Ecological agricultural waste treatment system

A technology of ecological agriculture and treatment system, applied in the field of waste treatment, which can solve the problems of less stacking and waste of land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

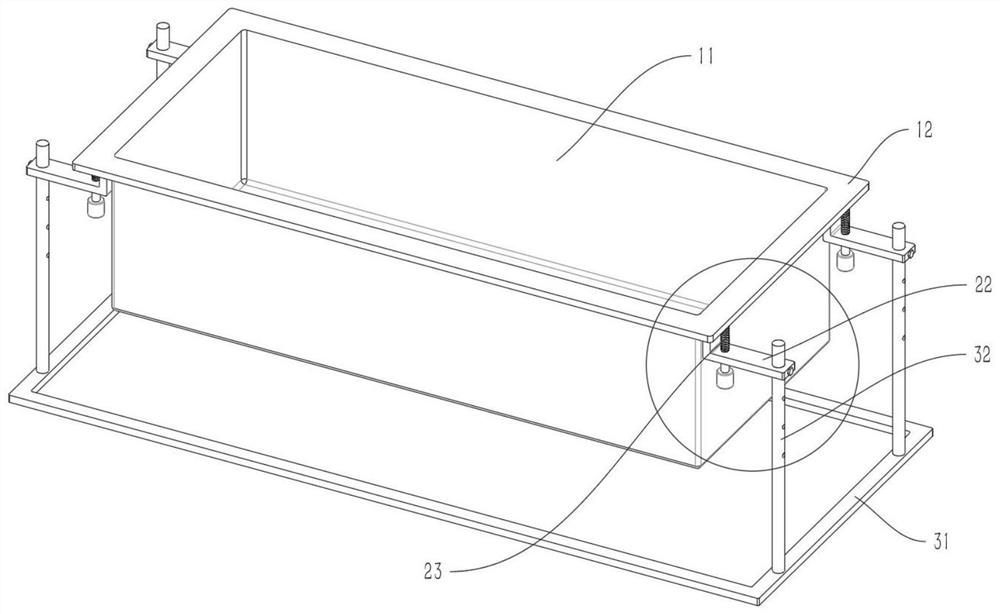

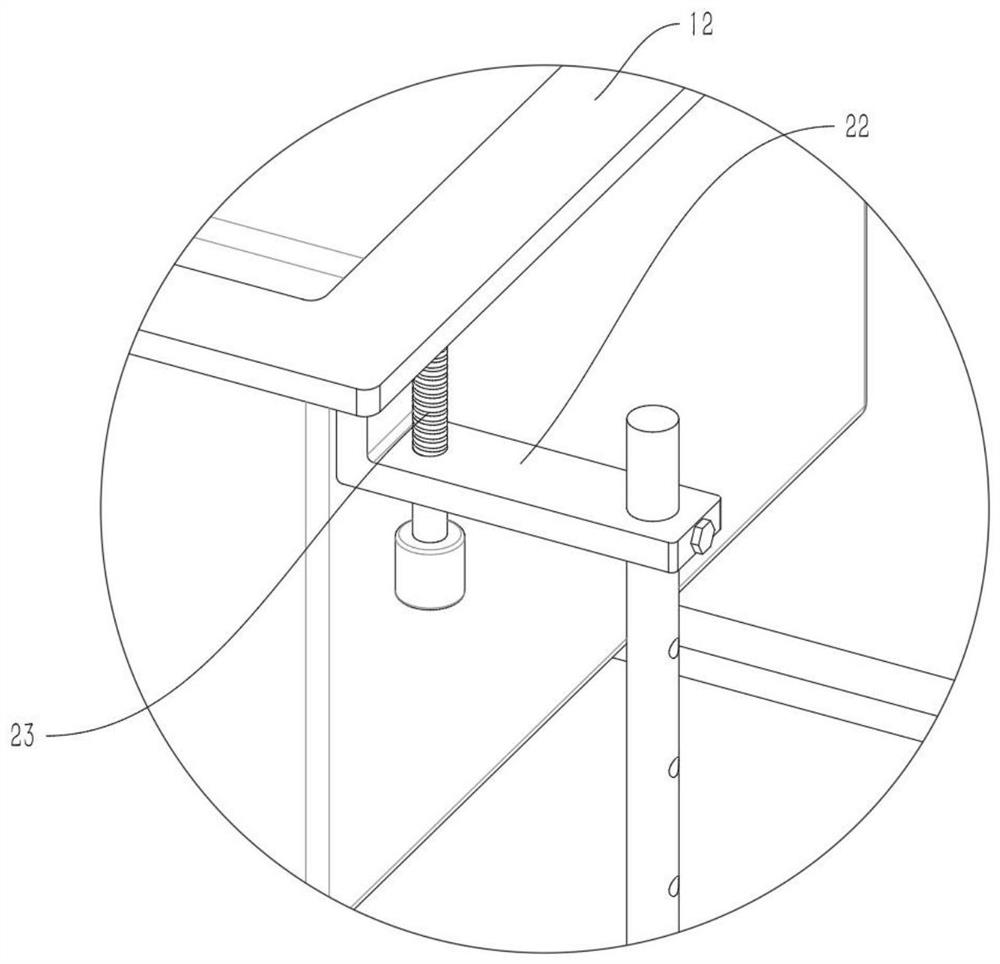

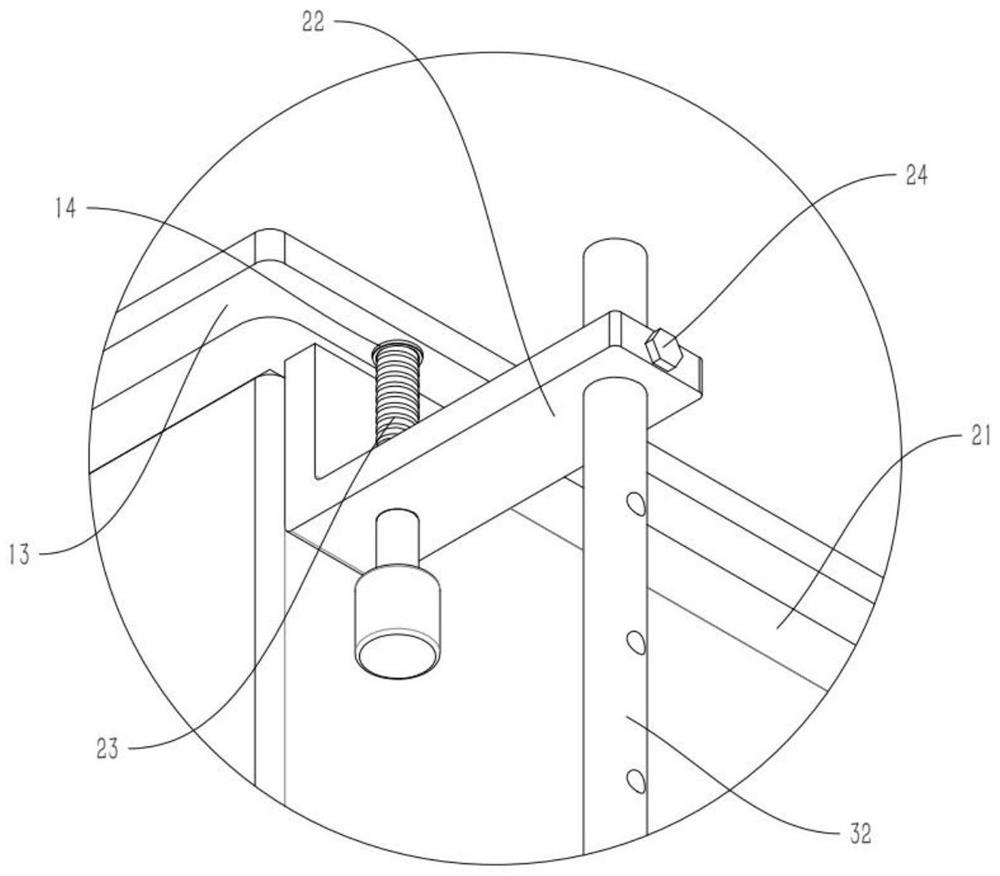

[0023] This part can be based on Figure 1 to 4 As shown in detail, an exemplary work process is described in detail:

[0024] The traditional stack of ecological agricultural waste will cause more lower part of the waste to the top of the waste, and the area is much more, and the amount of stack is relatively small. The waste is stored by the fabric pocket 11 capable of adjusting its own top height, and it is possible to ensure that the floor area is not changed, and the measurement of the waste is increased, while the top is the same as the lower amount, thereby increasing the quantity. The fabric pocket 11 can determine its own stack or exhibition according to the amount of stack.

[0025] The fabric pocket 11 can use a high-density fabric to preferably use a high molecular composite film employed by a film-type fermentation technique, which has a half transfusion capability that guarantees water vapor, air, and the transparent ability to prevent odor, bacteria, and dust, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com