Tray separation mechanism driven by air cylinder

A pallet separation and cylinder-driven technology, which is used in conveyors, object destacking, packaging, etc., can solve the problems of large equipment space and complex overall structure, and achieve the effect of compact mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

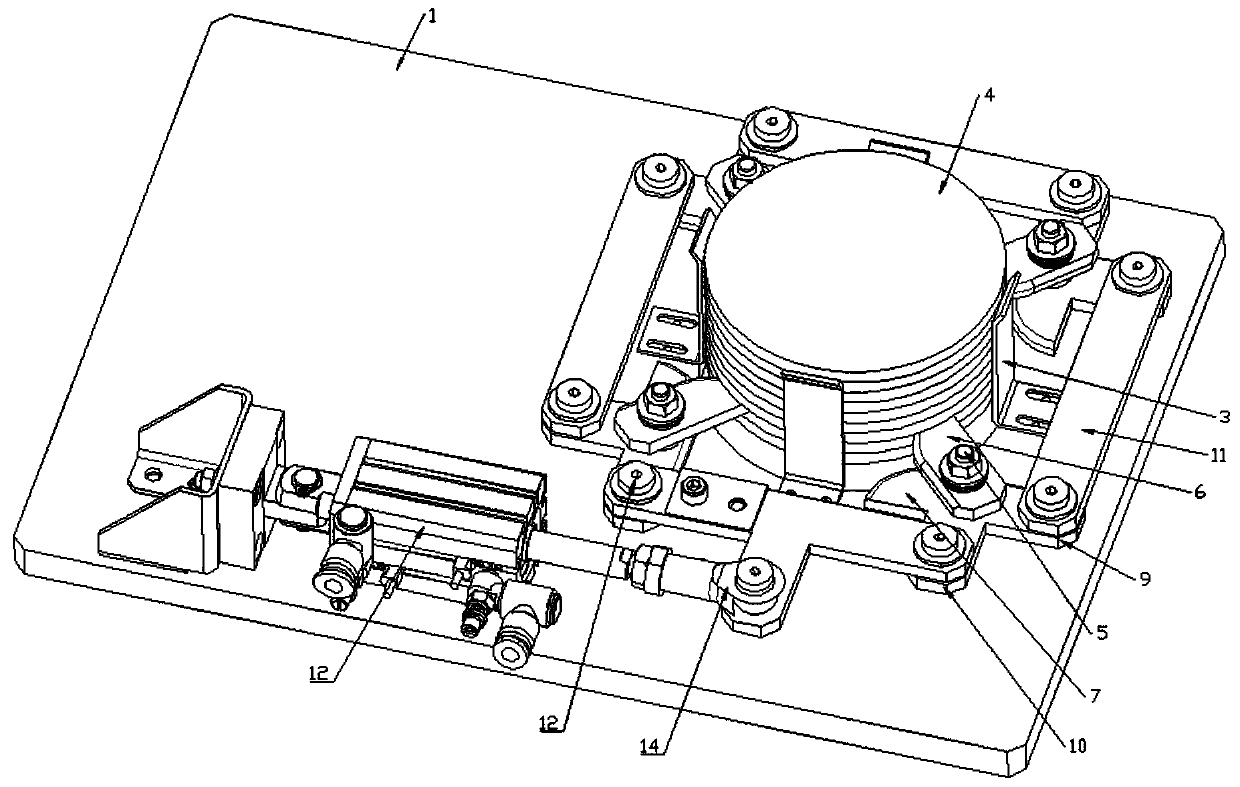

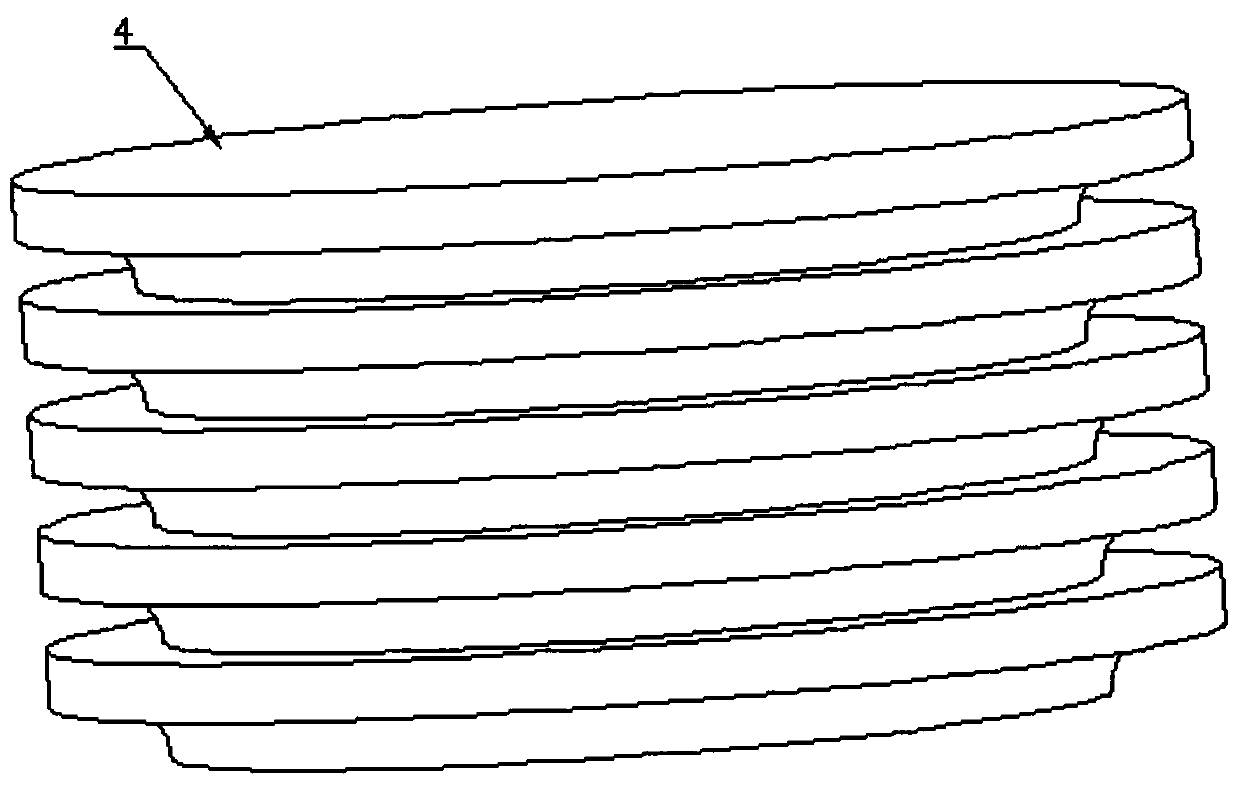

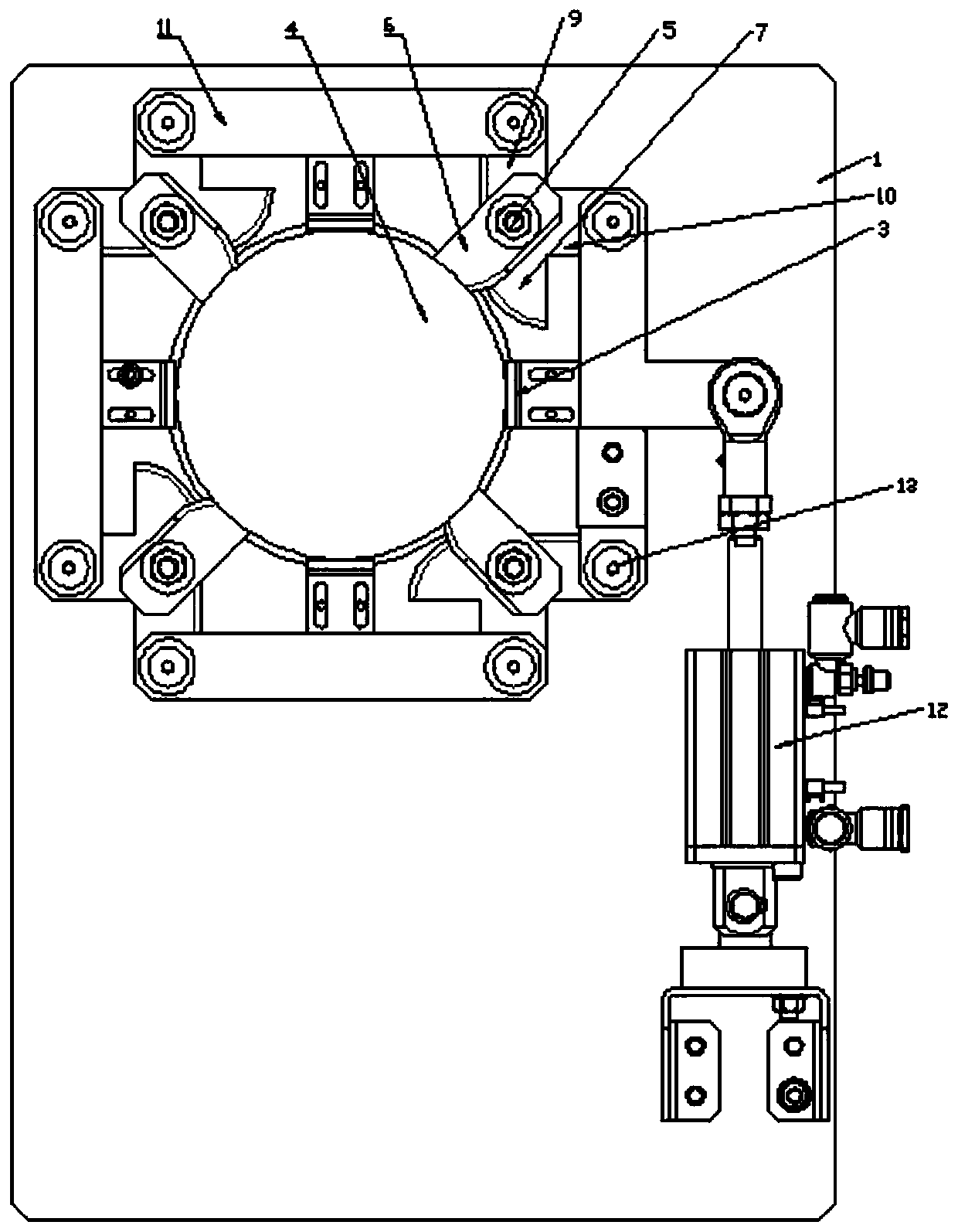

[0023] combine Figure 1 to Figure 9 The cylinder-driven tray separation mechanism shown in this embodiment includes a base plate 1, a drop hole 2 is provided on the base plate 1, and a limit plate 3 is fixed on the periphery of the drop hole 2, and the limit plate 3 will The stacked trays 4 are limited above the inside of the drop hole 2; four stripping assemblies are respectively connected to the substrate 1 through four first rotating shafts 5, and the first rotating shaft 5 rings are arranged on the periphery of the drop hole 2, and The annular axis where it is located is collinear with the axis of the drop hole 2, and the stripping assembly includes a first stripping sheet 6, a second stripping sheet 7 and a spacer 8 arranged between the first stripping sheet 6 and the second stripping sheet 7 , and the height of the pad 8 is set to the height of a tray 4, the first peeling sheet 6 is arranged above the second peeling sheet 7, and one end of the first rotating shaft 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com