Intelligent Inspection and Control Method of Online Working State of Continuous Casting Secondary Cooling System

A working state and cooling system technology, applied in the field of continuous casting of steel billets in the iron and steel metallurgy industry, can solve the problems of time-consuming, labor-intensive, and ineffective inspection and control methods, and achieve the effects of reducing pouring accidents, improving pouring quality, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

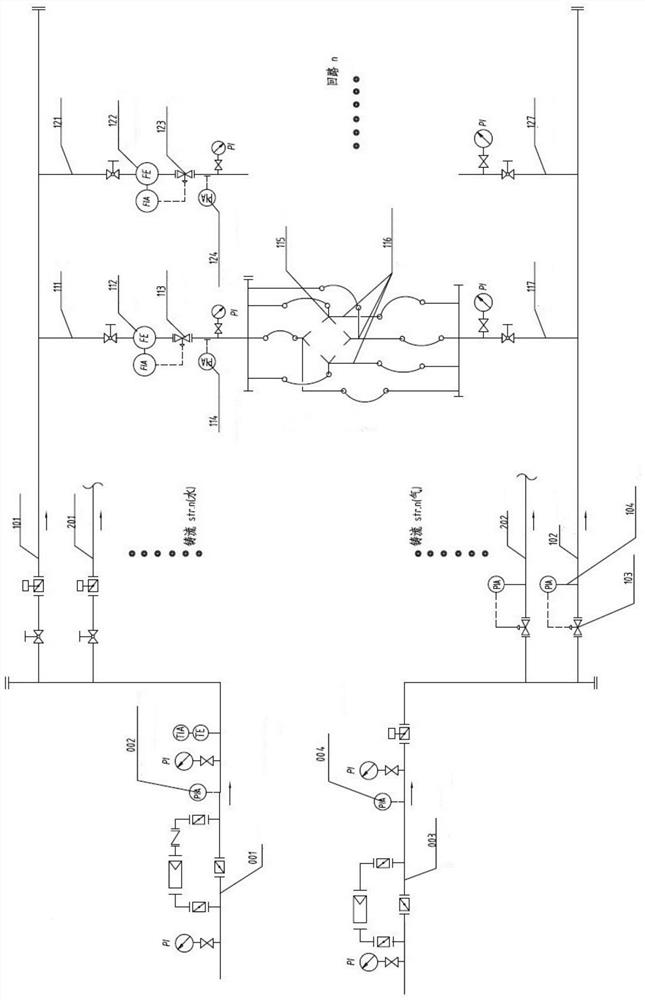

[0053] Embodiments of the present invention will be described below with reference to the accompanying drawings. Those skilled in the art would recognize that the described embodiments can be modified in various ways or combinations thereof without departing from the spirit and scope of the invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

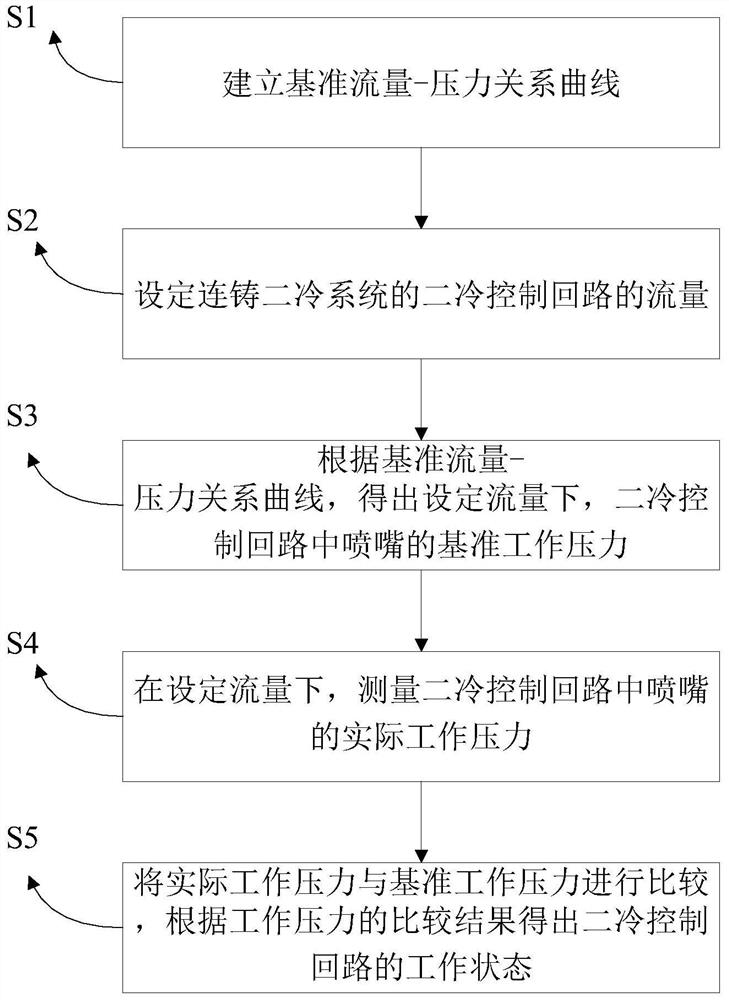

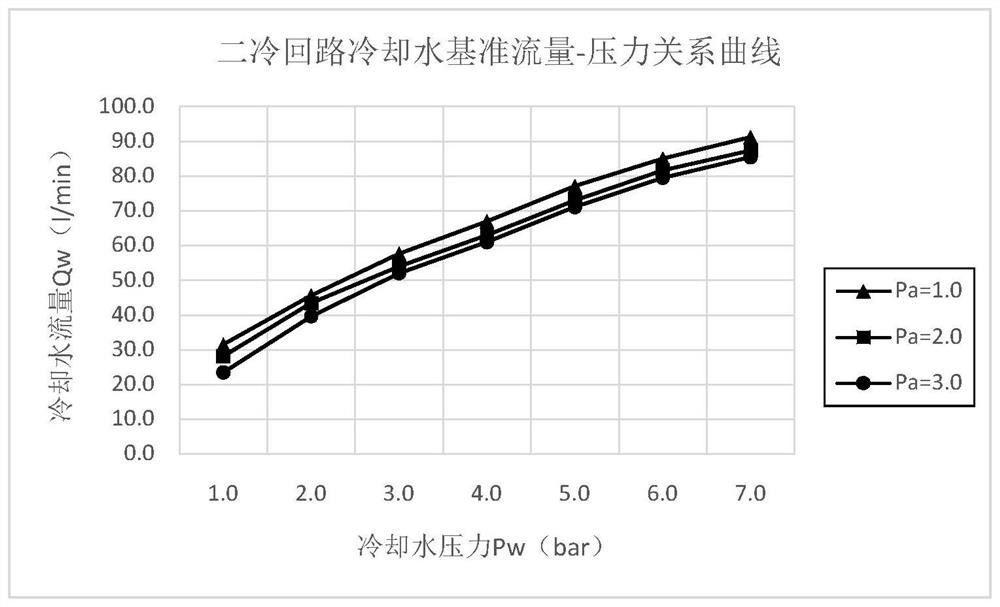

[0054] For the continuous casting secondary cooling system, under normal circumstances, the flow rate of each secondary cooling control circuit has a unique corresponding relationship with the nozzle working pressure (pressure after the valve) of the circuit. Under the target flow rate, when the nozzle or the pipeline behind the valve is blocked, the nozzle is used for too long to cause serious wear, and the pipeline behind the valve leaks, etc., t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap