Portable pneumatic puller

A portable, air hammer technology, used in hand-held tools, manufacturing tools, etc., can solve the problems of large volume, low efficiency, inconvenient operation, etc., and achieve the effect of flexible working space, improved efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

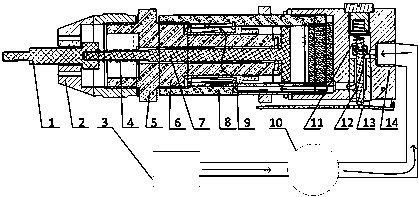

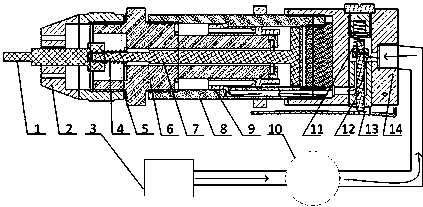

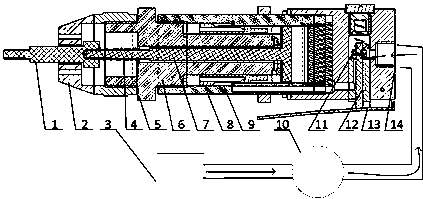

[0025] Specific embodiment: when the puller feeds gas, as Figure 1~2 As shown, the switch handle 13 presses the switch lever 12, so that the pressure gas in the air inlet of the sleeve 14 flows into the air inlet of the main body 8, and the pressure gas in the air inlet of the main body 8 pushes the air hammer 9 to move to the left. When the air hammer 9 movement to figure 2 position, the air inlet hole of the main body 8 is connected with the air hole of the air hammer 9, and the pressure gas enters the inner cavity of the main body 8. Since the pressure surface on the left side of the air hammer 9 is much larger than the pressure area on the right side of the air hammer 9, the air hammer 9 quickly moves to the right. Move, when the pressure gas in the inner cavity of the main body 8 disappears, the air hammer 9 will continue to move to the right due to inertia and hit the pulling shaft 7, and release the pressure gas at the same time, the pulling shaft 7 drives the pulling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com