Manufacturing method of PVC ball with multilayer structure

A production method and multi-layer structure technology, applied to chemical instruments and methods, inflatable hollow balls, coatings, etc., can solve the problems of high cost and complicated PVC ball technology, and achieve improved explosion-proof function, comfortable touch, and good The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

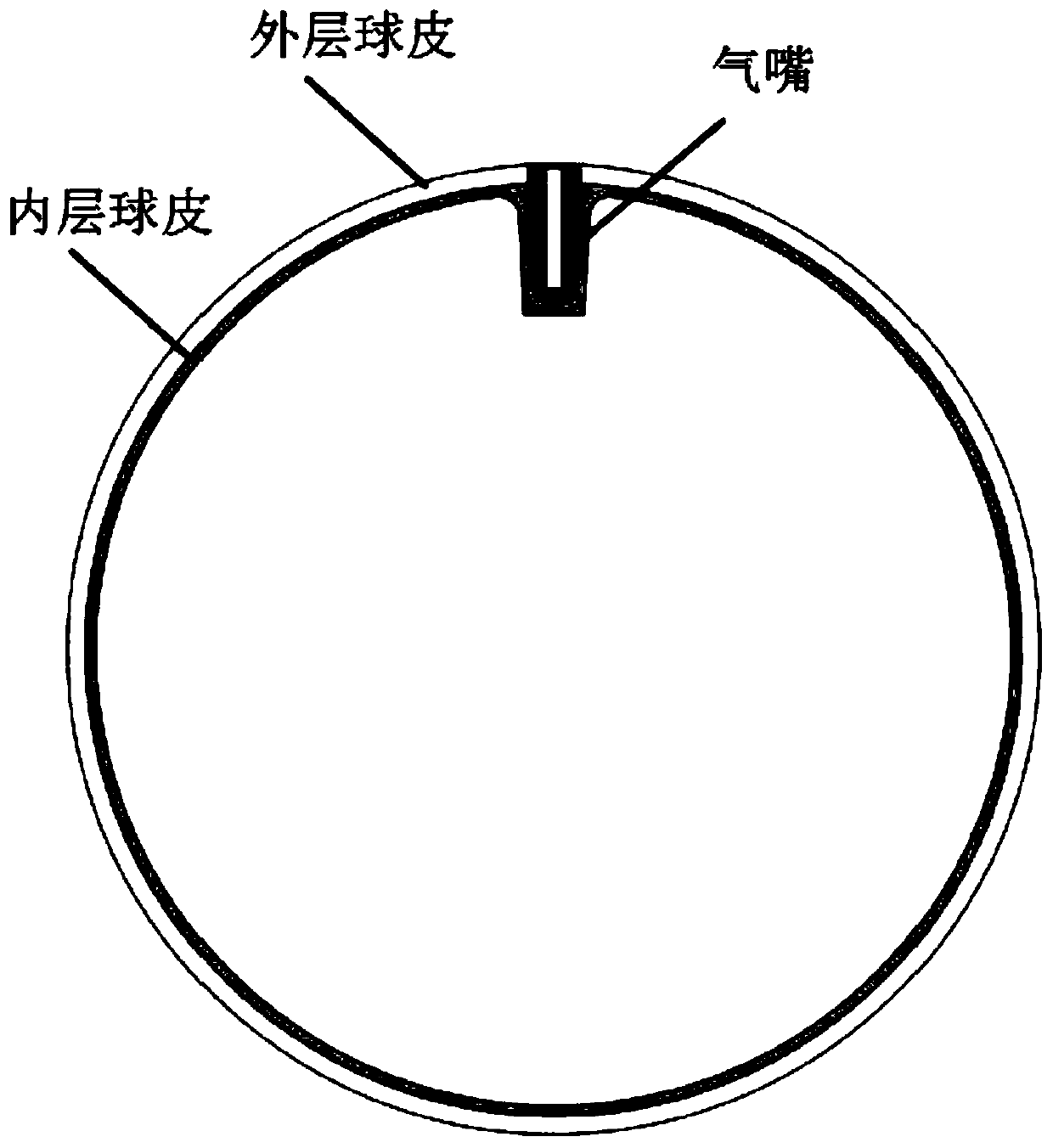

[0021] according to figure 1 As shown, the present embodiment provides a method for making a PVC ball with a multilayer structure, comprising the following steps:

[0022] Step 1: prepare the slurry of the soft and comfortable outer skin, the formula of the outer skin slurry is: 45% of PVC resin, 50% of plasticizer, 3% of auxiliary agent, The rest are coloring pigments;

[0023] Step 2: Prepare the inner layer ball skin slurry with high strength and strong support. The formula of the inner layer ball skin slurry is: 45% of PVC resin, 45% of plasticizer, and 3% of auxiliary agent , and the rest are coloring pigments;

[0024] Step 3: Inject the well-proportioned outer ball skin slurry into the vinyl or rotational molding mold and cover the mold locking screws, push the mold into the vinyl or rotational molding heating furnace body, and place it in the furnace body Heat and plasticize at medium temperature for 4 minutes, then pull the mold out of the furnace body and inject t...

Embodiment 2

[0028] A kind of manufacture method of the PVC ball of multilayer structure, comprises the following steps:

[0029] Step 1: Prepare the slurry of the soft and comfortable outer skin, the formula of the outer skin slurry is: 40% of PVC resin, 40% of plasticizer, 2% of auxiliary agent, The rest are coloring pigments;

[0030] Step 2: Prepare the inner layer ball skin slurry with high strength and strong support. The formula of the inner layer ball skin slurry is: 45% of PVC resin, 40% of plasticizer, and 2% of auxiliary agent , and the rest are coloring pigments;

[0031] Step 3: Inject the well-proportioned outer ball skin slurry into the vinyl or rotational molding mold and cover the mold locking screws, push the mold into the vinyl or rotational molding heating furnace body, and place it in the furnace body Heat and plasticize at medium temperature for 2 minutes, then pull the mold out of the furnace body and inject the inner ball skin slurry again from the secondary feedi...

Embodiment 3

[0035] A kind of manufacture method of the PVC ball of multilayer structure, comprises the following steps:

[0036] Step 1: Prepare the soft and comfortable outer skin slurry. The formula of the outer skin slurry is: 50% of PVC resin, 65% of plasticizer, 5% of auxiliary agent, The rest are coloring pigments;

[0037] Step 2: Prepare the inner ball skin slurry with high strength and strong support. The formula of the inner ball skin slurry is: 60% of PVC resin, 50% of plasticizer, and 4% of auxiliary agent , and the rest are coloring pigments;

[0038] Step 3: Inject the well-proportioned outer ball skin slurry into the vinyl or rotational molding mold and cover the mold locking screws, push the mold into the vinyl or rotational molding heating furnace body, and place it in the furnace body Heat and plasticize at medium temperature for 8 minutes, then pull the mold out of the furnace body and inject the inner ball skin slurry again from the secondary feeding part of the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com