Golf club rolling device

A technology of golf clubs and rolling devices, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems of reducing the strength of clubs, high production costs, and high processing costs, so as to improve processing efficiency, increase strength, and Clamp and remove for simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

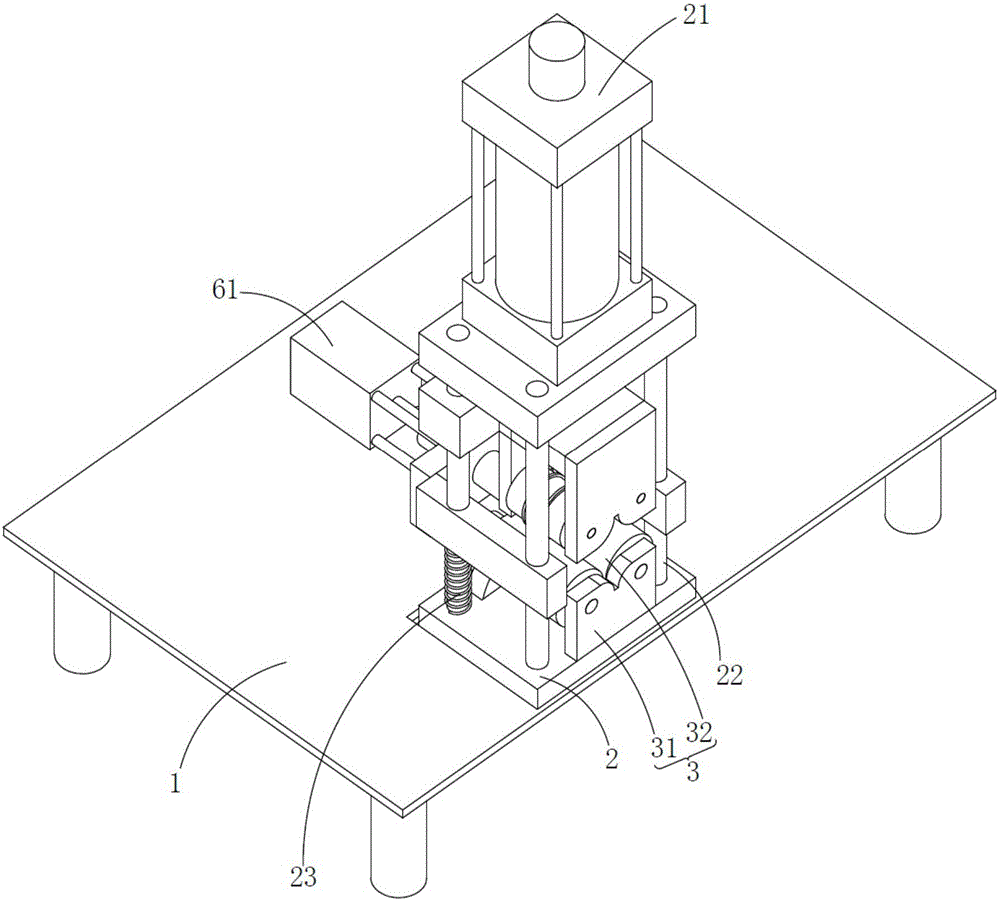

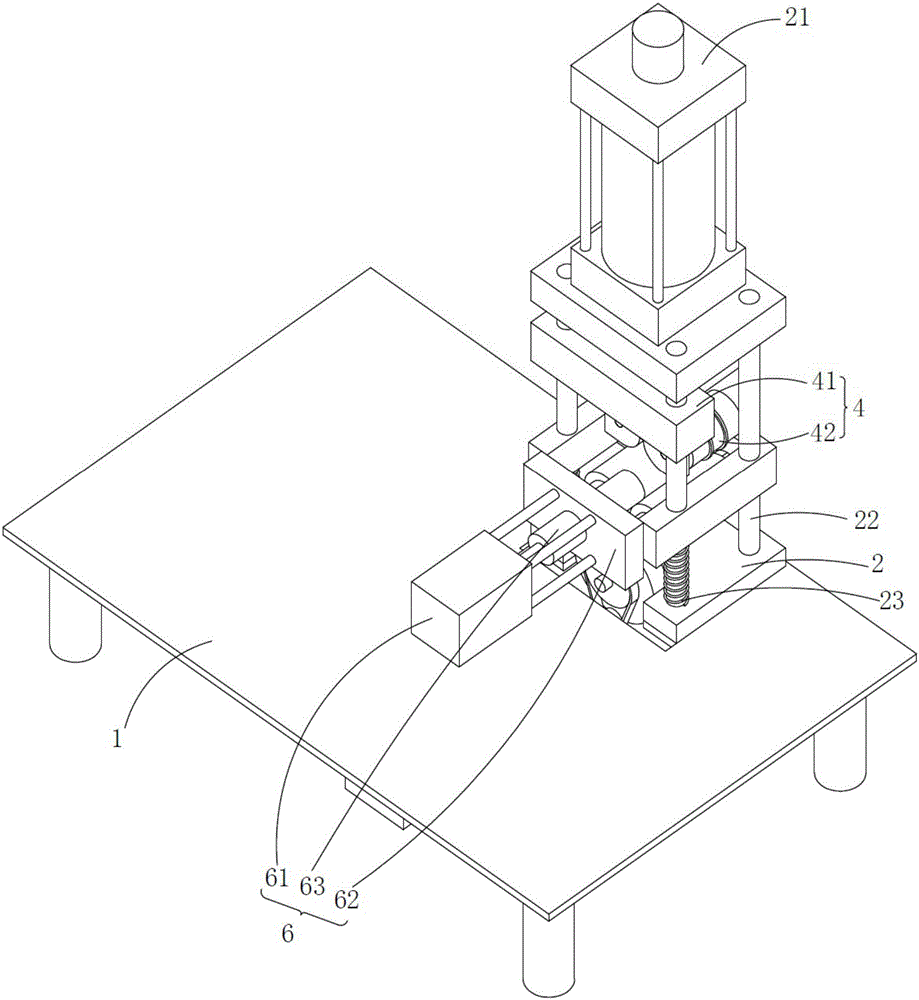

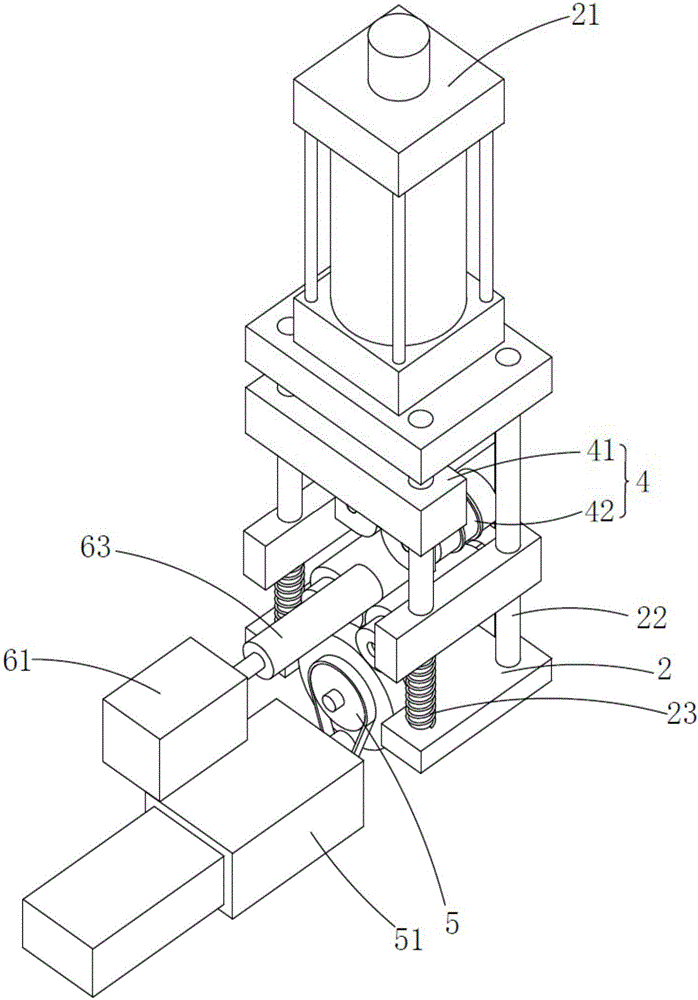

[0027] Examples, see Figure 1 to Figure 3 As shown, a golf club rolling device has a simple structure, a small volume, a fast processing speed, reduces production costs, and improves processing efficiency.

[0028] In order to achieve the above object, the technical solution adopted in the present invention is a golf club rolling device, including a worktable 1, on which a fixed seat 2 is arranged, and the fixed seat 2 includes a fixed active rolling mechanism 3, a floating Type passive rolling mechanism 4, transmission mechanism 5, motor 51 and push mechanism 6;

[0029] The fixed active rolling mechanism 3 is provided with a fixed base 31 and two active rollers 32, and the two active rollers 32 are rotatably installed in the fixed base 31 side by side, and the fixed base 31 is fixed on the lower part of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com