Molds capable of overcoming molding defects of simplicity in shrinkage, difficulty in cement saturation and air exhaust and the like

A mold core and glue position technology, which is applied in the field of plastic molds, can solve the problems of slow heat dissipation in the core, cold glue that cannot be solved by exhaust grooves, and reduced mold life, so as to improve the trapped air, the problem of insufficient glue, and the shrinkage problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

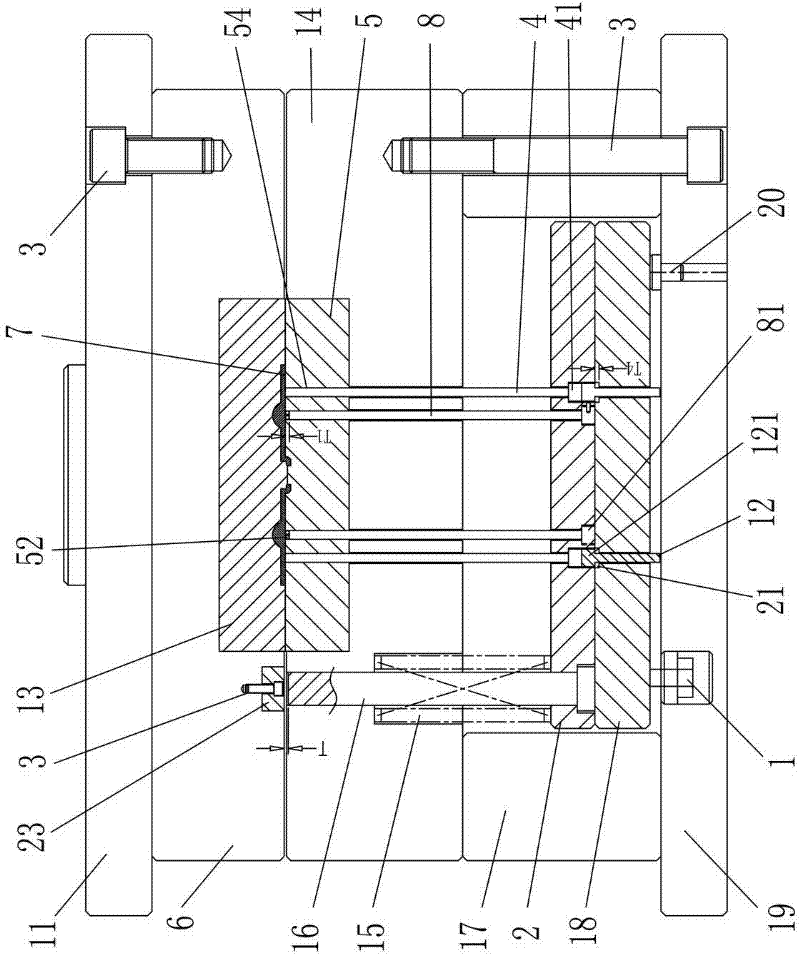

[0048] This mold (such as figure 1 As shown, the state before glue replenishment) is composed of static mold base 11, static template 6, movable mold base 19, movable mold plate 14, mold foot 17, injection molding machine top roller 22 and thick glue filling mechanism.

[0049] Static mold base 11 is provided with static template 6 below static template 6, is provided with static mold core 13 in static mold core 13, is provided with product mold cavity 53 in static mold core 13.

[0050] Die feet 17 are arranged on the movable mold base 19, a movable template 14 is arranged on the mold feet 17, a movable mold core 5 is arranged in the movable template 14, and product thimbles are arranged successively between the mold feet 17 from bottom to top. The top plate 18 and the product thimble fixing plate 2 are provided with a chute 21 on the product thimble fixing plate 2, and the product thimble 4 passes through the product thimble fixing plate 2 and the movable mold core 5 and con...

Embodiment 2

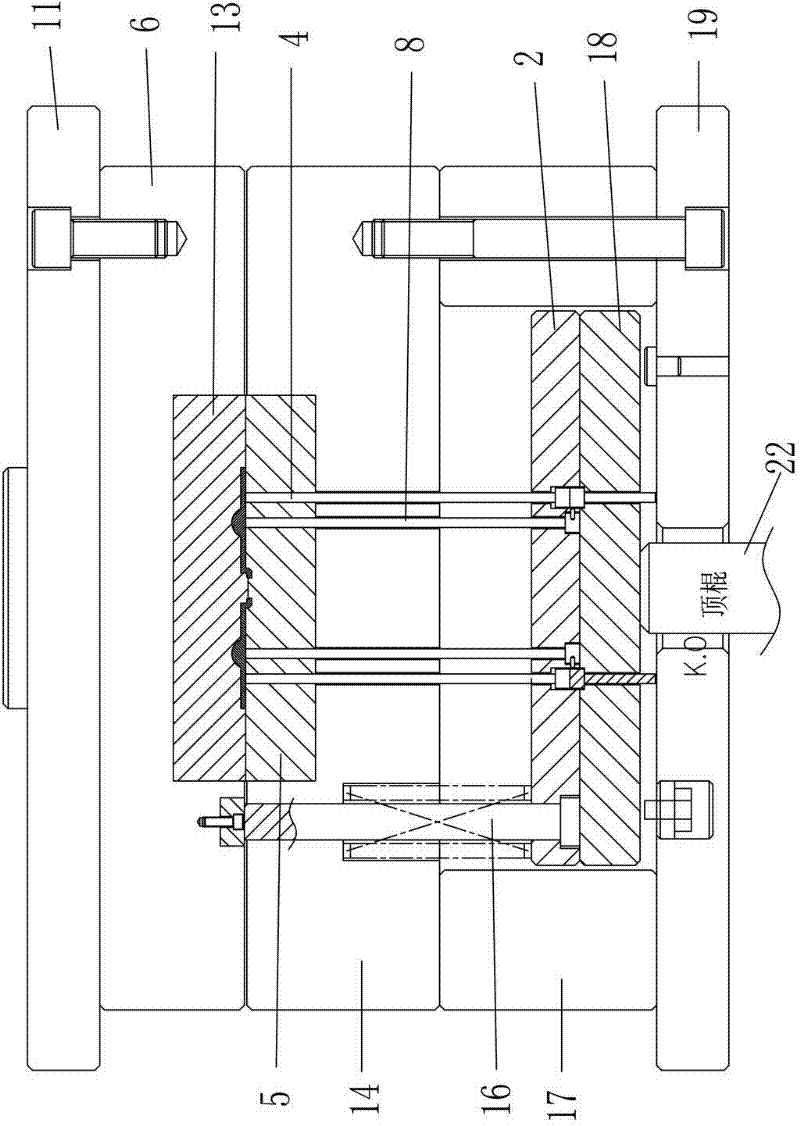

[0057] This mold (such as image 3 As shown, the state before glue replenishment) is composed of a static mold base 11, a static template 6, a movable mold base 19, a movable template 14, a mold foot 17, an injection molding machine top roller 22, and a thin rubber-position forming mechanism.

[0058] Static mold base 11 is provided with static template 6 below static template 6, is provided with static mold core 13 in static mold core 13, is provided with product mold cavity 53 in static mold core 13.

[0059] Die feet 17 are arranged on the movable mold base 19, a movable template 14 is arranged on the mold feet 17, a movable mold core 5 is arranged in the movable template 14, and product thimbles are arranged successively between the mold feet 17 from bottom to top. The top plate 18 and the product thimble fixing plate 2 are provided with a chute 21 on the product thimble fixing plate 2, and the product thimble 4 passes through the product thimble fixing plate 2 and the mov...

Embodiment 3

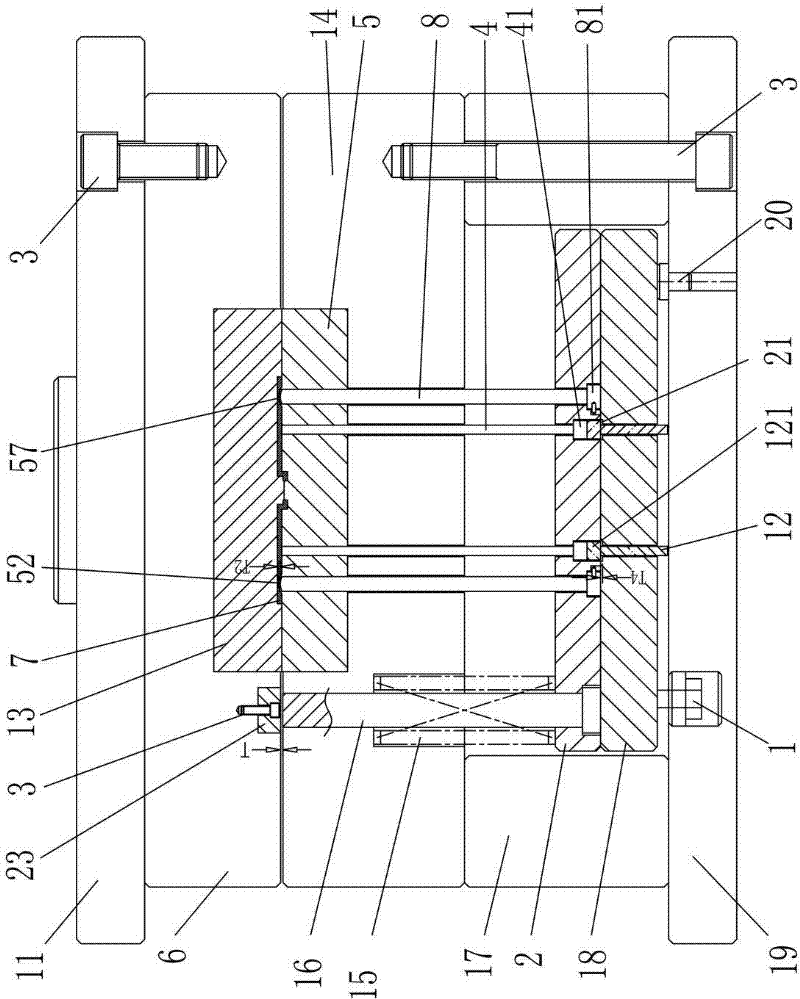

[0066] This mold (such as Figure 5 As shown, the state before glue replenishment) is composed of static mold base 11, static template 6, movable mold base 19, movable template 14, mold foot 17, injection molding machine top roller 22 and automatic in-mold cutting overflow hole mechanism.

[0067] Static mold base 11 is provided with static template 6 below static template 6, is provided with static mold core 13 in static mold core 13, is provided with product mold cavity 53 in static mold core 13.

[0068] Die feet 17 are arranged on the movable mold base 19, a movable template 14 is arranged on the mold feet 17, a movable mold core 5 is arranged in the movable template 14, and product thimbles are arranged successively between the mold feet 17 from bottom to top. The top plate 18 and the product thimble fixing plate 2 are provided with a chute 21 on the product thimble fixing plate 2, and the product thimble 4 passes through the product thimble fixing plate 2 and the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com