High-pressure damping line core liquid medicine dipping device

A technology of damping wire and potion, which is applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of low coating uniformity, power consumption, large cost, etc., and achieves simple equipment structure, energy saving and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

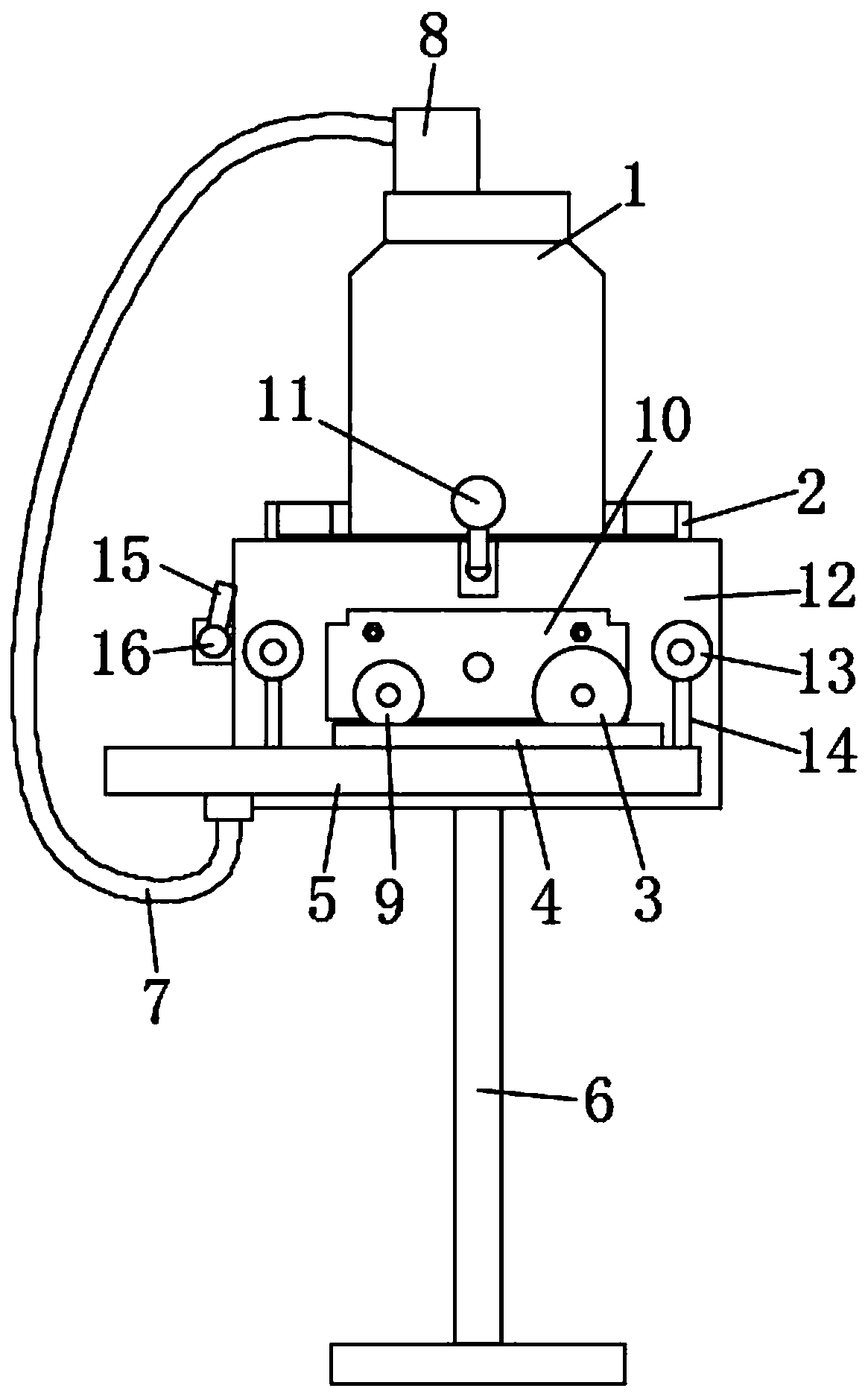

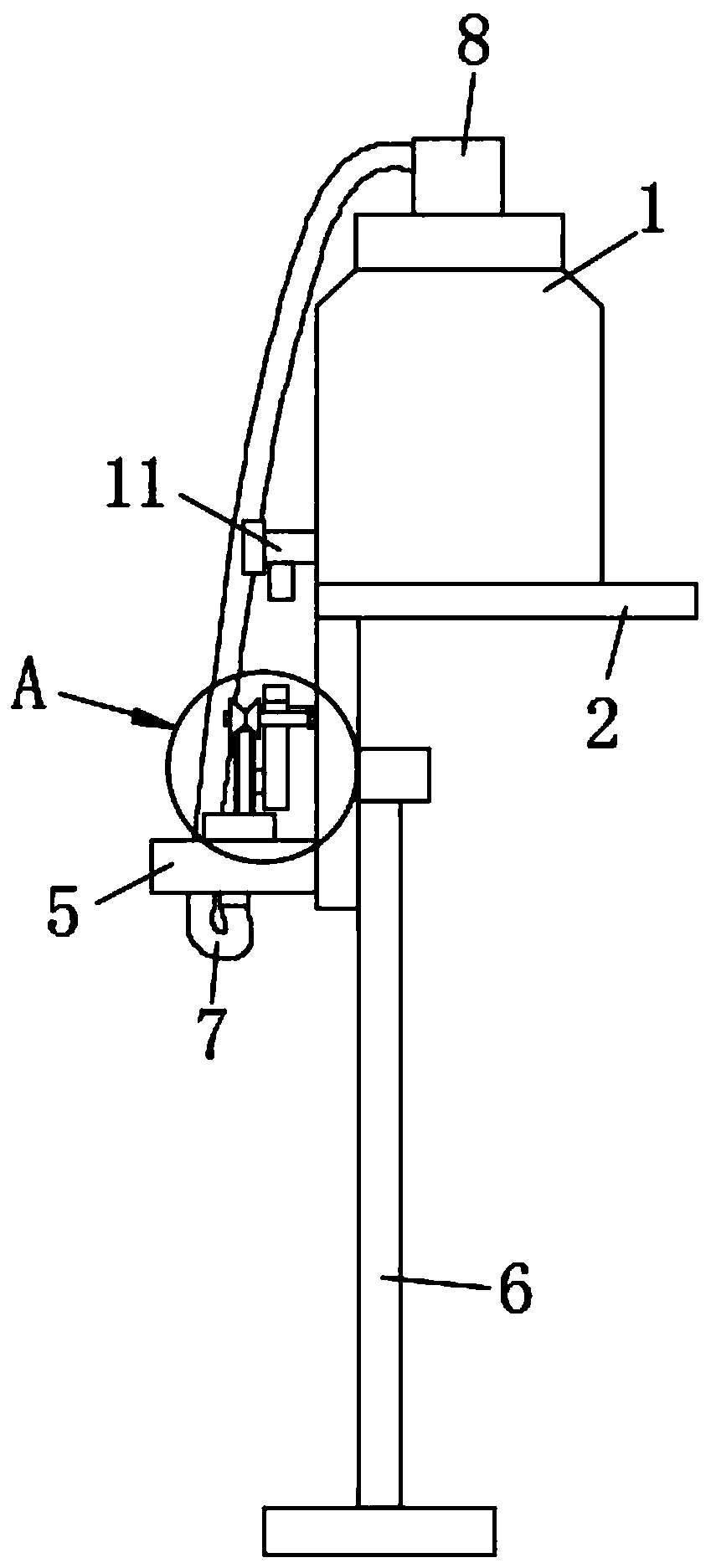

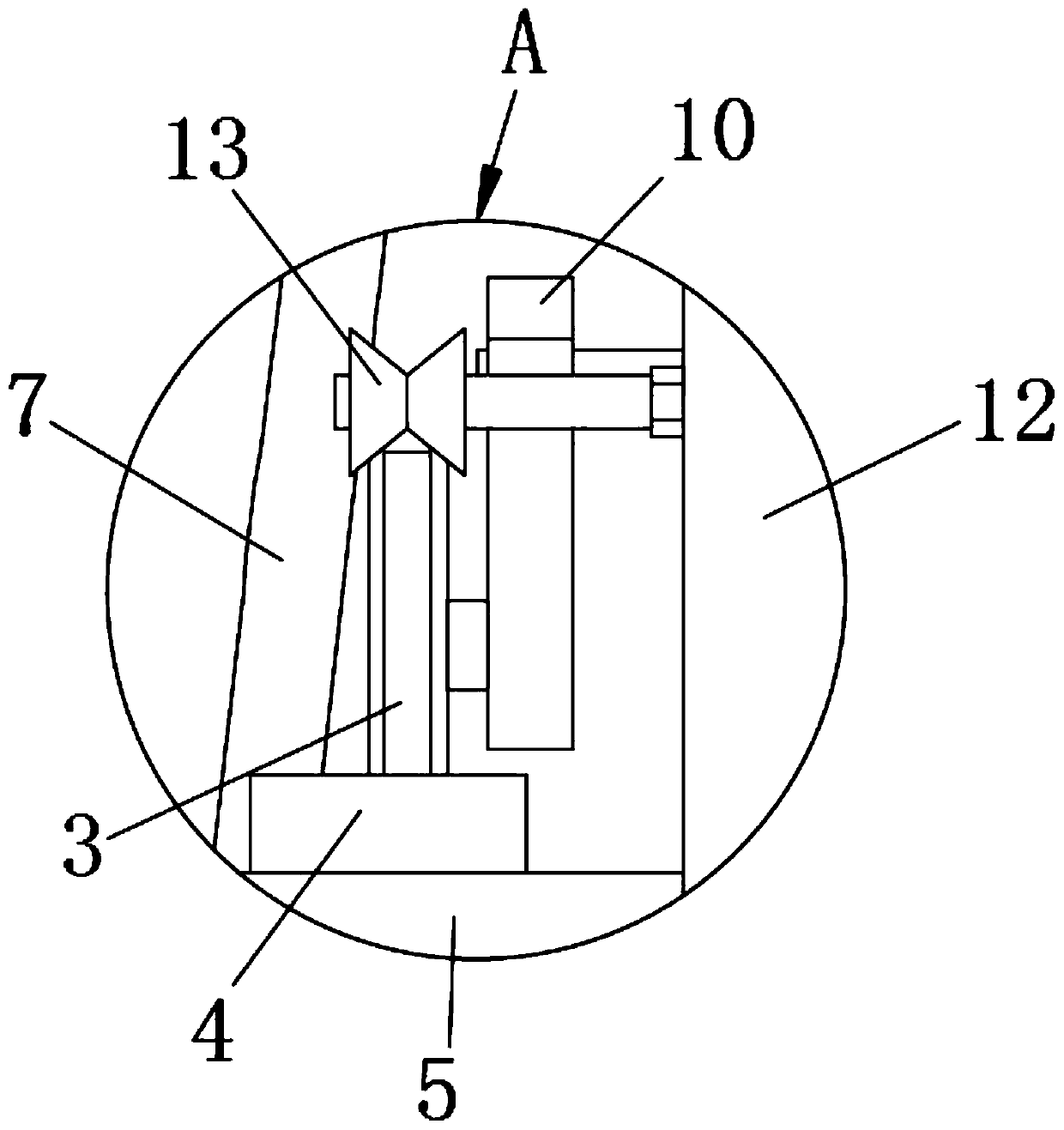

[0029] refer to figure 1 and figure 2 , this embodiment discloses a high-voltage damping wire core dipping device, including a bracket 6, a panel 12 whose surface is parallel to the direction of the high-voltage damping wire, a potion wheel set and a potion disc set rotatably connected to the panel 12. The panel 12 is mounted on the top of the bracket 6 . The medicine tray group is fixed on the panel 12 . The potion wheel set is arranged above the potion pan set. The bottom of the potion wheel set goes deep into the potion pan set. The high-pressure damping wire snaps into the wheel groove of the liquid medicine wheel set.

[0030] The bottom of the potion wheel group goes deep into the potion tray group, so that the wheel groove of the potion wheel group is stained with potion, and the high-pressure damping wire is stuck in the wheel groove of the potion wheel group. When the high-pressure damping line advances along the production line, it passes through the potion whee...

Embodiment 2

[0042] refer to Figure 5 The difference between the second embodiment and the first embodiment is that the wiper cover 17 is also included. The wiper cover 17 is arranged above the outer liquid medicine pan 5 . The wiper cover 17 is fixed on the outlet end of the panel 12 . The aperture of the wiper sleeve 17 is slightly larger than the wire diameter of the high-voltage damping wire. The axis of the high-voltage damping wire is the same as that of the wiper sleeve 17 .

[0043] When the high-voltage damping wire passes through the wiper sleeve 5, because its aperture is slightly larger than the high-voltage damping wire, the excess liquid medicine will be scraped off and dropped into the outer liquid medicine pan 5, and recycled through the return pipe 7, and the axis of the high-voltage damping wire is in contact with the wiper. The axes of the water jackets 17 are the same, which can ensure that the liquid medicine is evenly coated on the outer surface of the high-voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com