High-temperature cloth, photovoltaic module and preparation method thereof

A photovoltaic module and high-temperature cloth technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problem of delamination of surface materials and internal structure layers, appearance defects of small white spots, and low bonding strength between surface materials and internal structure layers and other problems, to achieve the effect of reducing small white spots, reducing pressure, and uniform bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

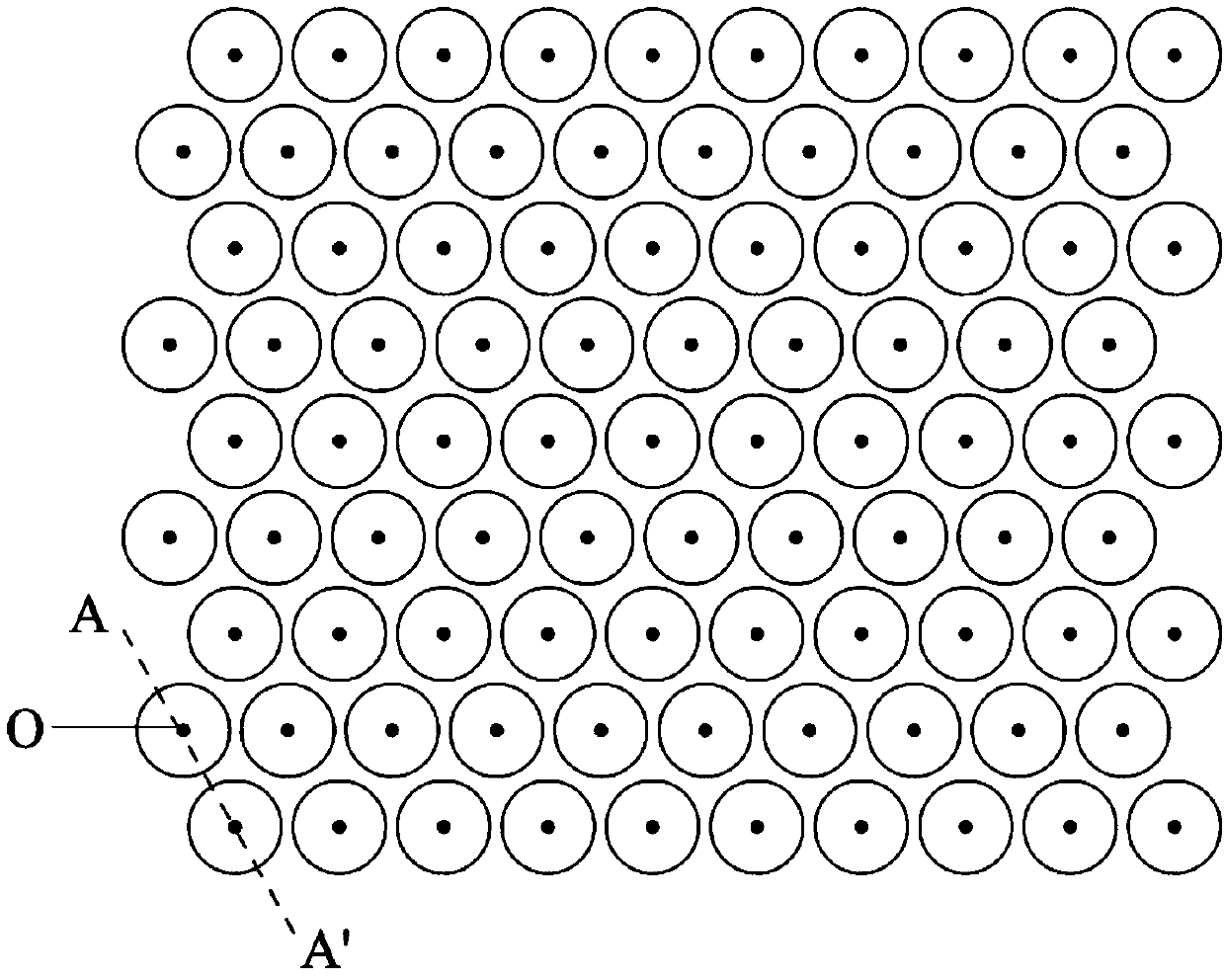

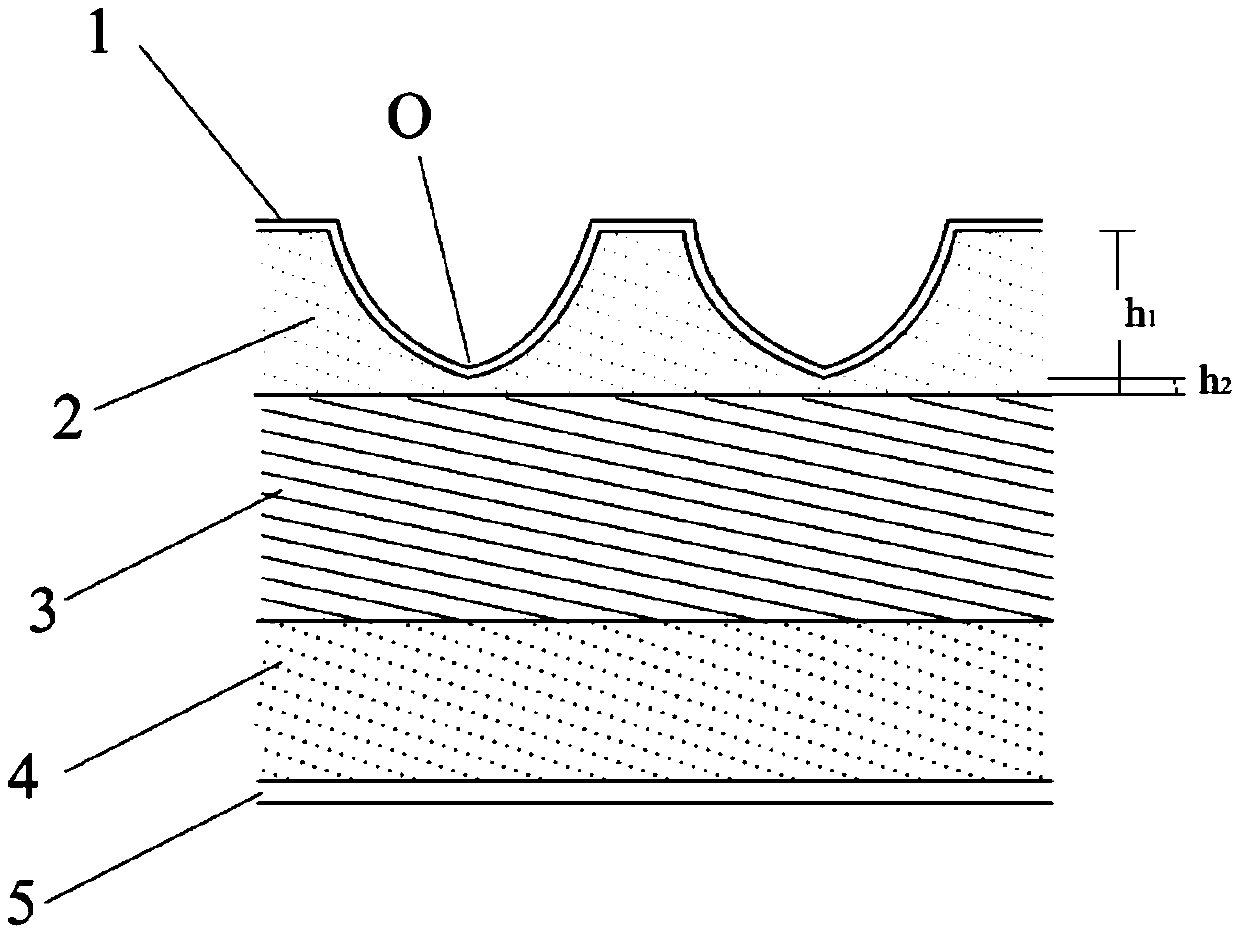

[0041] The function of the concave-convex texture on the surface of the photovoltaic module in the prior art is: on the one hand, it can shield the tiny appearance defects of the photovoltaic module, and on the other hand, it can give users a better hand feeling experience.

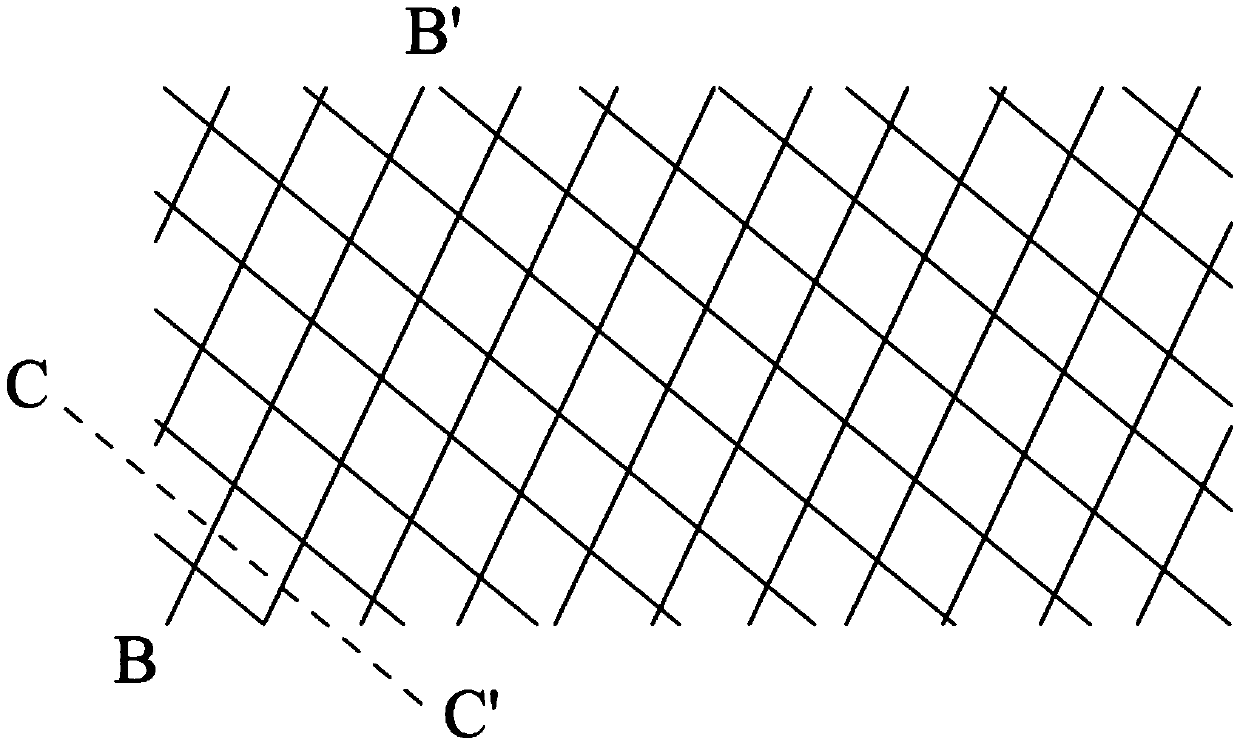

[0042] The preparation process of the concave-convex texture in the prior art is: during the lamination process, a high-temperature cloth with conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com