Three-dimensional pipeline stacking device

A three-dimensional, stacking technology, applied in the pipeline field, can solve the problems of inconvenient unloading, lack of lifting, and complicated operation, etc., and achieve the effects of reducing the risk of pipeline corrosion, improving space utilization, and increasing stacking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

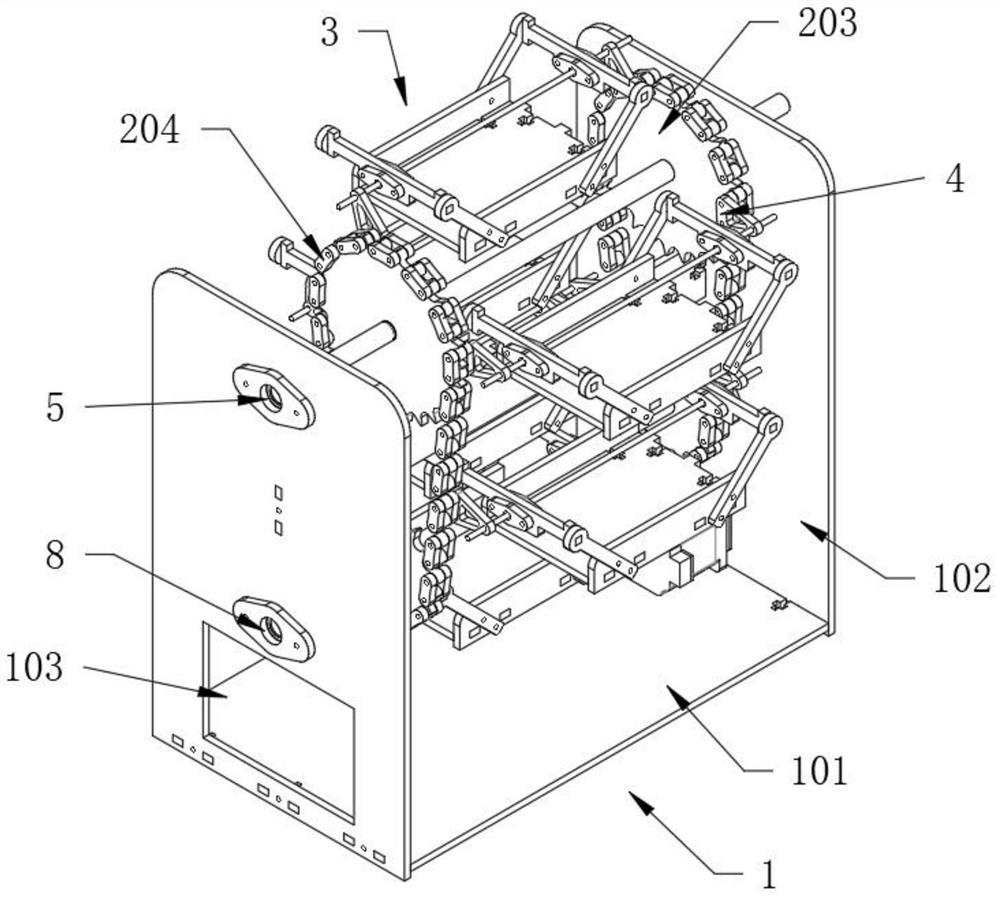

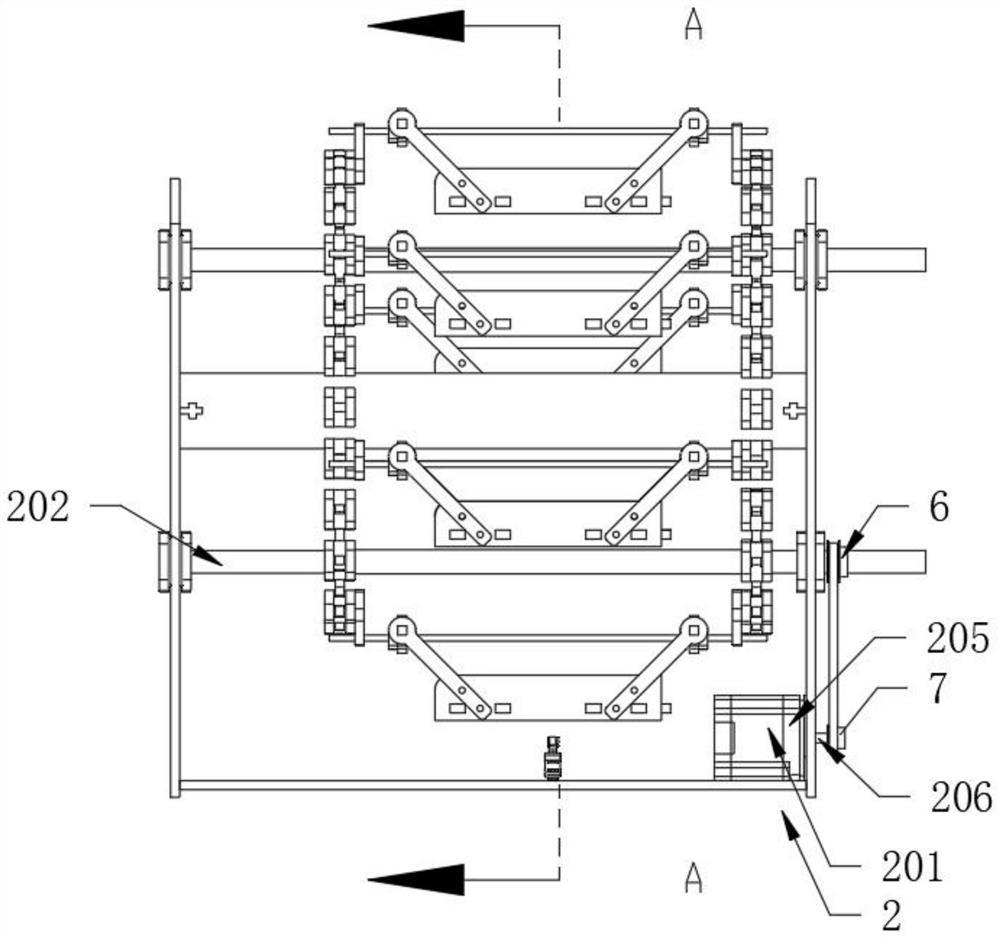

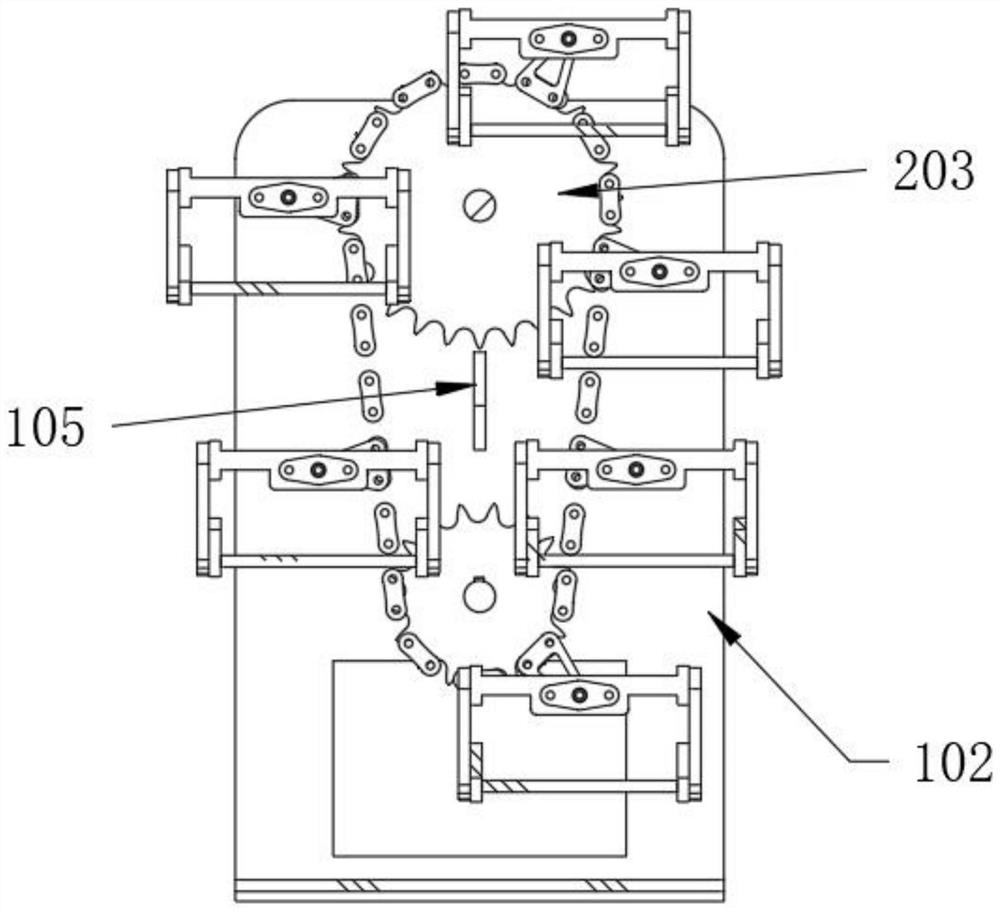

[0032] see Figure 1-8, the present invention provides the following technical solutions: a three-dimensional pipeline stacking device, comprising: a support structure 1, a drive mechanism 2 and a stacker 3 components.

[0033] Wherein the support structure 1 includes a support base 101, two sets of support risers 102 are fixedly connected to both sides of the support base 101, and a feed port 103 is opened below one of the support risers 102, and installation grooves are arranged on the two sets of support risers 102 104 , a support horizontal plate 105 is fixedly connected between two sets of support vertical plates 102 .

[0034] In this embodiment, the support structure 1 is used to support the entire device. The support base 101 is fixed on the ground of the factory building and fastened by expansion screws. Two sets of support risers 102 are fixed on both sides of the support base 101. Plate 102 is provided with installation groove 104, and installation groove 104 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com