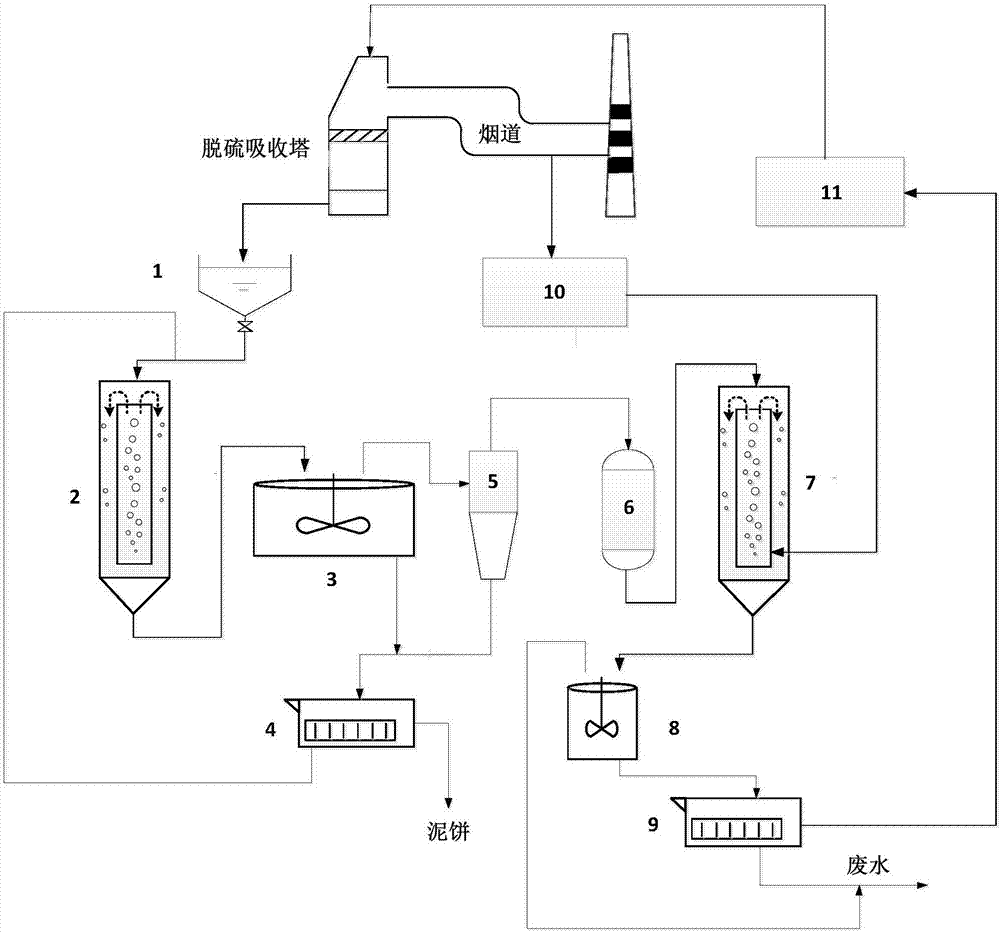

Wet desulphurization wastewater softening system based on air-lifting type circulating reactors and wet desulphurization wastewater softening method based on air-lifting type circulating reactors

A loop reactor, wet desulfurization technology, applied in chemical instruments and methods, gaseous effluent wastewater treatment, water/sewage treatment, etc., can solve the problems of increasing difficulty, large softener, large amount of sludge, etc., and achieve recycling Utilization, reduced operating costs, and efficient softening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

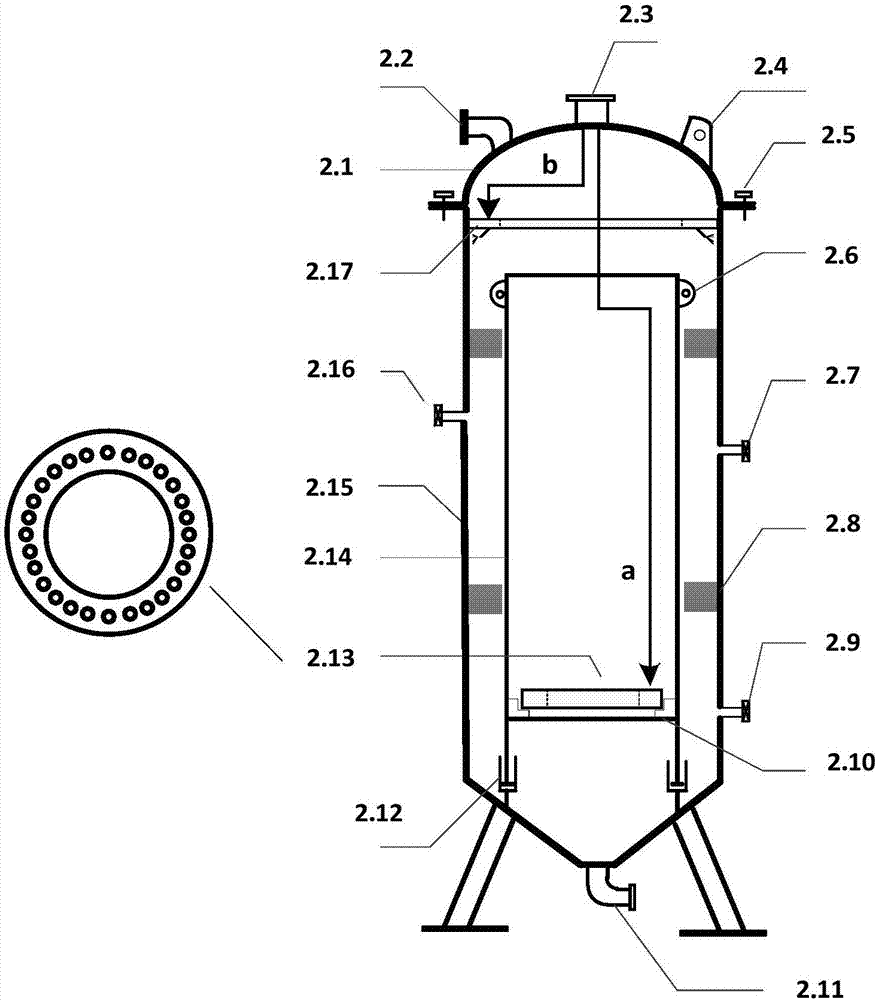

Embodiment 1

[0032] Adopt above-mentioned system and method to initial magnesium hardness and calcium hardness (as CaCO 3 Total) 20000mg / L, 6525mg / L of water is 15m 3 / h Desulfurization waste water A is softened, and the top inner wall of the external cylinder reactor is equipped with annularly distributed pressure nozzles. The height-to-diameter ratio of the two-stage air-lift loop reactor is 10. A waste water cyclone and a fiber filter are set before the second-stage airlift loop reactor. In the magnesium removal process, the selected alkaline softener is NaOH, and the alkali amount is 264kg / h (OH — / Mg 2+ The molar ratio is 2.2), and the reaction is carried out at superficial gas velocity and circulating liquid velocity of 0.03m / s and 5.07m / s; decalcification process, CO 2 It comes from the flue gas after desulfurization and denitrification, the content is 16%, the reaction is carried out at the superficial gas velocity of 0.01m / s, 3.36m / s, and the circulating liquid velocity, and th...

Embodiment 2

[0034] Adopt above-mentioned system and method to initial magnesium hardness and calcium hardness (as CaCO 3 Total) 14417mg / L, 10000mg / L of water is 20m 3 / h Desulfurization waste water B is softened, and the top inner wall of the external cylinder reactor is equipped with annularly distributed pressure nozzles. The height-to-diameter ratio of the two-stage air-lift loop reactor is 14. A waste water cyclone and a fiber filter are set before the second-stage airlift loop reactor. In the magnesium removal process, the selected alkaline softener is NaOH, and the alkali amount is 277kg / h (OH — / Mg 2+ The molar ratio is 2.4), and the reaction is carried out at superficial gas velocity and circulating liquid velocity of 0.02m / s and 4.35m / s; decalcification process, CO 2 It comes from the flue gas after desulfurization and denitrification, the content is 10%, the reaction is carried out at the superficial gas velocity of 0.002m / s, 1.84m / s, and the circulating liquid velocity, and ...

Embodiment 3

[0036] Adopt above-mentioned system and method to initial magnesium hardness and calcium hardness (as CaCO 3 The water volume of 9083mg / L and 4358mg / L respectively is 22m 3 / h desulfurization waste water C is softened, and the top inner wall of the external cylinder reactor is equipped with annularly distributed pressure nozzles. A waste water cyclone and a fiber filter are set before the second-stage airlift loop reactor. In the magnesium removal process, the selected alkaline softener is NaOH, and the alkali amount is 192kg / h (OH — / Mg 2+ The molar ratio is 2.4), and the reaction is carried out at superficial gas velocity and circulating liquid velocity of 0.01m / s, 3.36m / s; decalcification process, CO 2 It comes from the flue gas after desulfurization and denitrification, and the content is 12%. The reaction is carried out at the superficial gas velocity of 0.02m / s and 4.35m / s, and the circulating liquid velocity, and the CO 2 Solubility effect, calcium cannot be comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com