Inner profile all-purpose supporting tool based on lathe

A kind of internal surface and universal technology, applied in the field of parts processing, can solve the problems that the accuracy of turning features cannot be guaranteed, increase the preparation time of lathe processing, etc., improve the adaptability of clamping and processing, avoid loosening of clamping, and improve turning precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

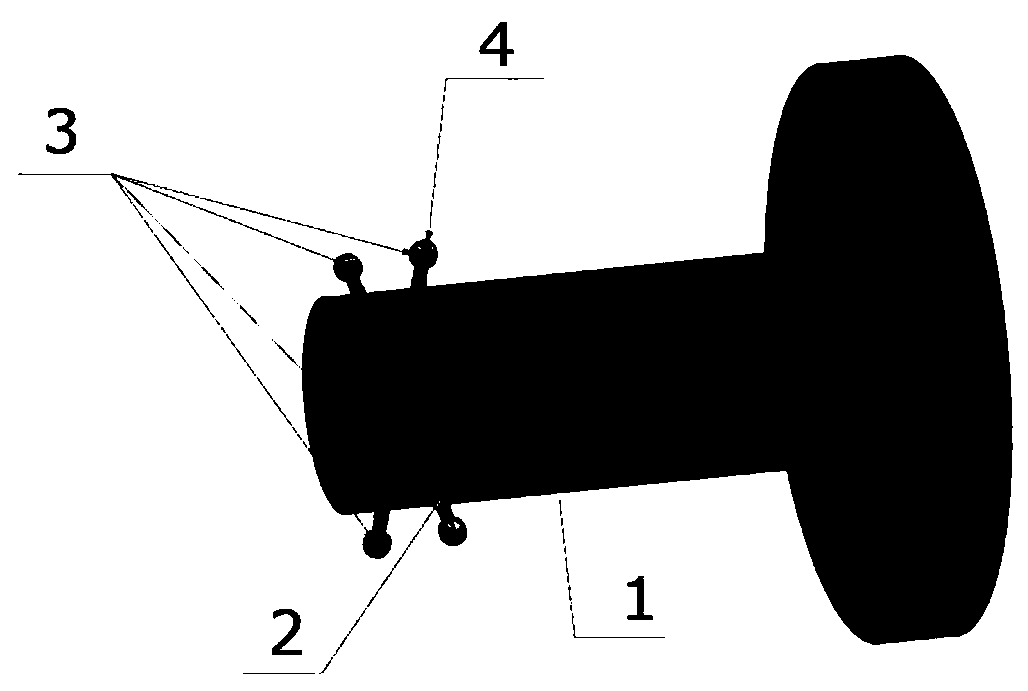

[0015] This embodiment proposes a lathe-based universal support tooling for the inner surface, the structure of which is as follows figure 1 shown. The universal support tooling includes threaded holes on the clamping round frame 1, and the contact rod 2 is screwed into the clamping round frame 1 through the threaded holes and can be adjusted in length to adapt to different sizes of the cabin cavity; the contact rod 2 The top of the ball pair 3 is provided with a ball pair 3, and the top of the ball pair 3 has a planar contact 4, and the contact 4 with the ball pair can rotate and fit with the shape of the cabin to adapt to different special-shaped inner profiles.

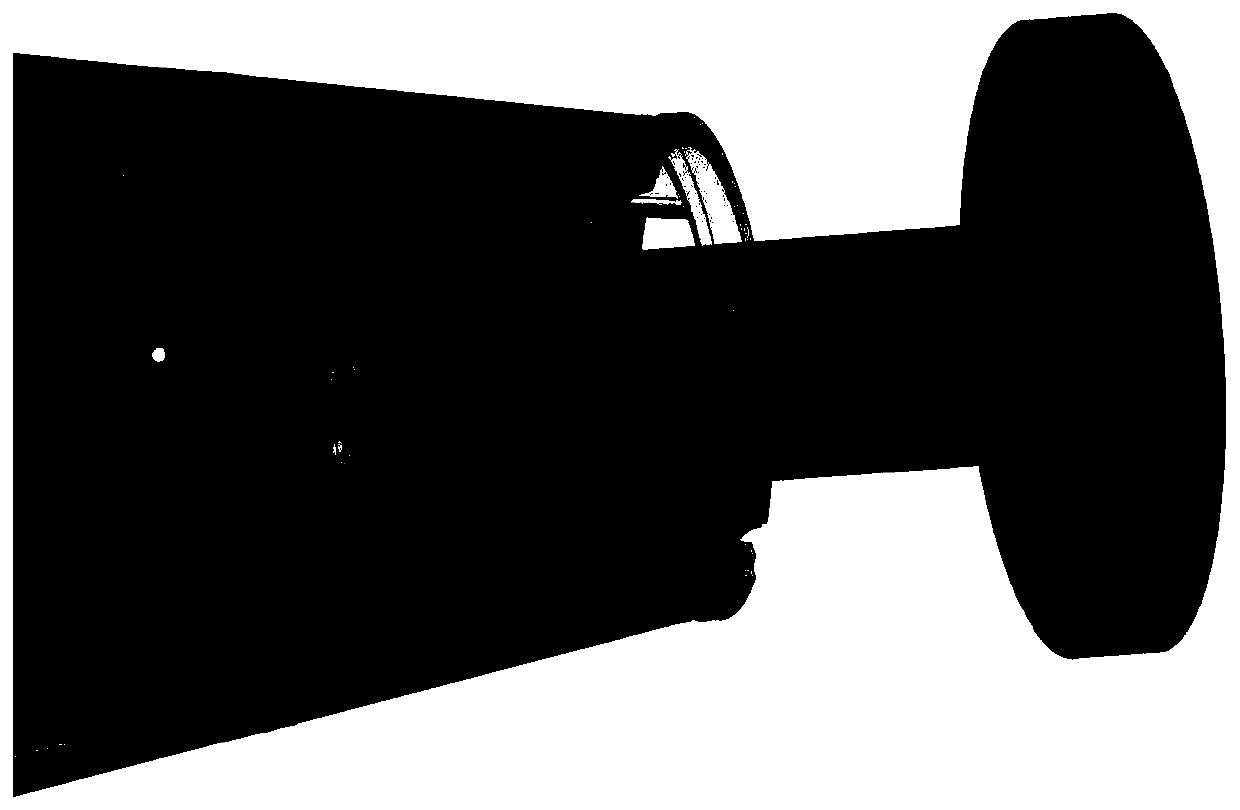

[0016] Such as figure 2 As shown, when the universa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com