Building solid waste treatment equipment with dustproof effect for high-rise building construction

A technology for solid waste and high-rise buildings, which is applied in grain processing, solid separation, and the use of liquid separation agents. It can solve problems such as dust generation, unfavorable production work, and inconvenience, and achieve the goal of reducing work difficulty and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

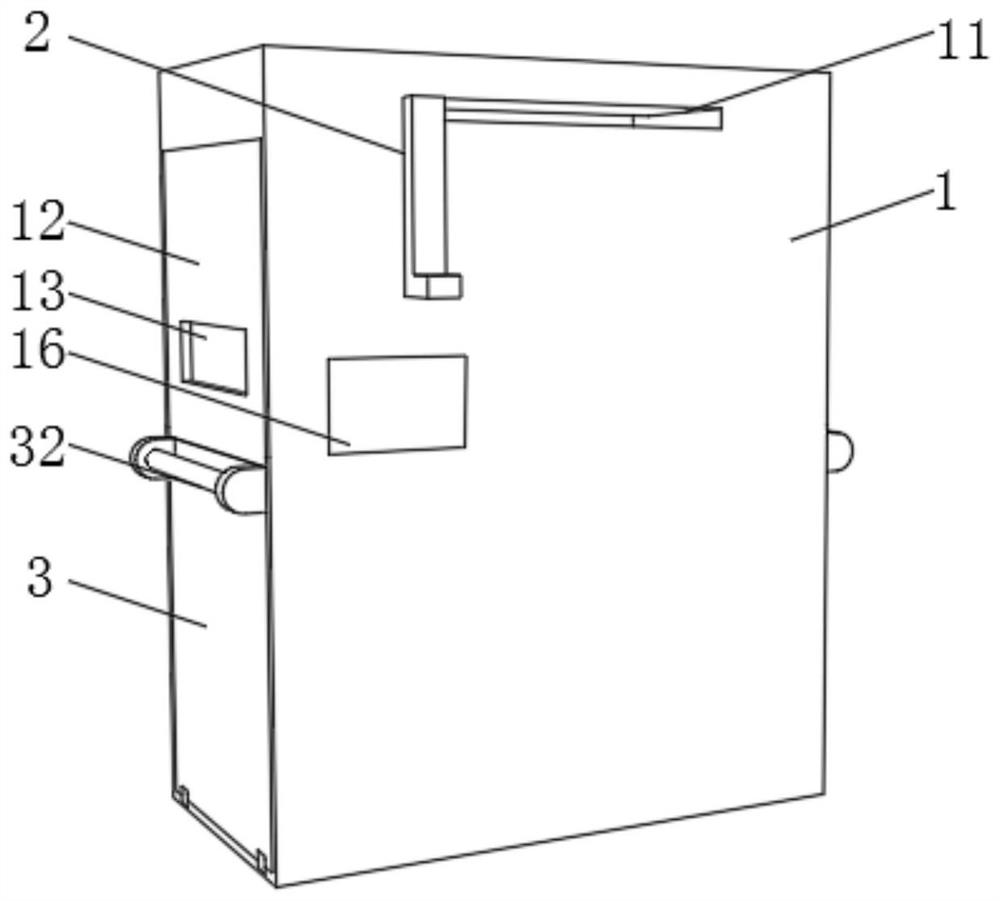

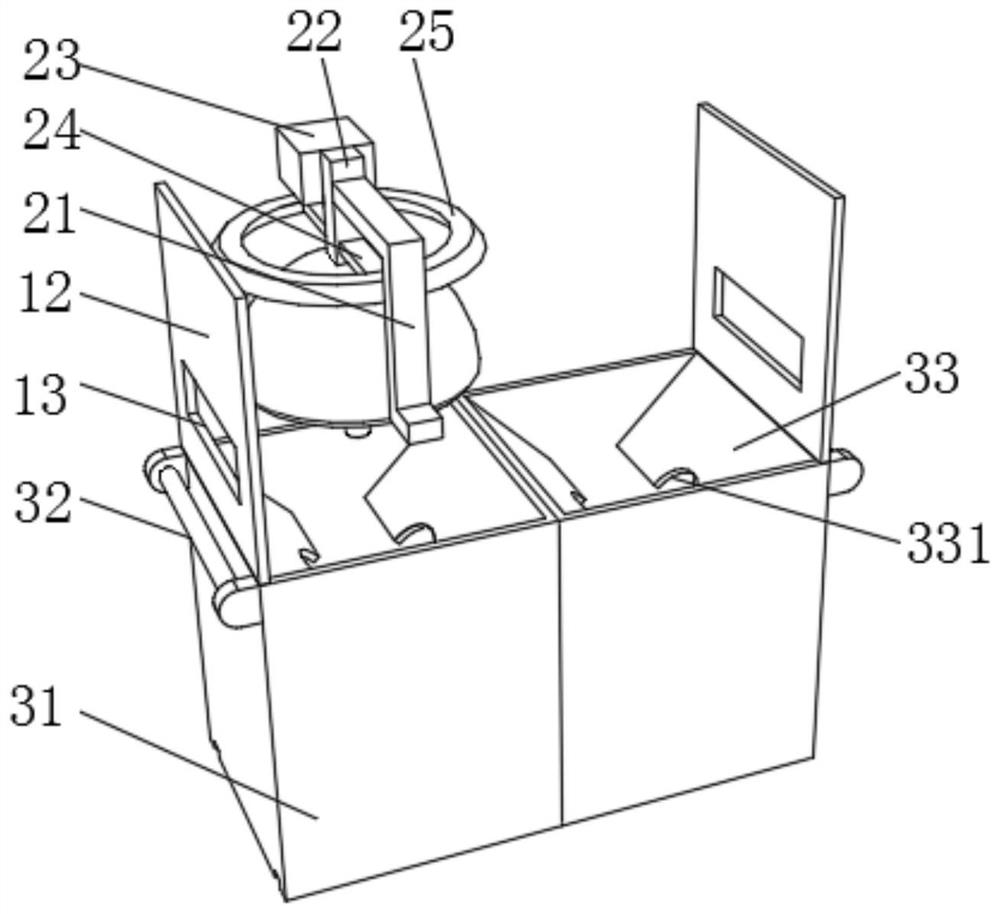

[0030] like Figure 1-5 As shown, the present invention provides a technical solution: a kind of construction solid waste treatment equipment with dust-proof effect for high-rise building construction. An adjustment groove 11 is opened on the front of the equipment main body 1, and the equipment main body 1 passes through the adjustment groove 11. A crushing mechanism 2 is slidingly connected, and the crushing mechanism 2 includes a moving rod 21, one end of the moving rod 21 is fixedly connected with a first telescopic rod 22, and the bottom of the first telescopic rod 22 is fixedly connected with a first hemispherical plate 26, and the first hemispherical plate 26 A circular hole 261 is evenly opened on the surface of the first telescopic rod 22, and a hydraulic cylinder 23 is fixedly installed on the side away from the moving rod 21. The inside of the first telescopic rod 22 is provided with a connecting rod 24, and the two ends of the connecting rod 24 are fixedly connected...

Embodiment 2

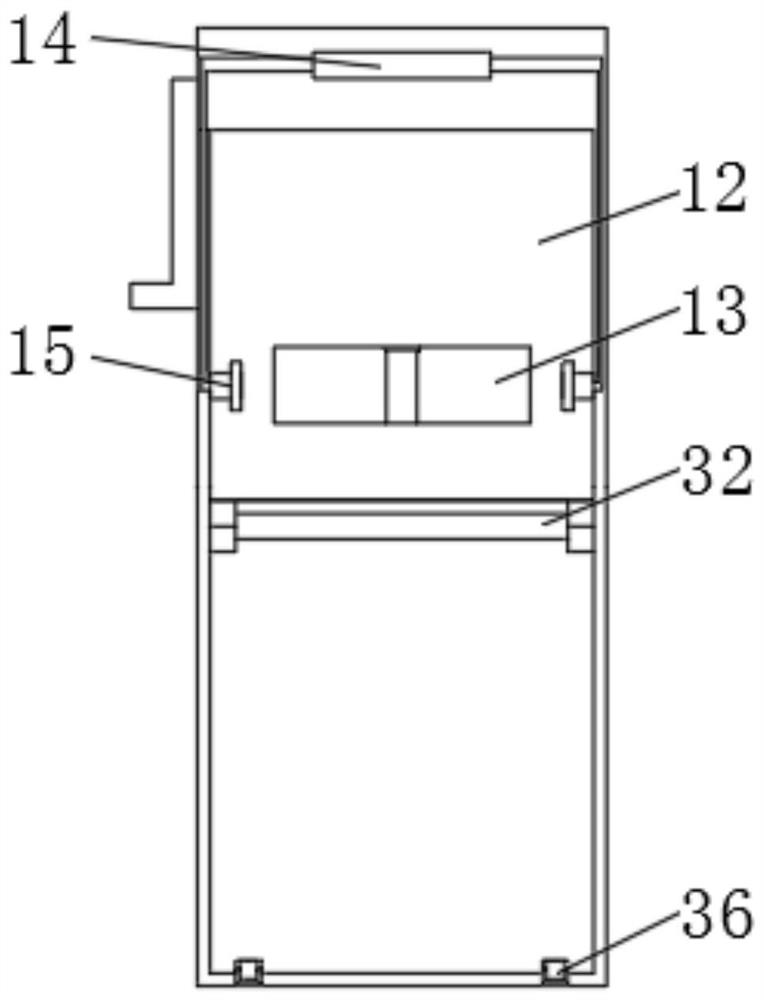

[0033] like Figure 1-4 As shown, the interior of the main body 1 of the device is equipped with a bearing mechanism 3, and the bearing mechanism 3 is symmetrically arranged. The interior of the bearing mechanism 3 is provided with a second hemispherical plate 35, and the bottom of the second hemispherical plate 35 is provided with a lifting rod 34. The top of the second hemispherical plate 35 is provided with a draw-in slot 351, and the second hemispherical plate 35 is movably engaged with the first hemispherical plate 26 through the draw-in slot 351 provided. The carrying mechanism 3 includes a transport box 31, and one side of the transport box 31 is provided with a handle 32 , the bottom of the transport box 31 is provided with rollers 36, and both sides of the top inner wall of the transport box 31 are rotatably connected with cover plates 33, and the adjacent sides of the cover plates 33 are provided with semicircular grooves 331.

[0034] In this embodiment, the discard...

Embodiment 3

[0036] like Figure 1-2As shown, both sides of the equipment main body 1 are rotatably connected with a rotating plate 12, the inside of the rotating plate 12 is provided with a delivery slot 13, the inner top of the equipment main body 1 is provided with a water tank 14, and the output end of the water tank 14 runs through the inner wall of the equipment main body 1 A spray head 15 is fixedly connected, and an operation panel 16 is provided on the front side of the device main body 1 .

[0037] In this embodiment, waste is put into the slot 13 during use, the cover plate 33 in the carrying mechanism 3 is squeezed by gravity, and the waste slides obliquely from the surface of the cover plate 33 into the second hemispherical plate inside the transport box 31 In 35, the cover plate 33 resets and closes to reduce a large amount of dust generated by the collision between the newly input waste and the internal waste. When the waste is placed, it can avoid the large amount of dust f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com