Tea cake pressing device for tea production

A forming device and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of high impurities in tea cakes and low cake pressing efficiency, and achieve the effects of less impurities in tea cakes, improved quality of tea cakes, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

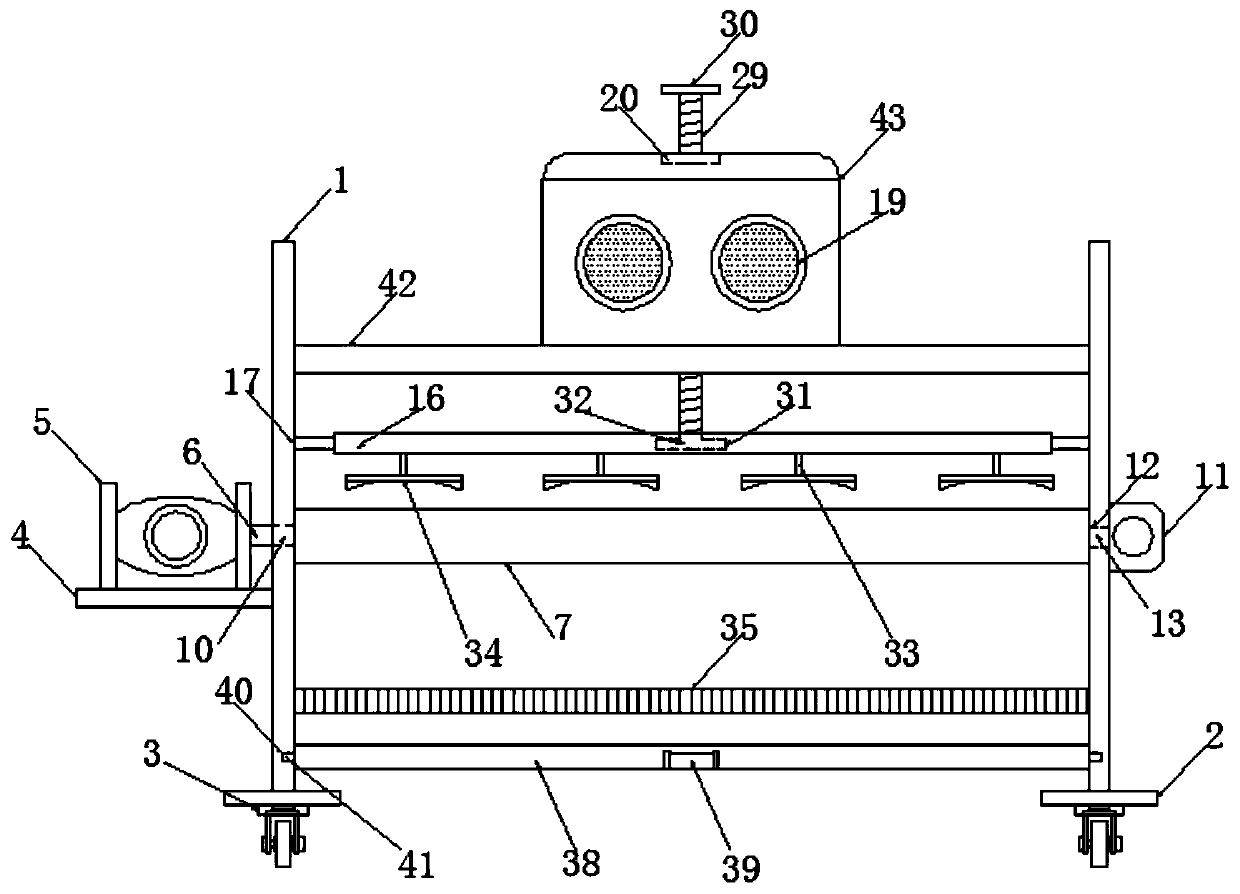

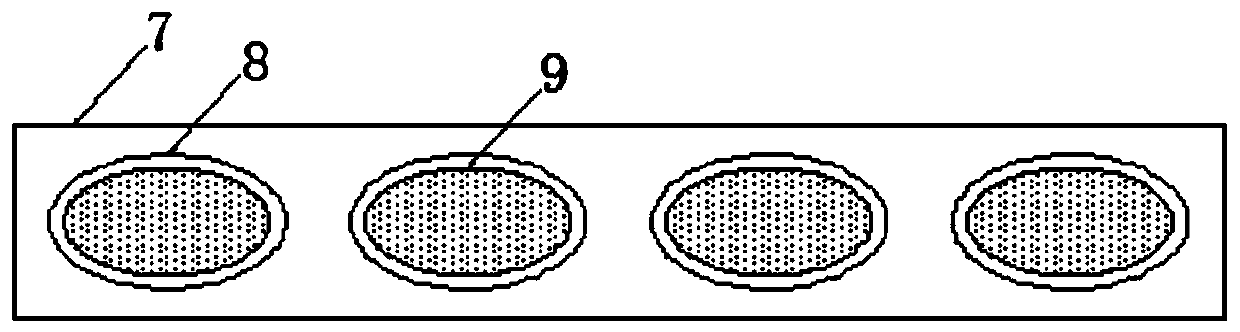

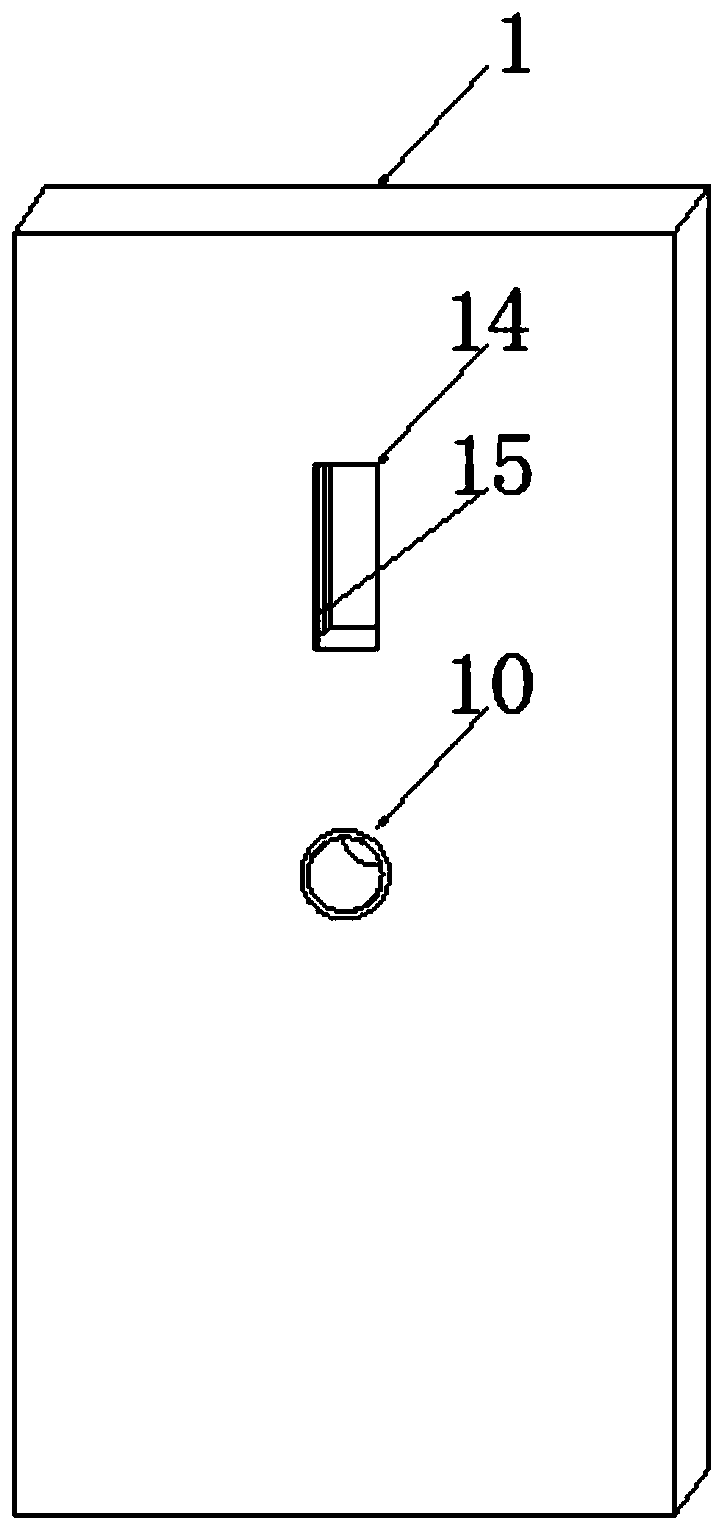

[0024] Such as Figure 1-8 As shown, this specific embodiment adopts the following technical solutions: a tea cake press forming device for tea production, including two side plates 1, the two side plates 1 have the same specifications and are oppositely arranged, and the two side plates 1 1 lower ends are provided with a base plate 2, and the longitudinal center axes of the upper end faces of the two base plates 2 are fixedly installed with the lower ends of the two side plates 1 respectively, and two universal wheels are fixedly installed on the lower end faces of the two base plates 2 3. The two universal wheels 3 on the lower end surface of each base plate 2 are distributed axisymmetrically with respect to the transverse centerline of the lower end surface of the base plate 2, and one of the lateral centerlines on one side of the side plate 1 is fixedly installed with an installation plate 4, a servo motor 5 is fixedly installed on the upper surface of the mounting plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com