Biomass particle furnace

A biomass particle and feeding device technology, which is applied in the directions of combustion air/fuel supply, combustion method, block/powder supply/distribution, etc. Safety hazards and the effect of improving heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

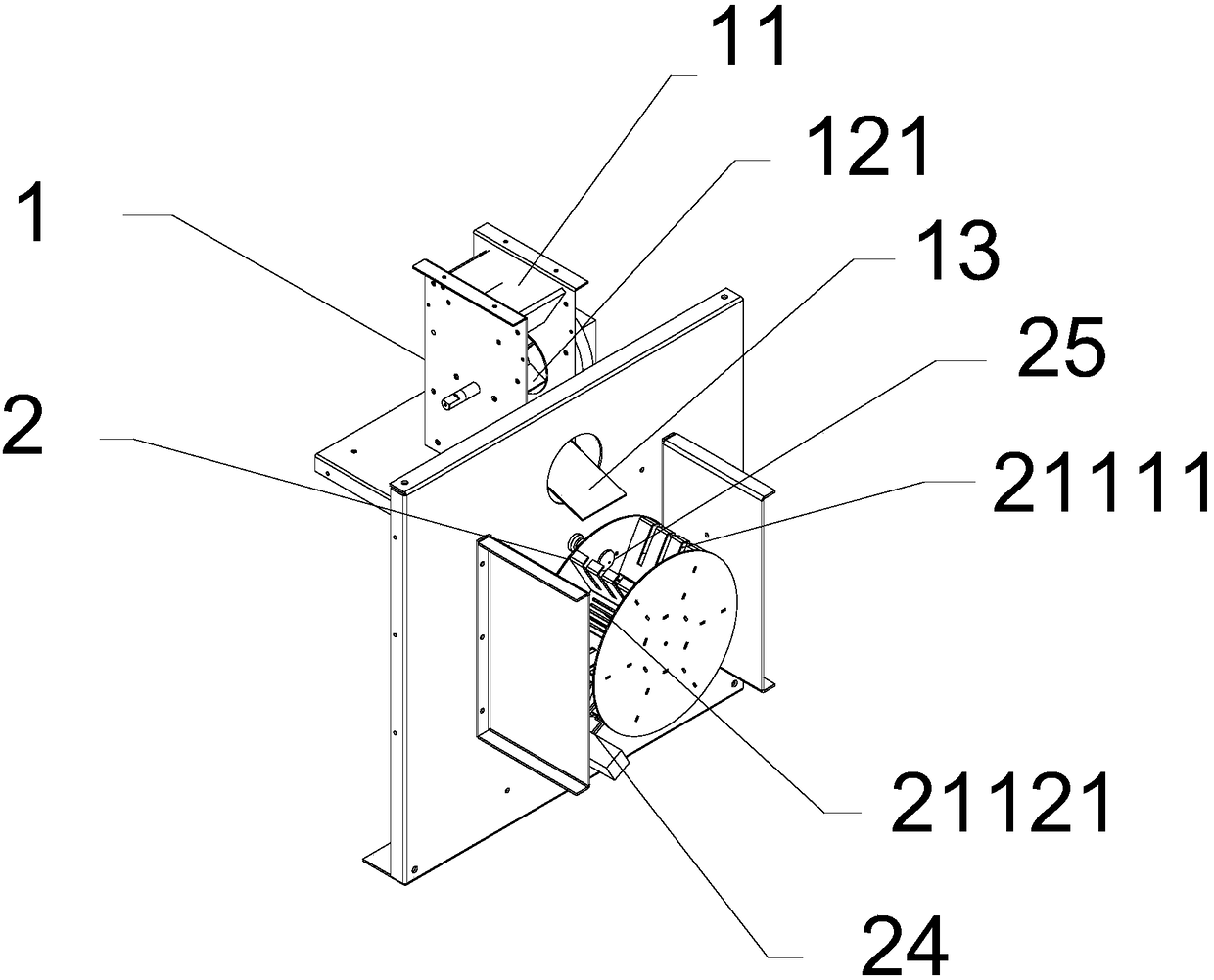

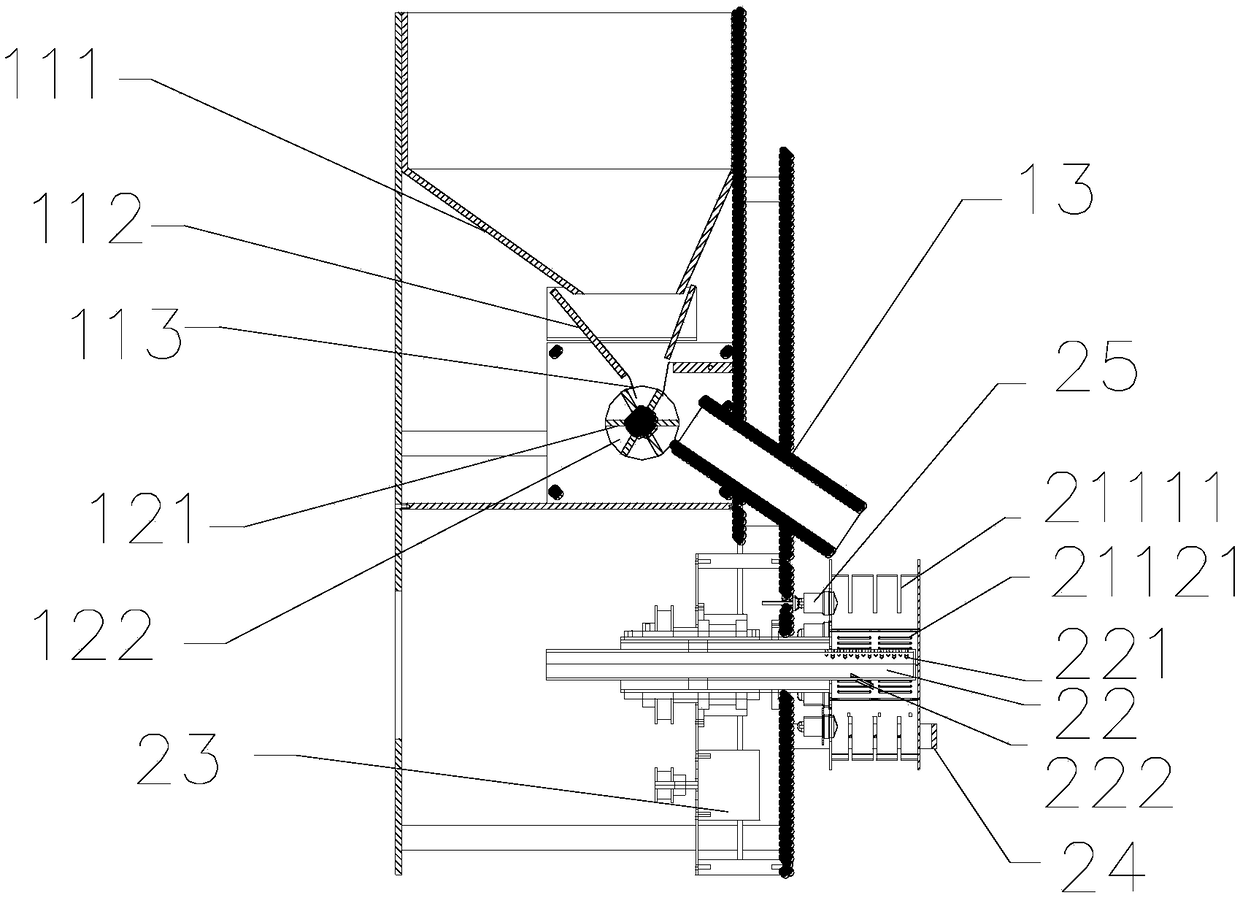

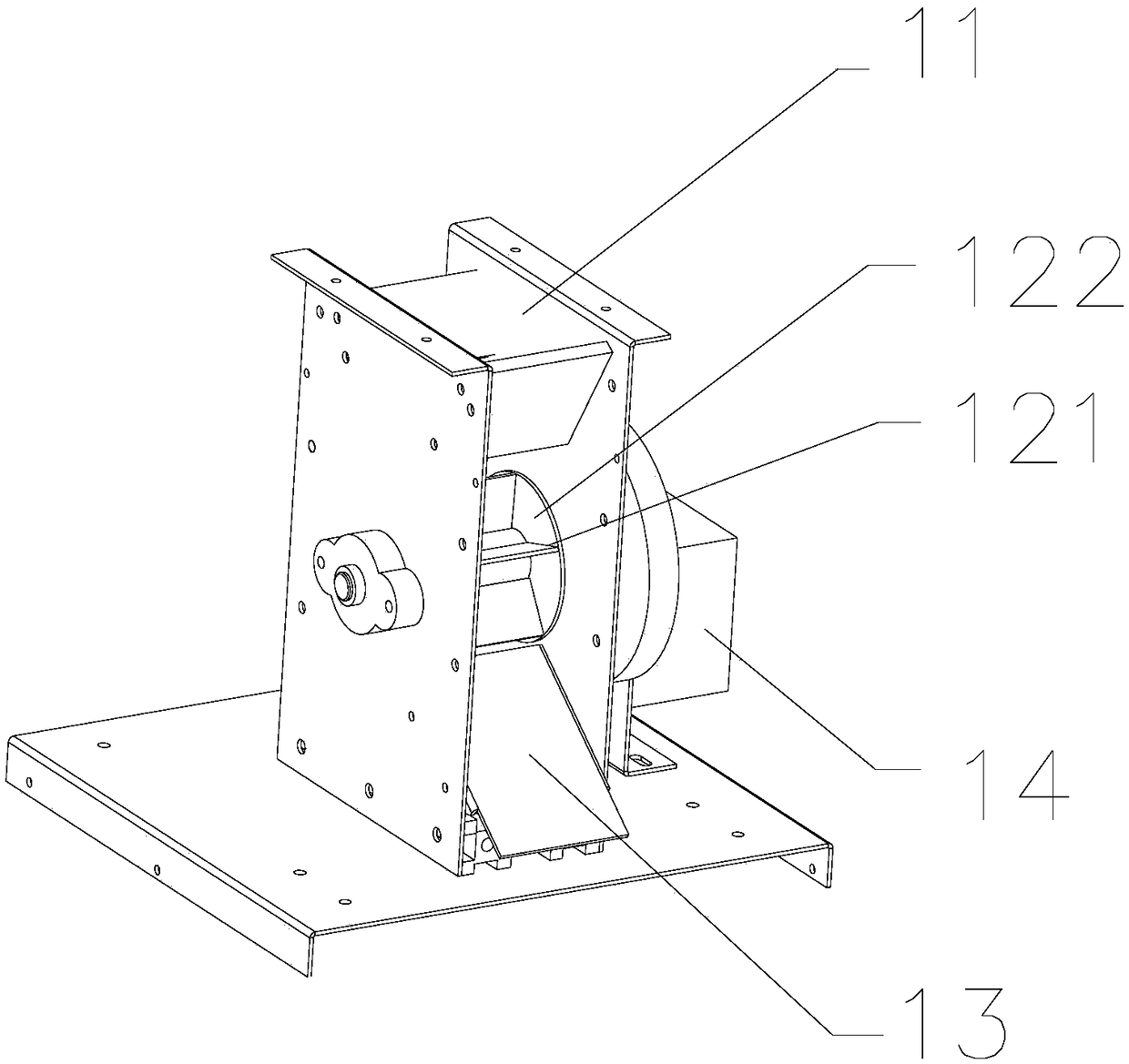

[0072] A biomass pellet stove, comprising a casing, a charging device 1 arranged inside the casing, a combustion device 2 arranged below the outlet of the charging device 1, a water circulation system connected to the casing, and a control system for controlling the operation of the charging device 1 and the combustion device 2 3. The operation panel is arranged on the outer surface of the shell, the feeding device 1 includes a hopper 11, a feeding chute 12 arranged below the outlet of the hopper 11, a feeding channel 13 arranged below the outlet of the feeding chute 12, and a feeding chute for controlling 12 The motor I14 that rotates, the feeding trough 12 is cylindrical, and the axis of the cylinder is used as the axis of rotation to rotate perpendicular to the ground plane. The opening of the lower bin 122 faces outward; the combustion device 2 includes a box body 21, an igniter 25 arranged on the inner surface of the box body 21, an ash box arranged below the box body 21, ...

Embodiment 2

[0089] A biomass pellet stove, the difference from Embodiment 1 is:

[0090] The rotating shafts of the feeding device 1 and the burning device 2 are connected by a chain for maintaining synchronous rotation.

Embodiment 3

[0092] A biomass pellet stove, the difference from Embodiment 1 is:

[0093] An igniter 25 is arranged on the rotation axis of the box body 21 to ignite the fuel in the combustion chamber 211 through the ventilation hole 21121 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com