Livestock and poultry manure solid-liquid separation and sewage treatment vehicle

A solid-liquid separation and sewage treatment technology, applied in water/sludge/sewage treatment, water/sewage treatment, animal husbandry wastewater treatment, etc., can solve problems such as incomplete filtration of impurities, environmental pollution, low filtration efficiency, etc., to achieve The effect of continuous and stable water purification, improved filtration effect, and high safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

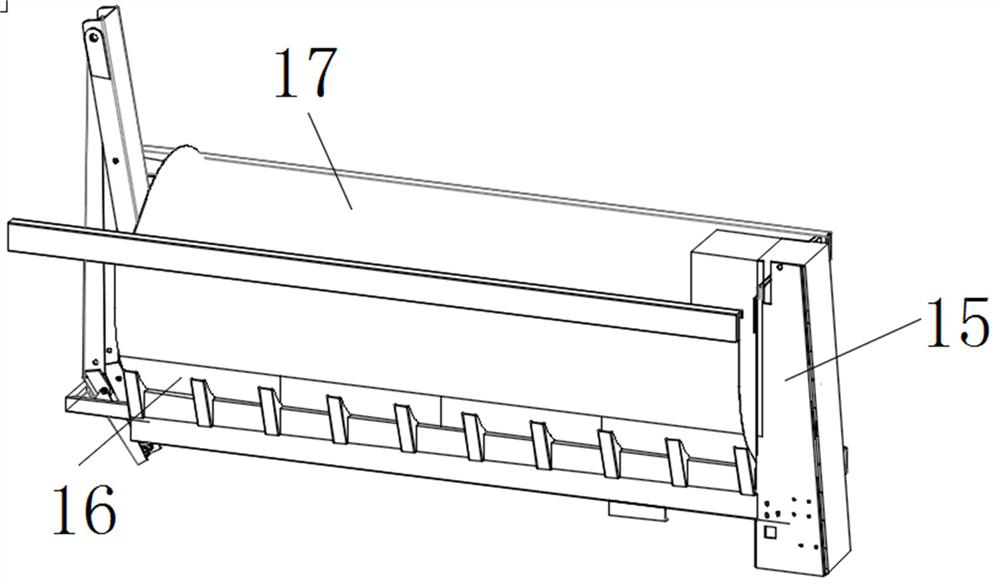

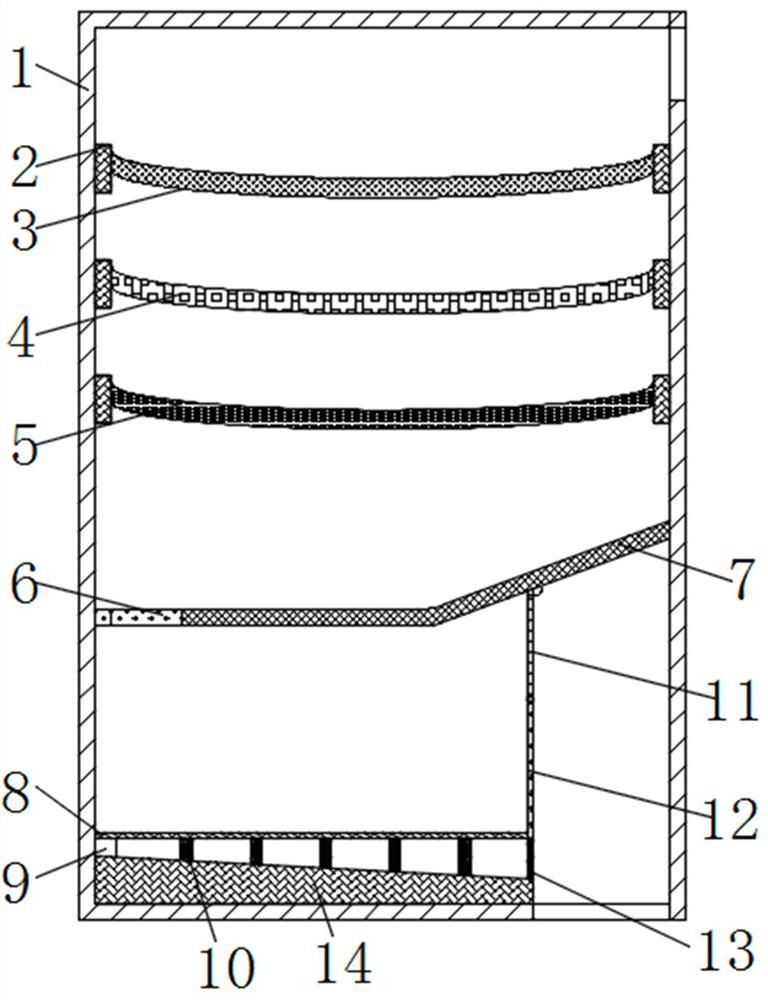

[0030] Such as Figure 1-6 As shown, a vehicle for solid-liquid separation and sewage treatment of livestock and poultry manure includes a vehicle body, a fixed storage chamber (17) is provided inside the vehicle body, and a liquid treatment chamber (16) is provided at the lower end of the fixed storage chamber (17). The tail of the storage chamber (17) is provided with a solid-liquid separator (15), and the interior of the liquid processing chamber (16) is divided into four processing structures, including a water purification structure (1), and the interior of the water purification structure (1) is set have a controller;

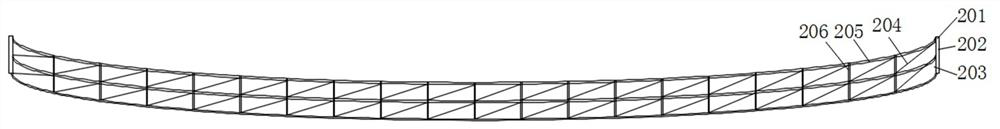

[0031]The two ends of the inner wall of the water purification structure (1) are provided with three fixed columns (2), and one end of the three sets of fixed columns (2) is clamped with a pp cotton layer (3), and the inside of the pp cotton layer (3) is divided into a No. cotton layer (201), No. 2 cotton layer (203) and support block (202), the inside o...

Embodiment 2

[0039] Such as Figure 1-6 As shown, a vehicle for solid-liquid separation and sewage treatment of livestock and poultry manure includes a vehicle body, a fixed storage chamber (17) is provided inside the vehicle body, and a liquid treatment chamber (16) is provided at the lower end of the fixed storage chamber (17). The tail of the storage chamber (17) is provided with a solid-liquid separator (15), and the inside of the liquid processing chamber (16) is divided into four processing structures, including a water purification structure (1);

[0040] The lower end of the water purification structure is provided with an inclined plate (7), the other end of the water purification structure is hinged with a rebound plate (6), one end of the rebound plate (6) is movably connected with the inclined plate (7), and the rebound plate (6) The downward turning angle relative to the inner wall of the water purification structure is 90 degrees, and the filtered water falls in the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com