An artificial quartz slab repair device

A quartz stone slab, artificial technology, applied in the field of artificial quartz stone, can solve the problems of low utilization rate of slabs, excellent products, low yield of quartz stone slabs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

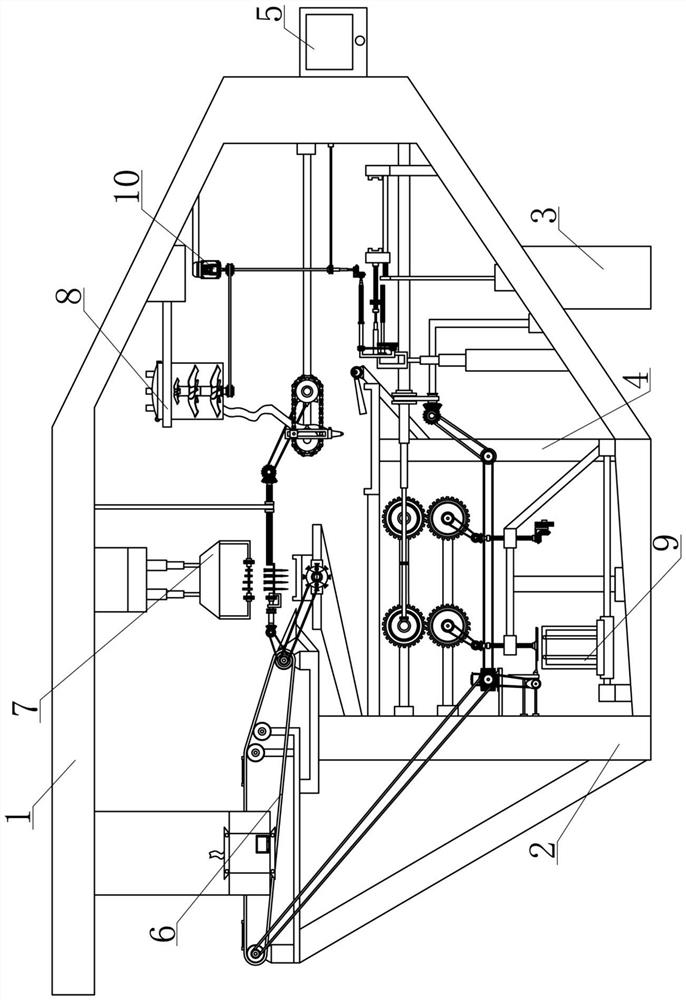

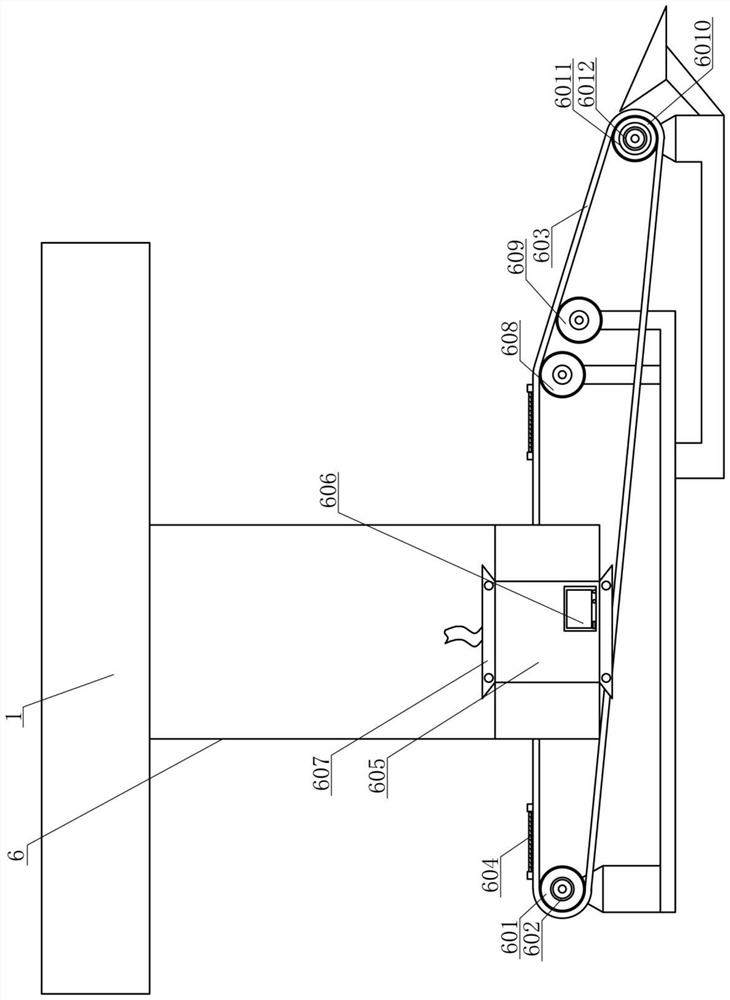

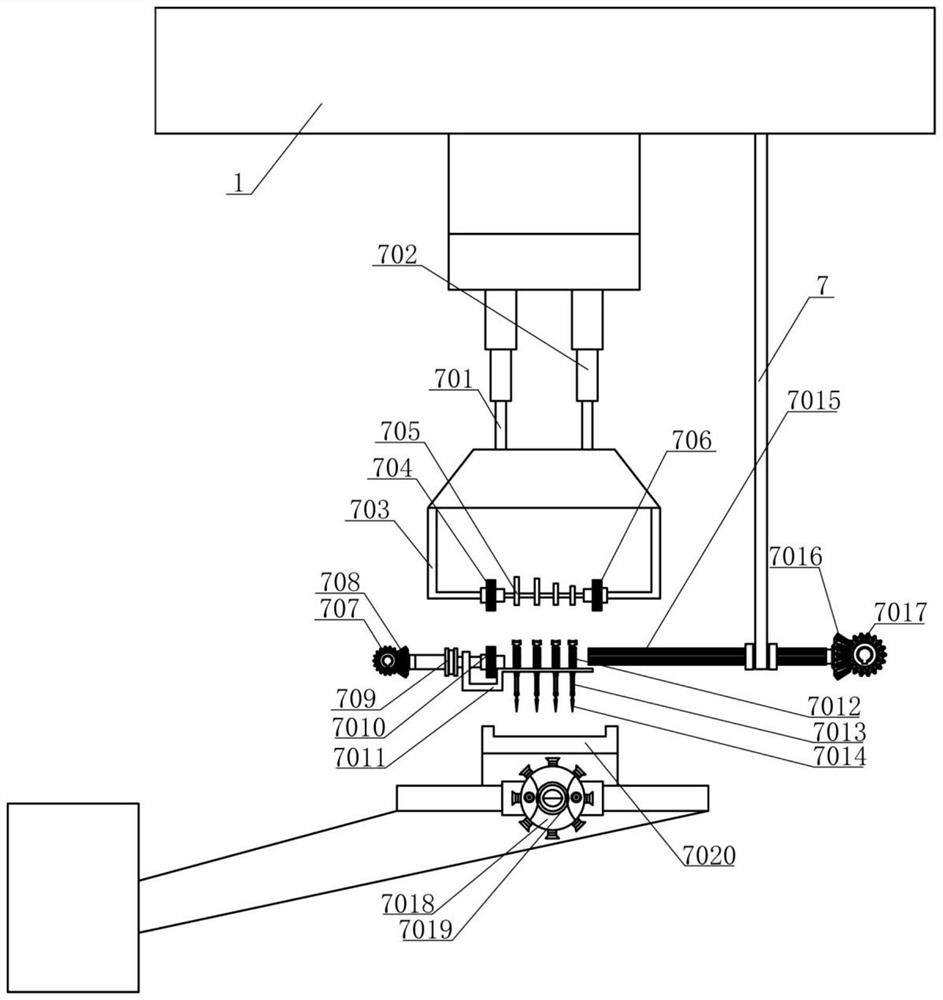

[0025] When using the artificial quartz slab repair device, first fix the device stably on the working plane, then connect the external power supply, and manually open the control panel 5; then open the power mechanism through the control panel 5, connect the internal circuit, and the device starts to run. The artificial quartz slabs with cracks are transported to the interior of the slab preheating gap softening mechanism 6 to heat and soften the cracks, and then the artificial quartz slabs enter the gap chipping mechanism 7 to crush and remove the original cracked materials, and then the slabs enter the gap 2 The secondary feeding and laminating mechanism 8, through the control panel 5, the motor 10 is turned on to drive the mechanism to run to complete the secondary feeding, and after the feeding is completed, it is squeezed and bonded, and the stone plate enters the gap polishing mechanism after the bonding and curing are completed. 9Complete the grinding and polishing trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com