A wafer etching equipment

A technology for etching equipment and wafers, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of etching liquid flow, different widths at different heights of etching positions, and difficulty in controlling, so as to achieve narrowing of differences The difference in height, the probability of reducing flow, and the effect of avoiding flow around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

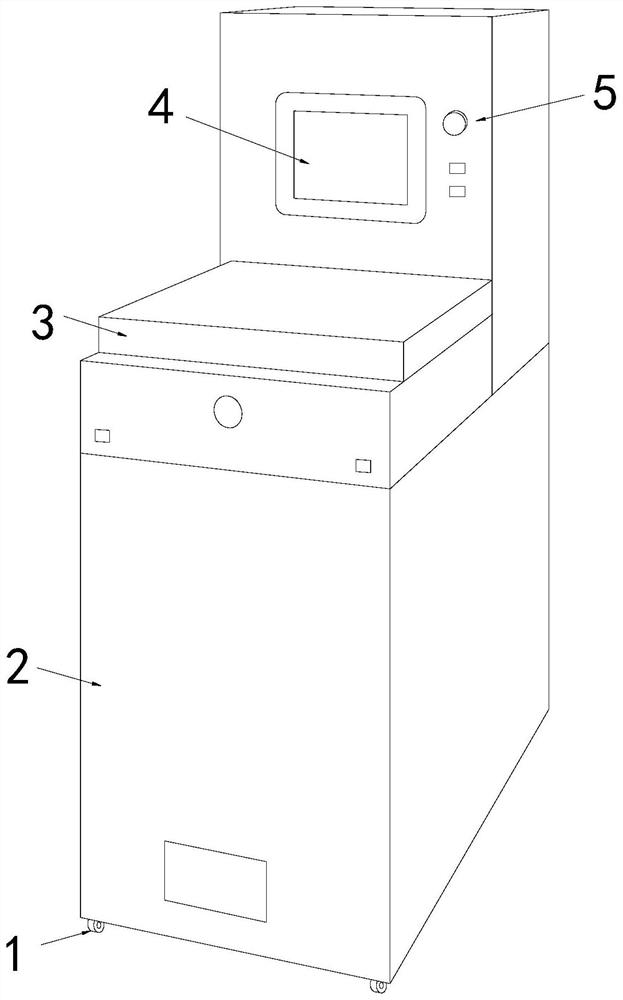

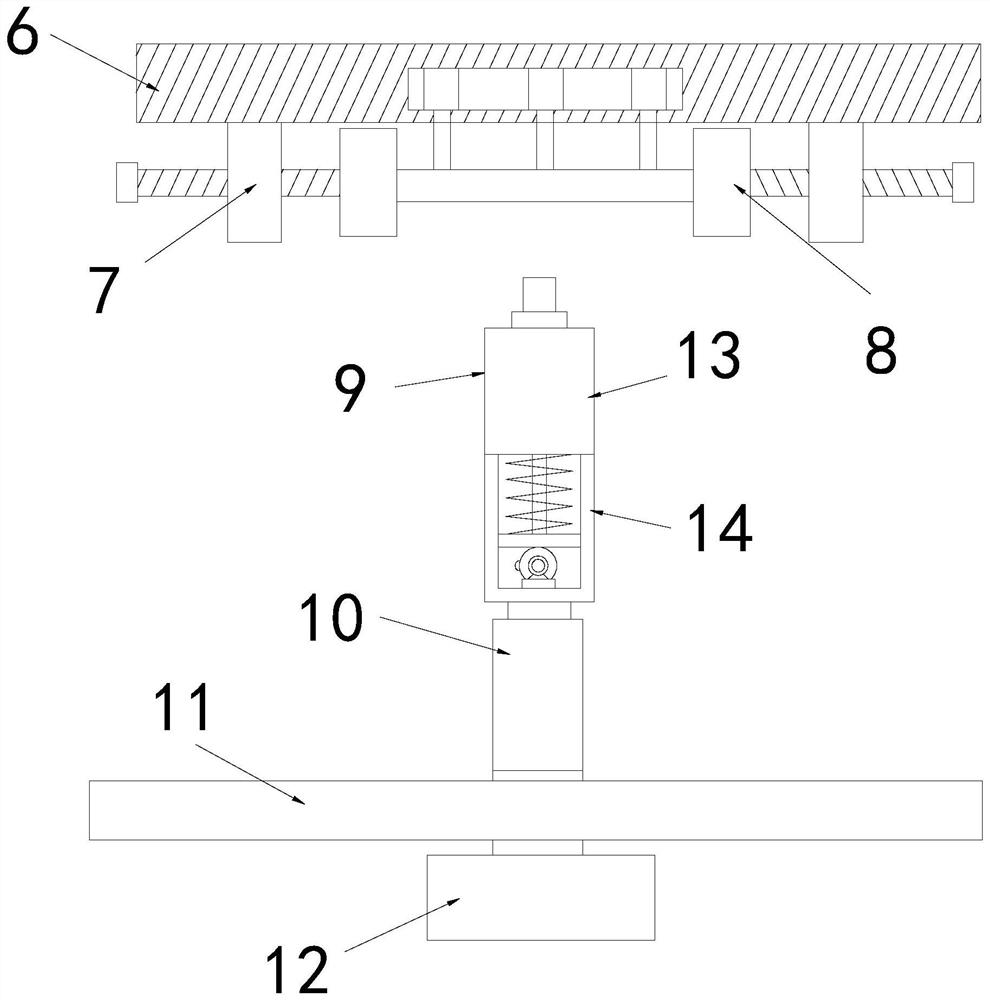

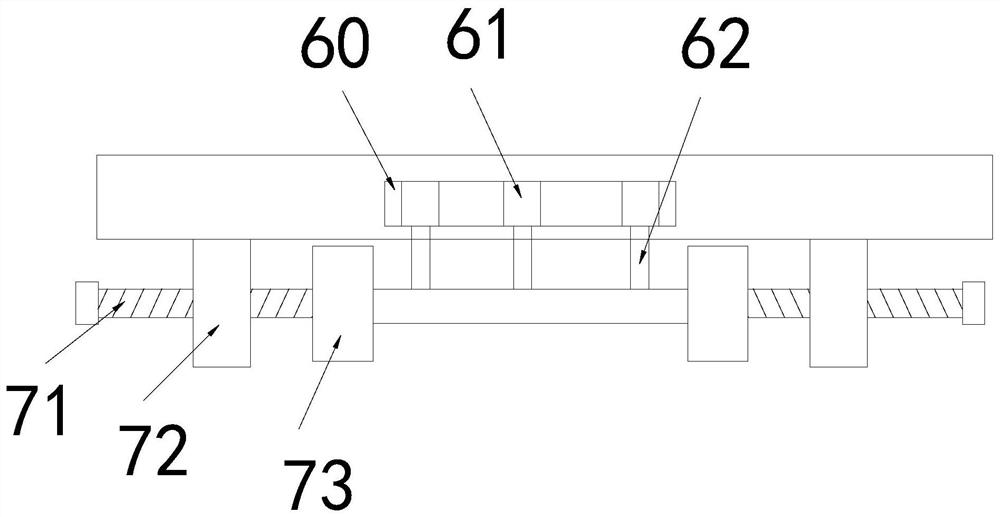

[0026] See Figure 1-4 The present invention provides a wafer etching apparatus for a wafer etching apparatus: its structure includes a moving wheel 1, a etching box 2, a cover 3, a display screen 4, a control tank 5, and a moving wheel at the bottom of the etching box 2. The top of the organic box 2 is provided with a cover 3, the control box 5, provided on the side of the cover 3 and is attached to the top of the etching case 2, the surface of the control box 5 is mounted 4, the etching The box 2 is provided with a stage 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com