Patents

Literature

30results about How to "Timely dump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

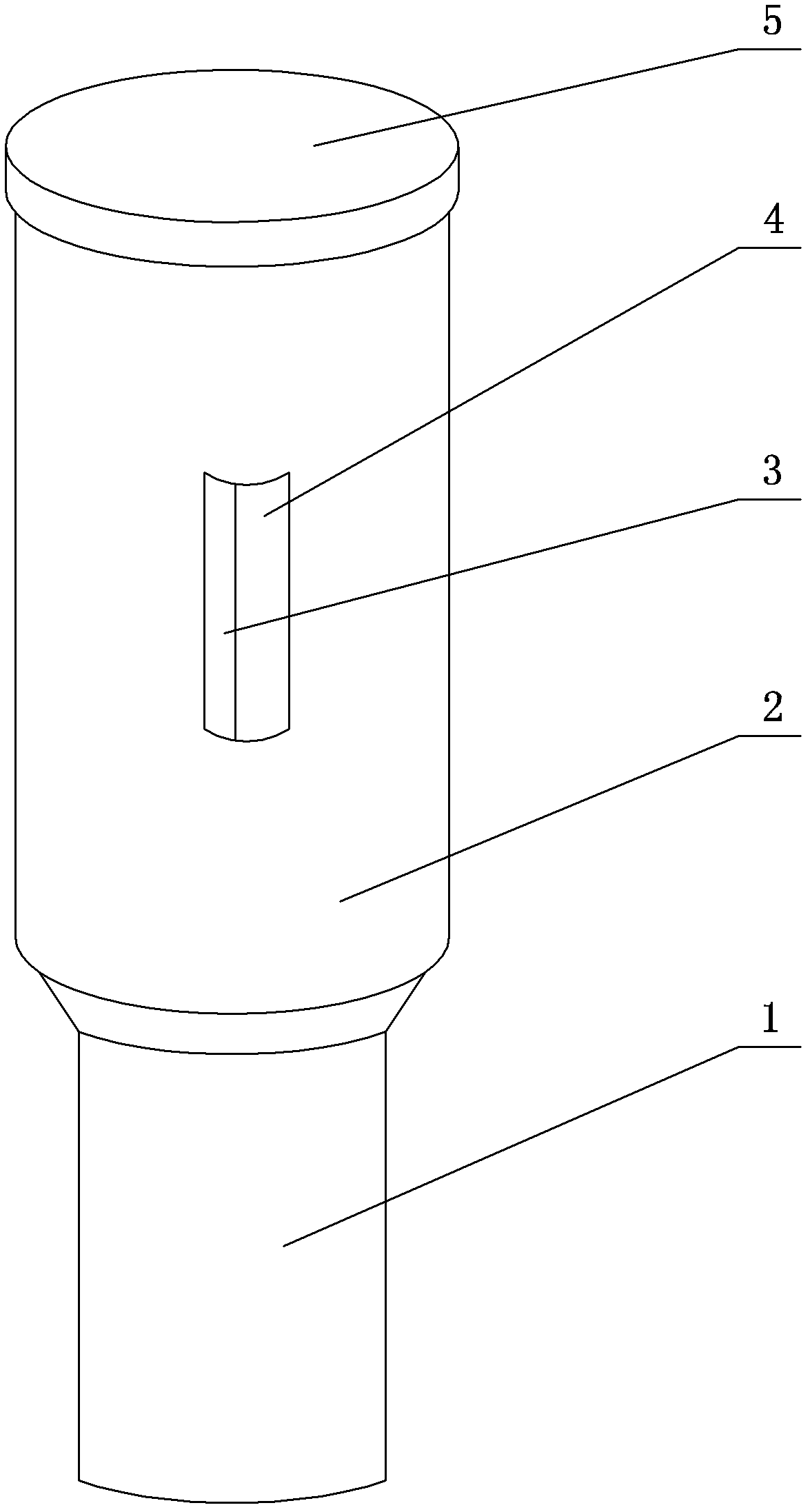

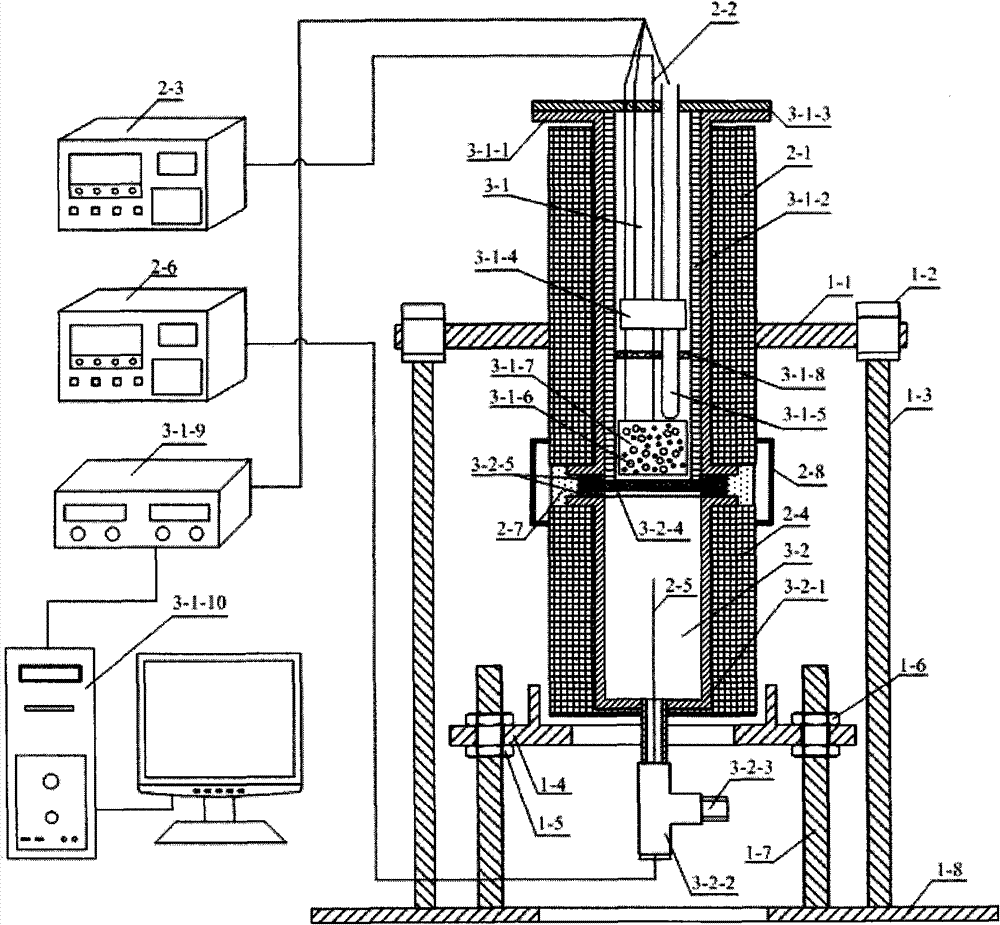

Test method and device for half cell of fluid bed electrode direct carbon fuel cell

InactiveCN102004225AHigh activitySimple structureFuel cell auxillariesElectrical testingPtru catalystElectrical battery

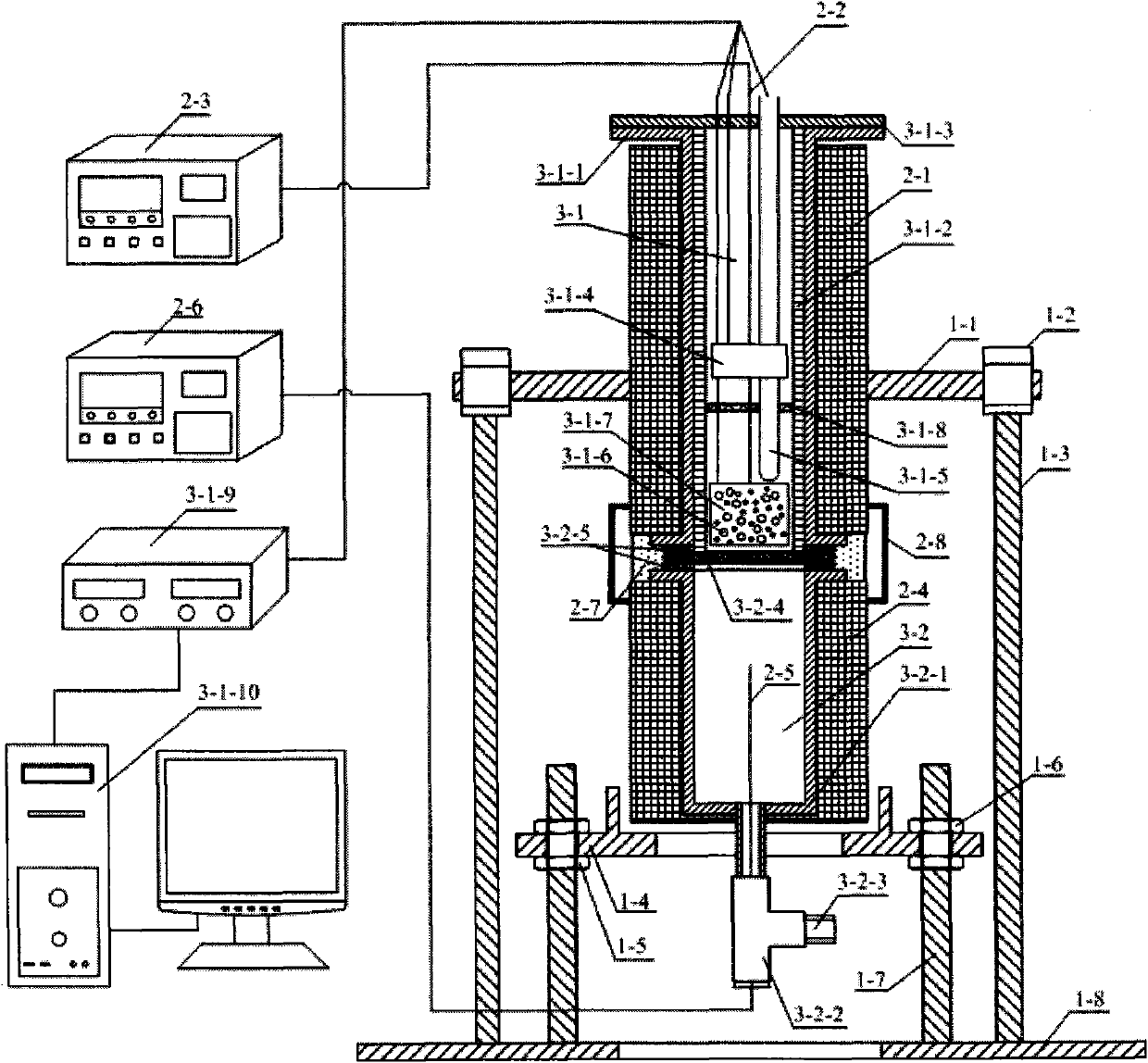

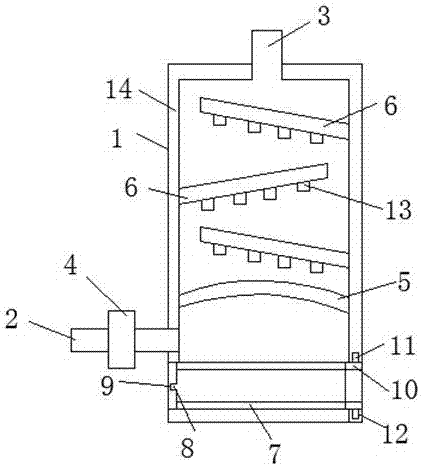

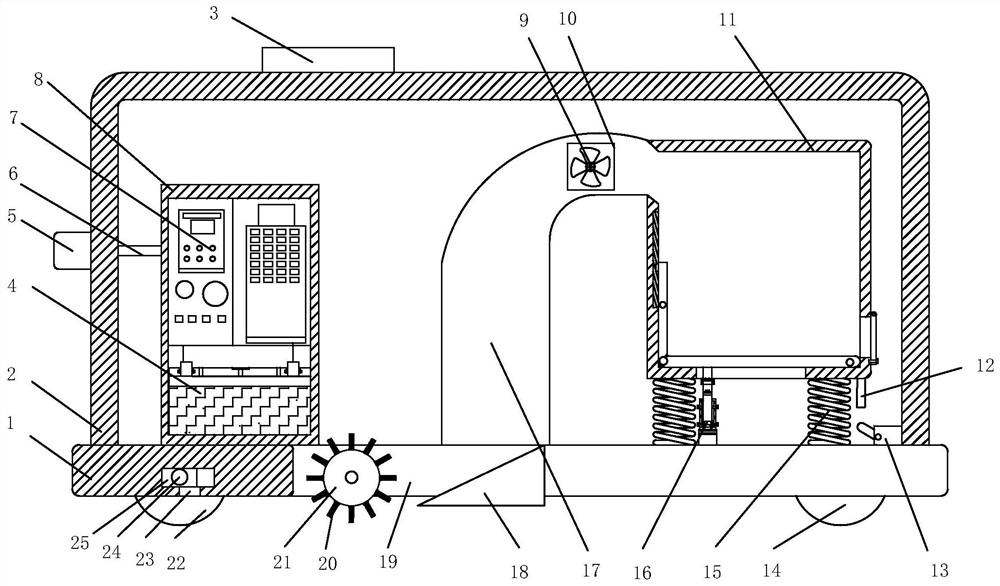

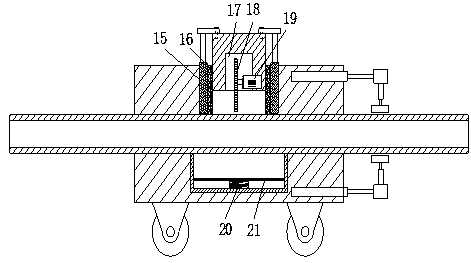

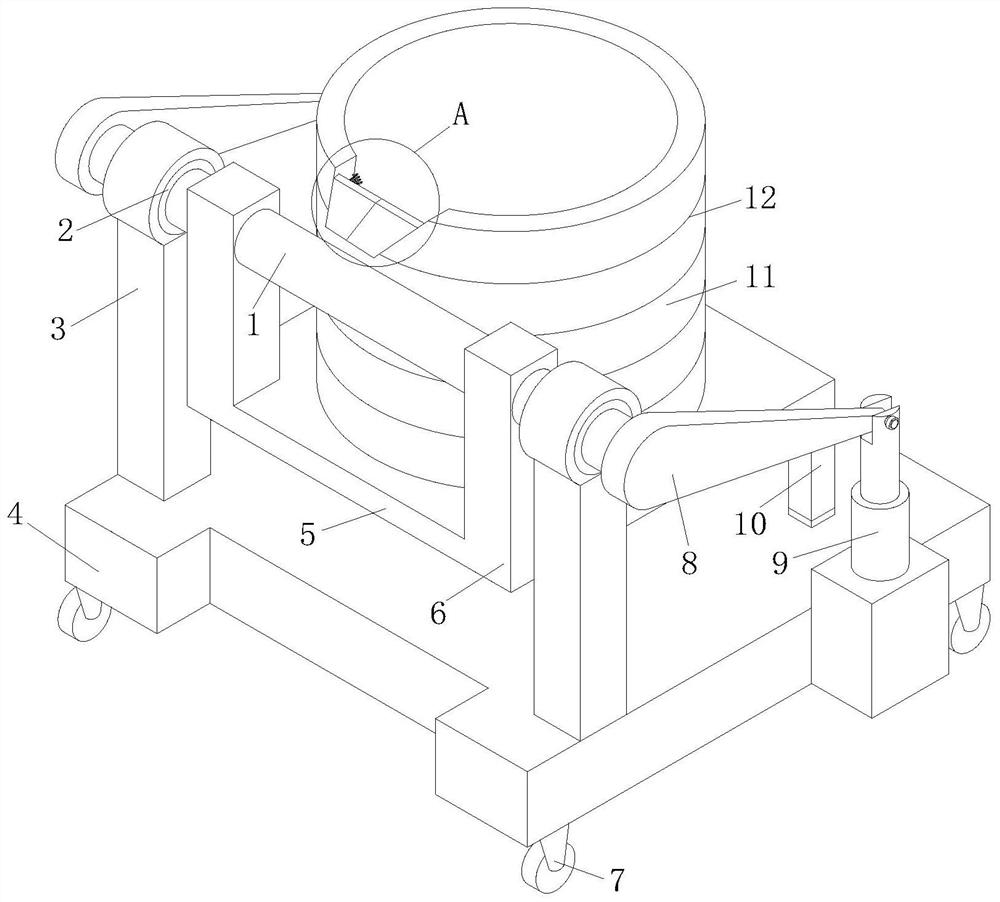

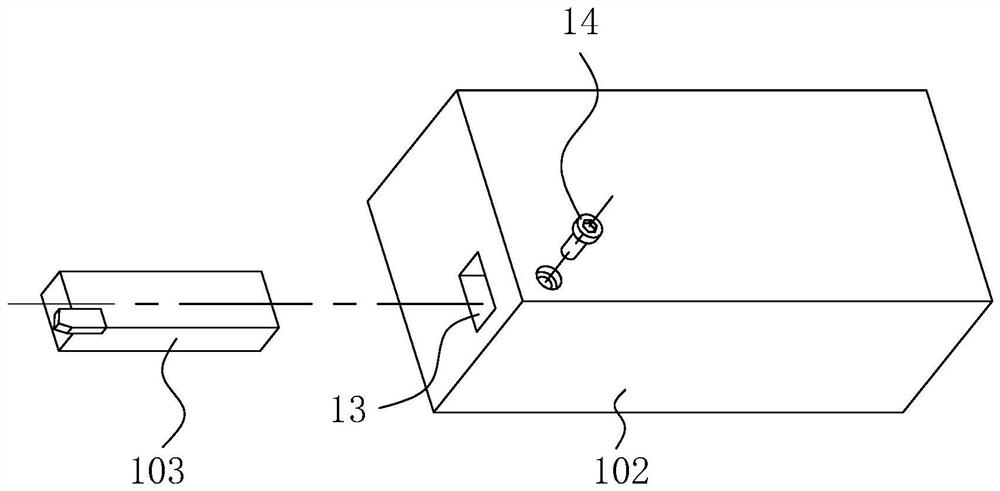

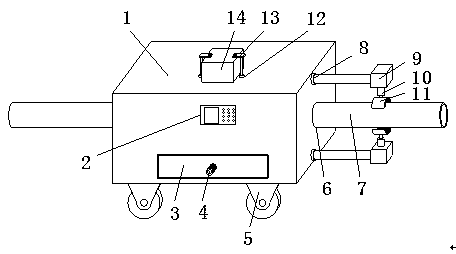

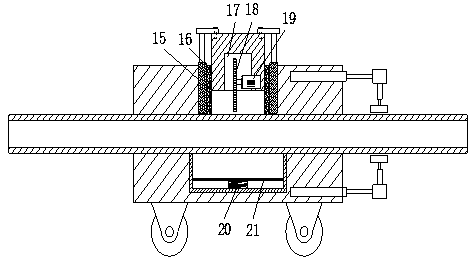

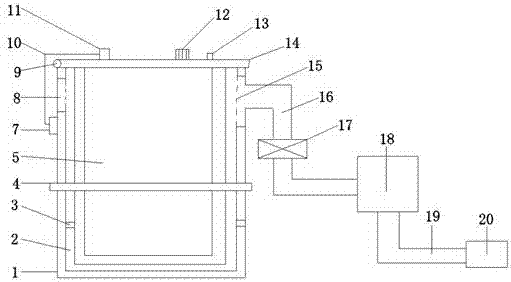

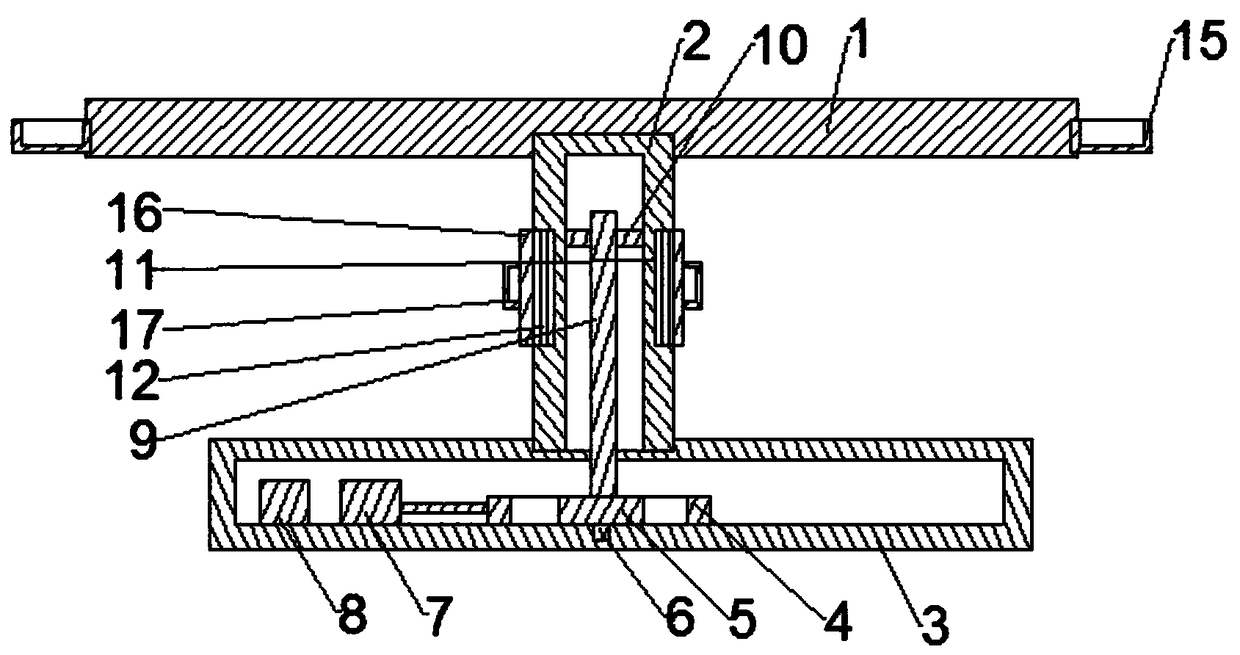

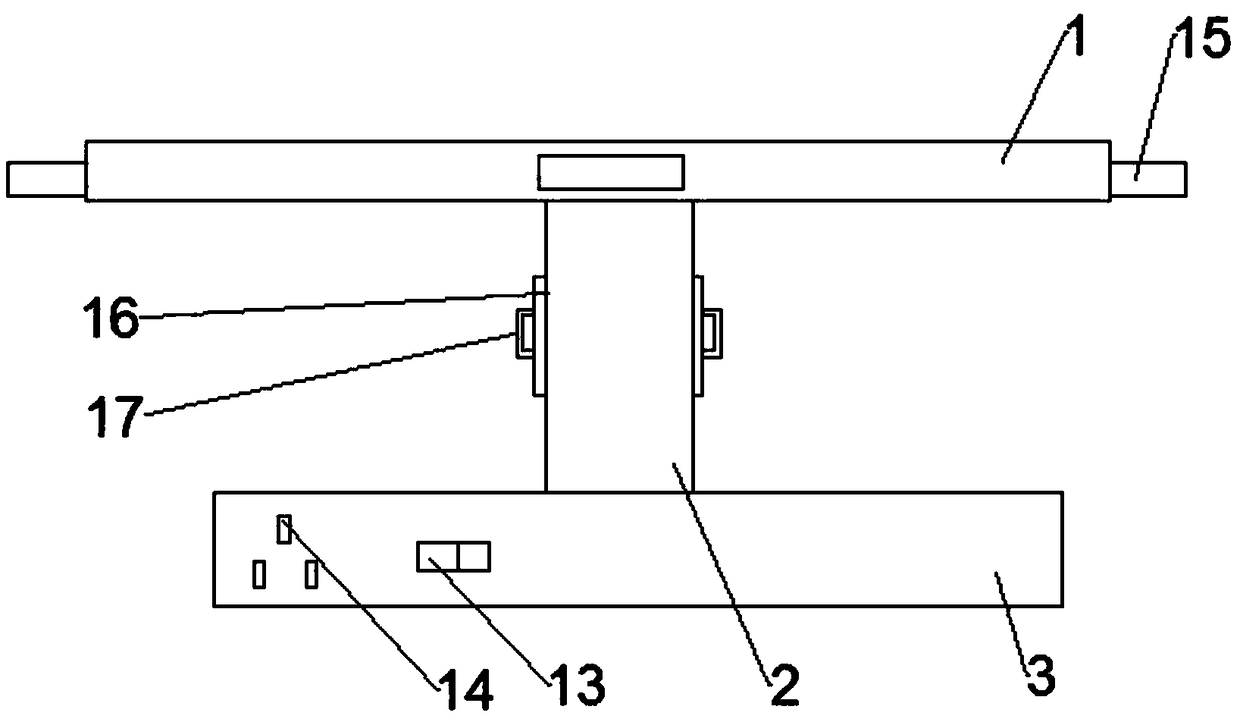

The invention provides a test method and device for half cell of fluid bed electrode direct carbon fuel cell. The method comprises the following steps: firstly, arranging a current collector and the mixture of carbon fuel and catalyst granules in a half cell; secondly, fixing a porous plate in a preset position, and sequentially adding an auxiliary electrode, a reference electrode and carbonate; then, introducing nitrogen gas into the half cell, heating the nitrogen gas to a preset reaction temperature, regulating the flow of the nitrogen gas, and introducing oxygen gas and carbon dioxide into the reference electrode to balance the gas; and finally, connecting to an external circuit to start experiment. The device for realizing the testing method is a half-cell reaction device and comprises a half-cell reactor and a gas preheater, two electric heating devices are respectively used for carrying out temperature control on the half-cell reactor and the gas preheater, and a rotatable support structure is used for supporting and fixing the half-cell reaction device and the electric heating devices and realizing the dumpage of molten carbonate in the half cell. By making full use of theadvantages of the fluid bed electrode and the direct carbon fuel cell, the performance of the cell can be improved.

Owner:SOUTHEAST UNIV

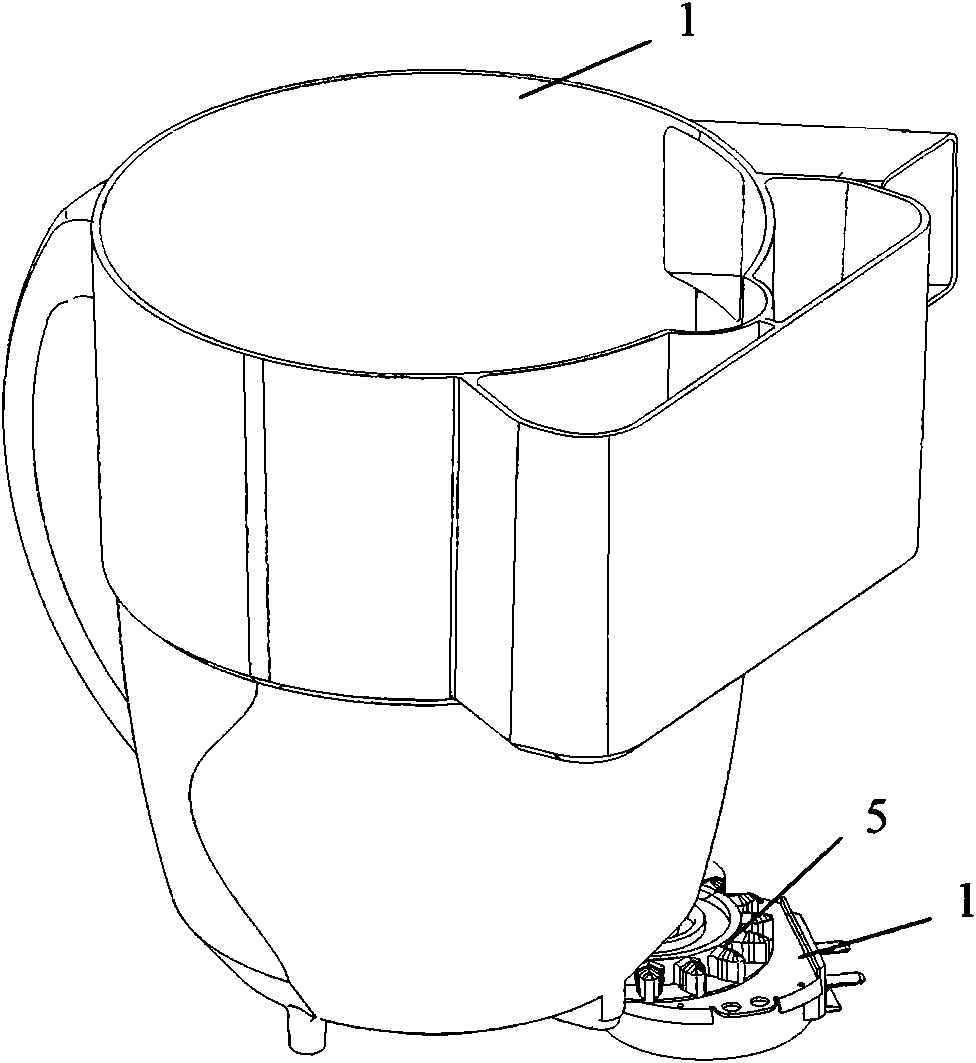

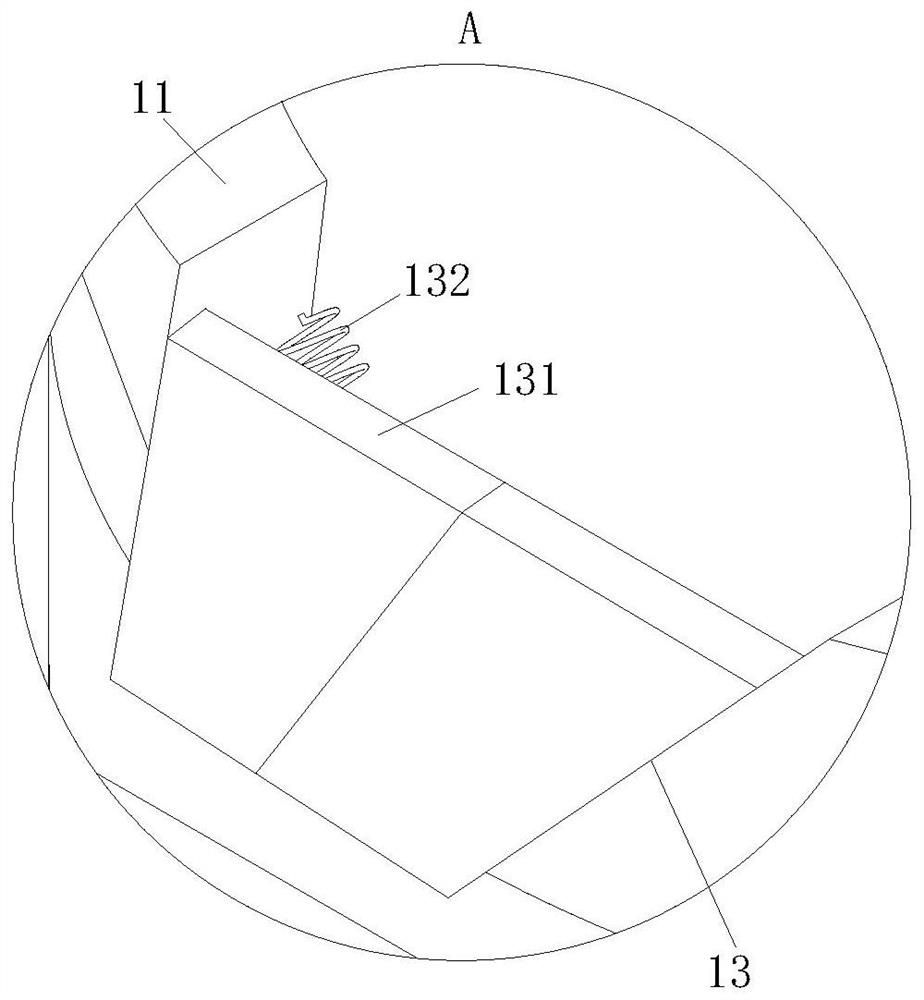

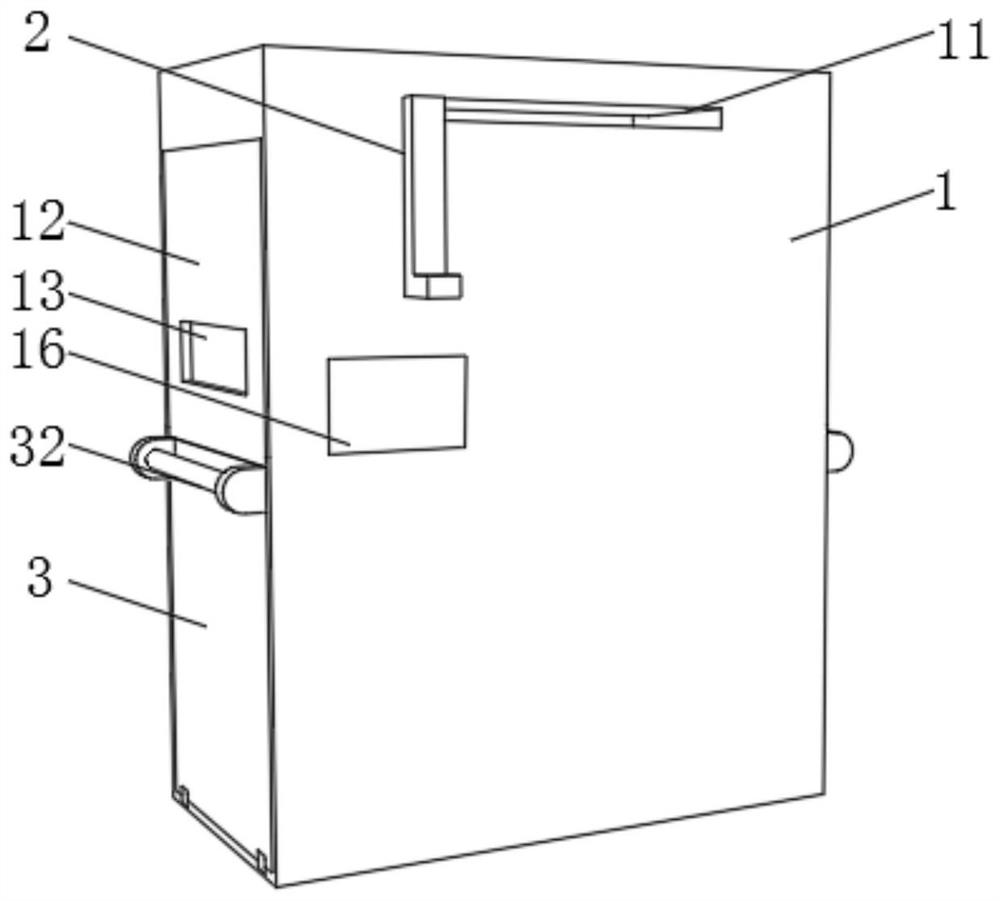

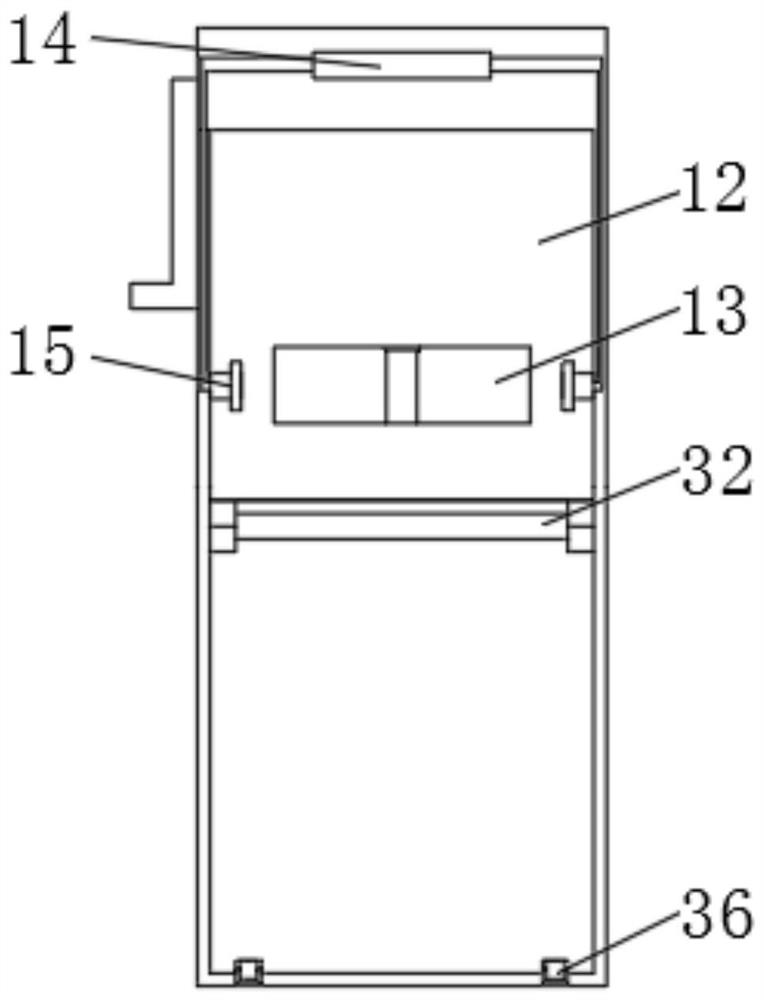

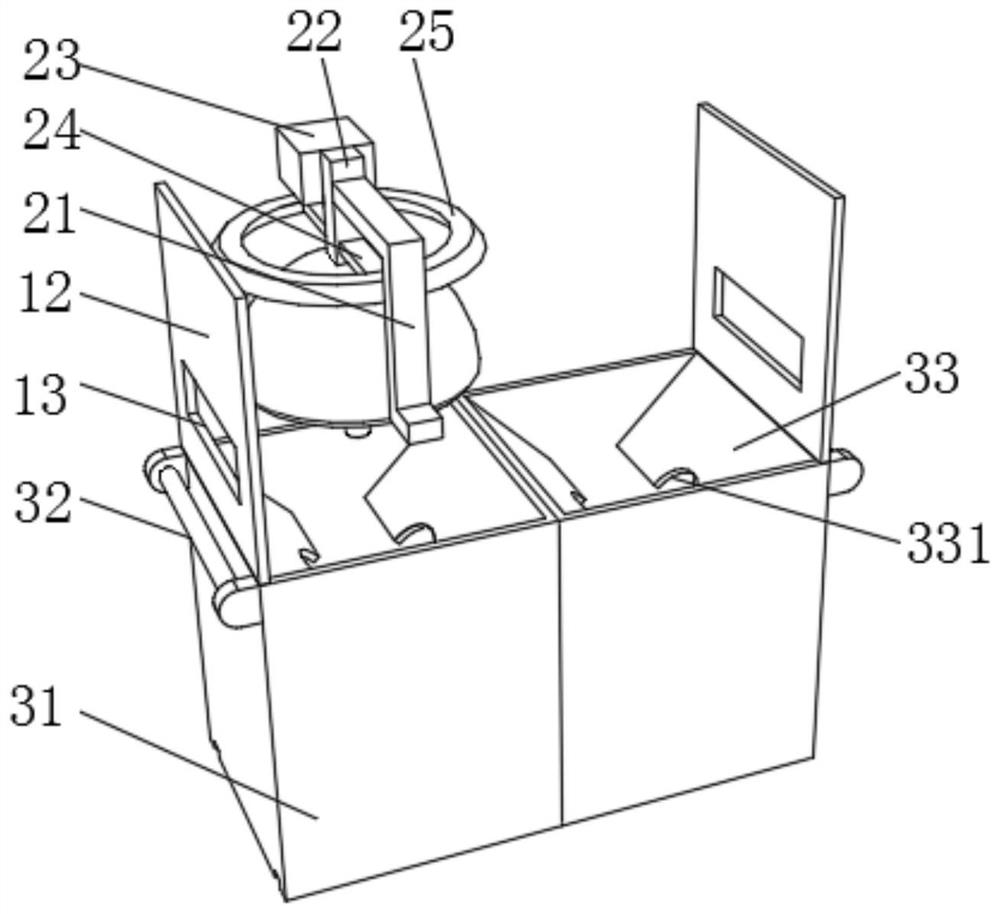

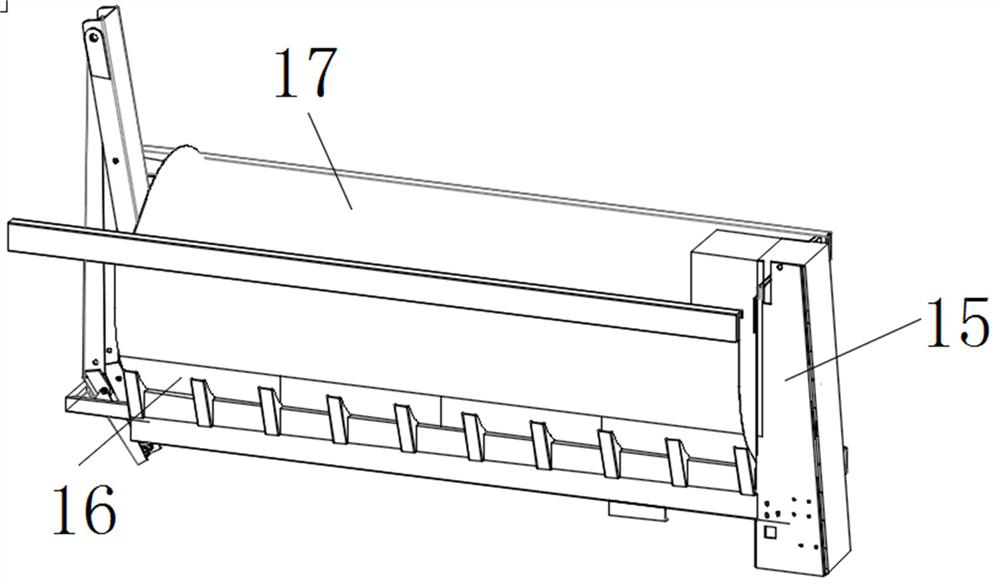

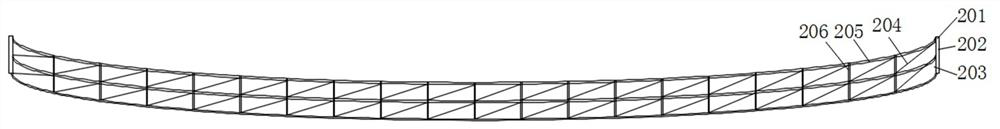

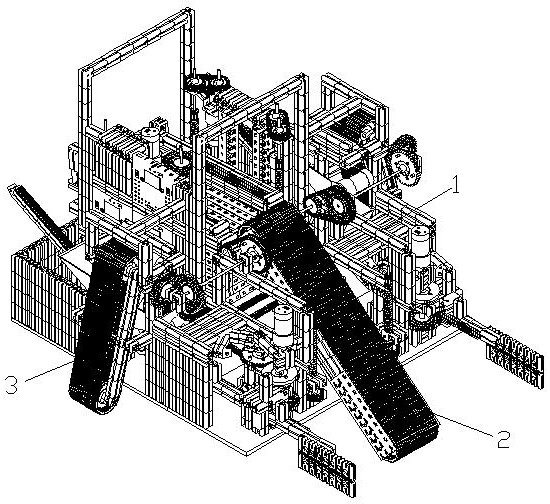

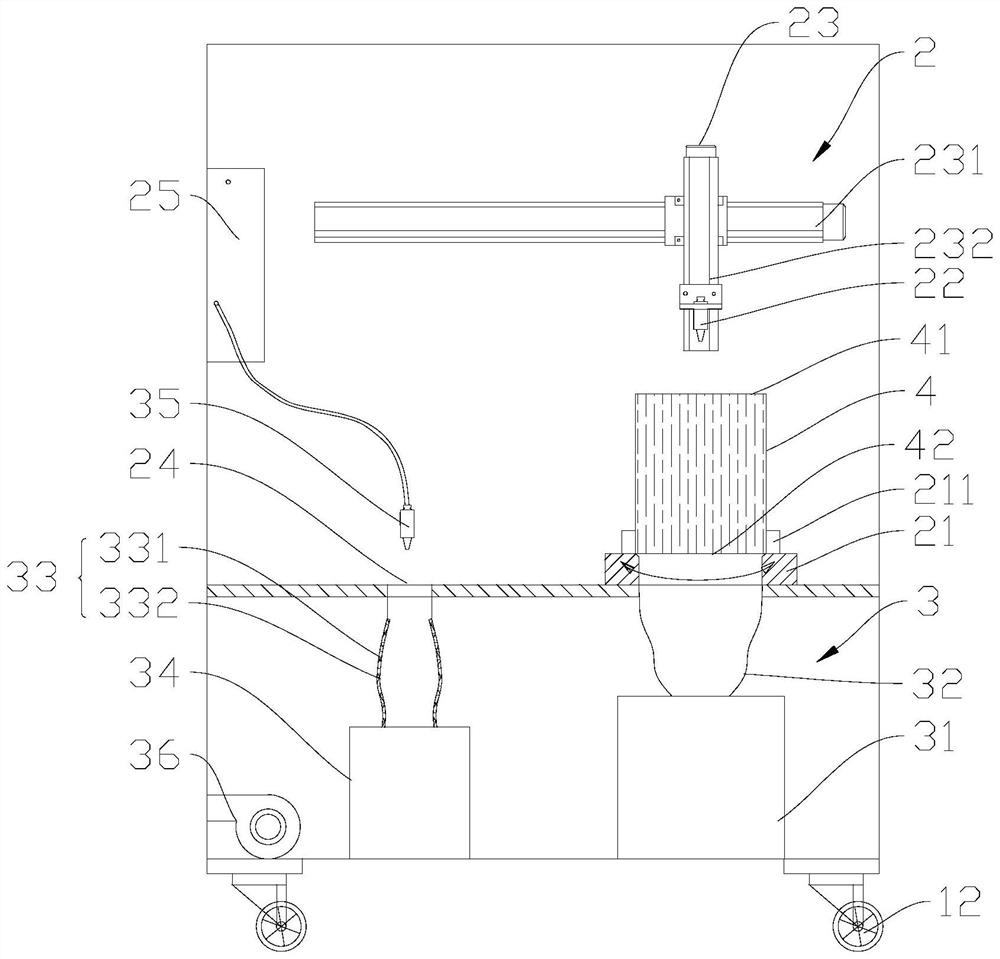

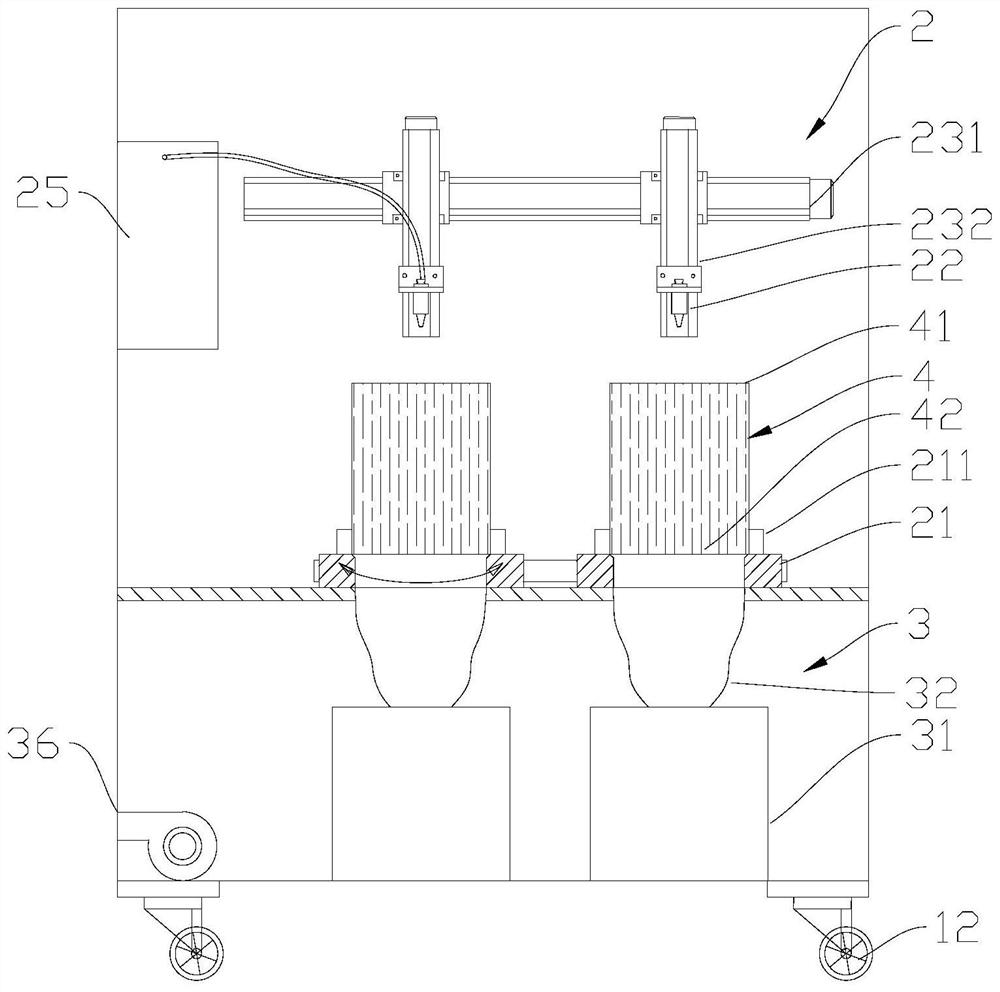

Biomass particle furnace

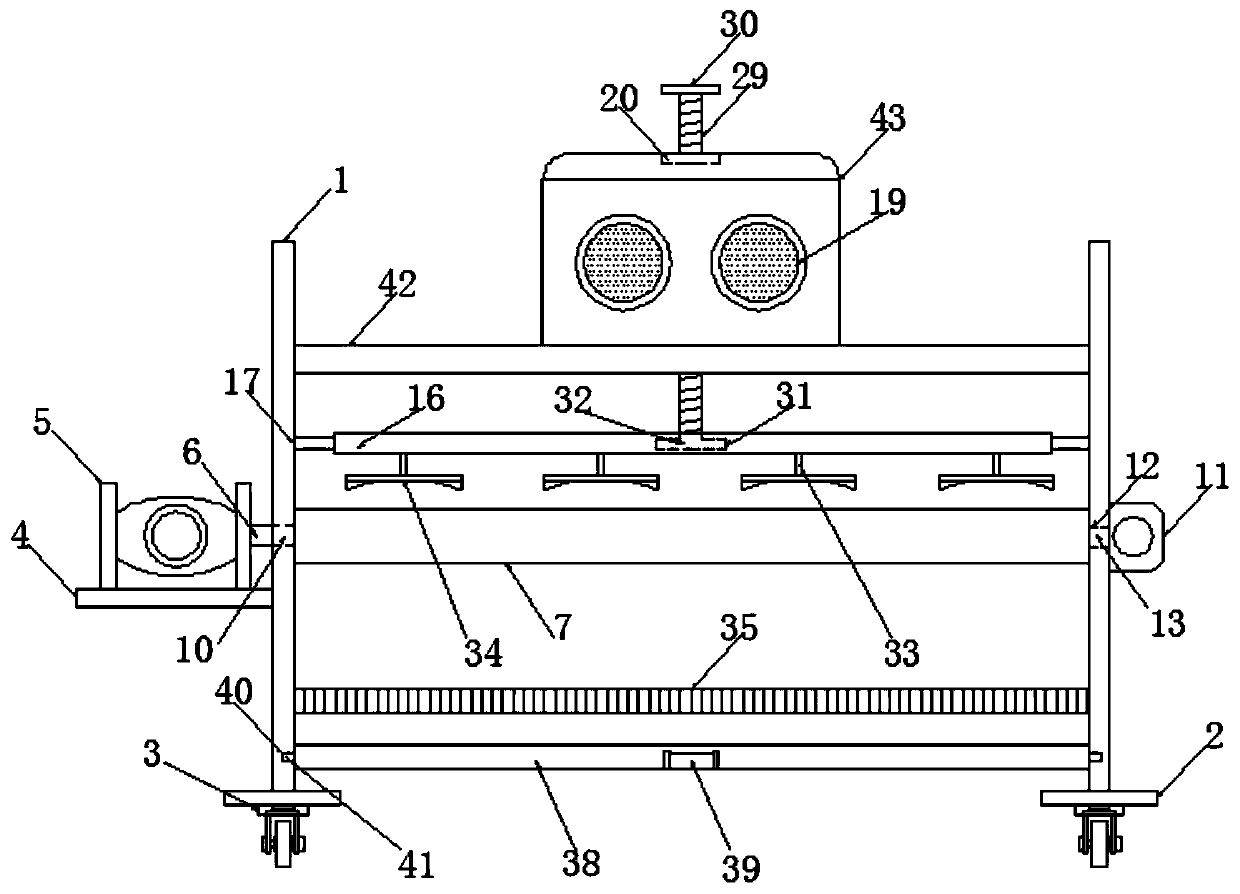

PendingCN108506924ATimely dumpAvoid cloggingFuel supply regulationSolid fuel combustionControl systemBiofuel

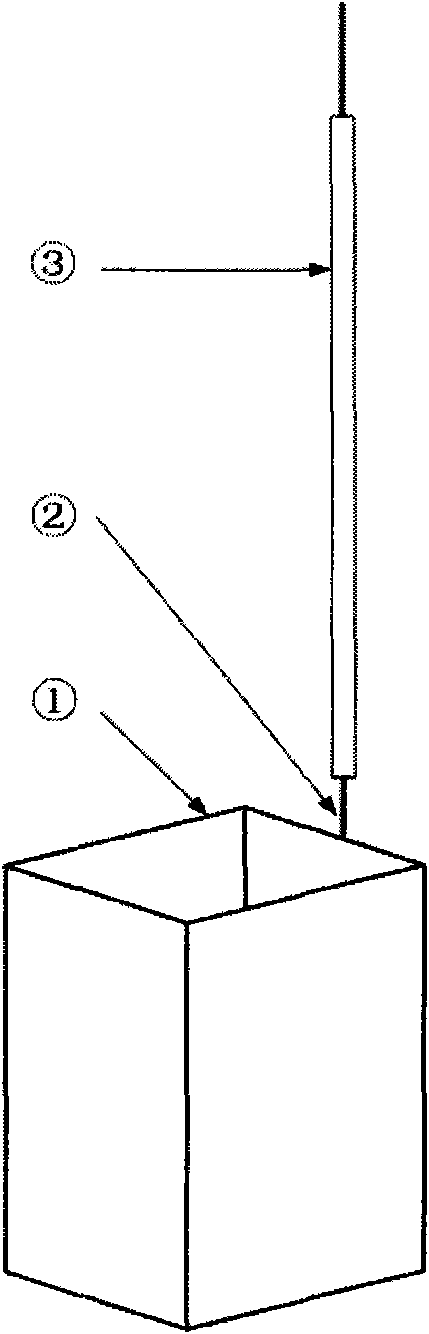

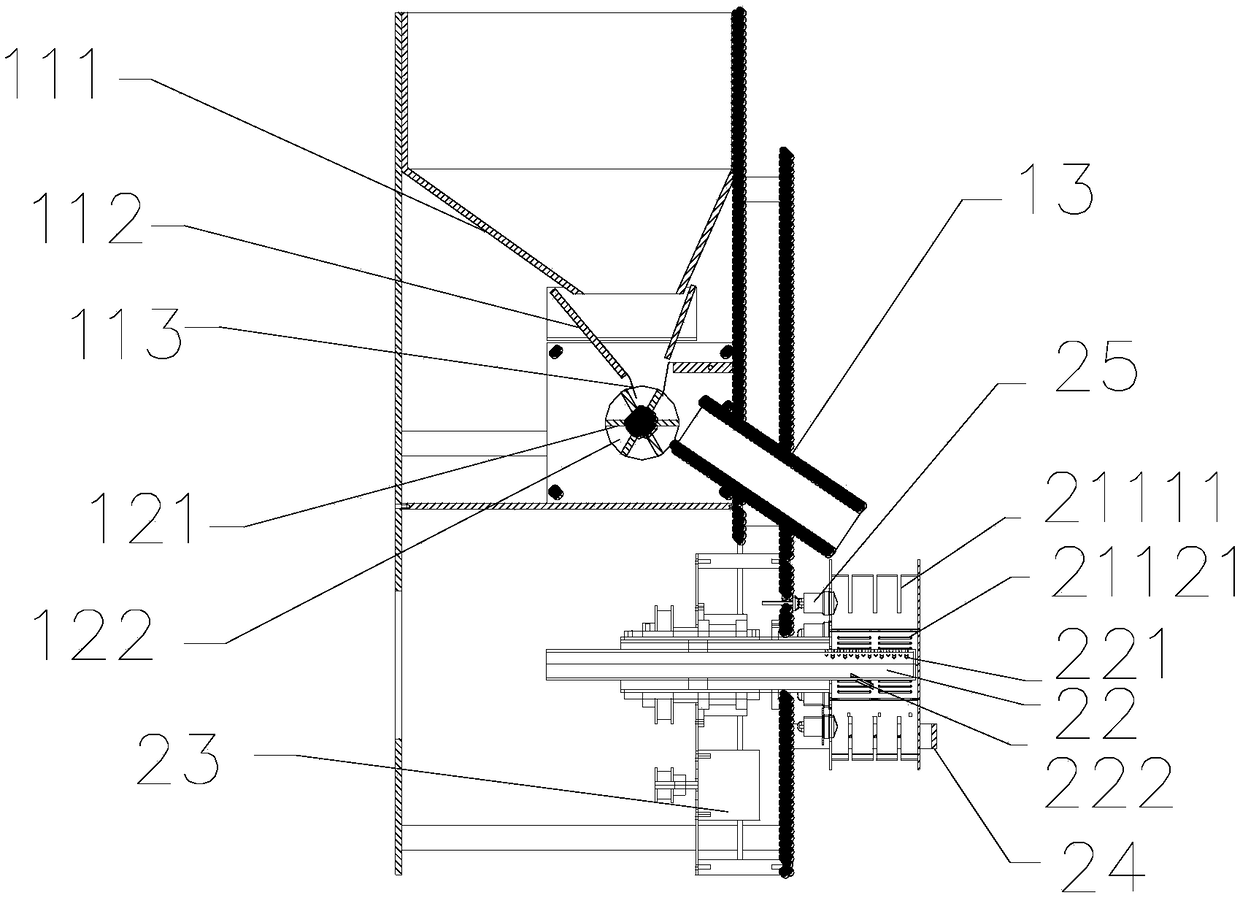

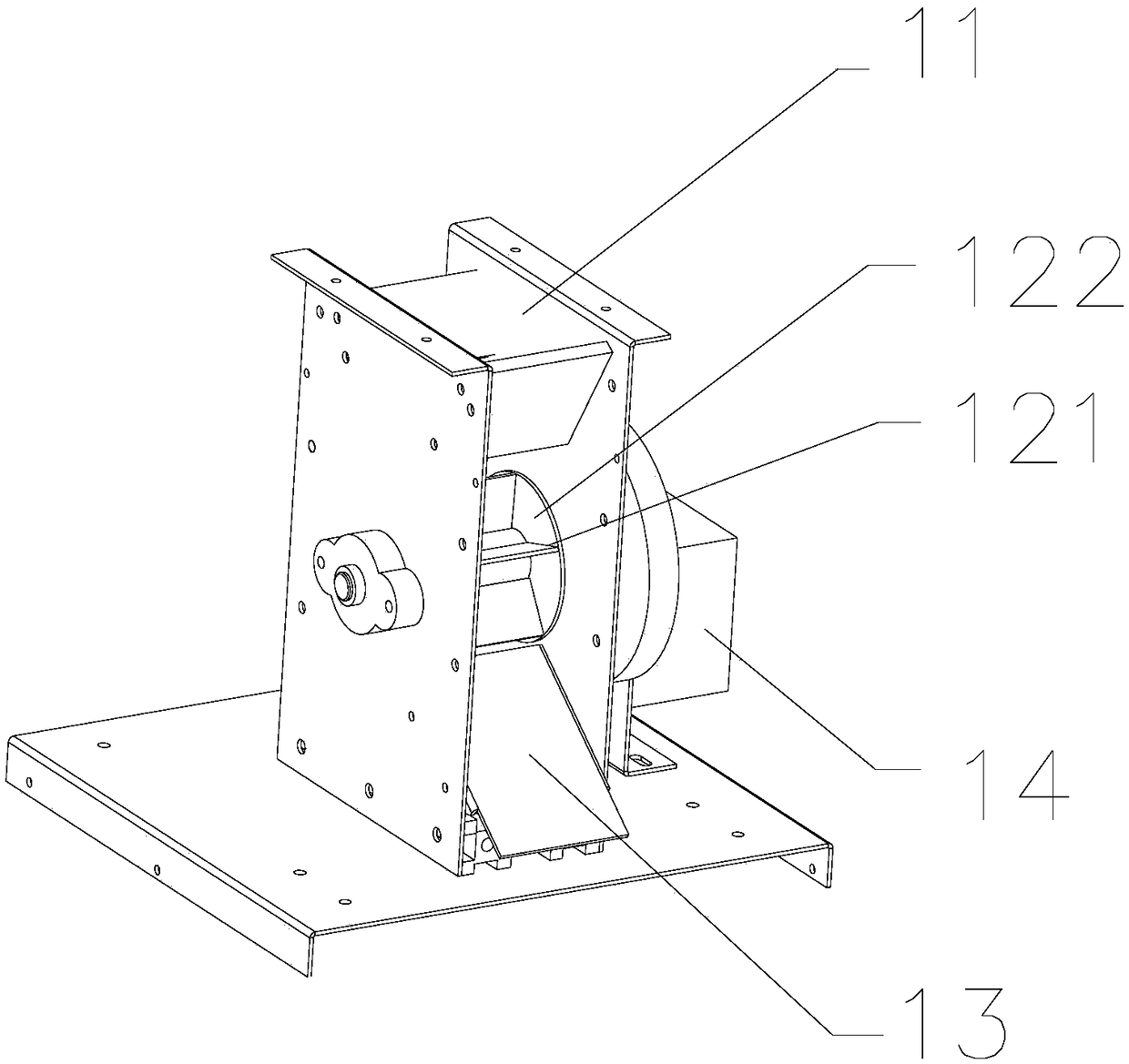

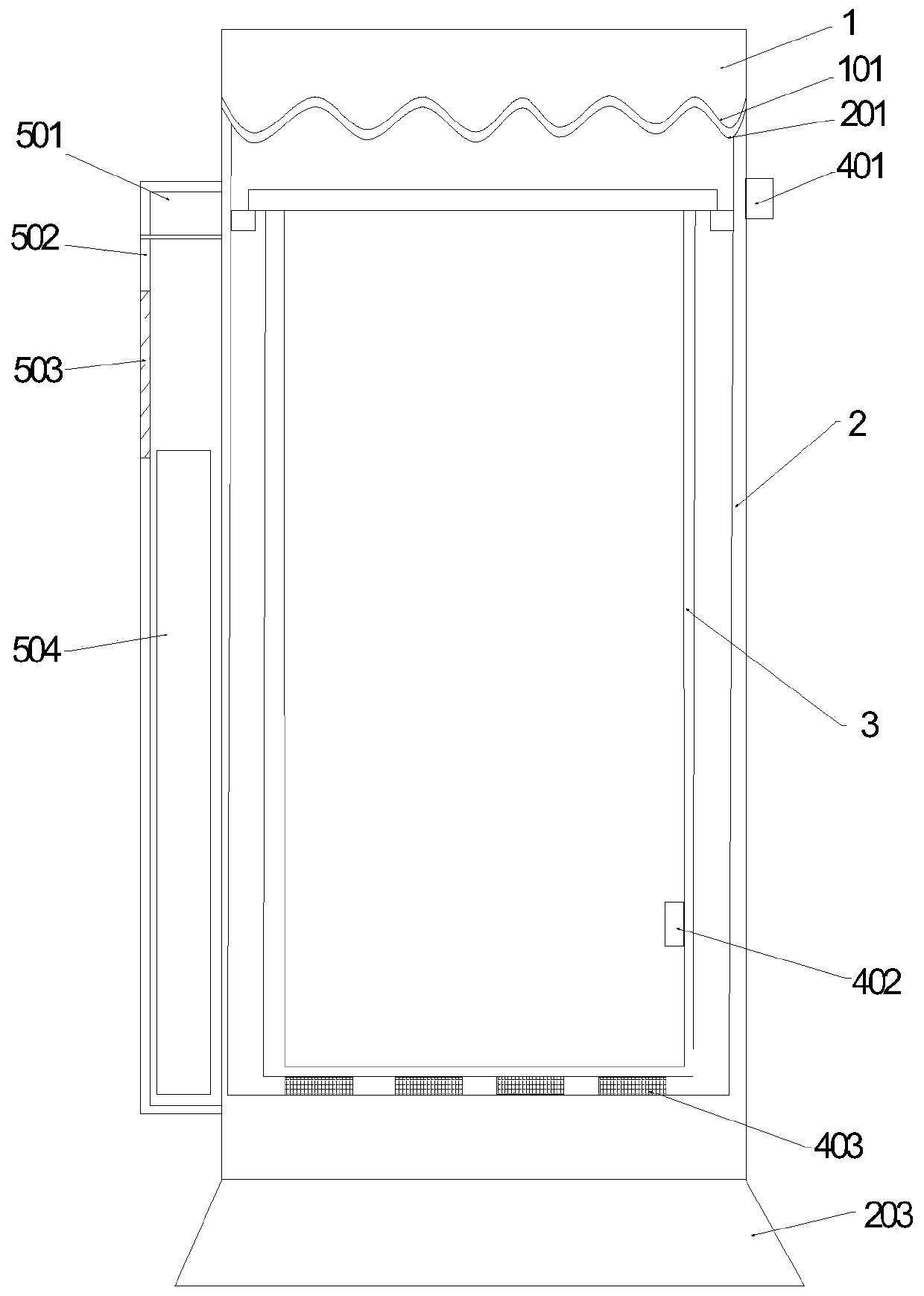

The invention discloses a biomass particle furnace which comprises a shell, a feeding device (1), a combustion device (2), a water circulation system, a control system (3) and an operation panel; thefeeding device (1) and a box body (21) of the combustion device (2) are both in a cylinder shape and rotate perpendicular to the ground plane by taking shafts of cylinders as rotation axes; an unloading groove (12) is divided into a plurality of unloading bins (122) by unloading bin partition plates (121); the box body (21) of the combustion device (2) is divided into 3-12 combustion cavities (211) by combustion cavity side walls (2111); openings of the unloading bins (122) and the combustion cavities (211) all face outwards; and the lower side of an outlet of an unloading passage (13) of thefeeding device (1) is the uppermost position of the box body (21). The invention provides the biomass densified biofuel combustion furnace which is automatic in unloading without blocking, full in combustion, timely in cleaning cokes and dust, efficient in running and relatively long in service life.

Owner:北京国奥天开信息技术有限公司

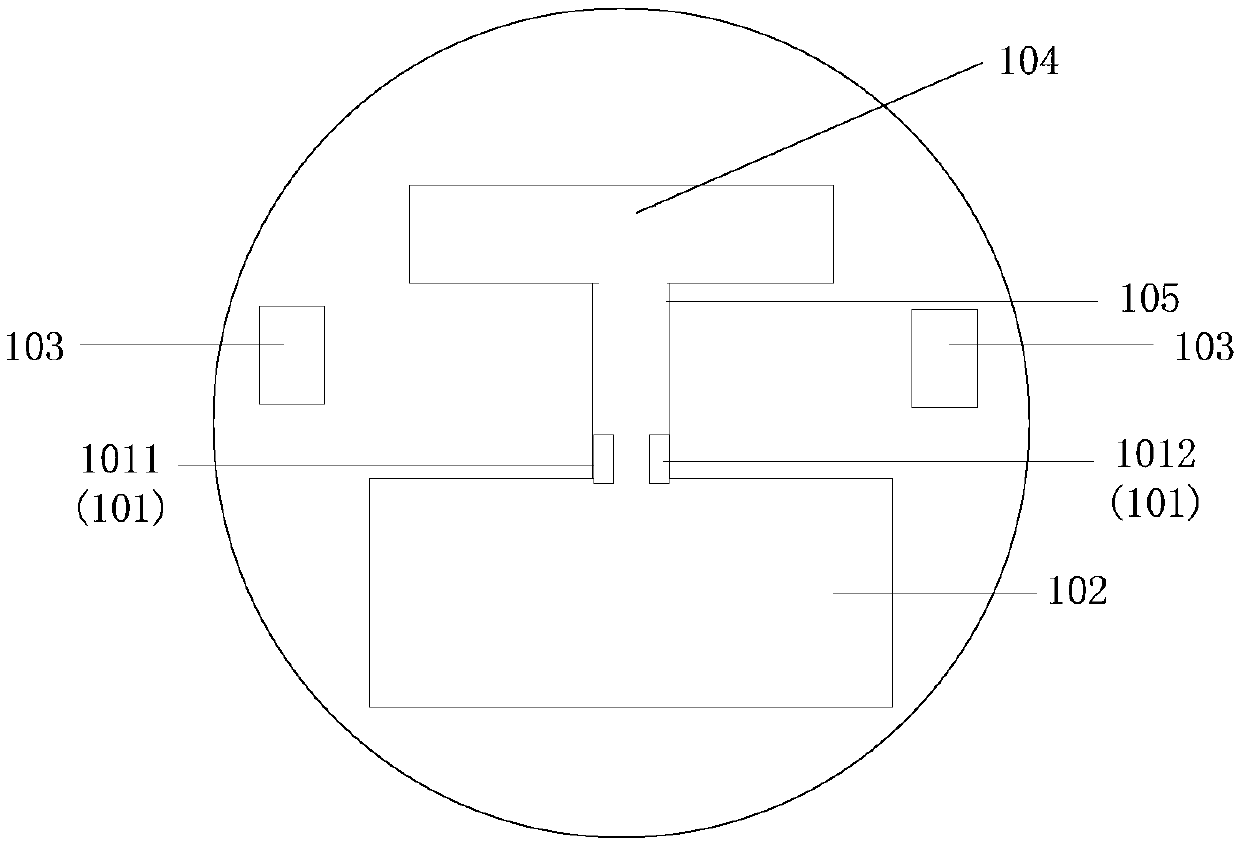

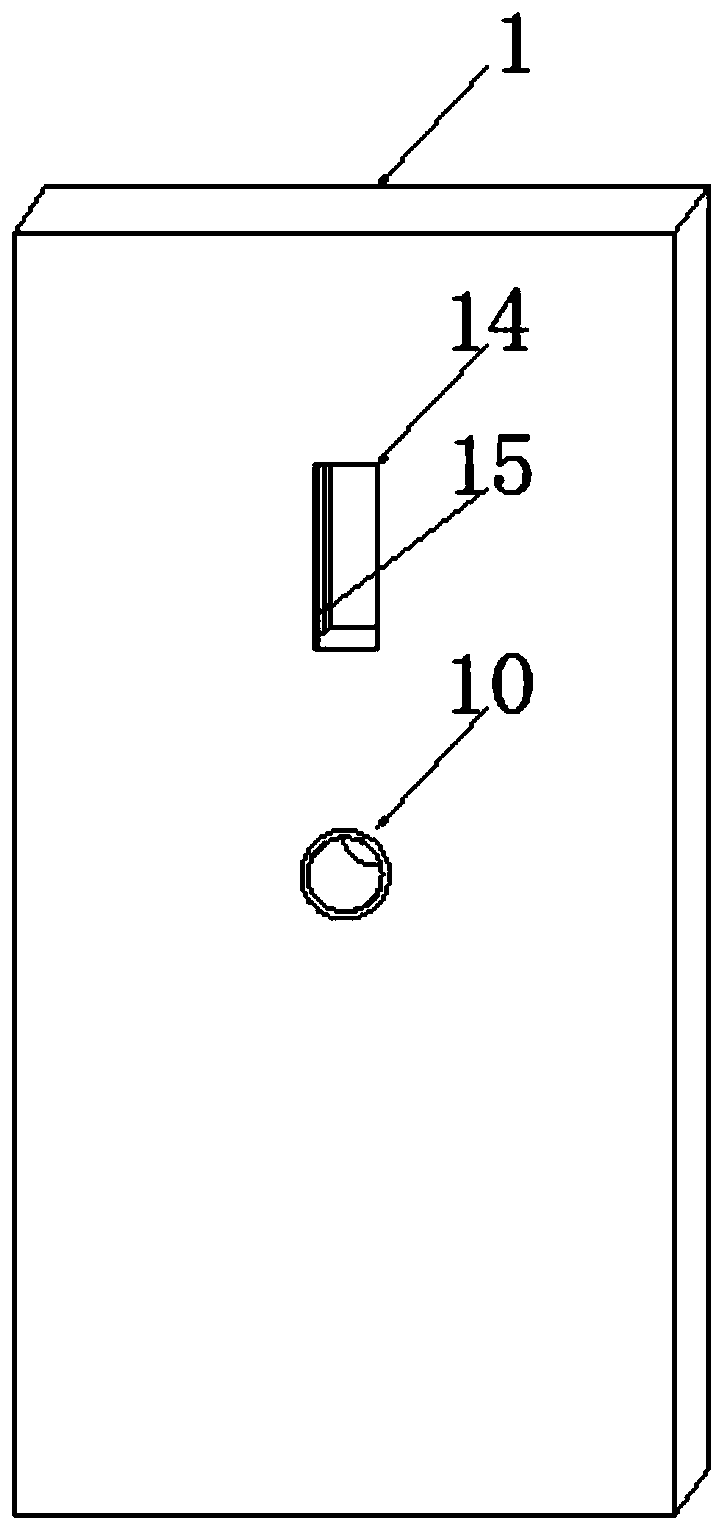

Dust box of sweeping robot, sweeping robot and control method

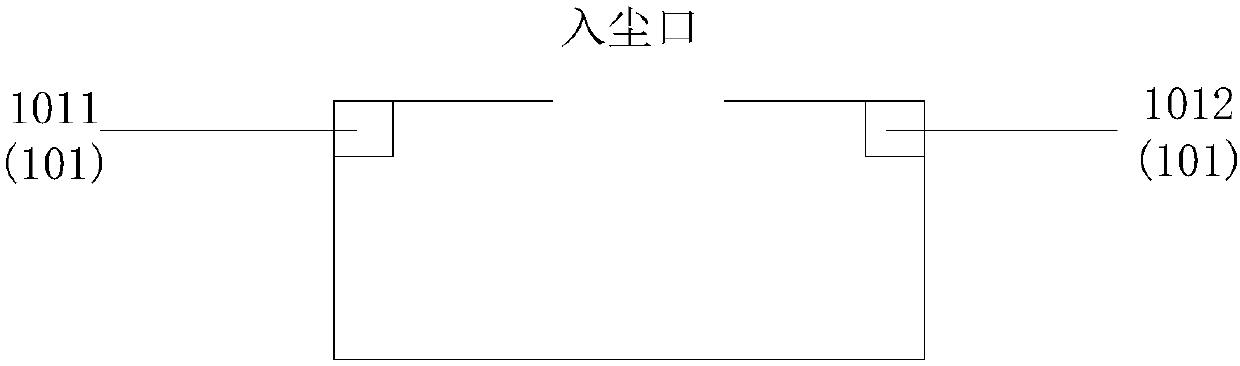

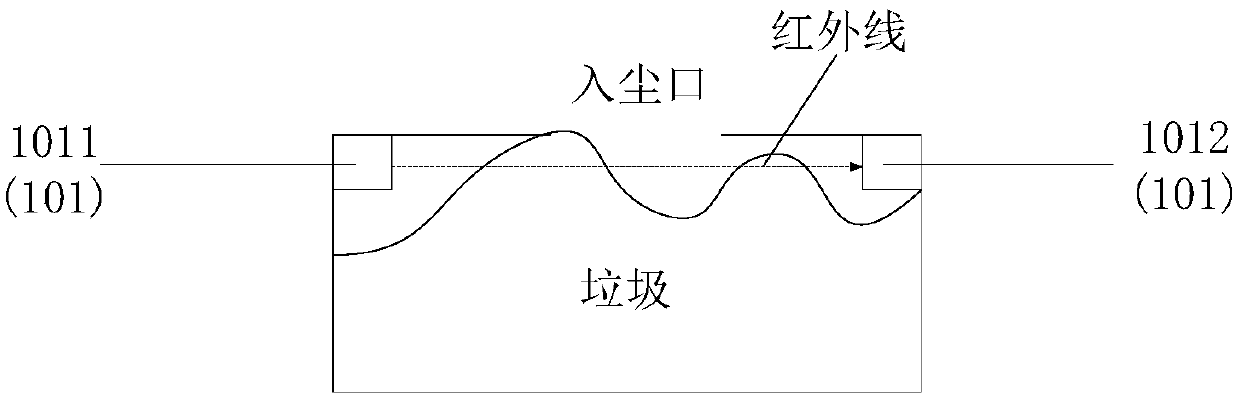

The invention provides a dust box of a sweeping robot, a sweeping robot and a control method. The dust box comprises infrared geminate transistors including an infrared transmitting tube and an infrared receiving tube, wherein the infrared transmitting tube and the infrared receiving tube are oppositely arranged at a preset position of a dust inlet of the dust box. In the working process of the sweeping robot, the infrared transmitting tube continuously transmits infrared rays to the infrared receiving tube. When garbage sucked into the sweeping robot reaches the preset position of the dust inlet of the dust box, optical signal transmission between the infrared transmitting tube and the infrared receiving tube is blocked, the infrared geminate transistors send an electric signal to a processor of the sweeping robot, and the processor controls the sweeping robot according to the electrical signal to send out a reminding signal, so that a user pours the garbage in the dust box in time, and meanwhile a system of the sweeping robot is perfected.

Owner:BEIJING QIHOO TECH CO LTD

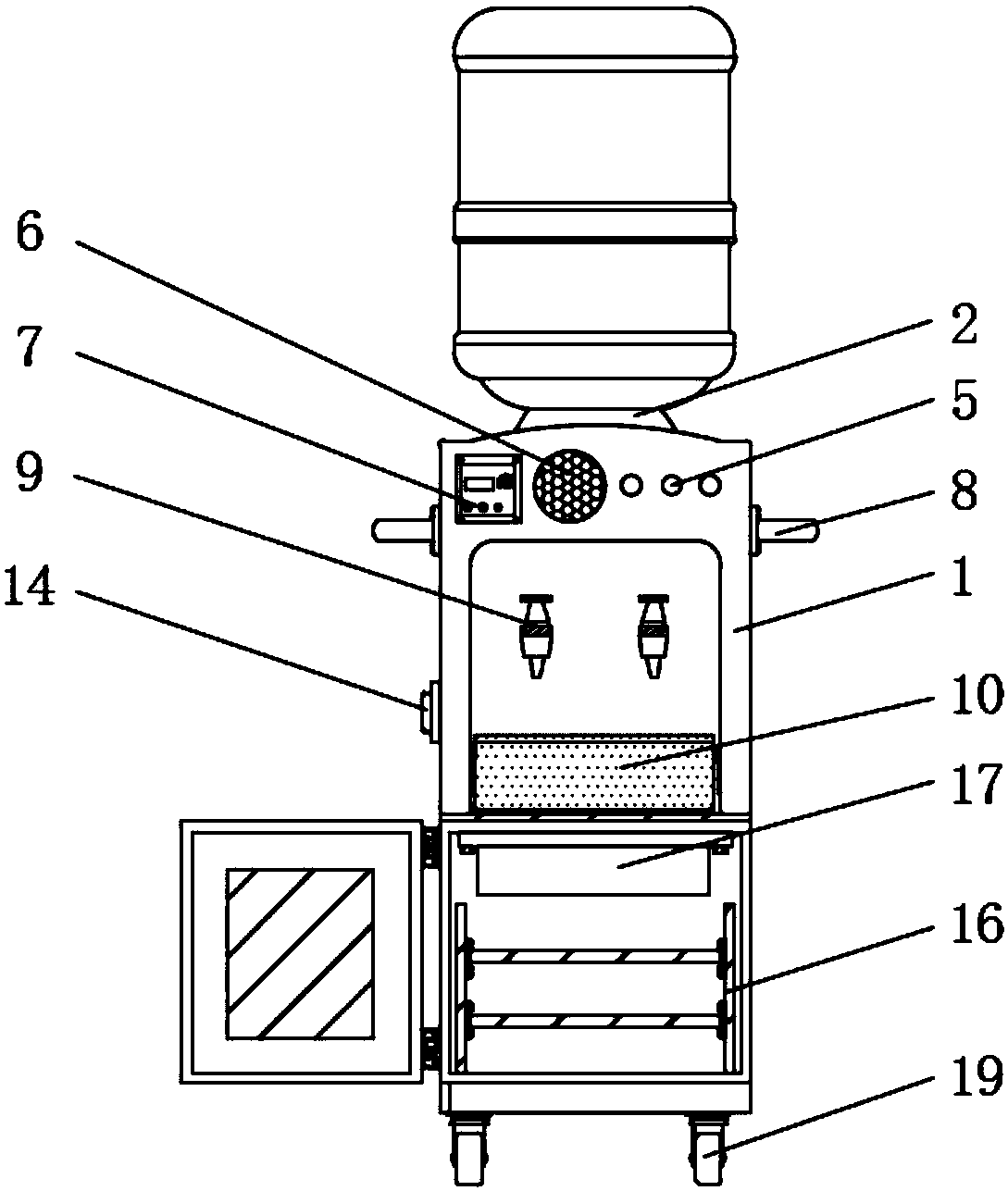

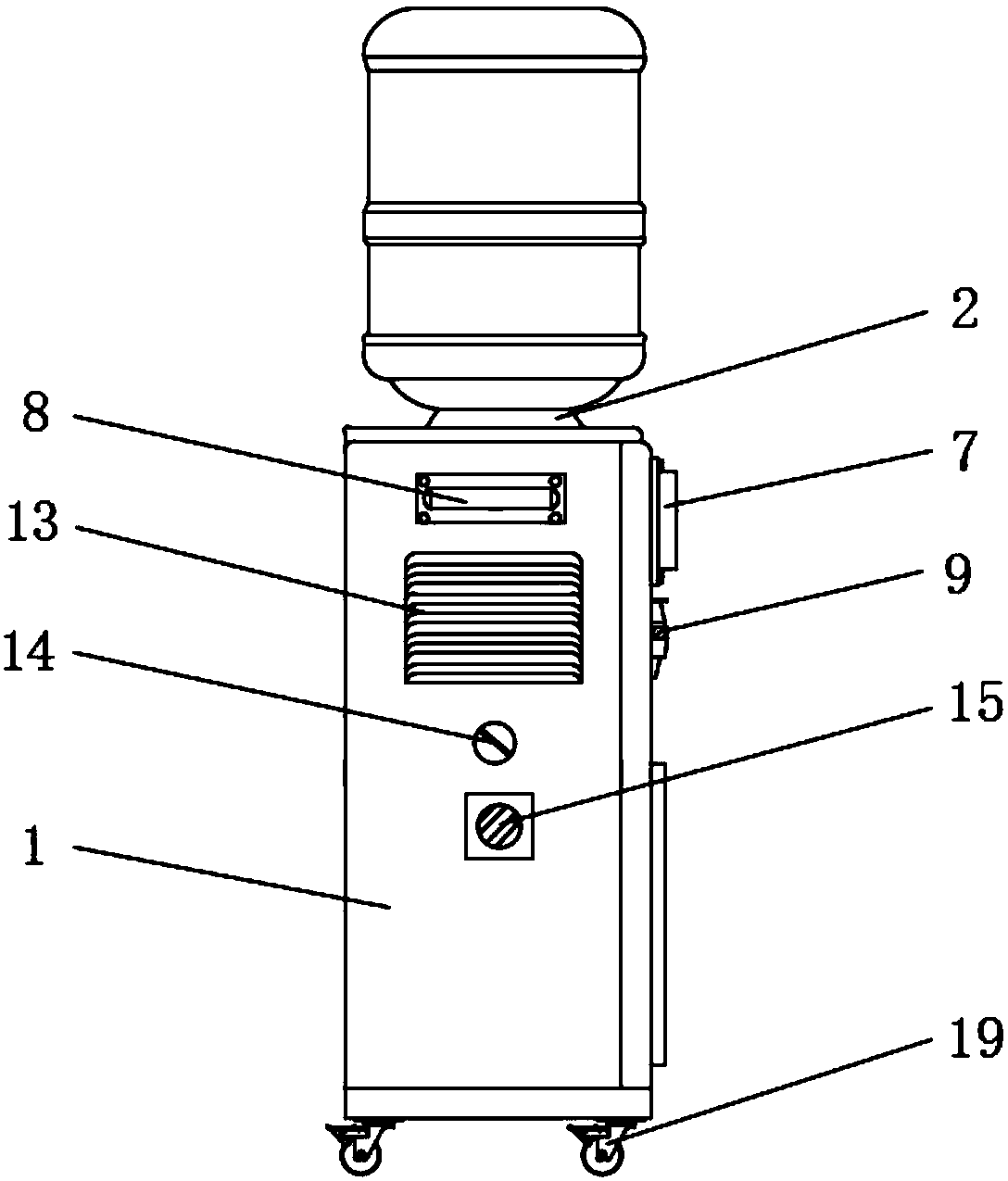

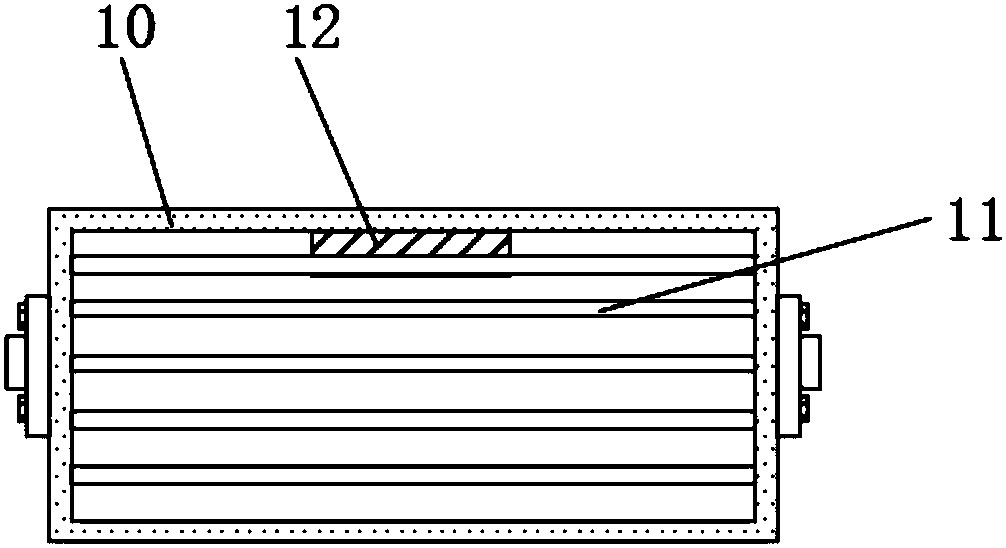

Spillover-preventing water dispenser

InactiveCN108185823AAvoid problems with diseases such as diarrheaMonitor level valueWater/sewage treatment bu osmosis/dialysisBeverage vesselsUv disinfectionEngineering

The invention discloses a spillover-preventing water dispenser, which comprises a water dispenser main body, wherein a smart seat is connected to the top of the water dispenser main body in a slidingmode; a drainage pipe is vertically fixed to the bottom of the smart seat; a biofilm is arranged at the bottom of the smart seat at the outer side of the drainage pipe; an embedded storage space is arranged at the lower side of the front side of the water dispenser main body; a storage platform is arranged in the storage space; an open protective box is arranged at the top of the storage space atthe upper side of the storage platform; a plurality of ultraviolet disinfecting lamps are horizontally arranged at the bottom of the open protective box; a water receiving box is arranged on the waterdispenser main body at the upper side of the storage space; a small grid is horizontally arranged on the upper surface of the water receiving box; and a liquid level sensor is arranged on the inner wall of the water receiving box. According to the spillover-preventing water dispenser provided by the invention, water cups, which are used, can accept disinfecting treatment via the ultraviolet disinfecting lamps, so that the problem that such diseases as diarrhea and the like are caused when the water cups that bacteria in environment are attached to the surfaces are used once again can be solved; and purified water, which is poured into the water dispenser, can be filtered once again.

Owner:XI'AN POLYTECHNIC UNIVERSITY

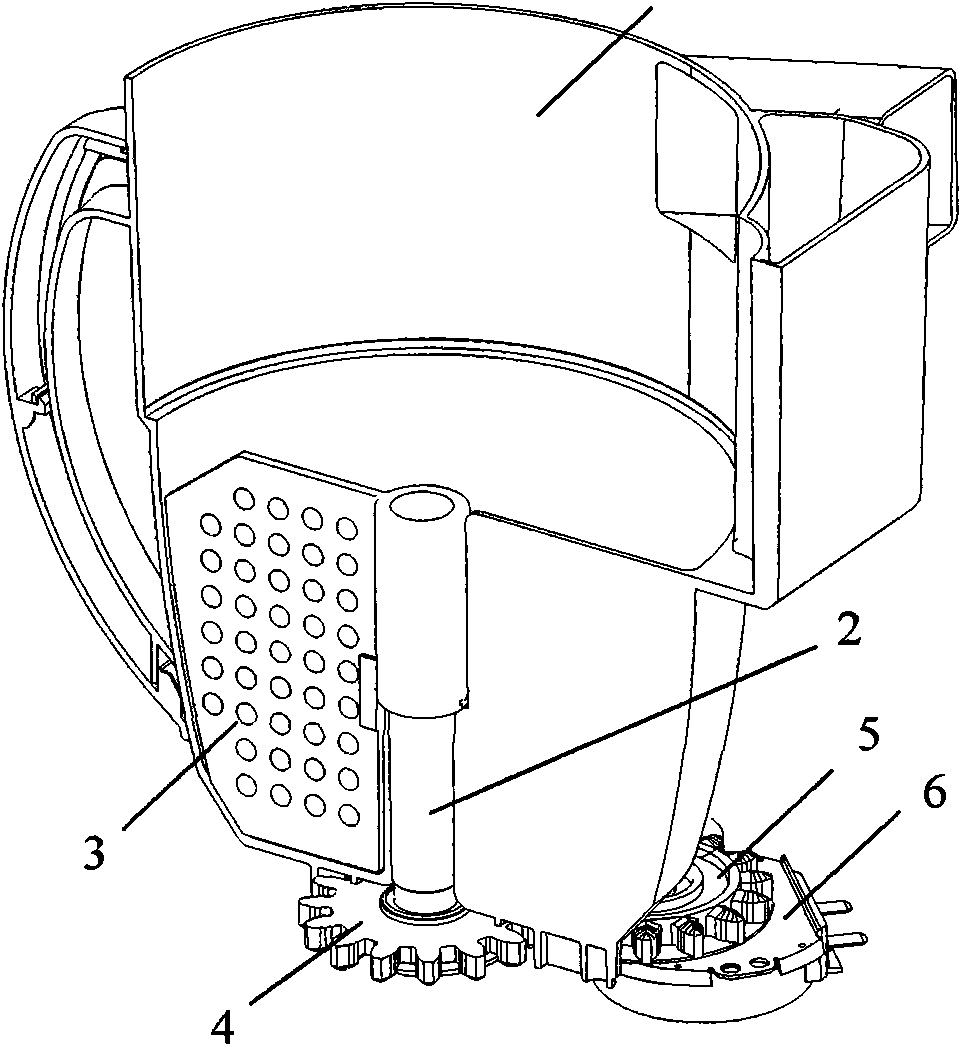

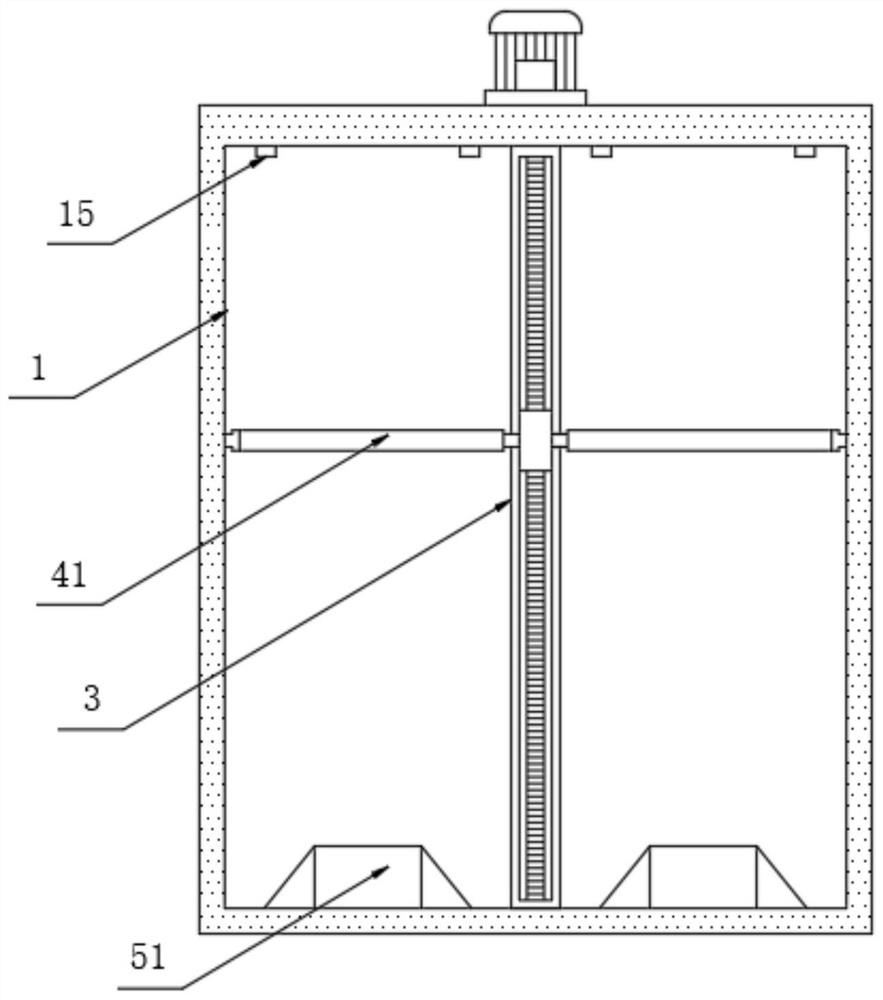

Self-cleaning dust collecting barrel of dust collector

InactiveCN101897566AExtended service lifeSolve the problem of easy to absorb dustCleaning filter meansEngineeringDust collector

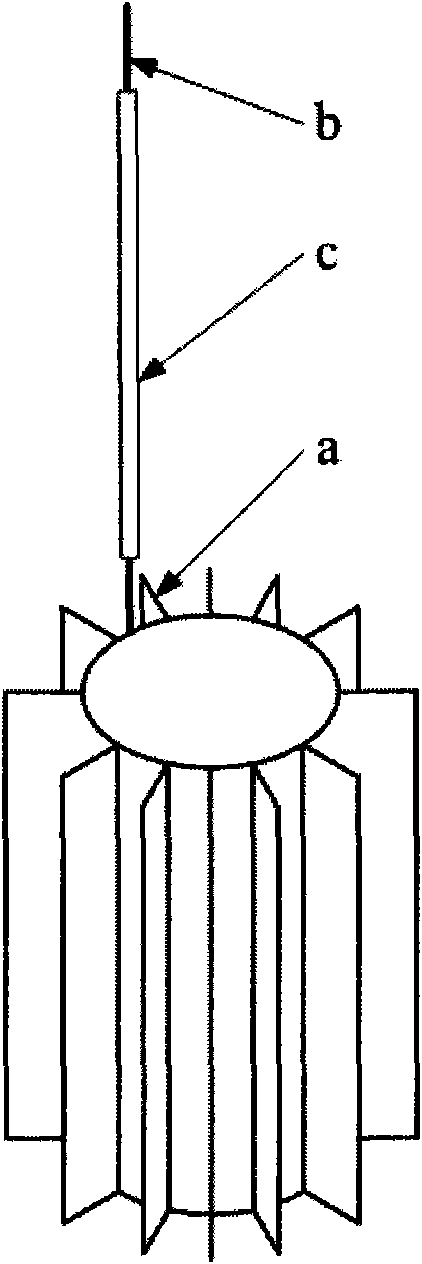

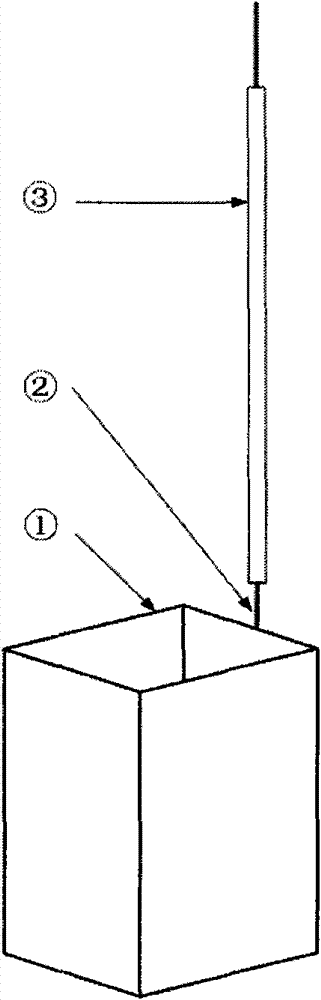

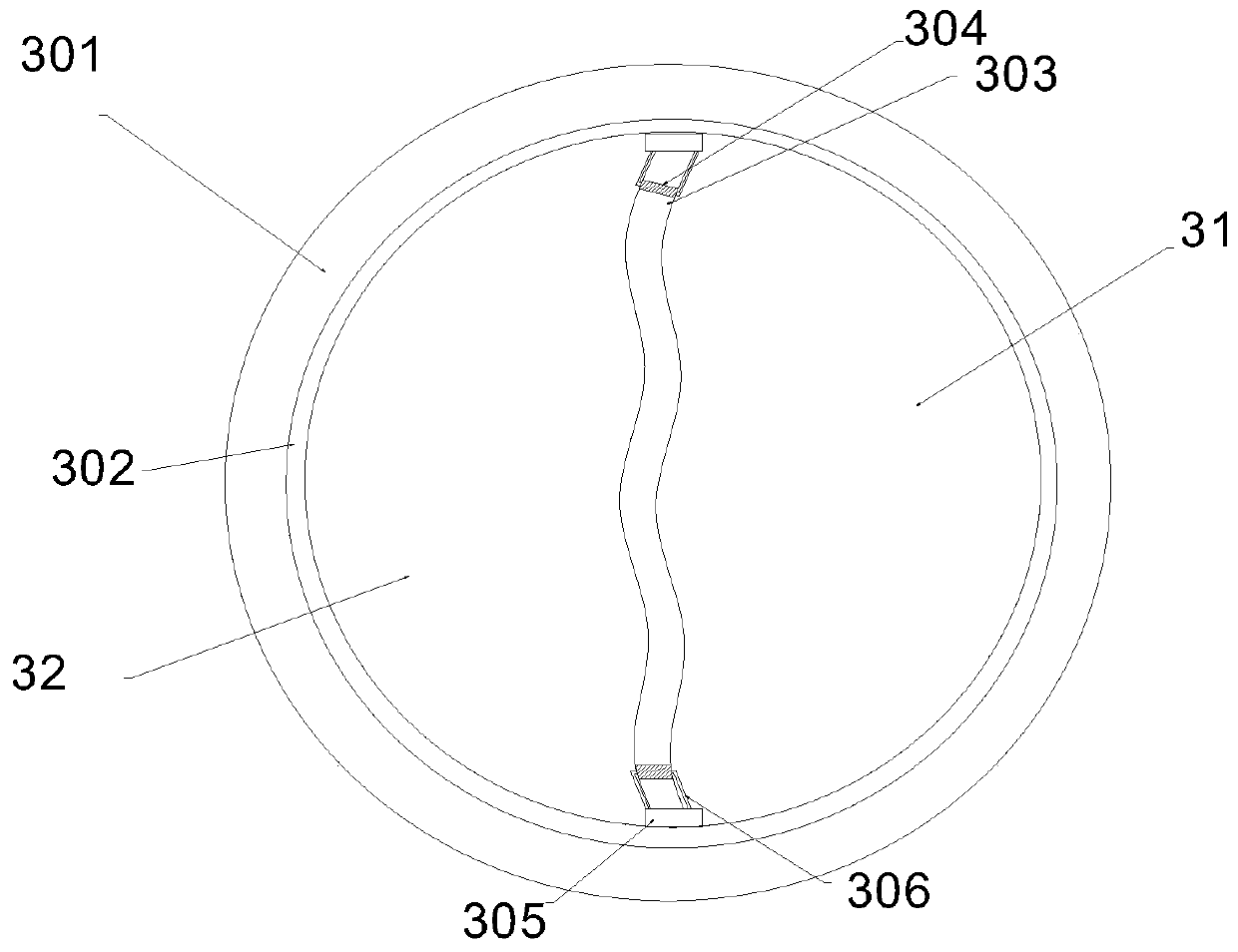

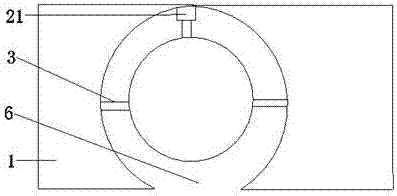

The invention discloses a self-cleaning dust collecting barrel of a dust collector. The dust collecting barrel comprises a dust collecting cabin (1); a rotary shaft (2) is arranged in the centre of the bottom of the dust collecting cabin (1); a longitudinally distributed compression piece (3) is fixedly arranged on an outer side wall of an upper part of the rotary shaft (2); the rotary shaft (2) has a hollow structure; an airflow inlet (31) is formed on the bottom of the rotary shaft (2); at least one airflow outlet (32) is formed on an outer edge of the compression piece (3); an air channel is formed in the compression piece (3), corresponds to the airflow outlet (32) and is communicated with the airflow inlet (31) and the air flow outlet (32) on the bottom of the rotary shaft (2); and the airflow inlet (31) is communicated with airflow outside the dust collecting barrel. The self-cleaning dust collecting barrel can effectively solve the problem that dust is easily adsorbed on an inner wall of the dust collecting cabin, clean the inner wall of the dust collecting cabin by the airflow timely, save electric energy and allow a user to observe the dust collecting condition in the dust collecting cabin through the wall body.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

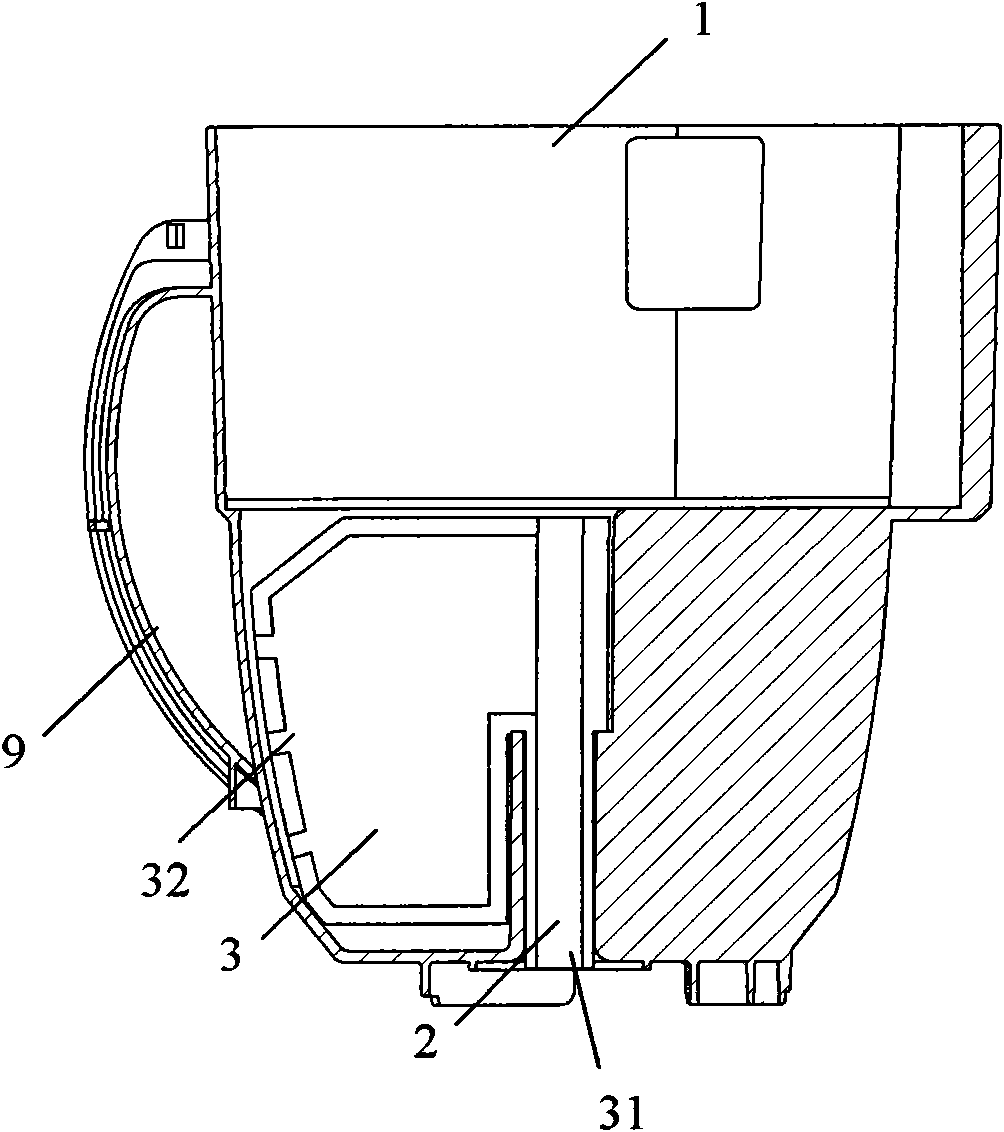

Peeler

The invention provides a peeler, belongs to the field of kitchenware, in particular relates to a peeler capable of collecting peels into the peeler body, and aims to provide a peeler capable of conducting peel collection and peeling at the same time. The peeler comprises a hollow cylinder with an opening formed in the upper end, and the lower end of the cylinder is connected with a handle, the peeler is structurally characterized in that a side wall opening is formed in the cylinder sidewall, and a blade is arranged on one side of the sidewall opening.

Owner:牛玉琴

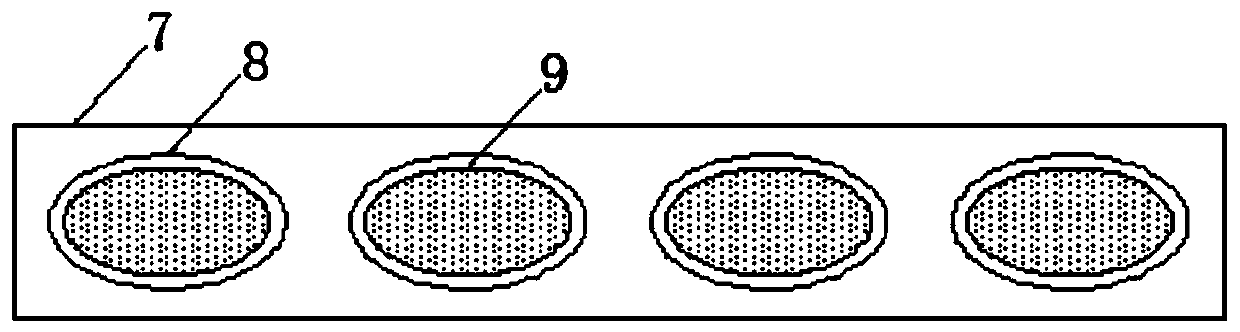

Air circularly filtering device

PendingCN107243197ASimple structureEasy to useGas treatmentDispersed particle filtrationAir filtrationAir filter

The invention relates to an air circularly filtering device. The air circularly filtering device comprises a shell, an air inlet and an air outlet, wherein the air outlet is formed in the upper end of the shell; the air inlet is formed in the left end of the shell; a filtering net is arranged in the shell, and is arranged above the air inlet; baffle plates are arranged above the filtering net, and are staggered on the inner side wall of the shell; a waste material collecting box is arranged at the lower end of the shell, and is arranged below the air inlet; a first fixing block is arranged at the left end of the waste material collecting box; a first fixing groove corresponding to the fist fixing block is formed in the lower half section of the side wall of the shell; elastic brackets are arranged at the upper end and the lower end of the right side of the waste material collecting box; second fixing blocks are arranged on the elastic brackets; second fixing grooves corresponding to the second fixing blocks are formed in the lower half section of the side wall of the shell. After the filtering net in the air circularly filtering device filters air for the first time, the air flows through the staggered baffle plates, and adsorbing blocks on the baffle plates adsorb harmful substances in the air, so that the air filtering efficiency is effectively improved.

Owner:NANJING BAIYUN CHEM ENVIRONMENTAL MONITORING

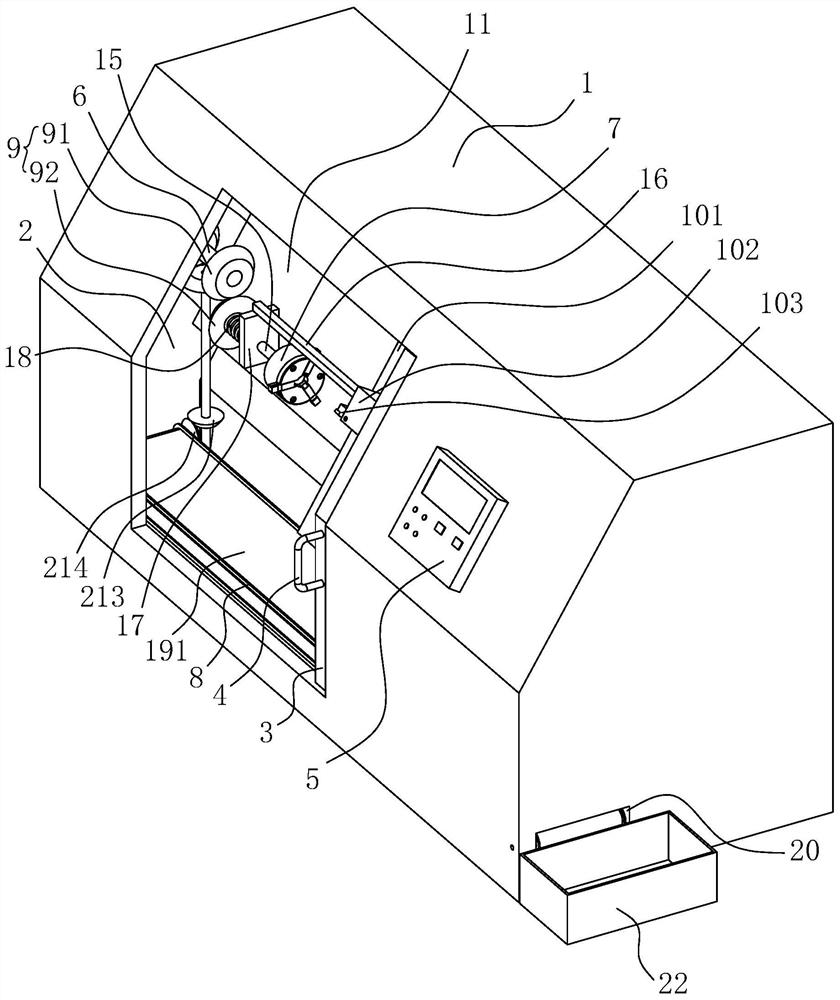

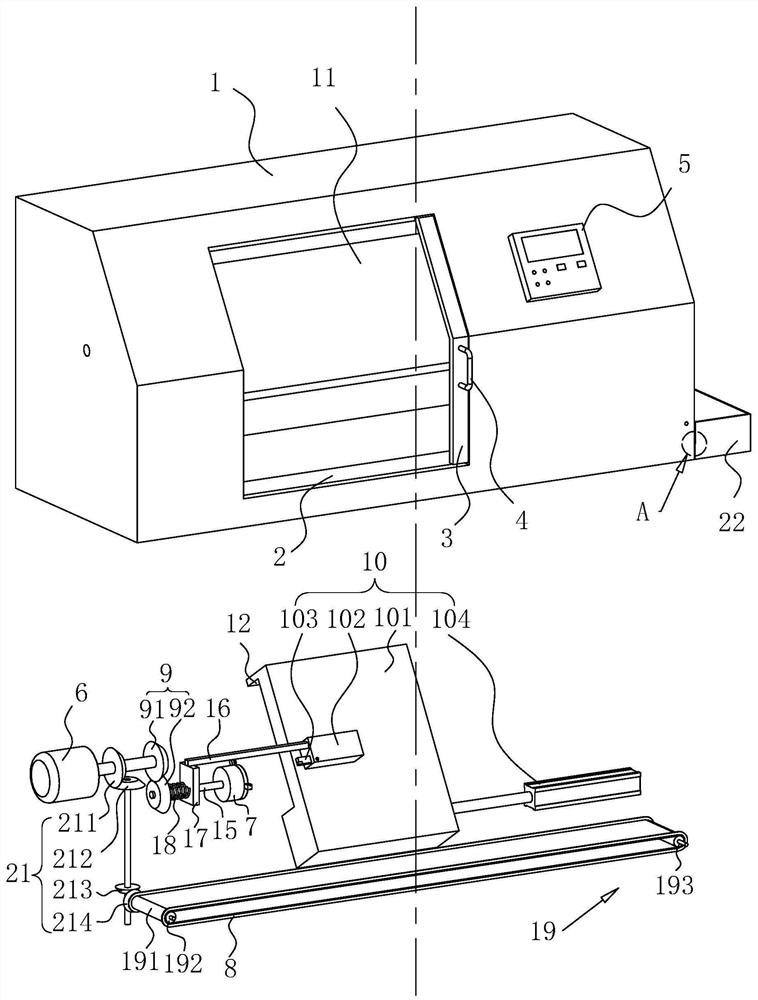

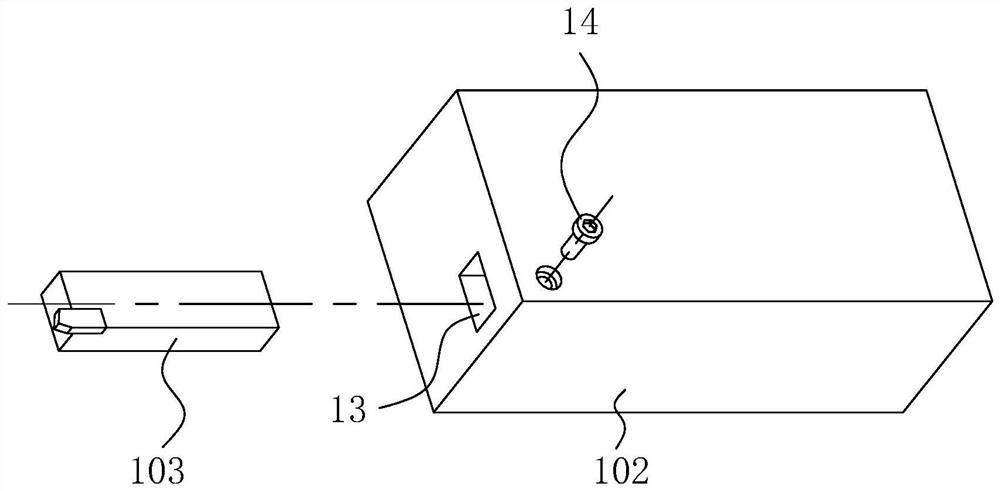

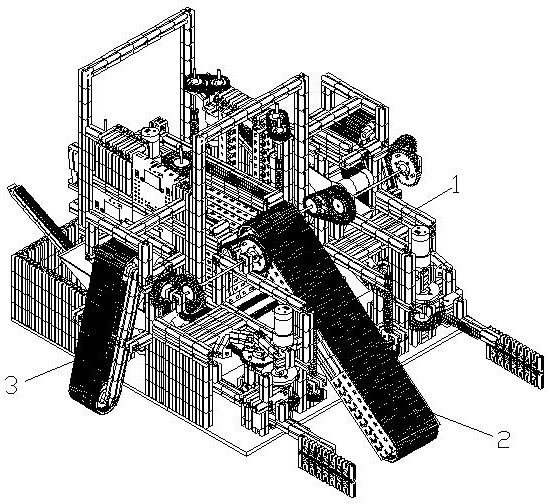

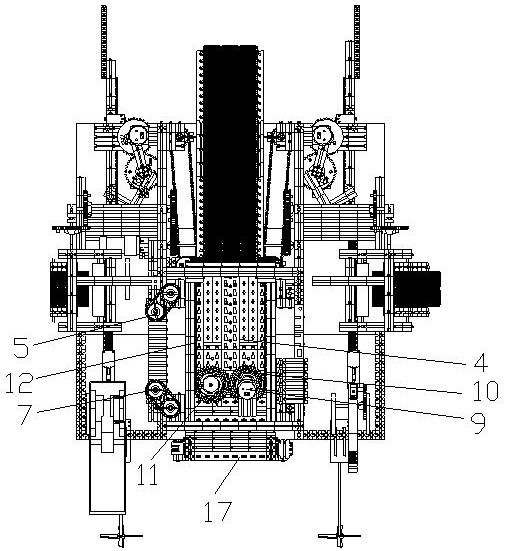

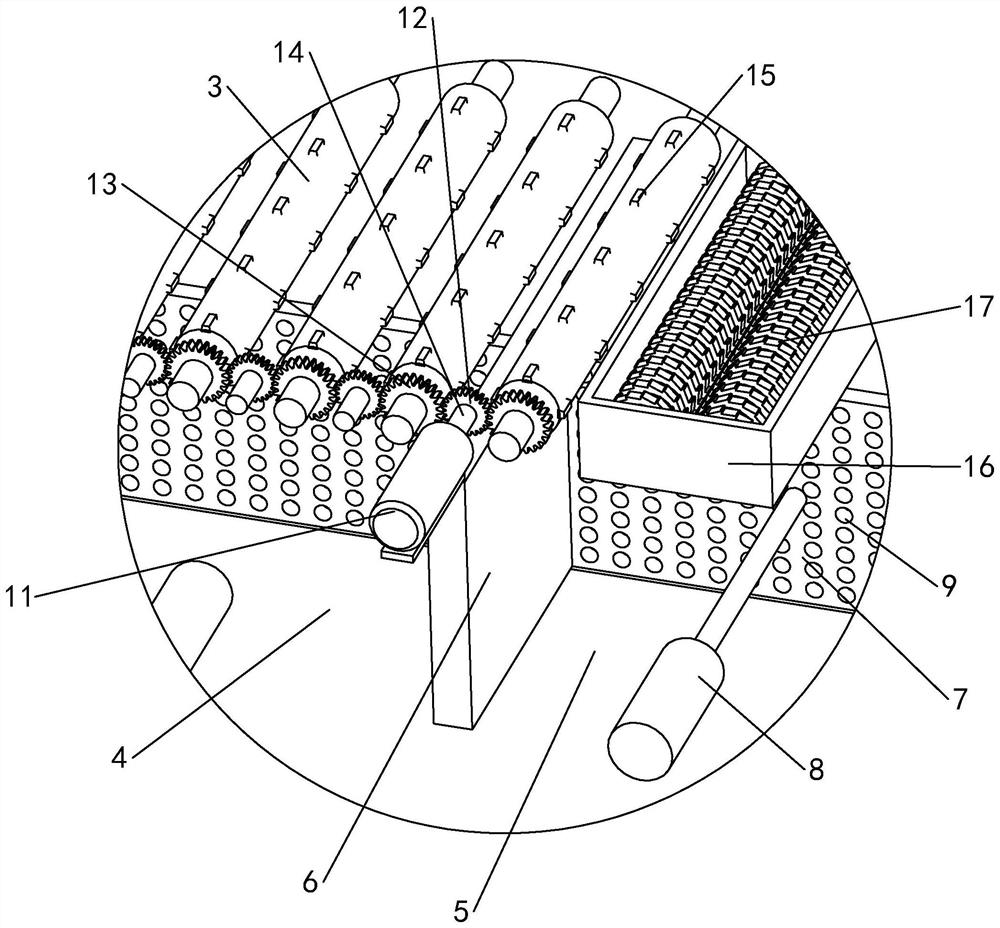

Planet gear rough machining numerical control lathe

ActiveCN112238261ANot easy to pile upImprove work efficiencyGear-cutting machinesMaintainance and safety accessoriesNumerical controlGear wheel

The invention relates to the field of numerical control lathes, in particular to a planet gear rough machining numerical control lathe which comprises a machine body. A working chamber is arranged inthe machine body, a cutting mechanism and a clamp corresponding to the cutting mechanism are arranged in the working chamber, and a rotation driving mechanism is further fixedly arranged on the machine body and is in transmission connection with the clamp. A waste output mechanism is arranged in the working chamber and is located below the clamp and the cutting mechanism, the waste output mechanism and the rotation driving mechanism are in transmission connection through a material conveying transmission mechanism, a discharging opening is formed in the side wall of the working chamber, and the waste output mechanism penetrates through the discharging opening. The planet gear rough machining numerical control lathe has the effects that cutting scraps are not prone to being accumulated in the working chamber, the waste output mechanism conveys the cutting scraps out of the machine body, manpower and time are saved, and the working efficiency of workers can be improved easily.

Owner:上海万众实业股份有限公司

Robot for road cleaning

InactiveCN112127307AAchieve the function of cleaning the groundTo achieve the function of sprinkling waterRoad cleaningAcoustic wave reradiationLow speedSimulation

The invention belongs to the field of cleaning robots, particularly relates to a robot for road cleaning, and aims at conventional problems of low road cleaning efficiency, low speed, incomplete cleaning, high cleaning cost and high working intensity of workers, and the following solution is proposed, which including a power supply module, an ultrasonic online detection module, a steering assemblyand a support base, the ultrasonic online detection module is electrically connected with the power supply module. The ultrasonic online detection module includes a front data acquisition probe, a data transmission wire and a signal data processing platform. In the present invention, the robot is driven forward by a driving assembly, and sprays water to the cleaned road by a spraying assembly, and cleans the road by a cleaning assembly, and stores the garbage by a garbage storage assembly, and reminds workers by a alarm assembly when the garbage reaches a certain amount, and detects obstaclesin front by the ultrasonic online detection module, and controls the steering assembly to turn direction. The invention has advantages of simple structure and convenient operation.

Owner:兴力洁道路保洁集团有限公司

Novel pipe material cutting table for building

InactiveCN109352069AEasy to cutAvoid damageTube shearing machinesMaintainance and safety accessoriesPush pullEngineering

The invention discloses a novel pipe material cutting table for building. The novel pipe material cutting table comprises a cutting table body. Moving wheels are installed at four corners of the bottom end face of the cutting table body correspondingly. A control panel is embedded in the center of the top of the front side wall of the cutting table body. A push-pull type drawer is installed on thebottom of the front side wall of the cutting table body in a sliding manner. A handle is installed on the push-pull type drawer. A pressure sensor is installed in the push-pull type drawer and electrically connected with the control panel. A partition plate is connected to the top end of the pressure sensor. A through hole is formed in the cutting table body. A pipe material is connected into thethrough hole in a sliding manner. First electric pushing rods are symmetrically embedded in the top of the right side wall and the bottom wall of the cutting table body. The first electric pushing rods are electrically connected with the control panel. The left side wall of a fixing block is installed at the top end of each first electric pushing rod. The top end of each second electric pushing rod is installed on the bottom wall of the corresponding fixing block. The second electric pushing rods are electrically connected with the control panel. The pipe material cutting table is compact instructure and convenient to move.

Owner:吴中华

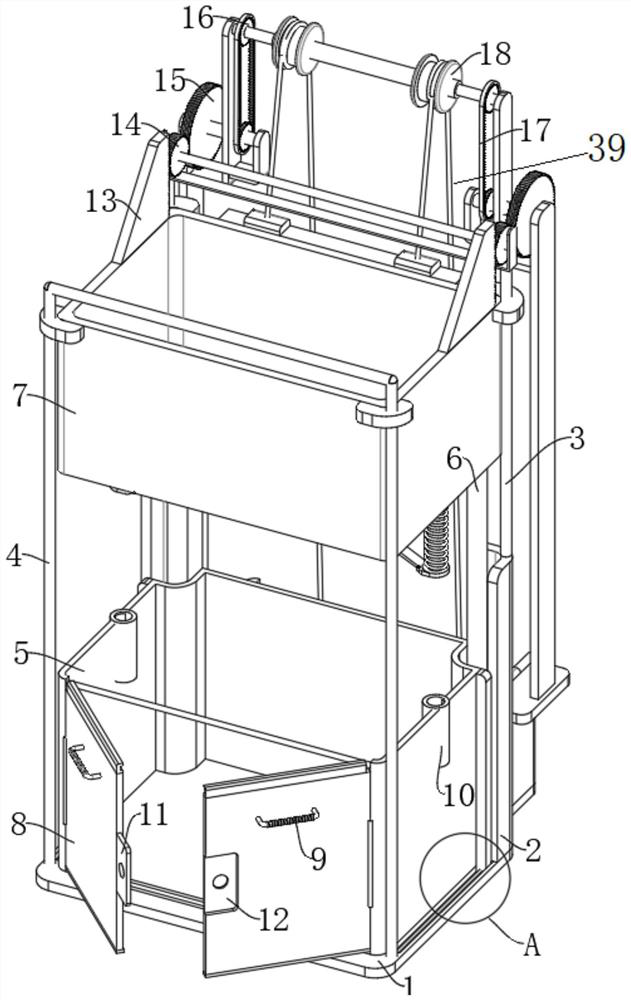

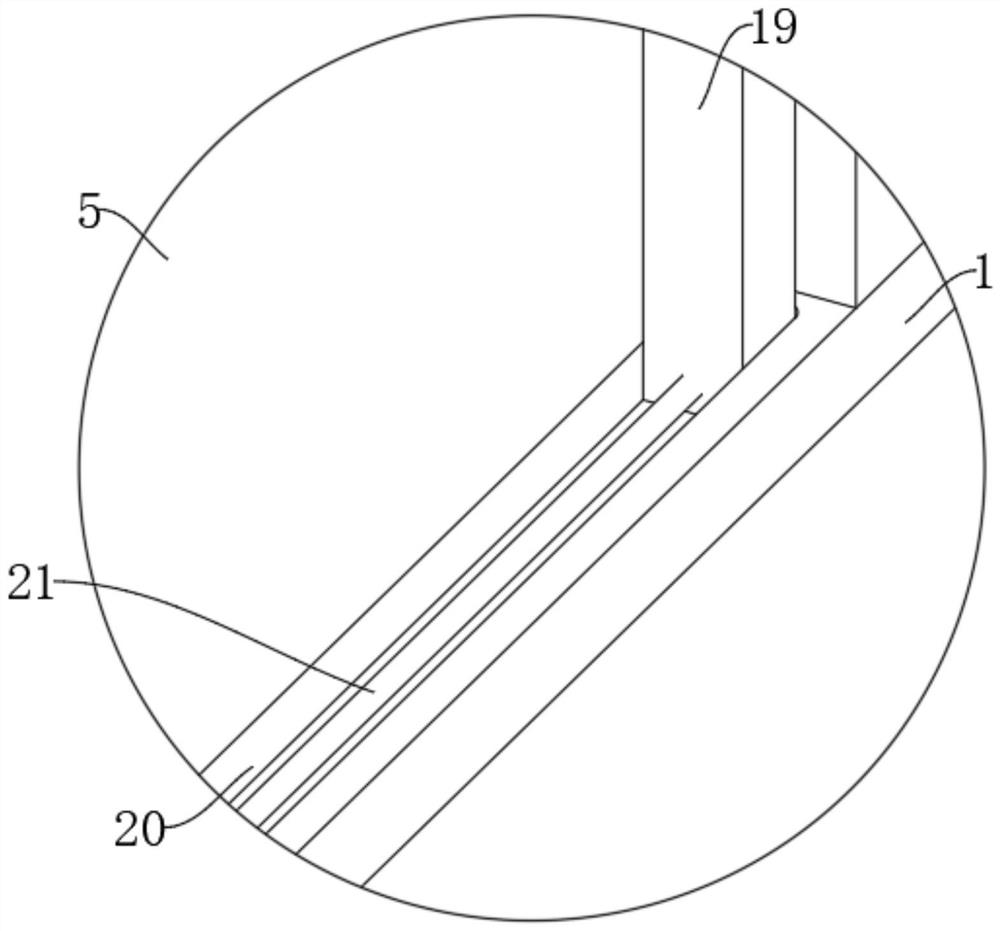

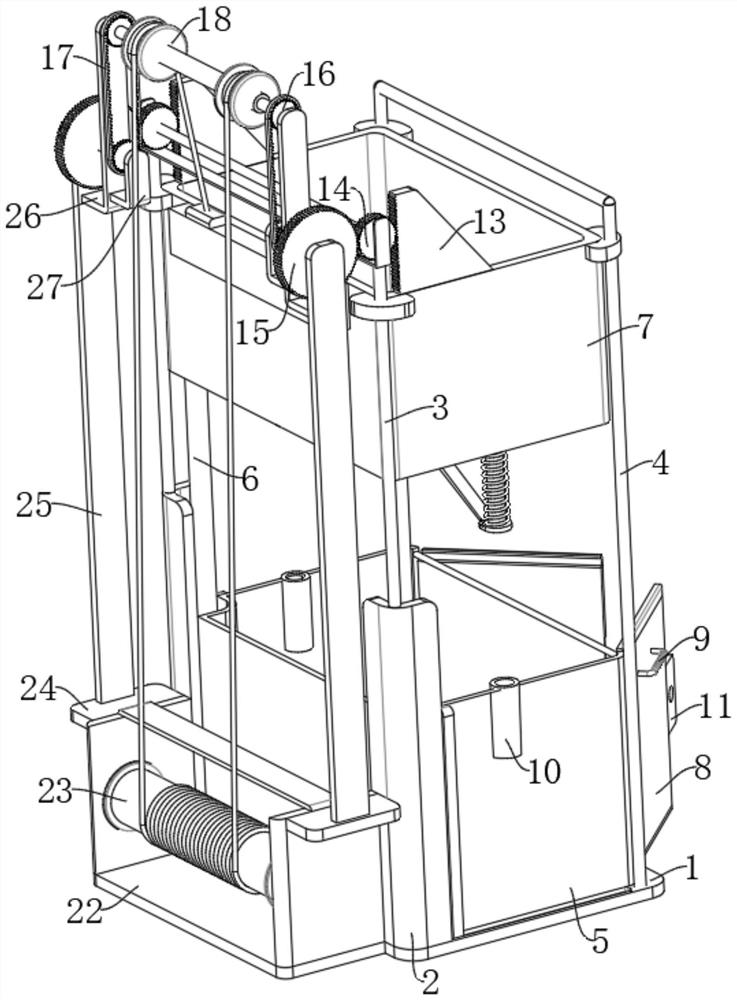

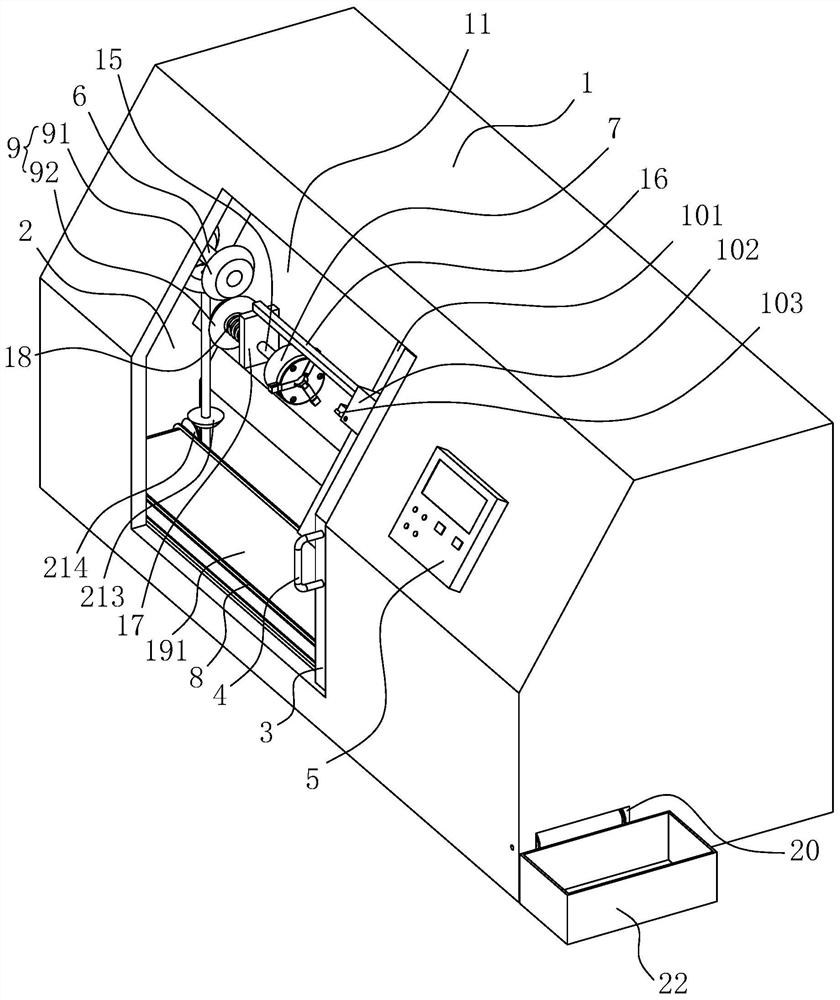

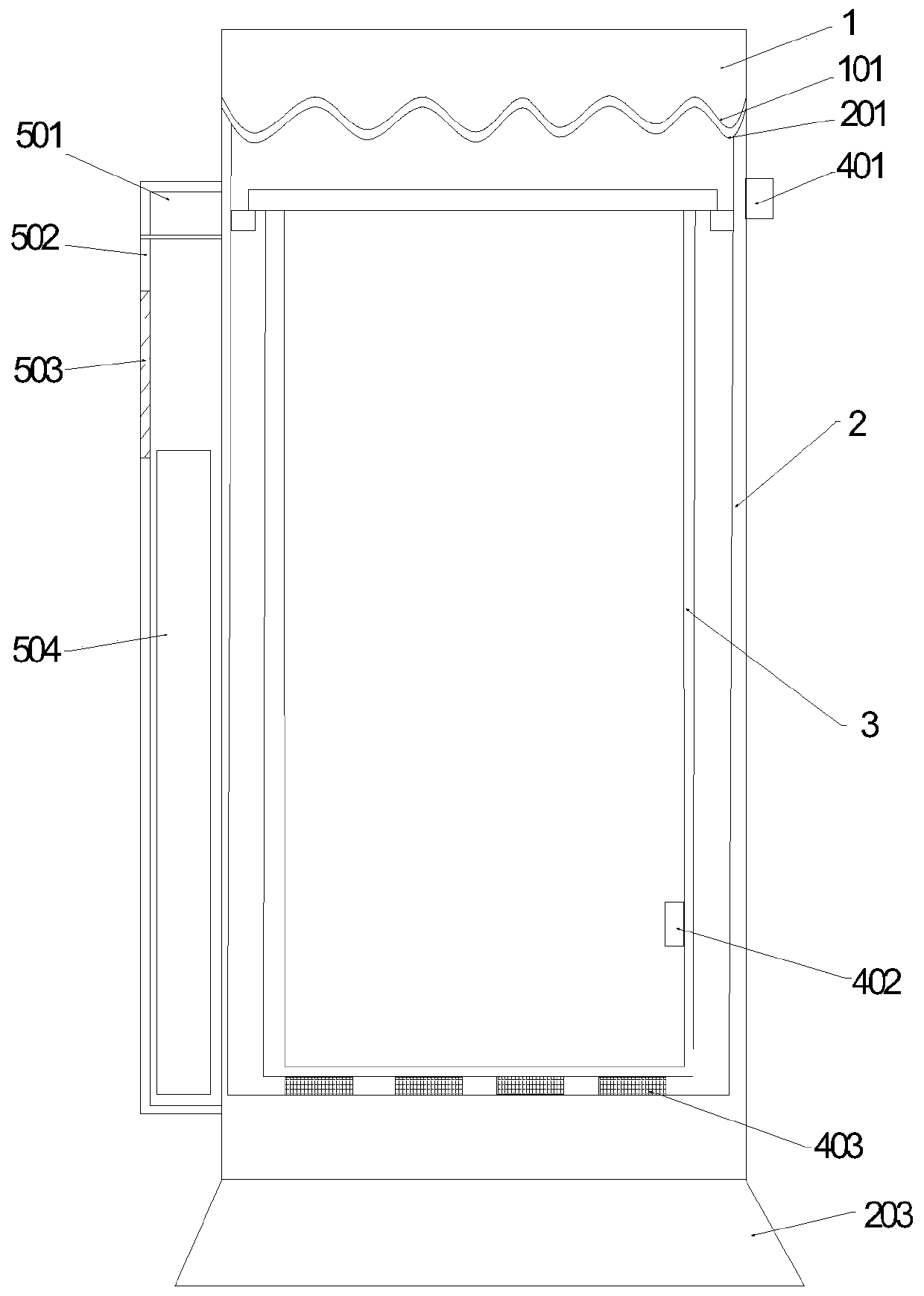

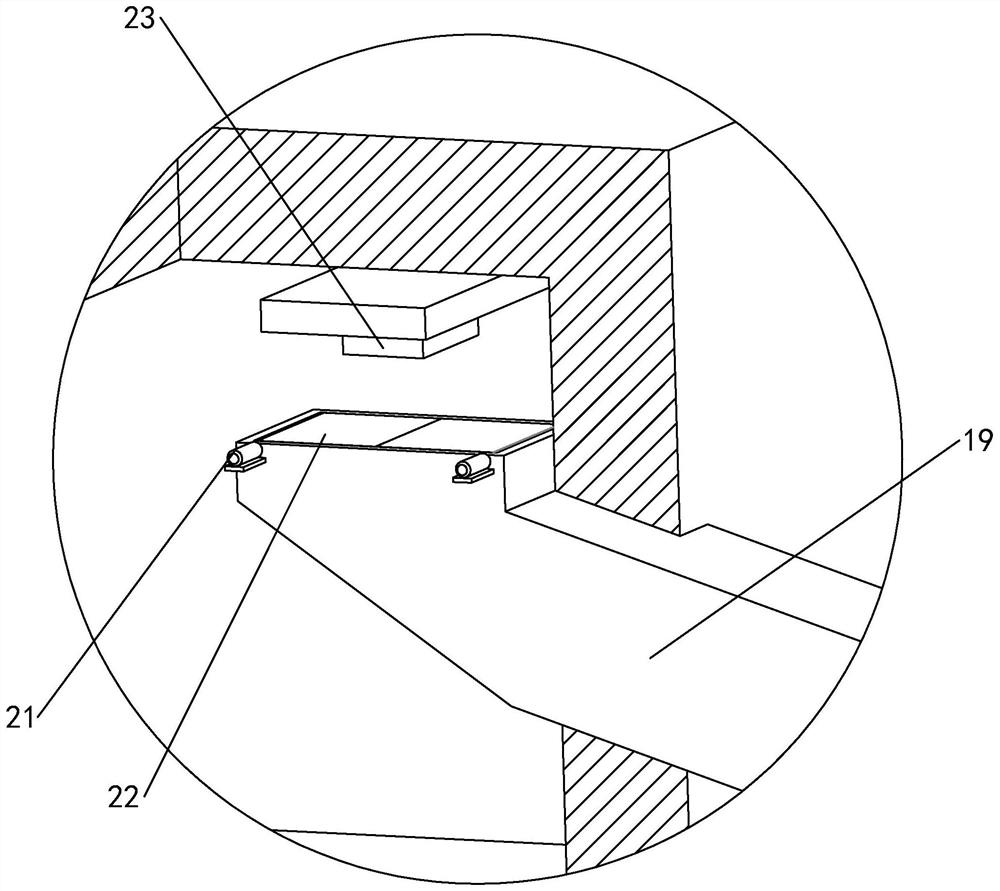

Automatic conveying system for construction waste

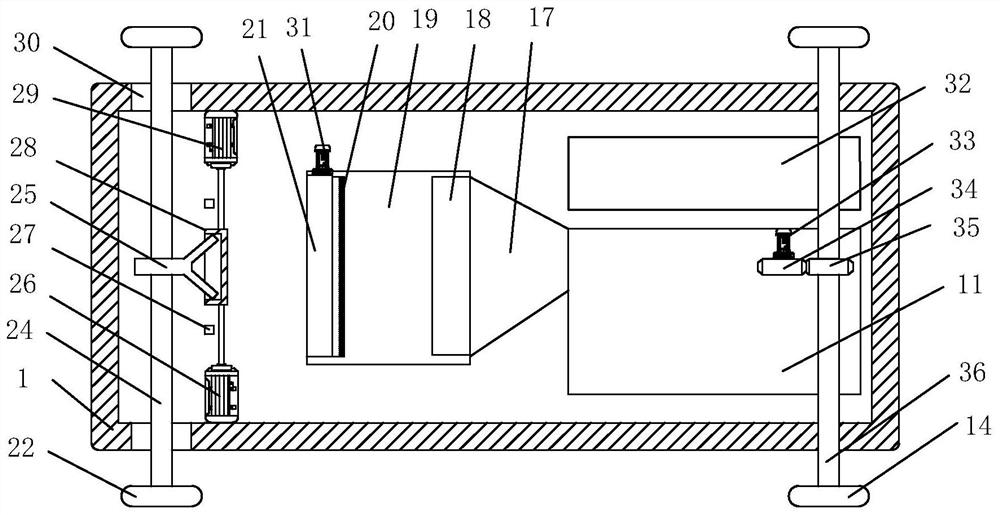

ActiveCN114132667AEasy to pourTimely dumpConstruction waste recoveryRefuse gatheringClassical mechanicsEngineering

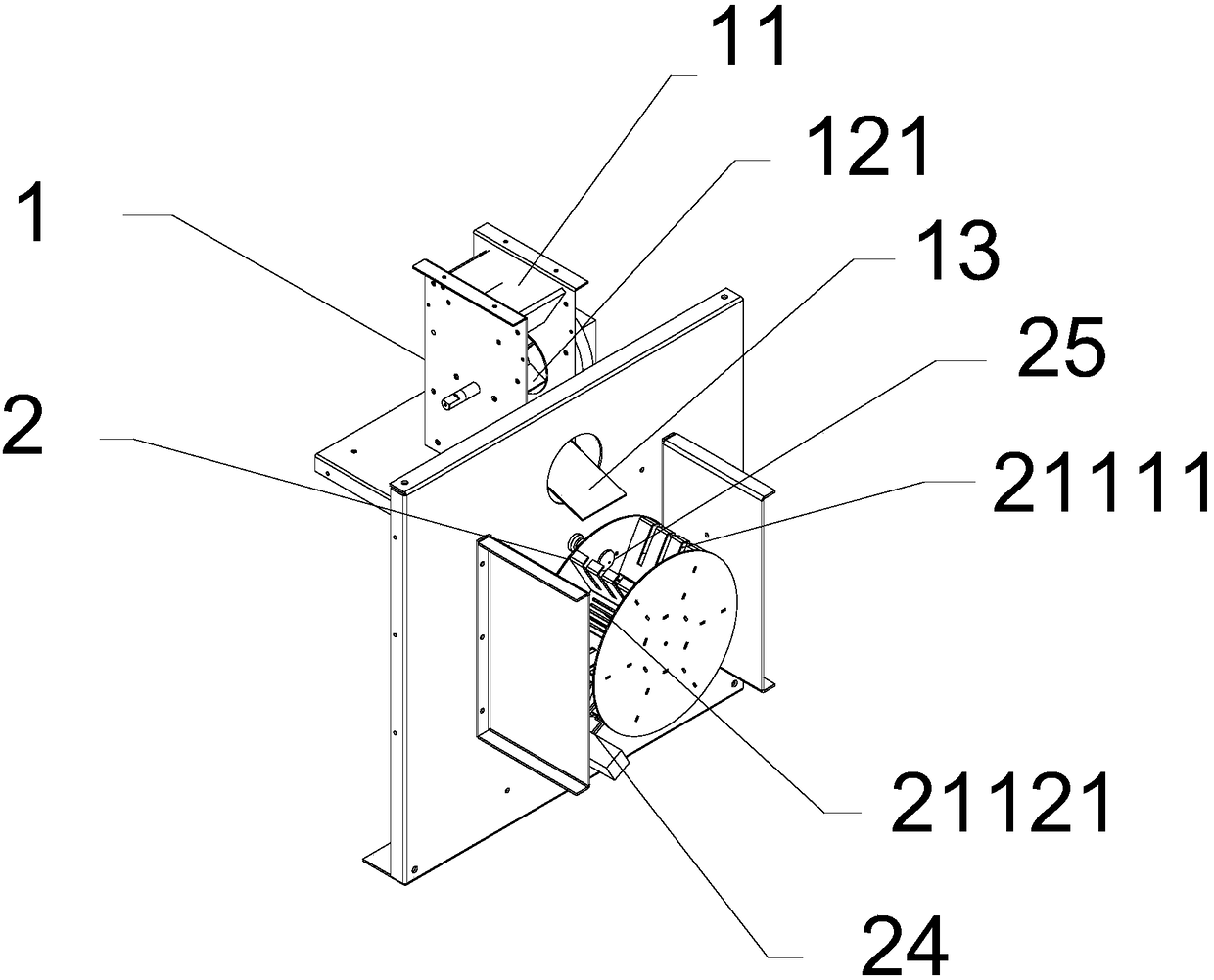

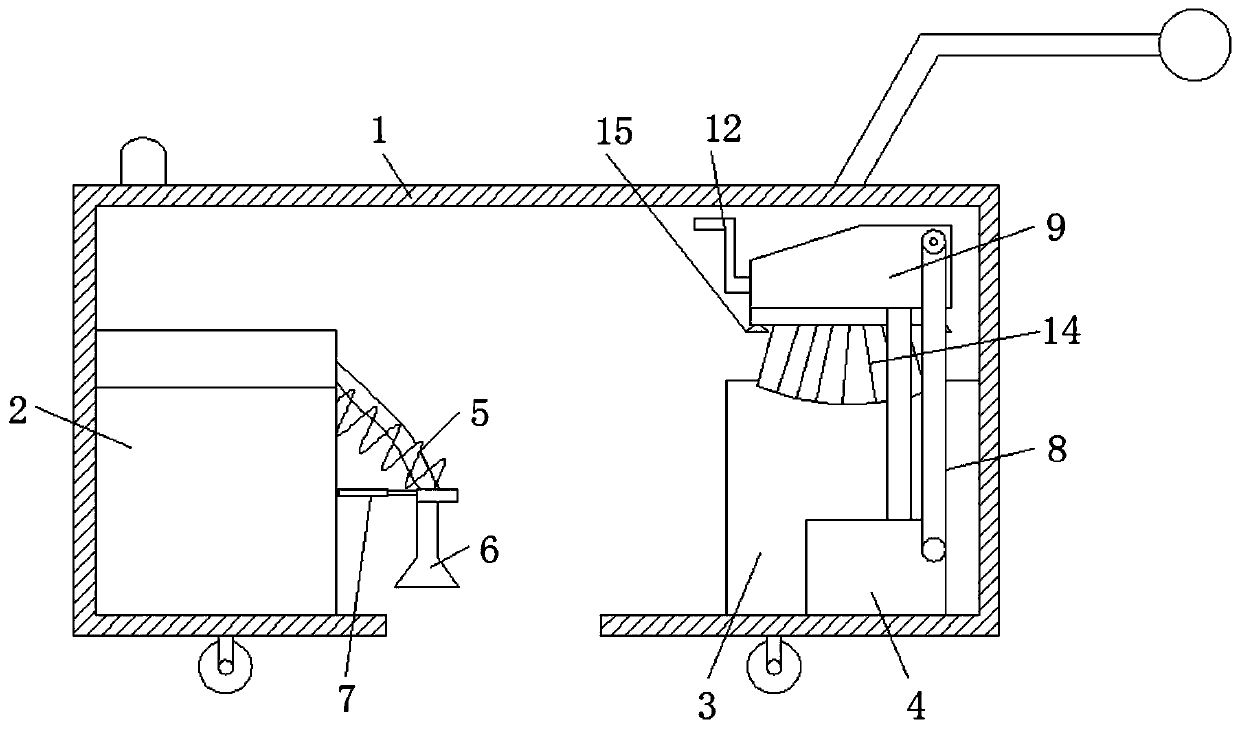

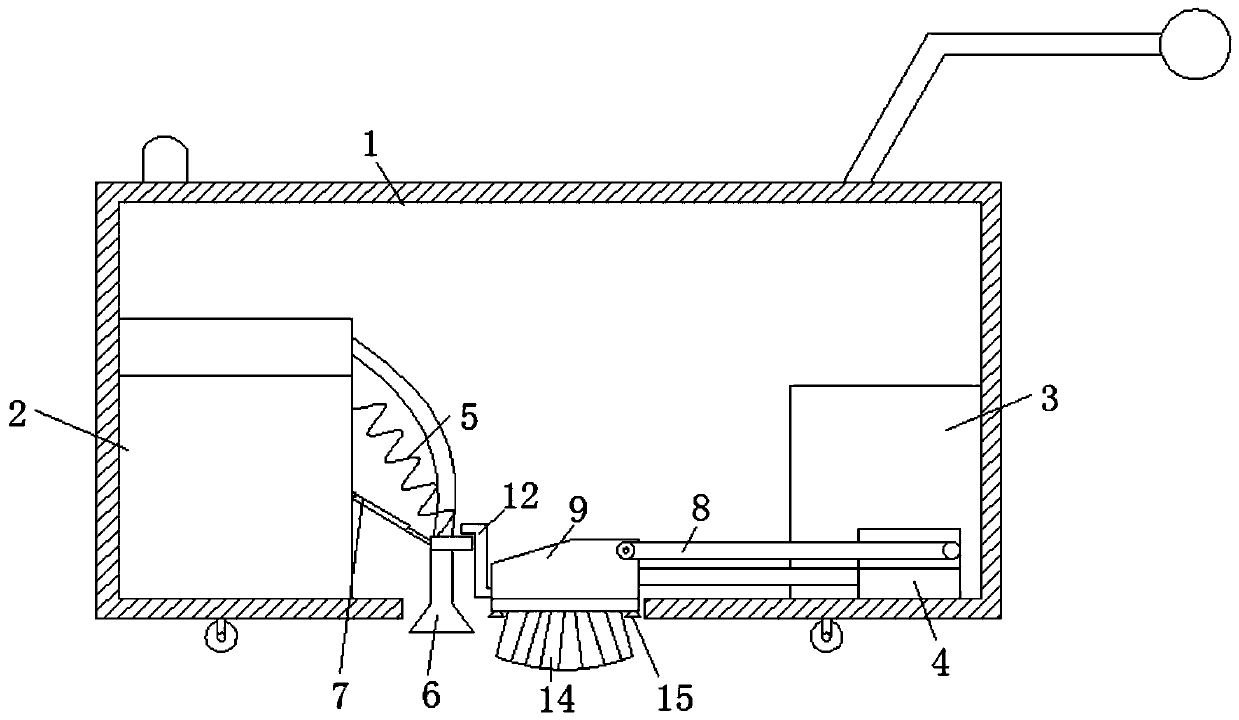

The invention discloses an automatic conveying system for construction waste. The automatic conveying system comprises a bottom plate (1), a supporting plate (2), a rear sliding rod (3), a front sliding rod (4), a storage box (5), a moving box (7), an inductive automatic hoisting assembly, an elastic automatic pulling and closing assembly, a convenient treatment sliding assembly and a control assembly. The supporting plate is vertically connected with the bottom plate, the rear sliding rod is vertically arranged on the supporting plate, and the front sliding rod is vertically connected with the bottom plate; the storage box is arranged on the bottom plate through the convenient processing sliding assembly, and the moving box vertically moves above the storage box along the rear sliding rod and the front sliding rod. The inductive automatic hoisting assembly is connected with the moving box and the bottom plate, a pulling-closing door (28) is installed at an opening in the bottom of the moving box through the springing automatic pulling-closing assembly, and the inductive automatic hoisting assembly and the springing automatic pulling-closing assembly are electrically connected with the control assembly. Storage, longitudinal transportation and cleaning of high-rise building construction waste can be achieved, and the treatment efficiency and safety of the building construction waste are improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

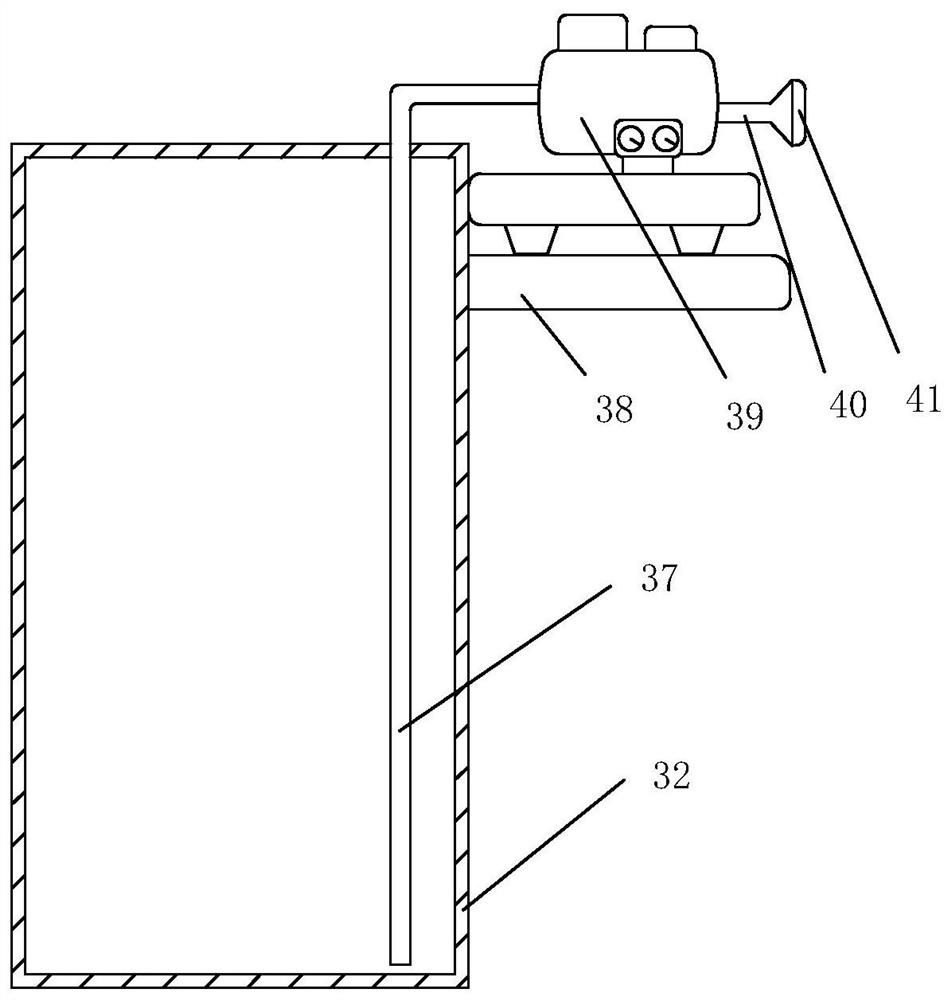

Smelting furnace for aluminum profile

PendingCN111649583ATimely dumpAvoid delayCharge composition/stateCharge treatment typeStructural engineeringMechanics

The invention belongs to the technical field of aluminum profile processing, and particularly relates to a smelting furnace for an aluminum profile. The smelting furnace comprises two first vertical columns, and first open holes are formed above the first vertical columns correspondingly; connecting rods are arranged in the first open holes above the first vertical columns in a penetrating mode, and the lower parts of the first vertical columns are connected with first bottom plates; universal wheels with locks are arranged at the four corners of the lower part of each first bottom plate correspondingly, and the two ends of the connecting rods are connected with connecting arms correspondingly; the ends, away from the first vertical columns, of the connecting arms are connected with electric push rods, and the sides, away from the connecting arms, of the first vertical columns are provided with second vertical columns which are connected with the connecting rods; and the lower parts ofthe second vertical columns are connected with second bottom plates. By redesigning the structure of the smelting furnace, the redesigned structure has the characteristic of stability, the rotating angle of a furnace body is larger, liquid in the furnace body can be completely poured out, and the trouble and the potential safety hazard that manual clearing is needed due to incomplete pouring areavoided.

Owner:蒋洪平

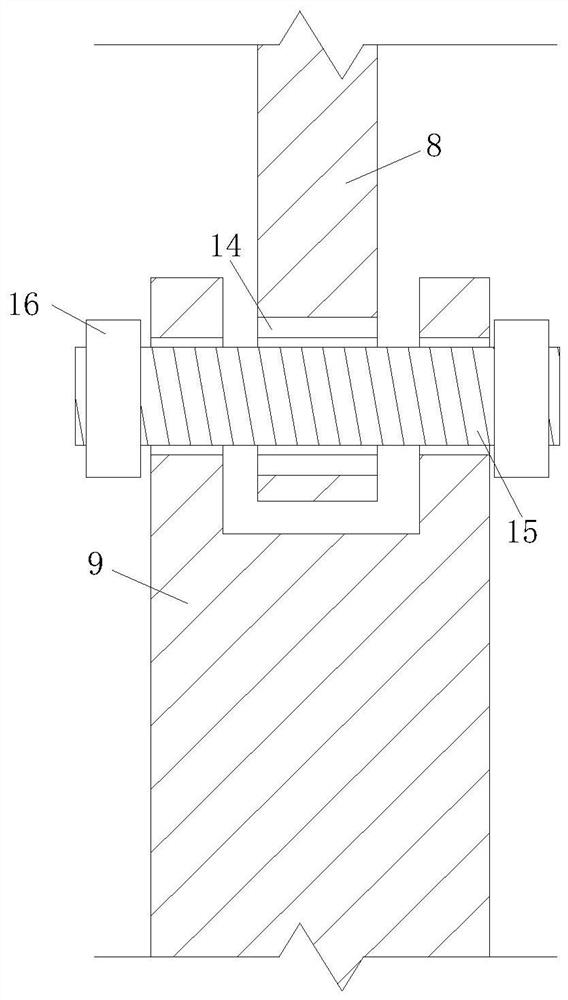

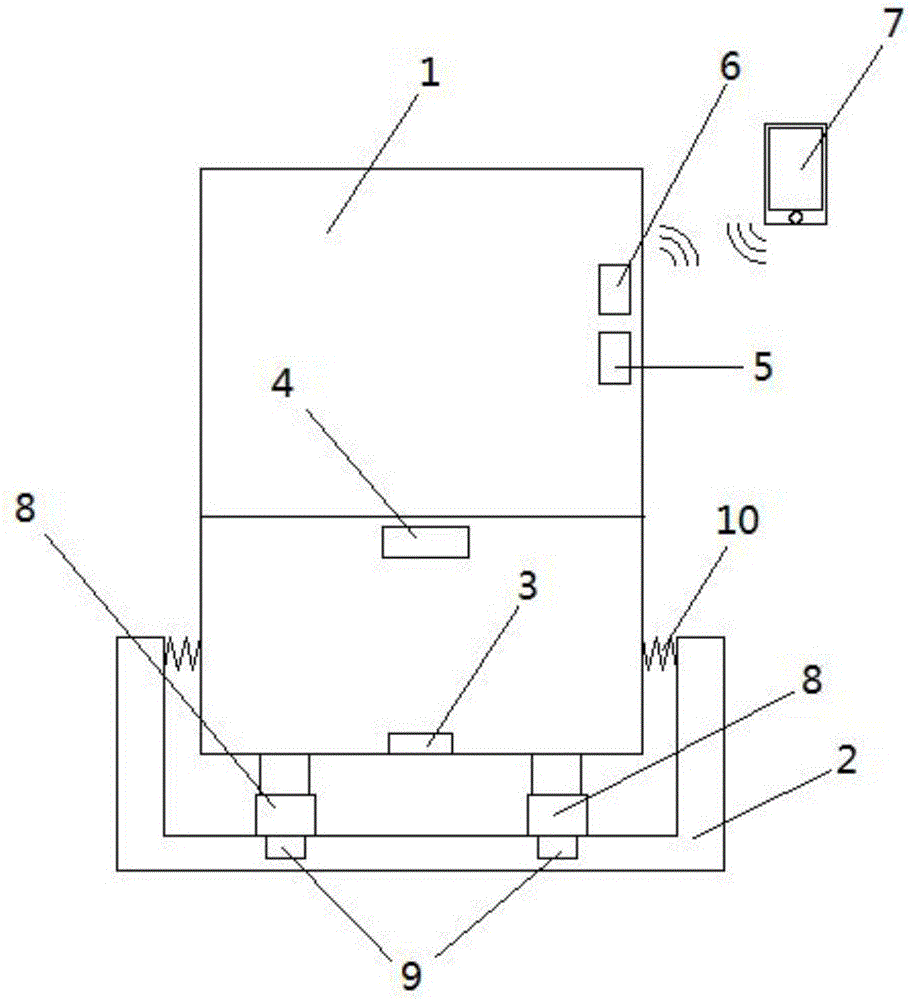

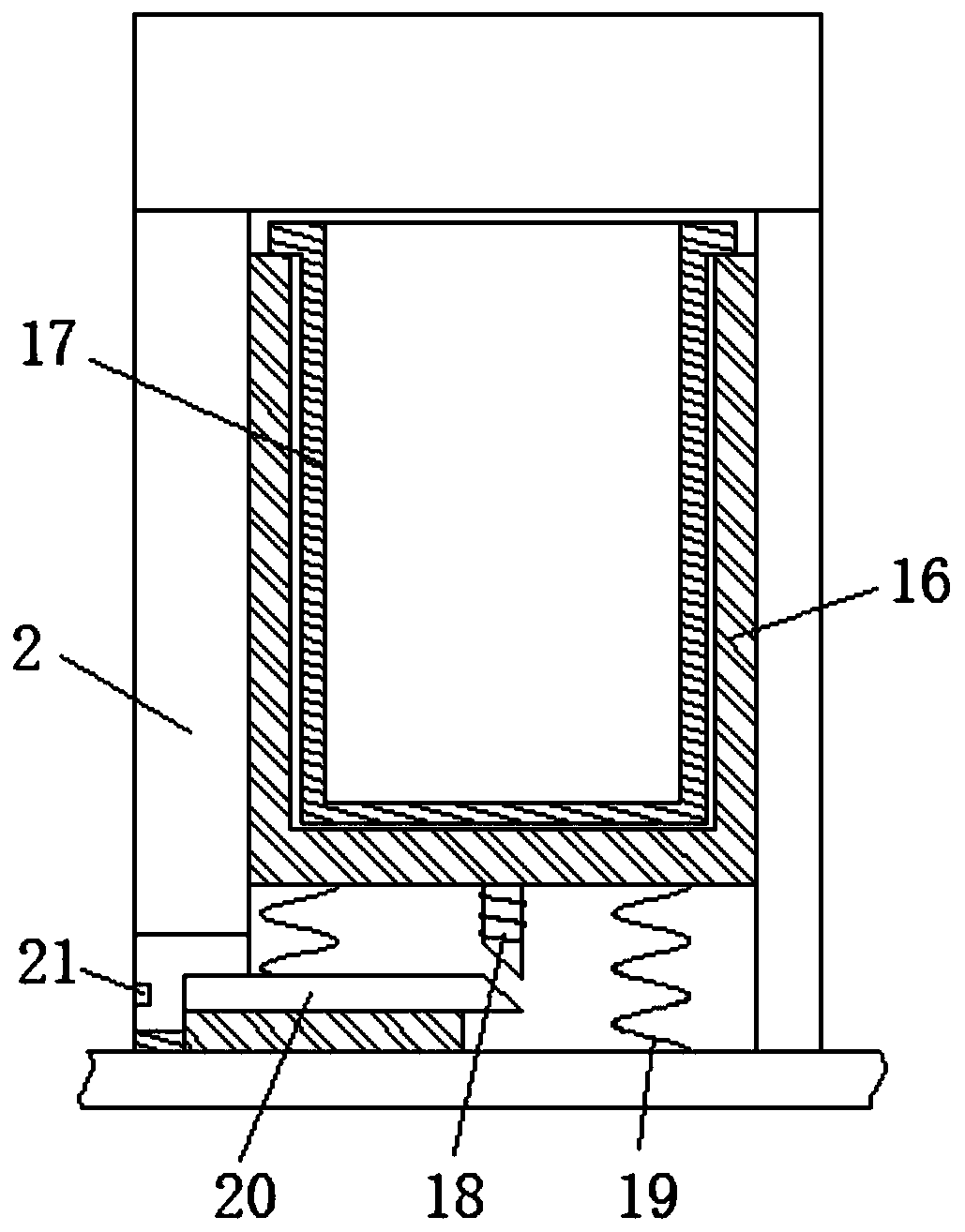

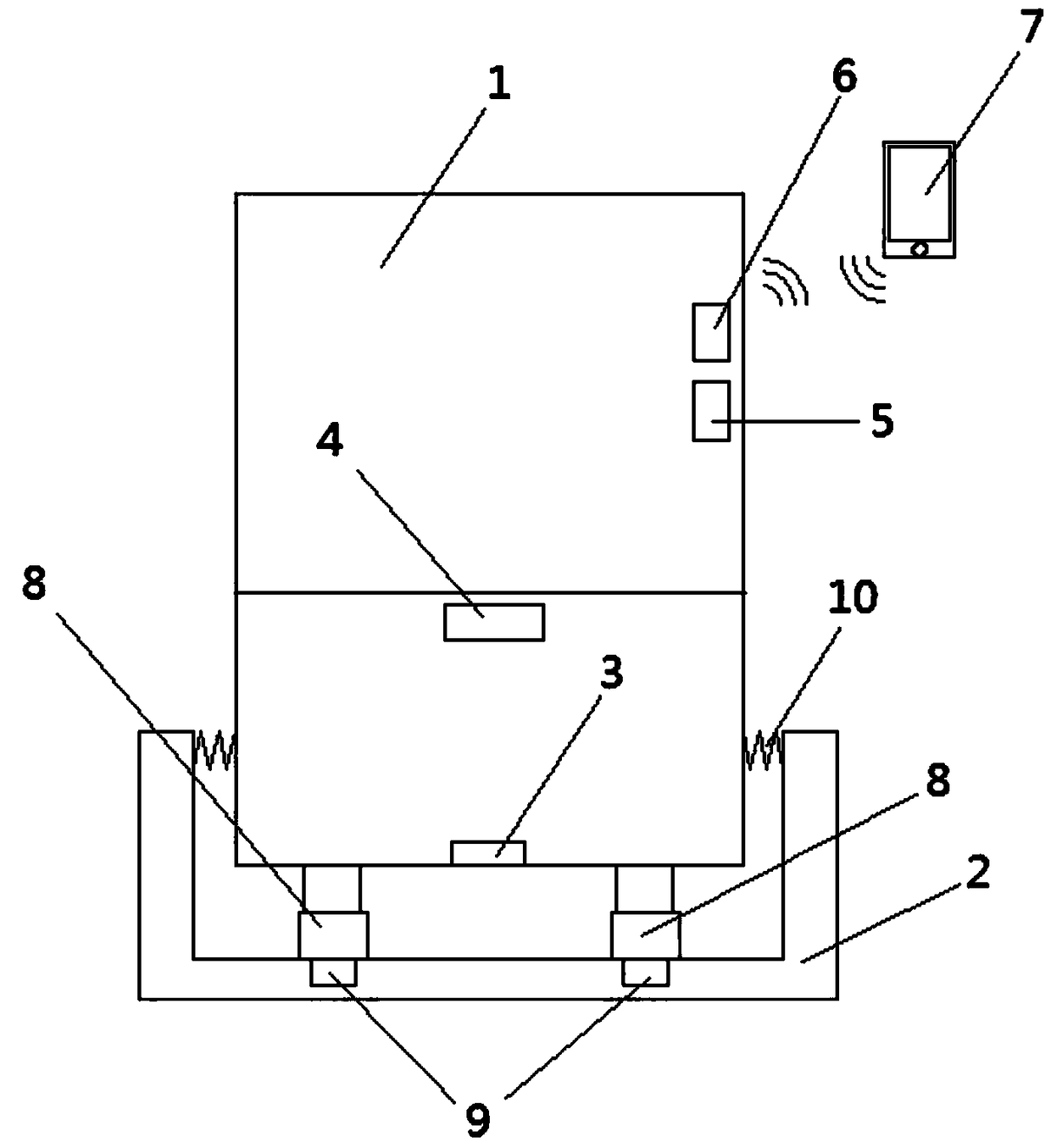

Anti-inclination dehumidifier

ActiveCN106123138ATimely dumpMechanical apparatusSpace heating and ventilation safety systemsComputer moduleEngineering

The invention relates to the field of dehumidifiers, in particular to an anti-inclination dehumidifier. The anti-inclination dehumidifier comprises a machine body and a base; the cross section of the base is in the shape of U; the machine body is arranged in a groove of the base; electric telescopic rods are fixedly arranged between the bottom of the machine body and the base and are at least four electric telescopic rods located at the positions of the four corners of the machine body; the multiple electric telescopic rods are used in cooperation and used for adjusting the machine body to the horizontal position; a telescopic rod motor is fixed to the bottom of each electric telescopic rod and used for driving the electric telescopic rod stretch out and draw back up and down; a horizontal sensor is arranged at the bottom of the machine body, and the inclination angle information of the machine body is acquired in real time; a liquid level sensor is located at the position of a preset liquid level of a water collecting box in the machine body and used for detecting whether the water collecting box is filled with collected water or not; a middle controller is electrically connected with the horizontal sensor, the liquid level sensor, the telescopic rod motors and a wireless communication module and used for comprehensively controlling various power utilizing devices; and the wireless communication module is in communication with a wireless monitoring terminal so that a user can conveniently monitor various parameters of the dehumidifier.

Owner:HEFEI MEILING PURIFYING EQUIP

Building solid waste treatment equipment with dustproof effect for high-rise building construction

ActiveCN113426534AAchieve the role of separate classificationIncrease the amount of stackingConstruction waste recoveryUsing liquid separation agentArchitectural engineeringWaste treatment

The invention provides building solid waste treatment equipment with a dustproof effect for high-rise building construction, and relates to the technical field of waste treatment. The building solid waste treatment equipment comprises an equipment main body, an adjusting groove is formed in the upper portion of the front face of the equipment main body, the equipment main body is slidably connected with a crushing mechanism through the formed adjusting groove, and the crushing mechanism comprises a moving rod. A first hemispherical plate and a second hemispherical plate are closed, a crushing cutter rotates for crushing, waste is thrown out during crushing due to centrifugal force, the waste can be thrown out from round holes when the size of the waste is crushed to be small, if metal contained in the thrown-out waste is adsorbed by a magnetic suction ring, and the effect of independently classifying the metal waste is achieved. When two transport boxes are full, unified treatment is carried out, the difficulty of high-rise building construction transportation is avoided, the waste is crushed and stored, the stacking amount of the waste is increased, the working difficulty of workers is reduced, mist spraying is formed through a water tank and spray heads, and dust falls down under the gravity of water.

Owner:赵亚飞

Livestock and poultry manure solid-liquid separation and sewage treatment vehicle

PendingCN112093924AEffective interceptionAvoid slipperyWaste water treatment from animal husbandryTreatment involving filtrationAgricultural engineeringPoultry manure

The invention discloses a livestock and poultry manure solid-liquid separation and sewage treatment vehicle, which comprises a vehicle body, a fixed storage cavity is formed in the vehicle body, a liquid treatment cavity is formed in the lower end of the fixed storage cavity, a solid-liquid separator is arranged at the tail of the fixed storage cavity, and the interior of the liquid treatment cavity is divided into four treatment structures, one of the four treatment structures is a water purification structure, three fixing columns are arranged at the two ends of the inner wall of the water purification structure, pp cotton layers are connected to one ends of the three fixing columns in a clamped mode, and a z-shaped overlapped combination face is combined with an adjacent combination face. According to the livestock and poultry manure solid-liquid separation and sewage treatment vehicle, the filtering area can be increased, the filtering quality can be improved, sewage can be comprehensively covered, and the filtering effect can be greatly improved; the filtering quality and effect can be fully guaranteed, the overall filtering area can be increased, the filtering effect is improved, the overall contact area with water is further increased, and the overall precision of water filtering is high.

Owner:ANHUI JIULI MACHINERY EQUIP

Test method and device for half cell of fluid bed electrode direct carbon fuel cell

InactiveCN102004225BHigh activitySimple structureFuel cell auxillariesElectrical testingElectrical batteryReaction temperature

The invention provides a test method and device for half cell of fluid bed electrode direct carbon fuel cell. The method comprises the following steps: firstly, arranging a current collector and the mixture of carbon fuel and catalyst granules in a half cell; secondly, fixing a porous plate in a preset position, and sequentially adding an auxiliary electrode, a reference electrode and carbonate; then, introducing nitrogen gas into the half cell, heating the nitrogen gas to a preset reaction temperature, regulating the flow of the nitrogen gas, and introducing oxygen gas and carbon dioxide into the reference electrode to balance the gas; and finally, connecting to an external circuit to start experiment. The device for realizing the testing method is a half-cell reaction device and comprises a half-cell reactor and a gas preheater, two electric heating devices are respectively used for carrying out temperature control on the half-cell reactor and the gas preheater, and a rotatable support structure is used for supporting and fixing the half-cell reaction device and the electric heating devices and realizing the dumpage of molten carbonate in the half cell. By making full use of theadvantages of the fluid bed electrode and the direct carbon fuel cell, the performance of the cell can be improved.

Owner:SOUTHEAST UNIV

Tea cake pressing device for tea production

InactiveCN110637897AQuality improvementImprove efficiencyPre-extraction tea treatmentStructural engineeringMechanical engineering

The invention discloses a tea cake pressing device for tea production. The tea cake pressing device for tea production comprises two side plates, the two side plates are of the same size and are arranged opposite to each other, base plates are arranged at the lower end edges of the two side plates, and longitudinal center axes of the upper end surfaces of the two base plates and lower end edges ofthe two side plates are fixedly arranged, two universal wheels are fixedly installed on the lower end surfaces of the two base plates, the two universal wheels on the lower end surface of each base plate are symmetrically distributed with respect to the horizontal center lines of the lower end surfaces of the base plates, a mounting plate is fixedly installed on the lower part of the horizontal center line of one side surface of one of the side plates, a servo motor is fixedly installed on the upper end surface of the mounting plate, and a first driving shaft is fixedly connected to the output end of the servo motor. According to the tea cake pressing device for tea production, a material poring device is additionally arranged, tea cakes which are pressed into the cake and formed are poured in time, on the one hand, the production of the subsequent tea cakes is not delayed, and on the other hand, tea residues appearing on a production layer are completely poured from a mold discharging groove, and the quality of the tea cakes is improved.

Owner:林奕丞

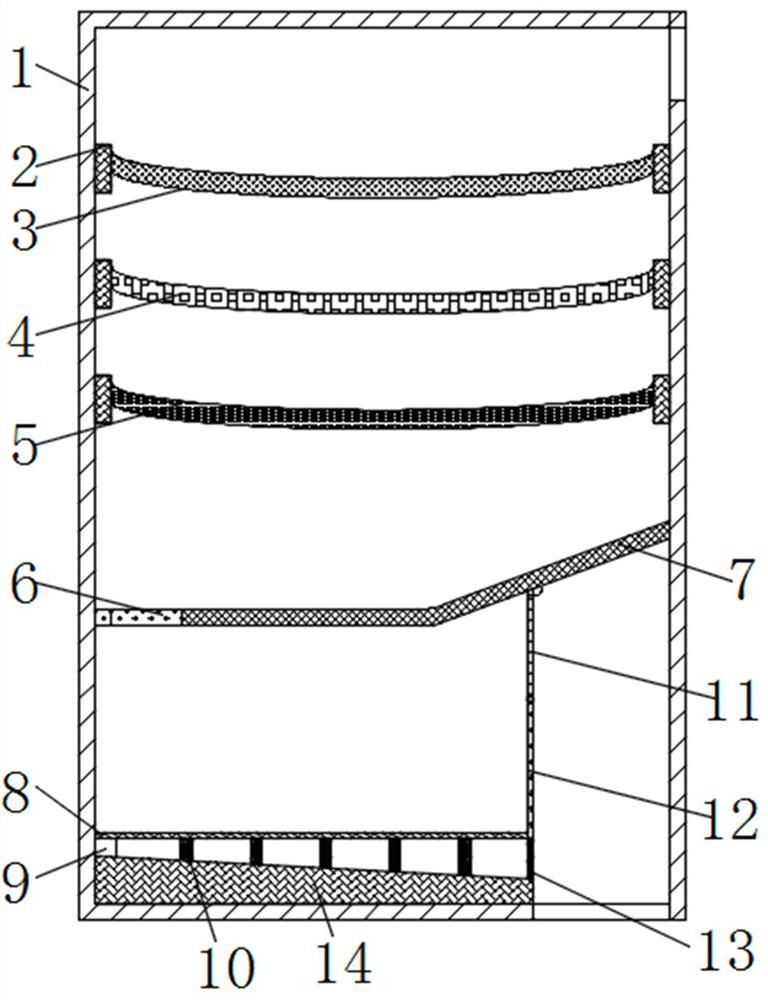

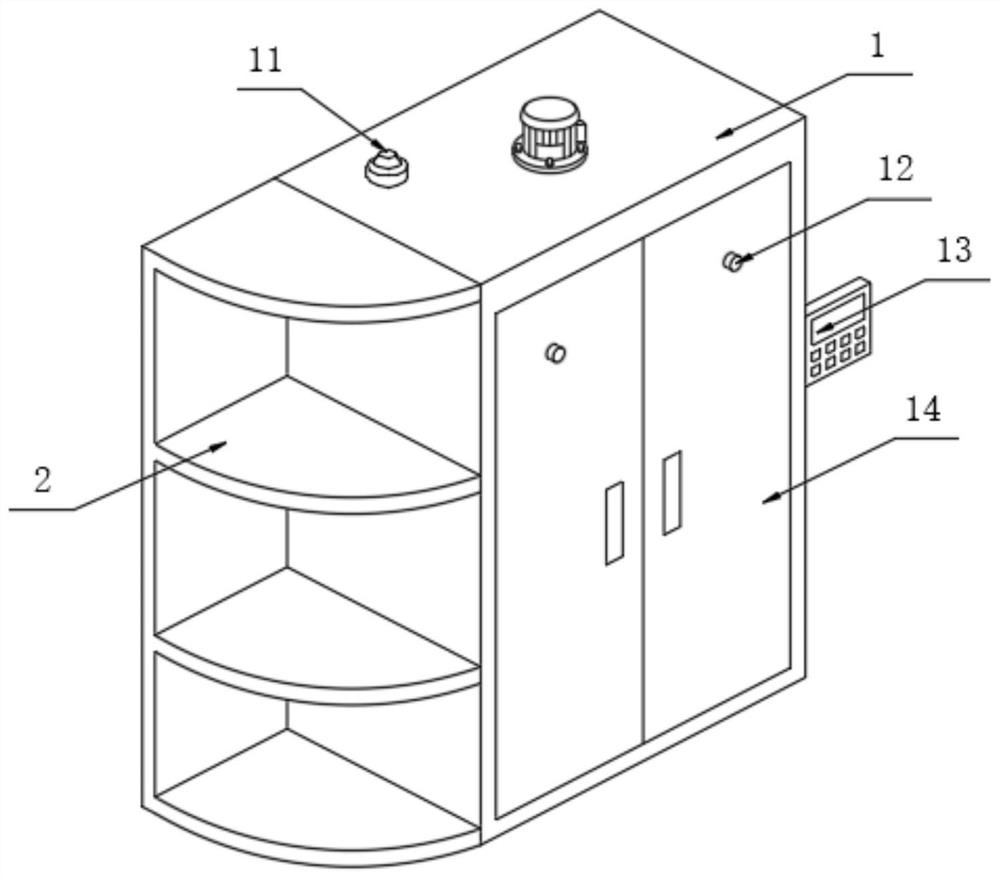

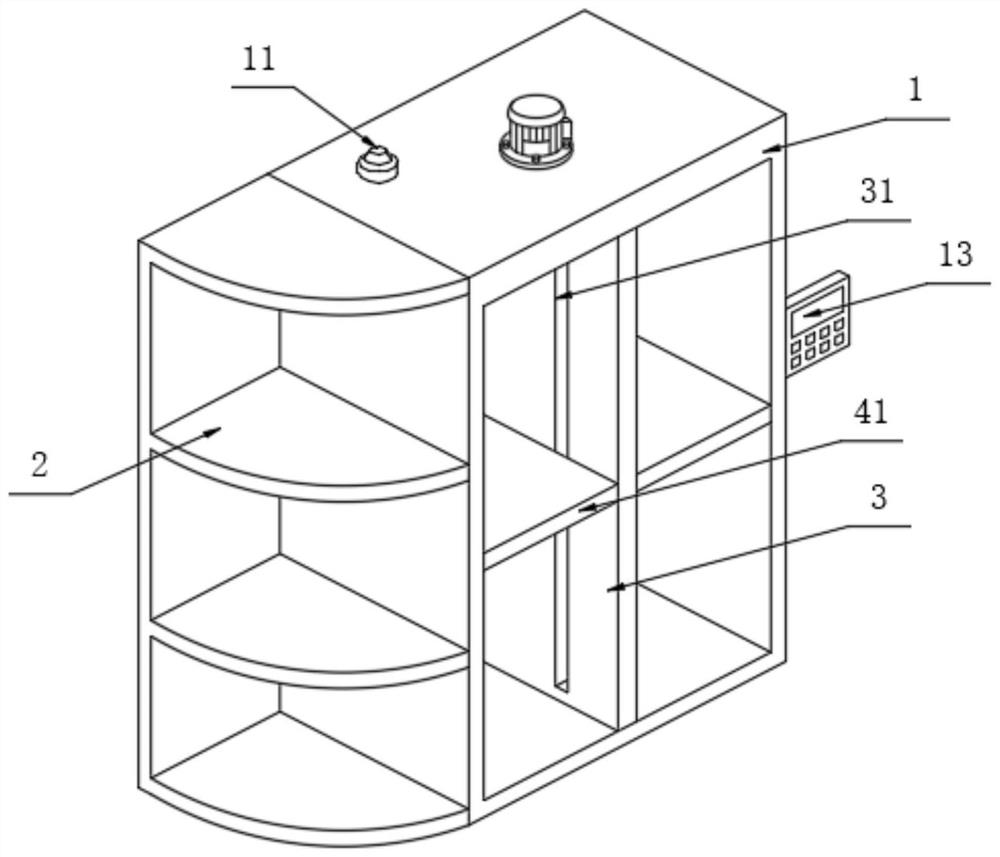

Space-adjustable wardrobe with intelligent lamplight induction

PendingCN114027627AChange storage spaceEasy to placeWardrobesCarpet cleanersControl theoryMechanical engineering

The invention relates to the technical field of wardrobes, and discloses a space-adjustable wardrobe with intelligent lamplight induction. The space-adjustable wardrobe is characterized in that, the front surface of a wardrobe body is hinged with a wardrobe door, the interior of the wardrobe body is fixedly connected with a partition plate, the front surface of the wardrobe door is fixedly connected with an infrared sensor, both sides of the partition plate are longitudinally provided with limiting grooves, the partition plate is provided with an adjusting mechanism, an illuminating lamp is fixedly connected to the top end of the interior of the wardrobe body, a mouse luring mechanism is further installed on the bottom surface of the interior of the wardrobe body, and an alarm is further fixedly connected to the corner of the upper surface of the wardrobe body. According to the invention, a first supporting plate and a second supporting plate can be driven to move upwards and downwards through an adjusting mechanism, so that the storage space in a wardrobe body can be changed, a user can conveniently place objects of different sizes in the wardrobe body, and the application range is widened; and mice and the like entering the wardrobe body can be trapped through a mouse luring mechanism, so that the mice is prevented from gnawing and polluting the clothes in the wardrobe body, and the cleanliness and safety of the clothes in the wardrobe body are guaranteed.

Owner:福瑞智能家居股份有限公司

Pollutant treatment device of water surface sewage disposal boat

ActiveCN114802615AImprove cleaning efficiencyLow costWater cleaningWaterborne vesselsRefuse collectionSewage

The invention discloses a pollutant treatment device of a water surface sewage disposal ship. The pollutant treatment device comprises a floating garbage treatment mechanism and an oil spill treatment mechanism which are arranged on a sewage disposal ship body. When the storage cabin on the sewage disposal ship is full of garbage, the water surface sewage disposal ship runs to a sewage centralized disposal site, then the garbage disposal mechanism automatically dumps the garbage in the storage cabin, and the spilled oil disposal mechanism automatically dumps spilled oil collected in the oil storage cabin into a recycling bin. The water surface sewage disposal boat comprises the floating garbage collection mechanism, the floating garbage disposal mechanism, the sea surface spilled oil collection mechanism and the spilled oil disposal mechanism, floating garbage and spilled oil on the sea surface can be collected and disposed at the same time, that is, only the water surface sewage disposal boat is needed in the same polluted sea area, the sewage disposal efficiency is greatly improved, and the cost is saved.

Owner:HOHAI UNIV

A CNC lathe for rough machining of planetary gears

ActiveCN112238261BNot easy to pile upImprove work efficiencyGear-cutting machinesMaintainance and safety accessoriesNumerical controlGear wheel

This application relates to the field of numerical control lathes, in particular to a numerical control lathe for rough machining of planetary gears, which includes a machine body, a working room is arranged in the machine body, a cutting mechanism and a fixture corresponding to the cutting mechanism are arranged in the working room, and the machine body is also fixedly installed There is a rotating drive mechanism, which is connected to the fixture by transmission. There is a waste material output mechanism in the working room. The waste material output mechanism is located below the fixture and the cutting mechanism. The waste material output mechanism and the rotary drive mechanism are connected through a transmission transmission mechanism. A discharge port is provided on the side wall, and the waste material output mechanism penetrates the discharge port. The application has the advantages that the cutting waste is not easy to accumulate in the working room, and the waste material output mechanism transports the cutting waste to the outside of the body, saving manpower and time, and improving the working efficiency of the staff.

Owner:上海万众实业股份有限公司

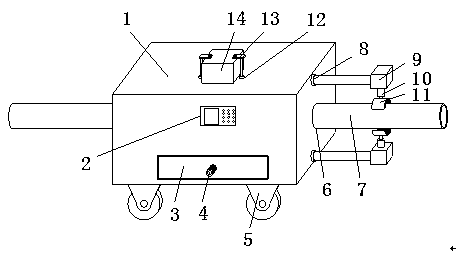

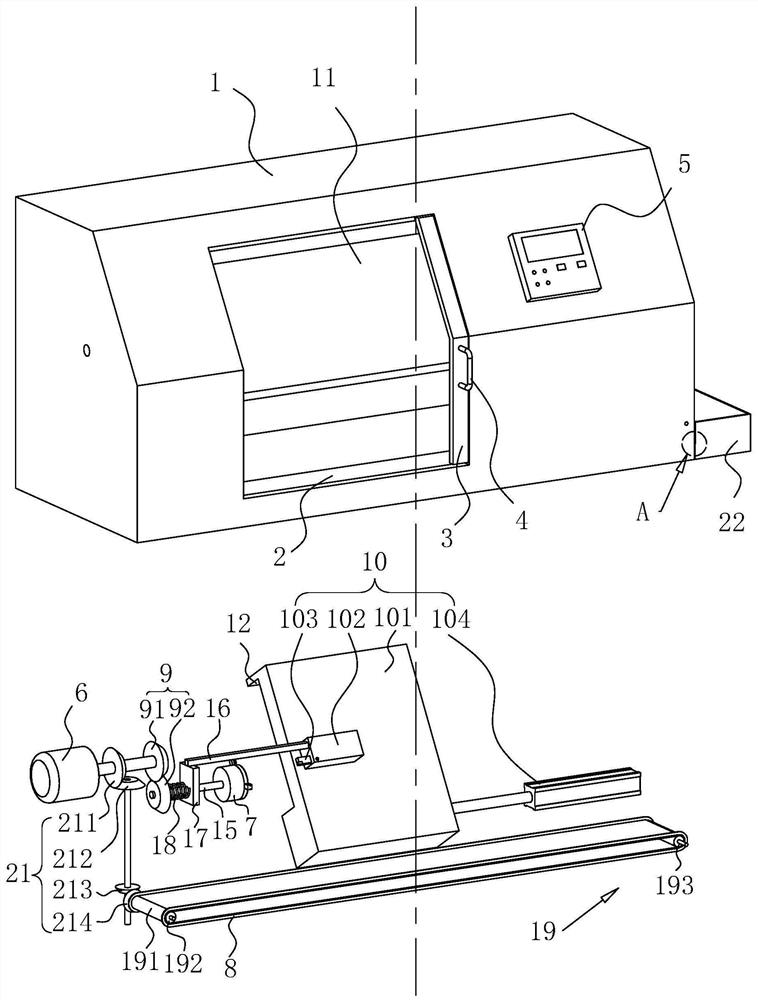

Novel pipe cutting table for buildings

InactiveCN107639284AEasy to cutAvoid damageTube shearing machinesMaintainance and safety accessoriesPush pullArchitectural engineering

The invention discloses a novel pipe cutting table for buildings. The cutting table comprises a cutting table body, mobile wheels are installed at four corners of the bottom end face of the cutting table body, a control panel is inlaid in the center of the top of the front side wall of the cutting table body, a push-pull drawer is installed at the bottom of the front side wall of the cutting tablebody in a sliding mode, a handle is installed on the push-pull drawer, a pressure sensor is installed in the push-pull drawer, the pressure sensor is electrically connected with the control panel, apartition plate is connected to the top of the pressure sensor, the cutting table body is internally provided with a through hole, a pipe is connected into the through hole in a sliding mode, first linear actuators are symmetrically inlaid in the top of the right side wall and the bottom wall of the cutting table body, the first linear actuators are electrically connected with the control panel, the left side wall of a fixed block is installed on the top of each first linear actuator, the top of a second linear actuator is installed on the bottom wall of each fixed block, and the second linearactuators are electrically connected with the control panel. The pipe cutting table is compact in structure and convenient to move.

Owner:威海红印食品有限公司

Household garbage classifying can

InactiveCN111169851AEasy to adjust the volume ratioEfficient use ofRefuse receptaclesEngineeringStructural engineering

The invention discloses a household garbage classifying can. A can body comprises an outer can and an inner can; the inner can is sleeved in the outer can; a separation structure is movably connectedwith the wall of the inner can through a first connecting structure; an inner cavity of the inner can is adjustably cut to form a first cavity and a second cavity; multiple grooves are formed by downwards recessing the edge of an opening of the outer can; the edge of a can lid downwards extends to form multiple convex blocks matched with the grooves; multiple pressure-sensitive sensors are fixed on the bottom surface in the outer can; and a support base for preventing the can body from tilting is arranged on the outer bottom surface of the outer can. The volume ratio of the first cavity to thesecond cavity of the inner can is conveniently adjusted according to the life styles of users, so that the space of the can body is effectively utilized, and the client base is extensive; through combination of the grooves and the convex blocks, a garbage bag sleeved inside is stably hung without easily generating sliding friction; and through general control of an intelligent control module, theusers are intelligently prompted to timely pour garbage.

Owner:WENZHOU POLYTECHNIC

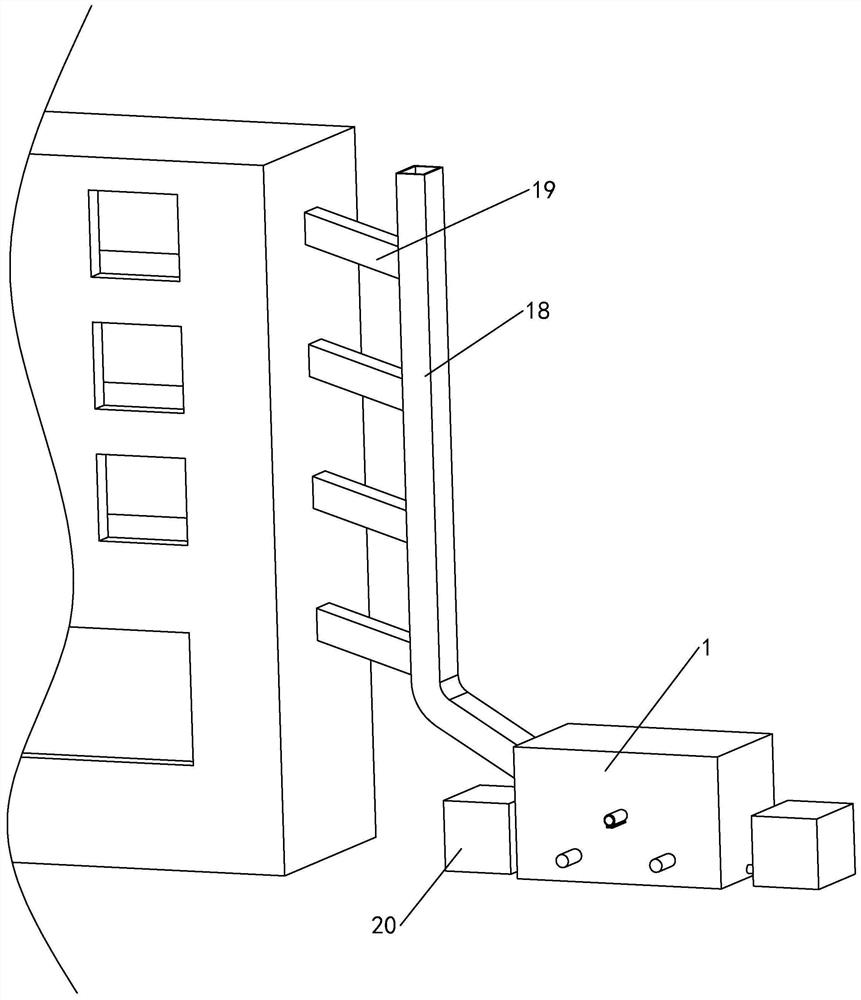

Comprehensive treatment and resource utilization method for automatically gathering kitchen waste

The invention discloses a comprehensive treatment and resource utilization method for automatically gathering kitchen waste, which comprises a channel, the channel is connected to the side surface of a building, a connecting channel is arranged between the channel and each floor, the connecting channel is provided with a detection mechanism, the kitchen waste directly falls down from the channel through the detection mechanism in the connecting channel to the first floor to be collected and then conveyed to a fermentation bin, a crushing mechanism and an extruding mechanism are arranged in the fermentation bin, and the fermentation bin is connected with an oil-water separator. The generated kitchen waste is treated in time, so that the life of people is not influenced.

Owner:浙江绿楹环境科技有限公司

A system for managing office sanitation

ActiveCN108053569BEasy storage managementReturn in timeMechanical apparatusLighting and heating apparatusIdentification deviceObject storage

The invention discloses a system for managing office environment health. The system comprises an object storage cabinet, an electronic door lock, a RFID label, a RFID label identification device, a loudspeaking device, an attendance device and a computer background managing system, wherein the RFID label comprises first RFID labels and second RFID labels, the first RFID labels are arranged on allpublic objects and used for identifying storage positions of all the public objects, and the second RFID labels are arranged on staff work cards and used for identifying staff identity information; the RFID label identification device is used for identifying the RFID labels on the public objects; the computer background managing system comprises a storage module and a control module, the storage module is used for recording position information of the public objects in the object storage cabinet and recording borrowed public objects and information of borrowers, and the control module is connected with the electronic door lock, the RFID label identification device, the attendance device and the loudspeaking device. The system has the function of keeping the office environment to be tidy and clean.

Owner:泛亚信息技术江苏有限公司

Cleaning device of particulate trap

PendingCN113350907AReduce particulate matterAvoid dustDispersed particle filtrationParticulatesEnvironmental engineering

The invention relates to the field of diesel engine emission aftertreatment, and discloses a cleaning device of a particulate trap, which comprises a cleaning bin and a dust collecting bin, a fixed seat, a first nozzle and a moving mechanism are arranged in the cleaning bin, the fixed seat is used for fixing the particulate trap, the first nozzle is connected with a compressed air source to clean the particulate trap, and the moving mechanism can drive the nozzle and the fixed seat to move relatively, so that the nozzle and the ash removal end of the particulate trap move relatively to complete the cleaning action, and the cleaning bin is further provided with an exhaust hole; a first dust collecting box is arranged in the dust collecting bin, the first dust collecting box is communicated with the dust discharging end of the particle trap so as to collect particles discharged by the particle trap, a filtering device is further arranged in the dust collecting bin, and the filtering device is communicated with the exhaust hole; and the cleaning device also comprises a fan, and the fan is communicated with the dust collecting bin so as to extract gas in the dust collecting bin. Dust and other particulate matter in the cleaning bin can be cleaned, and secondary pollution to the particulate filter is relieved.

Owner:SHANDONG UNIV +1

Energy-saving iron smelting furnace

The invention discloses an energy-saving iron smelting furnace, which mainly includes a furnace body, an outer frame, a furnace cover and a gas processing device. A groove frame for accommodating the furnace body is arranged on the inner side of the outer frame, and a rotating shaft is installed on the corresponding two sides of the outer frame. , the furnace body is connected to the outer frame through a rotating shaft, an opening is provided on one side of the slot frame, a baffle is provided on the opening surface, the baffle is welded on the outer frame, and a heat dissipation Hole and hollow body, the heat dissipation holes connect the slot frame with the hollow body, the top of the outer frame is connected to the furnace cover through a circular hinge, a gas treatment device is provided on one side of the outer frame, and a gas treatment device is provided on one side of the furnace cover. A camera, the camera is connected to the display through wires, and the other side of the furnace cover is also provided with a temperature sensor and an alarm lamp. The invention has simple structure and reasonable design, and the hydrogen sulfide gas generated during iron melting is discharged after being treated by a gas treatment device, thereby reducing waste gas discharge.

Owner:MAANSHAN NIUZE TECH SERVICE

Side road cleaning device with automatic reminding and dust raising prevention functions

InactiveCN111305125AEasy to solveTimely dumpRoad cleaningStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of road garbage cleaning, and a discloses a side road cleaning device with automatic reminding and dust raising prevention functions. An outer cylinder isarranged in a storage box, an inner cylinder is arranged in the outer cylinder, a push block and a supporting spring are fixedly connected to the lower portion of the outer cylinder, a pin block is movably connected to the inner bottom of the storage box, and a switch is arranged on the left side of the storage box. Impurities sucked by a dust suction port enter the inner cylinder in the storage box through a pipeline, more and more impurities are sucked in, the mass of the inner cylinder is increased, the outer cylinder is pressed down, the push block fixedly connected with the outer cylinderis made to move downwards, the push block extrudes the pin block leftwards and presses the switch, and after the switch is turned on, an alarm lamp communicated with the switch is powered on and emits light, so the purpose of reminding cleaning personnel to dump garbage in time is achieved, and the problem that the adsorption effect is poor due to overflow of garbage in the storage box is solved.

Owner:涂玉根

A tilt-proof dehumidifier

ActiveCN106123138BTimely dumpMechanical apparatusSpace heating and ventilation safety systemsComputer moduleEngineering

The invention relates to the field of dehumidifiers, in particular to an anti-inclination dehumidifier. The anti-inclination dehumidifier comprises a machine body and a base; the cross section of the base is in the shape of U; the machine body is arranged in a groove of the base; electric telescopic rods are fixedly arranged between the bottom of the machine body and the base and are at least four electric telescopic rods located at the positions of the four corners of the machine body; the multiple electric telescopic rods are used in cooperation and used for adjusting the machine body to the horizontal position; a telescopic rod motor is fixed to the bottom of each electric telescopic rod and used for driving the electric telescopic rod stretch out and draw back up and down; a horizontal sensor is arranged at the bottom of the machine body, and the inclination angle information of the machine body is acquired in real time; a liquid level sensor is located at the position of a preset liquid level of a water collecting box in the machine body and used for detecting whether the water collecting box is filled with collected water or not; a middle controller is electrically connected with the horizontal sensor, the liquid level sensor, the telescopic rod motors and a wireless communication module and used for comprehensively controlling various power utilizing devices; and the wireless communication module is in communication with a wireless monitoring terminal so that a user can conveniently monitor various parameters of the dehumidifier.

Owner:HEFEI MEILING PURIFYING EQUIP

Electric warming oven

InactiveCN109140568ANot easy to catch a coldAvoid distributingHeating fuelLighting and heating apparatusReciprocating motionEngineering

The invention discloses an electric warming oven and belongs to the technical field of electric warming ovens. A gear is connected into a rectangular frame in an engagement mode. A rotating shaft is arranged at the bottom of the gear and is further connected with a base in a rotating mode. The toothed portion of the gear is equal to semi cycle of a wheel flange. One width edge of the rectangular frame is connected with an air cylinder used for pushing the rectangular frame to make reciprocating motion. A motor used for controlling the air cylinder is further arranged inside the base. The center of the gear is vertically and fixedly connected with a fixed shaft. A stand column is of a hollow structure, and one end of the fixed shaft is located inside the stand column. A plurality of connecting rods are arranged inside the stand column. One end of each connecting rod is fixedly connected with the fixed shaft and the other end of each connecting rod is fixedly connected with the inner wall of the stand column. A plurality of radiating grooves are formed in the outer wall of the stand column at intervals, and a plurality of heating wires are arranged in the corresponding radiating grooves. A switch used for starting the motor is arranged on the base, and supply hubs used for communicating with the heating wires are further arranged on the base. When the electric warming oven is used for warming, more comfort is guaranteed in the warming process of people.

Owner:遵义市炬人电器有限公司

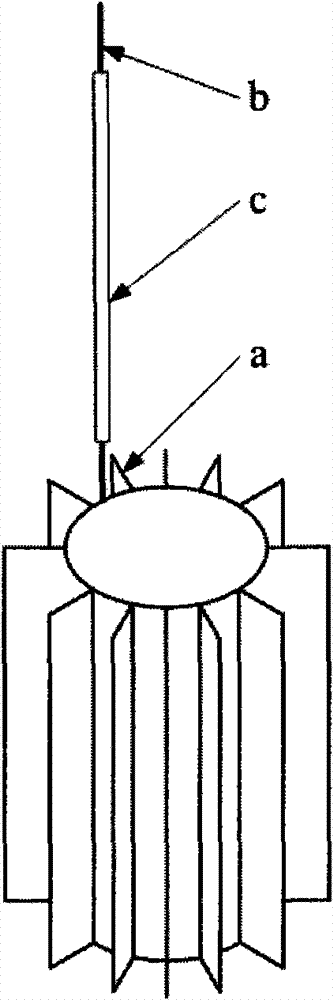

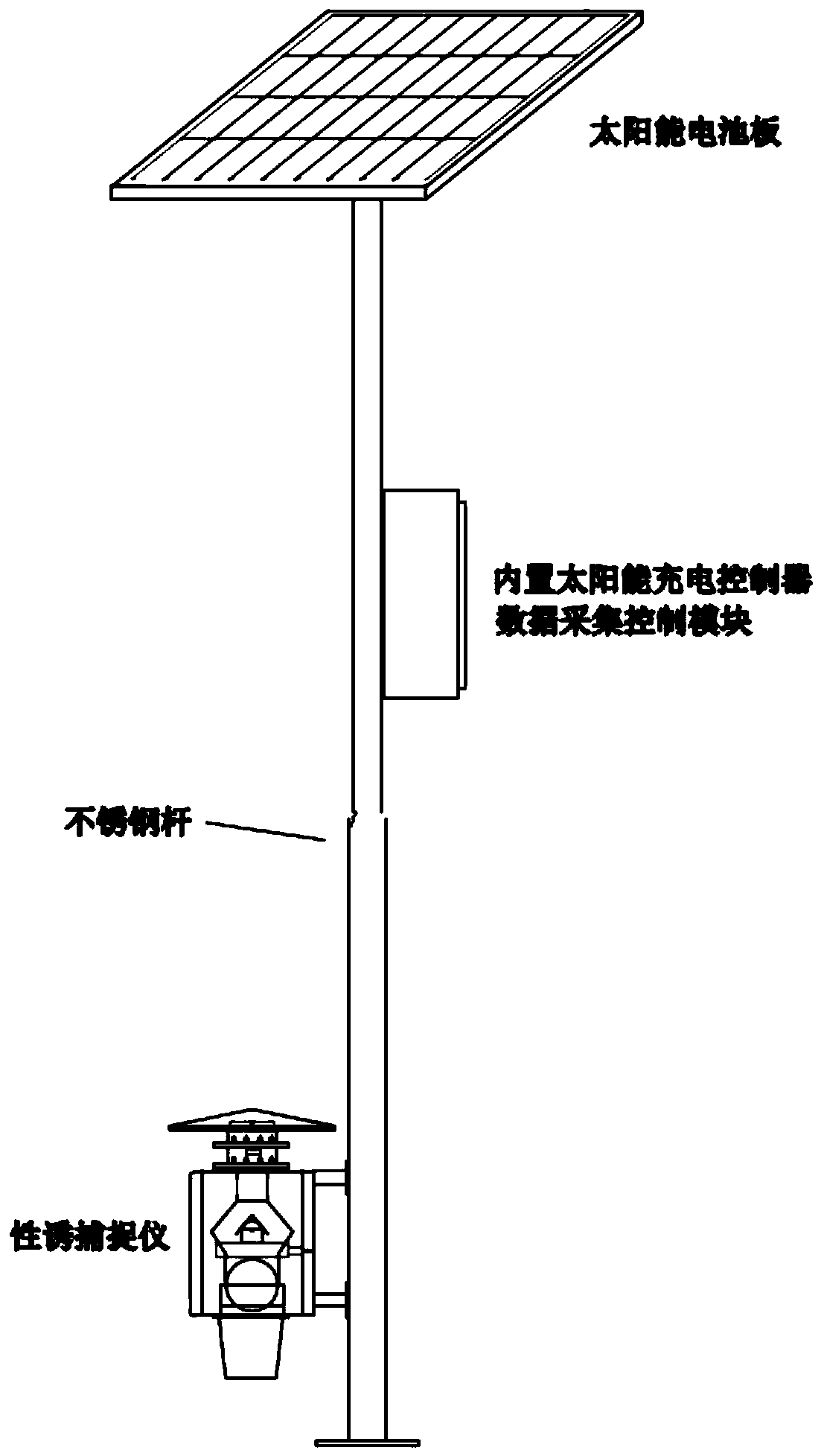

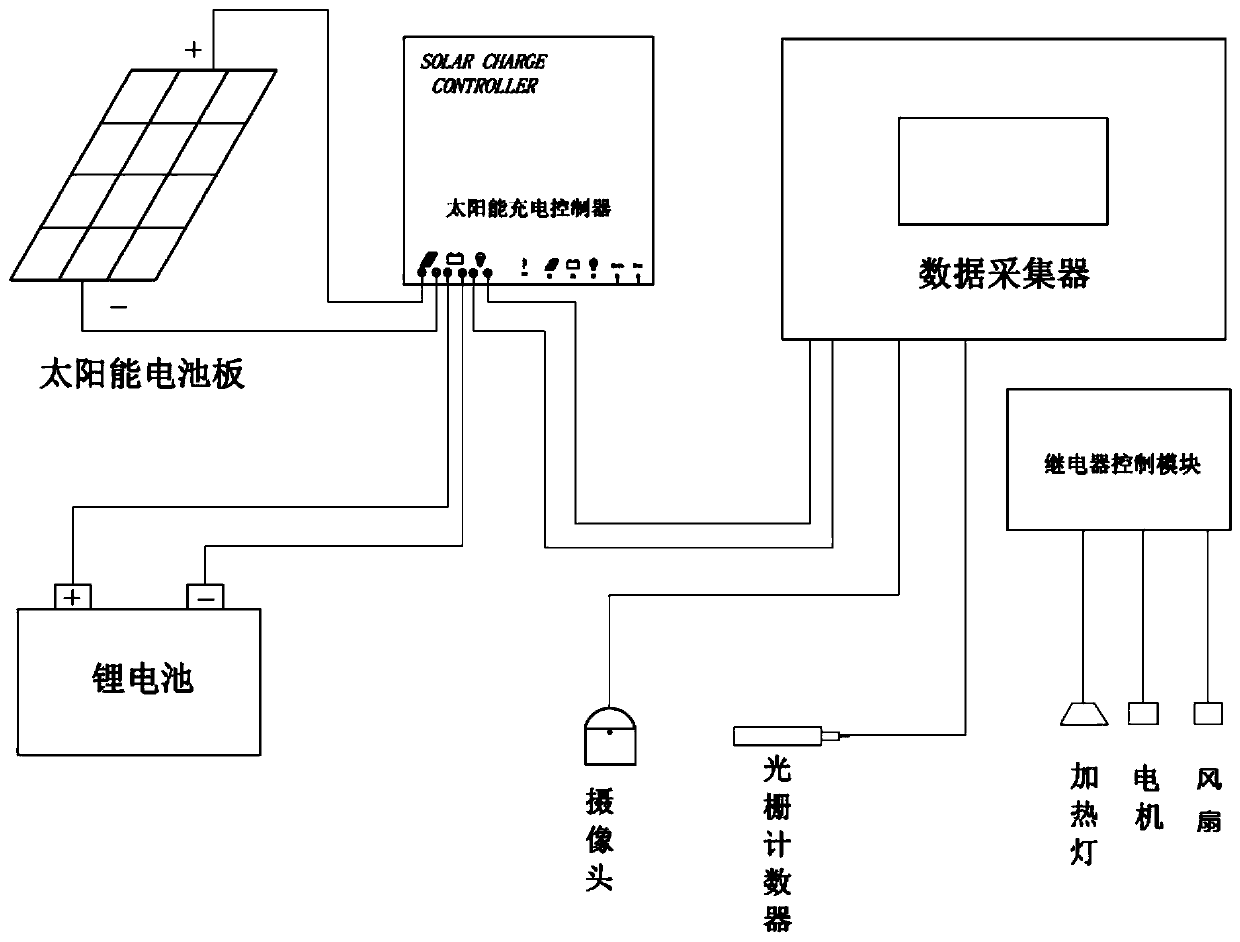

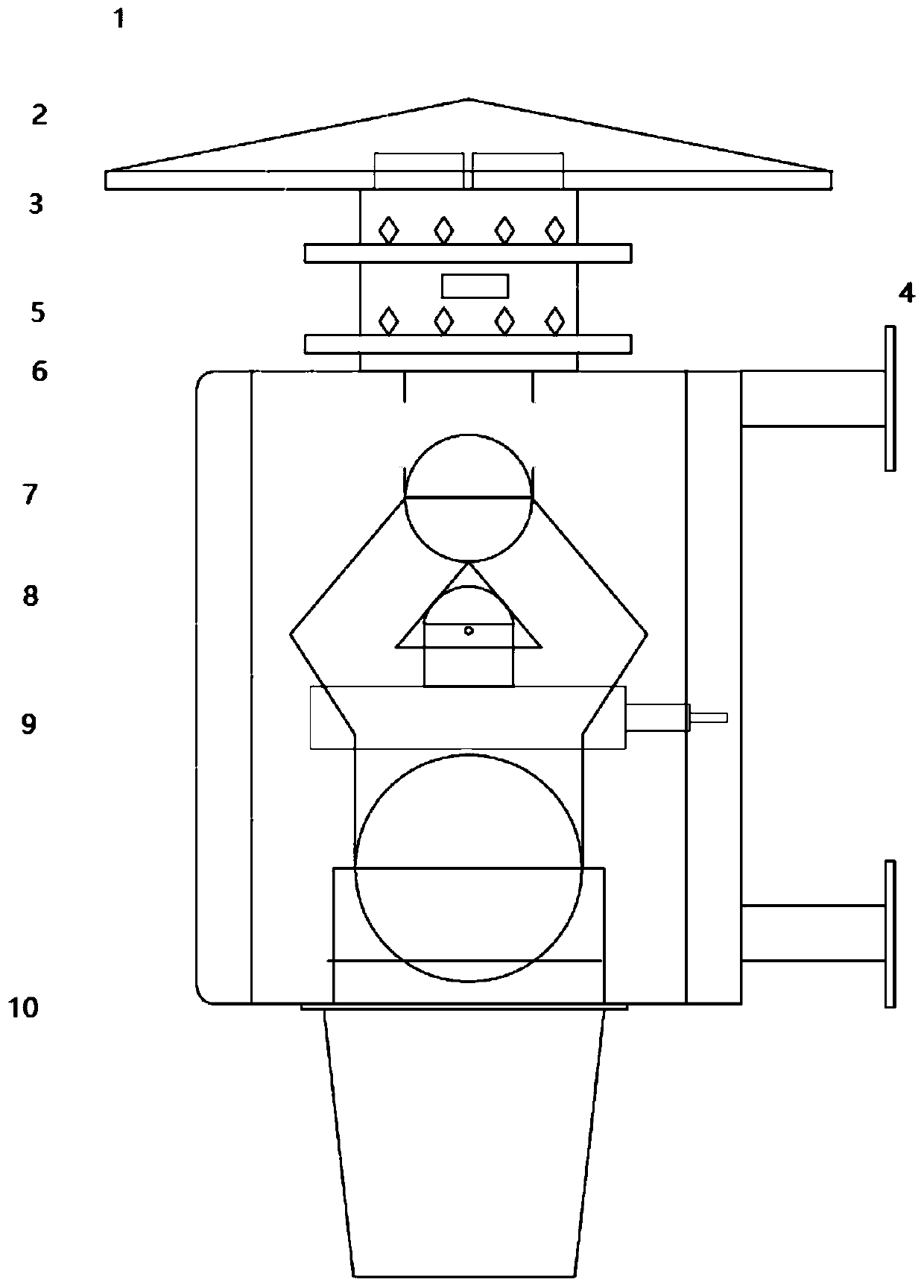

Pest target sex attraction monitoring system

PendingCN110250125APrevent flying outTimely dumpInsect catchers and killersGratingAgricultural science

The invention relates to the technical field of pest control, and discloses a pest target sex attraction monitoring system. The technical problem about pest control for reducing pollution and not influencing human health is solved. The pest target sex attraction monitoring system is characterized by comprising a solar cell panel, the solar cell panel is fixedly connected with a stainless steel rod, a data acquisition module is arranged on the stainless steel rod, a solar charging controller is arranged in the data acquisition module, and a sexual attraction trapping instrument is arranged at the bottom end of the stainless steel rod. The sexual attraction trapping instrument comprises a pest blowing fan, a pest feeding platform is arranged below the pest blowing fan, a sex attractant is placed in the pest feeding platform, a pest treatment device is connected with the lower portion of the pest feeding platform, and a pest collecting box is connected with the lower portion of the pest treatment device. A camera and a grating counter are sequentially arranged below a pest turning motor, and a pest target sex attraction monitor adopts a 4G communication mode.

Owner:上海云农信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com