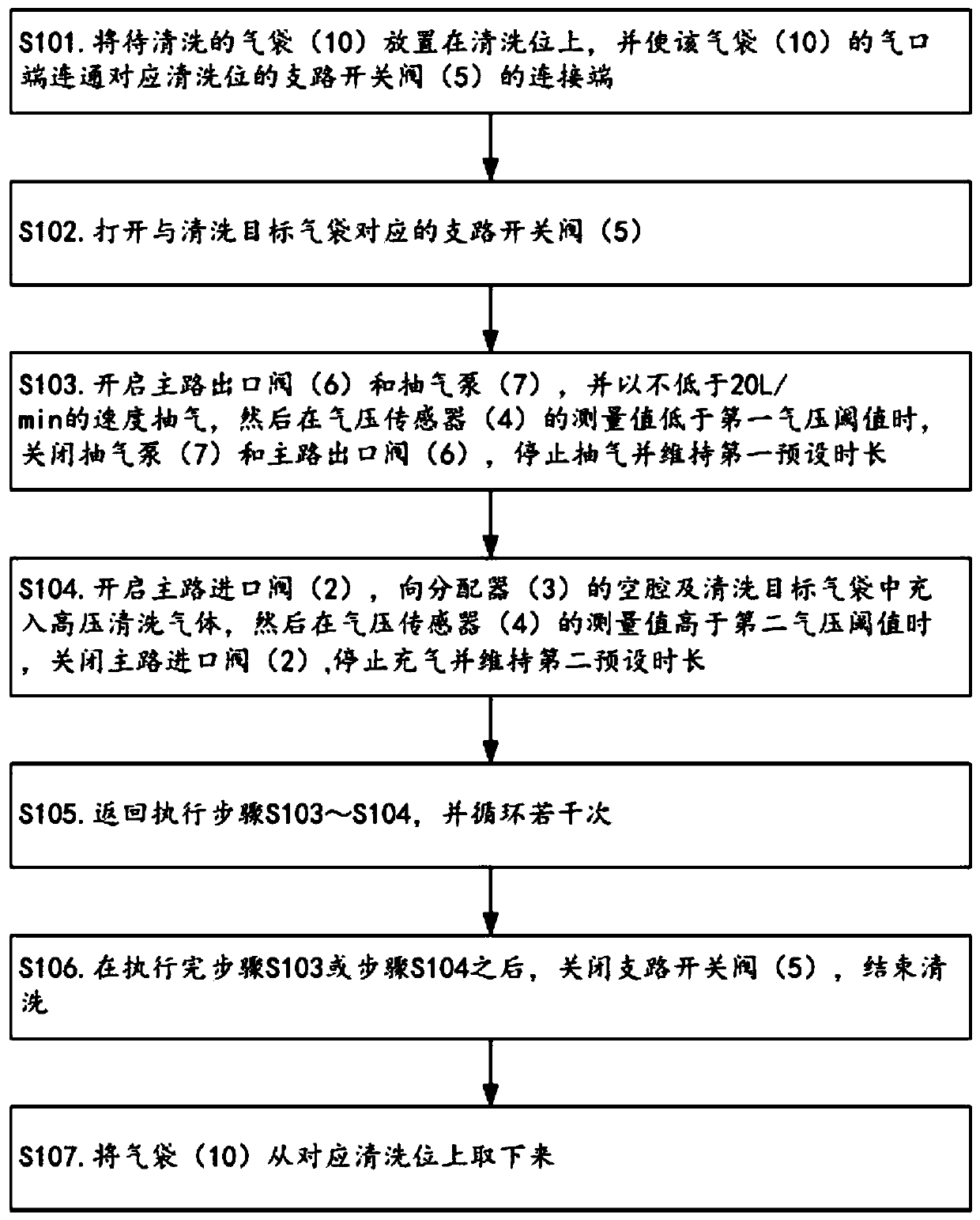

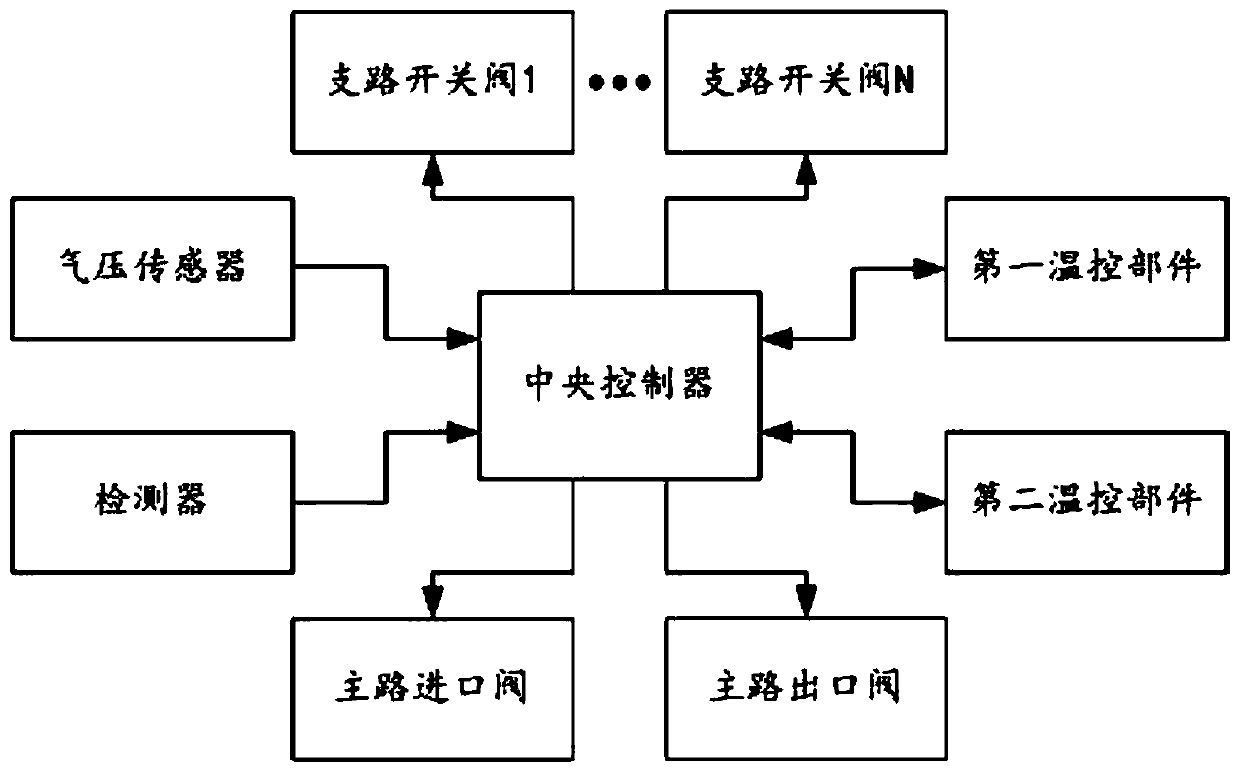

[0048] like Figure 1~3 As shown, the air bag cleaning machine provided in this embodiment includes an air source 1, a main road inlet valve 2, a distributor 3, an air pressure sensor 4, a branch switch valve 5, a main road outlet valve 6 and an air pump 7, Wherein, the gas source 1 stores high-pressure cleaning gas, and the distributor 3 is provided with a cavity; the outlet end of the gas source 1 is connected to one end of the main road inlet valve 2, and the main road inlet valve The other end of 2 communicates with the cavity of the distributor 3, and the air inlet end of the air pressure sensor 4 communicates with the cavity of the distributor 3; the number of the branch switch valves 5 is several and one end communicates with the distributor. The cavity of the dispenser 3, the other end is used as a connection end to communicate with the air bag 10 on the corresponding cleaning position, wherein the branch switch valve 5 corresponds to the cleaning position one by one; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com