A rapid demoulding device capable of continuously knocking electrolytic aluminum

A mold release device and electrolytic aluminum technology, applied in the field of electrolytic aluminum die-casting and mold release, can solve problems such as low work efficiency, limitation, dangerous industrial accidents, etc., and achieve the effect of saving transmission energy and improving linkage ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

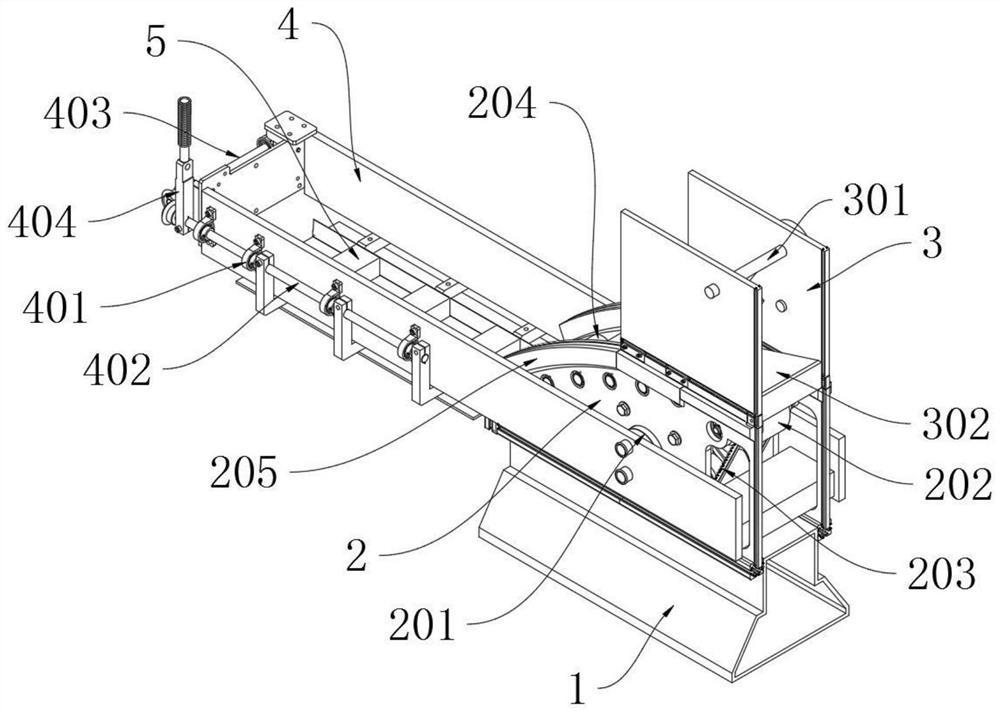

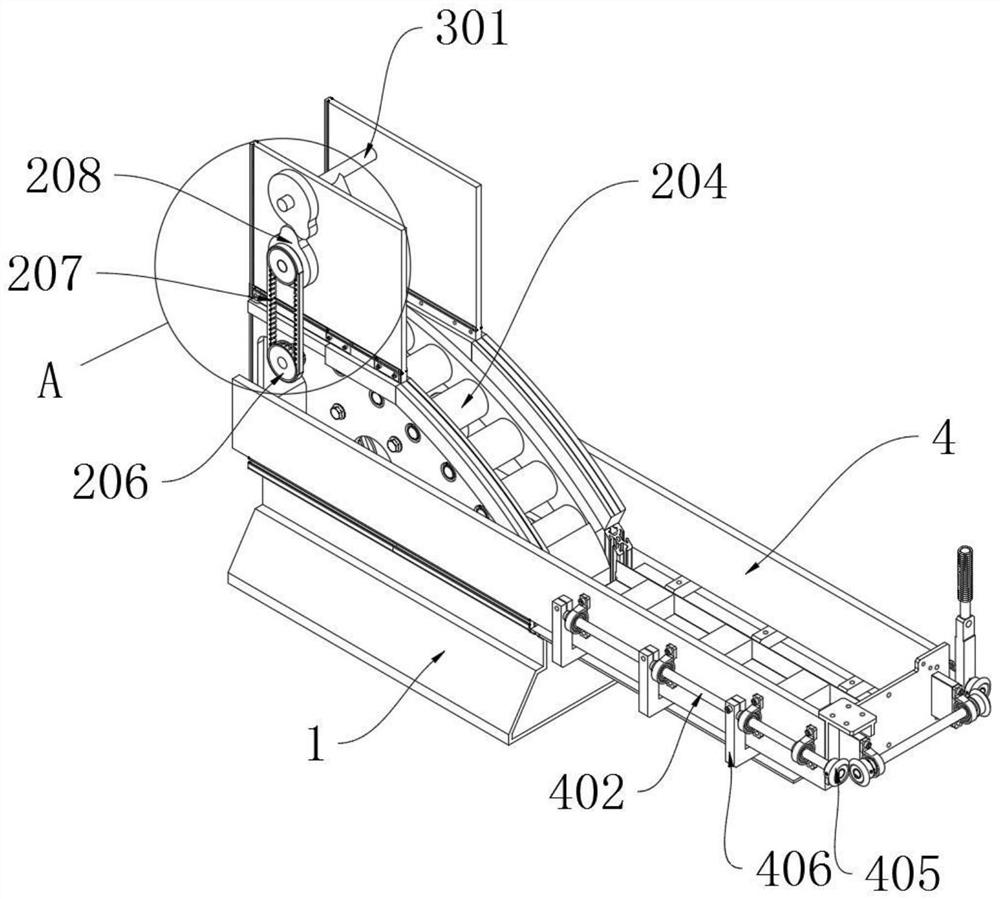

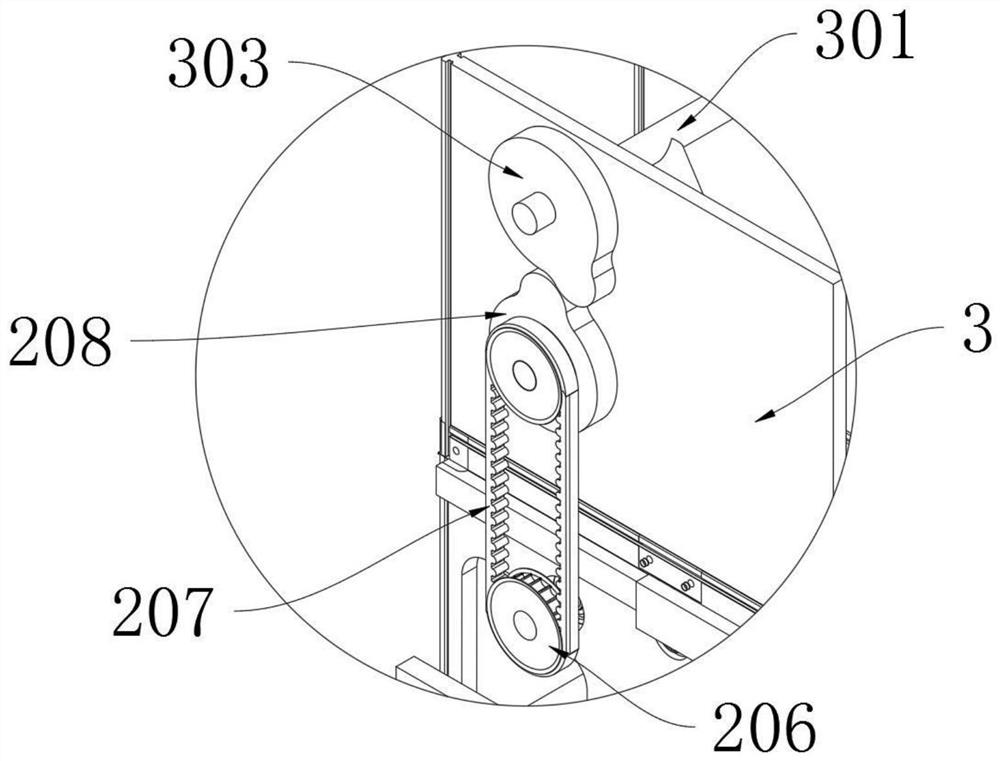

[0028] Please refer to Figure 1 to Figure 9 .

[0029]In order to solve the problem of the rapid demoulding device that can continuously knock electrolytic aluminum in the prior art, because of the heavy weight of electrolytic aluminum, workers can only intermittently knock the die-cast electrolytic aluminum. If the tapping frequency is too fast, it may It will cause hand injuries to workers who are transferring and clamping electrolytic aluminum. In severe cases, more dangerous industrial accidents are likely to occur, and the work efficiency is not high. It needs to be determined according to the frequency of workers knocking, and it is also limited by the transfer. workers, many factors, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com