A power system suitable for small vertical take-off and landing fixed-wing aircraft

A vertical take-off and landing and power system technology, applied in the field of power systems, can solve problems such as heavy weight, single function, and complex structure, and achieve the effects of improving efficiency, reducing structural weight, and simplifying structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

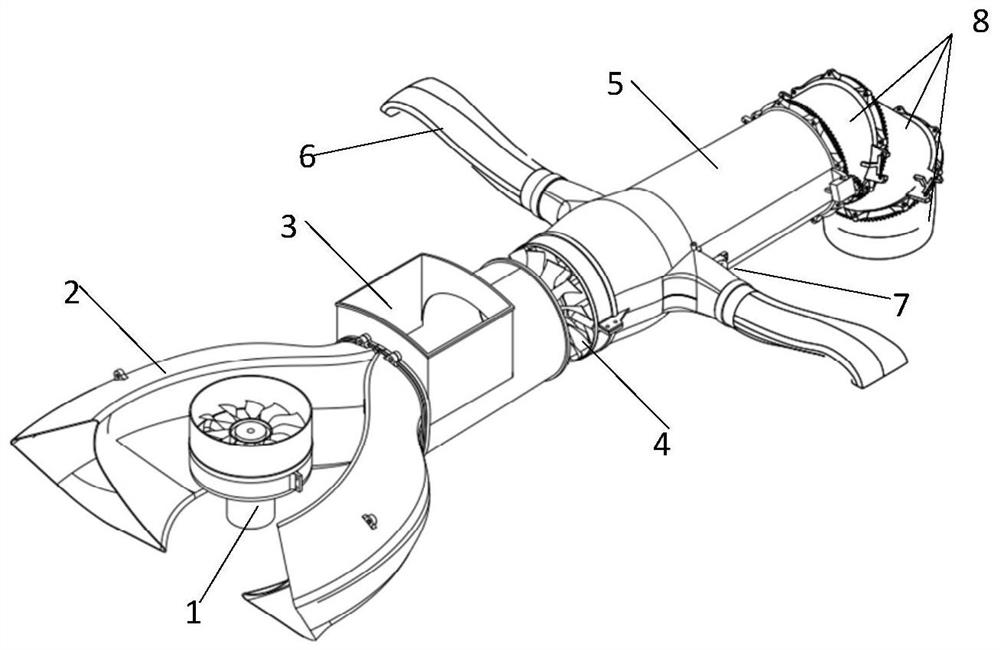

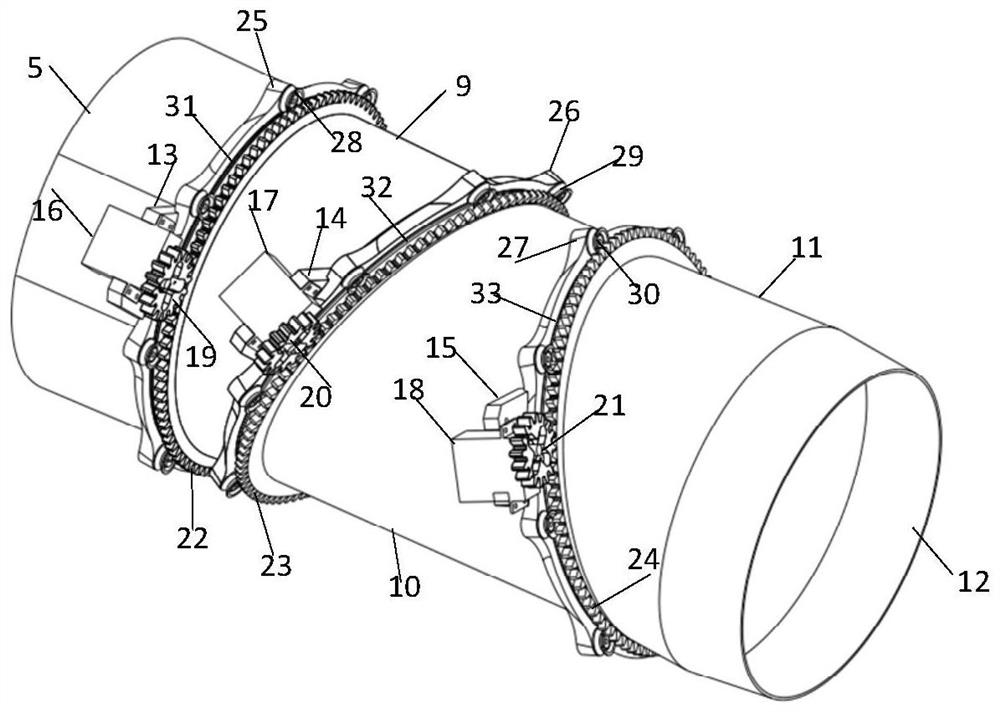

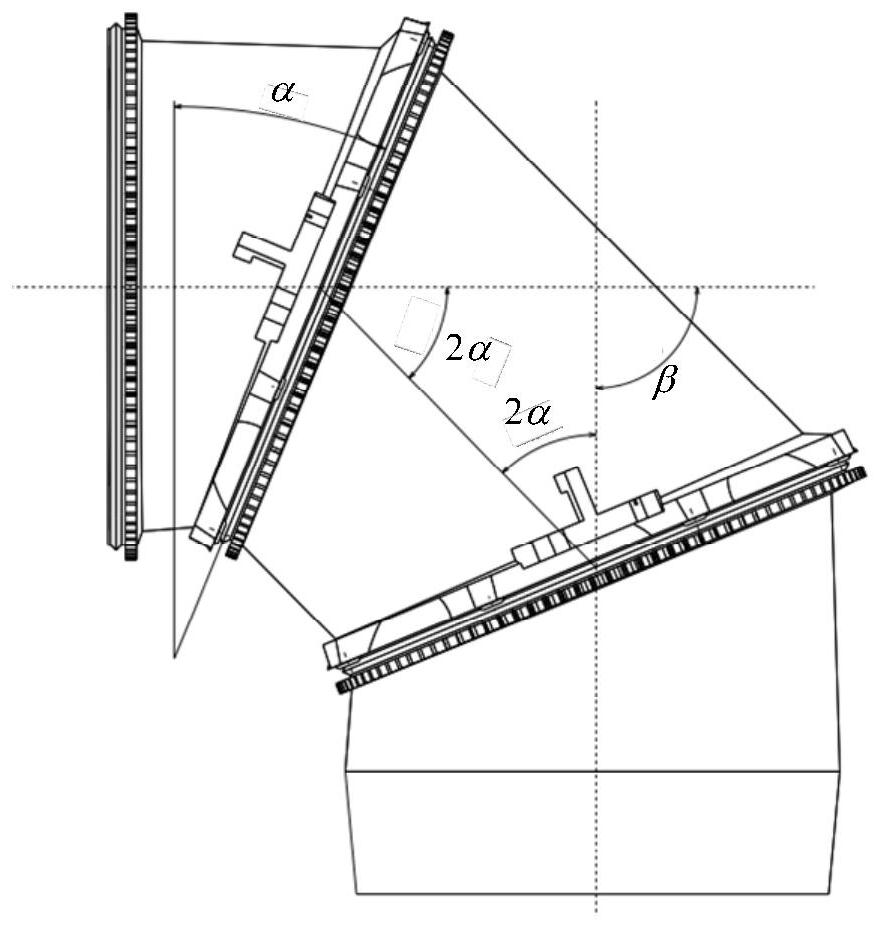

[0041] refer to figure 1 Shown, the power system that the present invention is applicable to small vertical take-off and landing fixed-wing aircraft comprises two independent power subsystems, is respectively lift fan and auxiliary motor power subsystem 1 and main ducted fan and main motor power subsystem, and A biasing system.

[0042] The lift fan and the auxiliary motor power subsystem 1 are installed in the front fuselage section; the main ducted fan and the main motor power subsystem include two main air intakes 2 symmetrically arranged on both sides of the front of the fuselage, one on the fuselage side and connected between the main air inlet 2 and the main duct fan 4, the guide cylinder 5 behind the main duct fan 4, and the vector nozzle connected to the rear of the guide cylinder 5 Pipe 8; the deflection system includes two rolling nozzles 6 installed on both sides of the guide cylinder 5 wall, and the rolling control adjustment mechanism 7 in the rolling nozzle 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com