A hydraulic check valve automatic testing system and method

An automatic test system and one-way valve technology, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc., can solve the problem of abnormal use of one-way valves, less detection and detection of one-way valves Complicated and inaccurate problems, to achieve the effect of preventing loss and convenient selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The utility model is described in further detail below in conjunction with the accompanying drawings.

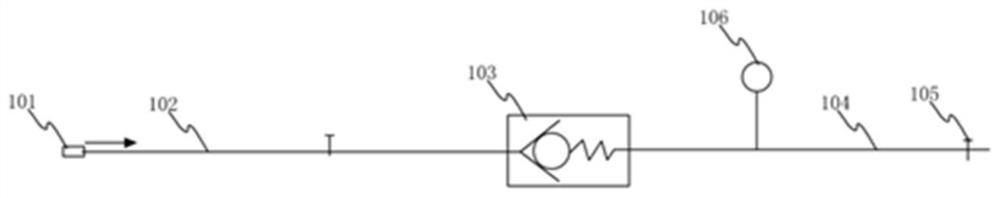

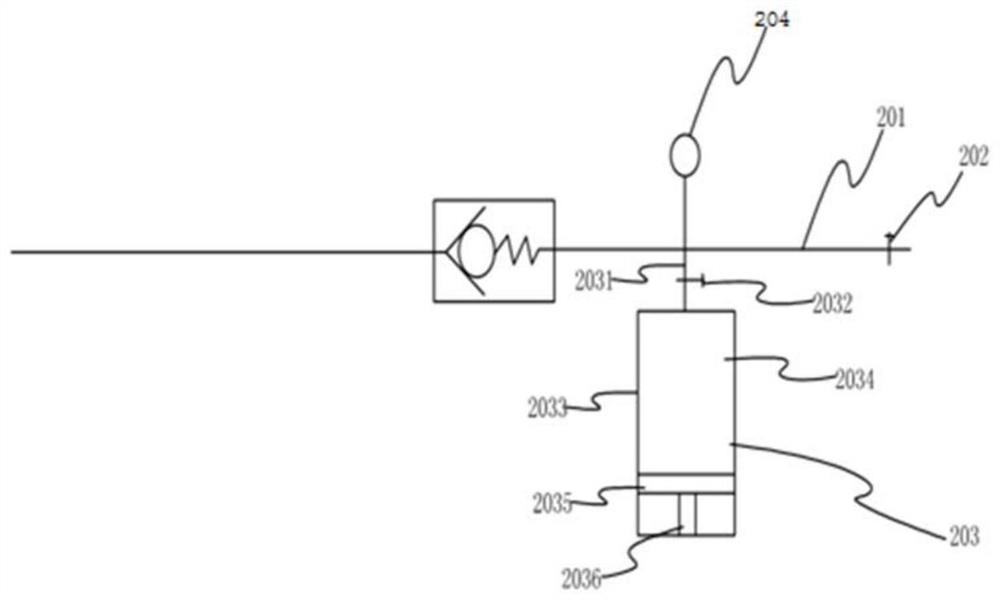

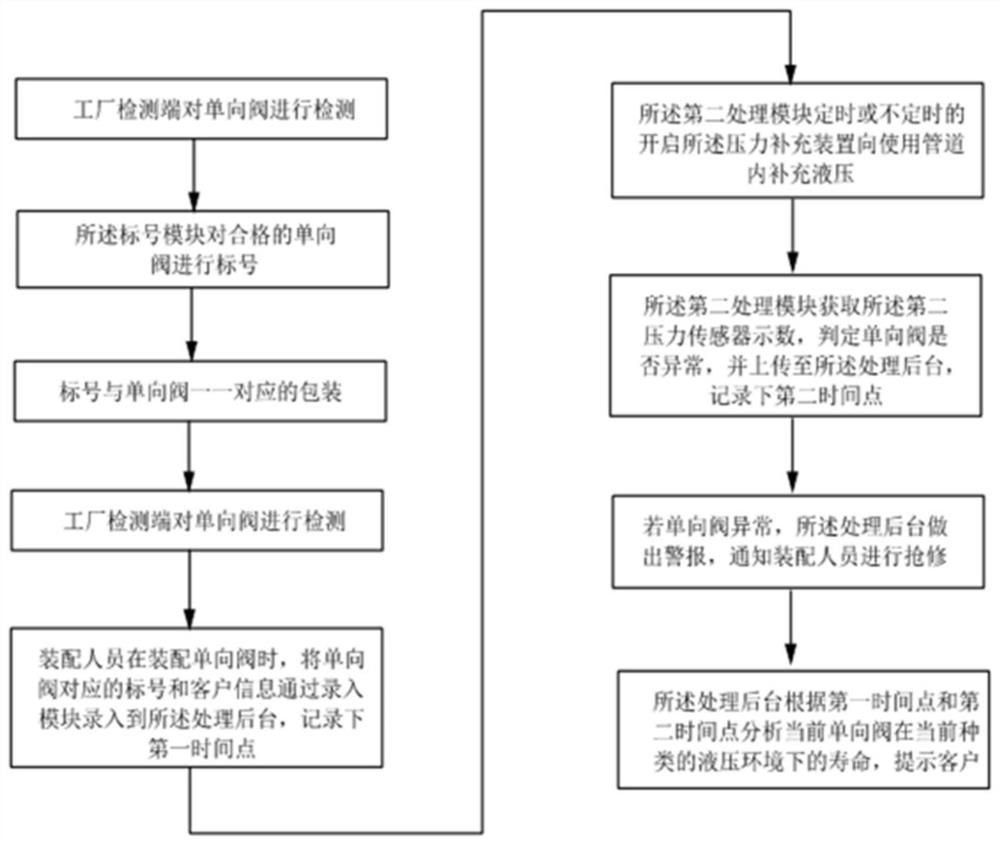

[0029] Such as figure 1 ——As shown in 5, a hydraulic one-way valve automatic testing system includes a factory testing terminal, a customer testing terminal and a processing background;

[0030] Wherein, the factory detection end includes a liquid oil injection device 101, the liquid oil injection device 101 is connected to one end of the first oil pipe 102, the other end of the first oil pipe 102 is connected to a check valve detection area 103, and the check valve detection area 103 is connected to a One end of the second oil pipe 104, the other end of the second oil pipe 104 is also provided with a first valve 105, and the part of the second oil pipe 104 between the check valve detection area 103 and the first valve 105 is provided with a first pressure sensor 106; The factory detection terminal also includes a labeling module for labeling qualified checked check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com