Container Ship

A container ship and container technology, applied in ship construction, deck loading, ship accessories, etc., can solve the problems of being unable to stack containers, affecting the loading capacity of container ships, and small stacking volume of containers, so as to increase the overall loading capacity and main deck space The effect of reducing and increasing the amount of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

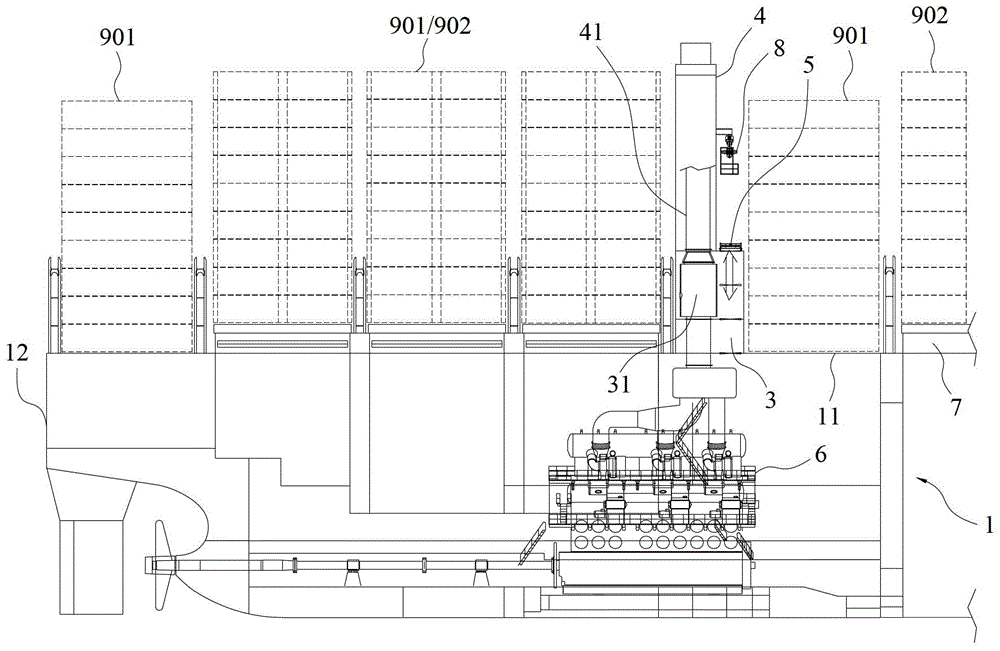

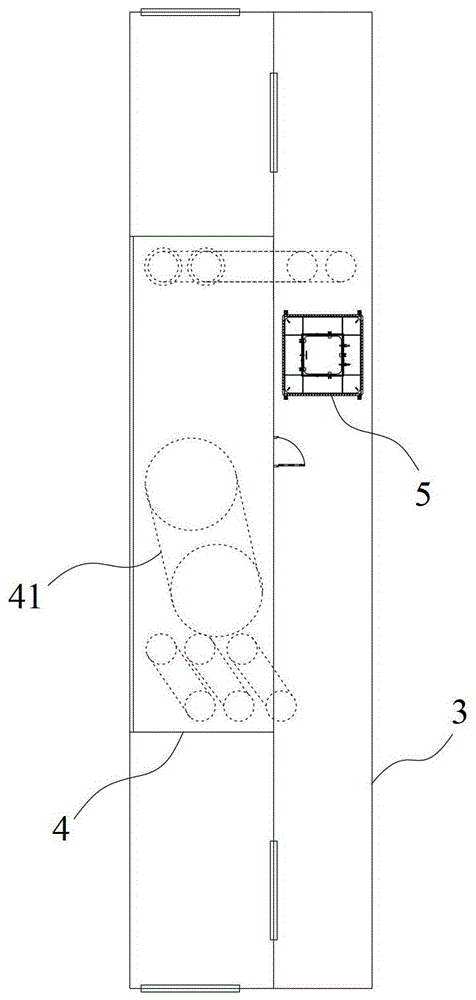

[0018] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

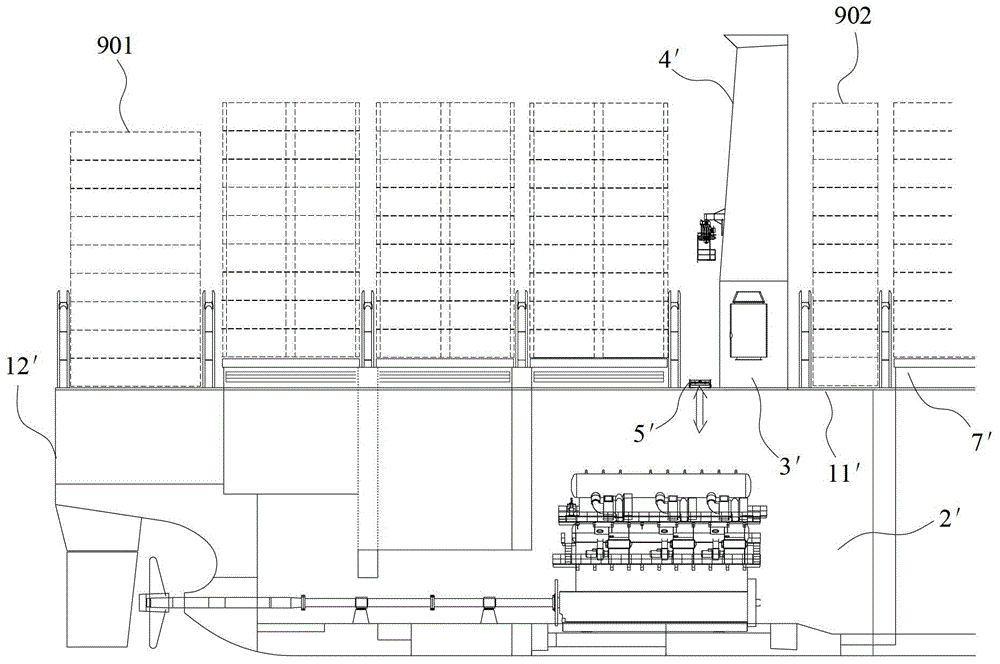

[0019] see figure 2 and image 3 As shown, the container ship of the present invention includes a main hull 1, an engine room 2, an engine room shed 3, a chimney 4 and an engine room hoisting port 5, and may also include a main engine 6, a hatch enclosure 7 and a crane 8.

[0020] The top of the main hull 1 is provided with a main deck 11 on which containers 901 / 902 can be stacked. Looking at the bow, the outer edge of the main hull positioned on the left side of the center longitudinal line of the main hull 1 is the port side, and the outer edge of the main hull positioned on the right side of the center longitudinal line of the main hull 1 is the starboard side.

[0021] The engine room 2 is located below the main deck 11 , and the engine room 2 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com