Smelting furnace for aluminum profile

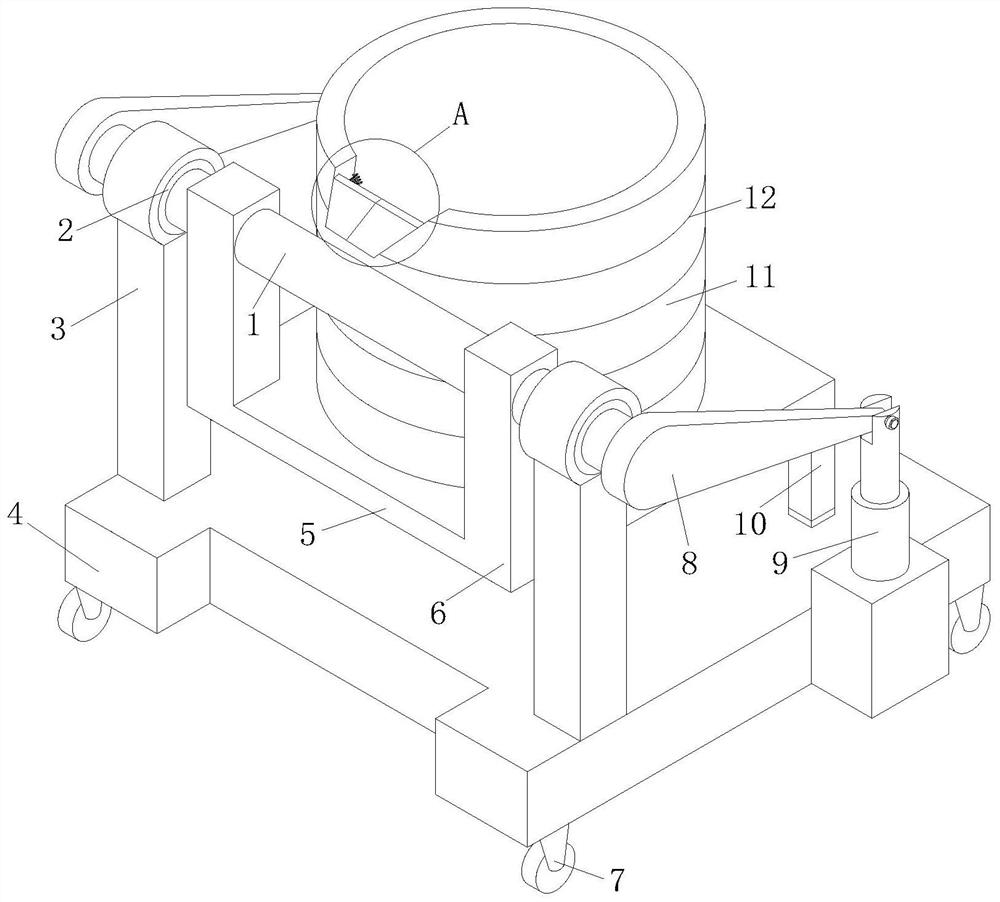

A technology for smelting furnaces and aluminum profiles, which is applied in the field of aluminum profile processing, can solve the problems of manual processing of liquids, small rotation angle of the furnace body, and unstable structure, and achieves the effect of improving the dumping effect, the large rotation angle, and improving the practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

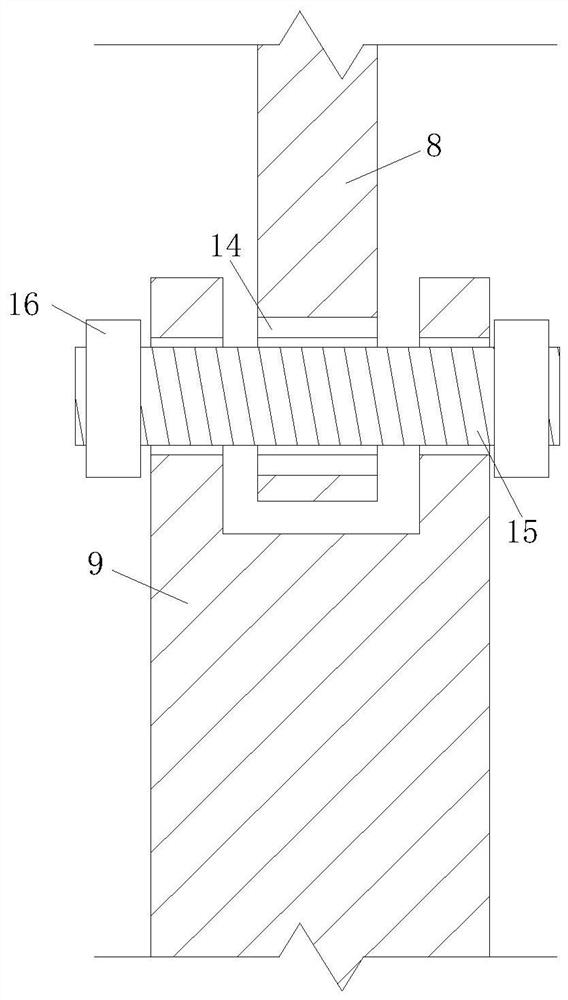

[0026]As a specific embodiment of the present invention, the first bearing 2 and the second bearing 14 are respectively installed in the first opening of the first column 3 and in the second opening of the connecting arm 8 using the interference fit method. ; By adopting the above-mentioned technical scheme, under the action of the electric push rod 9, the corresponding connecting arm 8 and the second bottom plate 5 can be driven to turn over immediately, so as to realize the dumping of the raw materials in the furnace body 11, thereby improving the dumping efficiency of the raw materials.

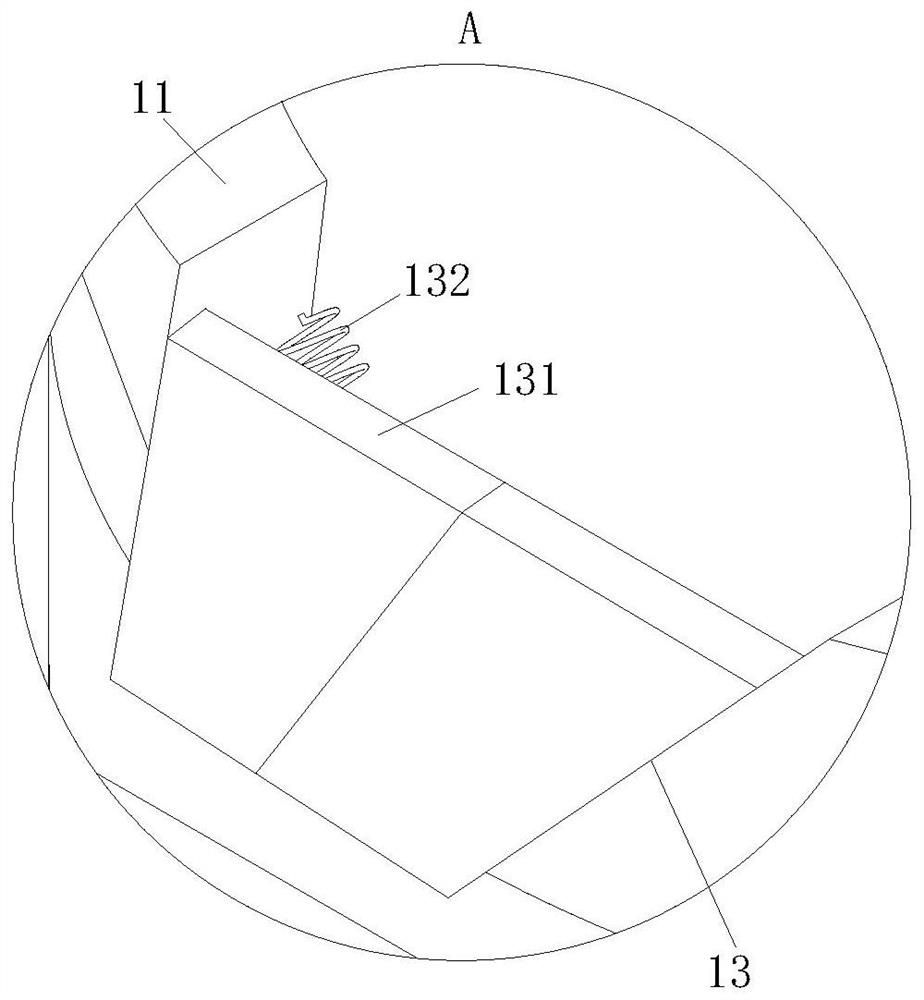

[0027] As a specific embodiment of the present invention, the pouring port 13 is provided with a pair of blocking elastic pieces 131, and one end of the pair of blocking elastic sheets 131 is fixedly connected to the pouring port 13, and the other ends are in contact with each other; Under the action of the electric push rod 9, it will be brought to the furnace body 11 to rotate rapidly, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com