Large-span steel bar truss floor bearing plate assembling type supporting and construction method

A steel truss and floor bearing plate technology is applied in the field of assembled support and construction of large-span steel truss floor bearing plates, which can solve the problems of increasing construction resources, insufficient rigidity, and large workload of steel pipe fastener brackets, and achieves strong adaptability. , saving materials, and solving the effect of large-span steel truss floor bearing plate support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

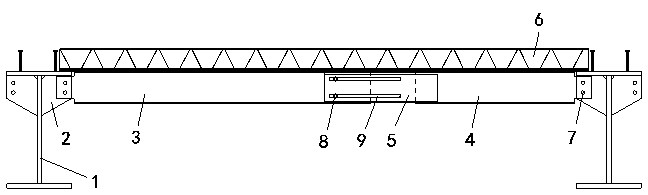

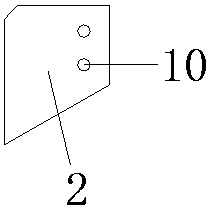

[0026] An assembled support for a large-span reinforced truss floor deck, comprising two longitudinal beams arranged in parallel, a number of load-bearing connecting devices are uniformly arranged on the longitudinal beams along the length direction, and a number of beams are evenly connected between the two longitudinal beams, so that The two ends of the beam are respectively fixedly connected with the corresponding load-bearing connection devices. The longitudinal beam is an I-shaped steel beam 1, the load-bearing connecting device is a load-bearing steel plate 2, the load-bearing steel plate 2 is welded to the web and the upper wing of the I-shaped steel beam 1, and the load-bearing steel plate 2 There are two bolt holes 10; the beam is a channel steel, and the two ends of the channel steel are fixedly connected with the load-bearing steel plate 2 through the first high-strength bolts 7 .

[0027] A large-span reinforced truss floor deck assembly type support construction m...

Embodiment 2

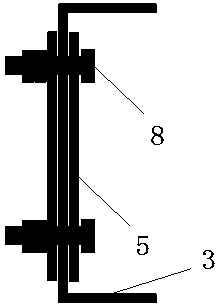

[0032] The difference between the assembled support of the large-span steel truss floor deck in this embodiment and the assembled support of the large-span steel truss floor deck in Embodiment 1 is that the beam is divided into two sections, and the two sections of beam are connected by a telescopic device . The beam is divided into two sections: a first channel steel 3 and a second channel steel 4; Web welding; the strip connecting steel plate 5 is provided with two parallel strip holes 9 along the length direction, and the first channel steel 3 is provided with round holes matching the two strip holes 9; The other end of the strip-shaped connecting steel plate 5 is fixedly connected with the first channel steel 3 through the strip-shaped hole 9 and the round hole through the second high-strength bolt 8 . Two strip connecting steel plates 5 are respectively located on the inner and outer sides of the web of the second channel steel 4 .

[0033] The difference between the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com