Dustproof packaging assembly line for producing adhesive

A packaging line and adhesive technology, applied in the field of packaging lines, can solve the problems of complicated operation, unsanitary, high labor intensity, etc., and achieve the effect of avoiding hygienic problems, reducing labor costs, and simple and convenient principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

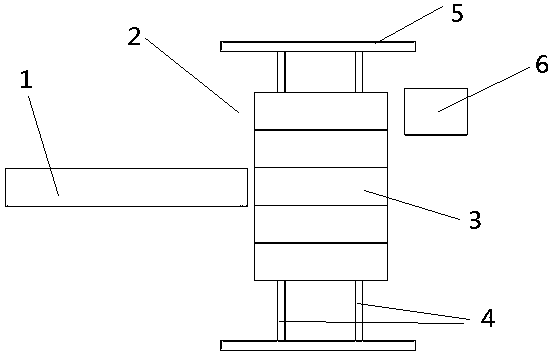

[0016] A dust-free packaging line for producing adhesives, comprising a conveyor belt 1 and a sub-packaging rack 2.

[0017] Described packing rack 2 is divided into a plurality of packing column 3, and the width of each packing column 3 and conveyer belt 1 is consistent; Described packing rack 2 is arranged on slide rail 4, can move, and packing column 3 The conveyor belt 1 is aligned to receive the products on the conveyor belt 1 ; the end of the subpackage rack 2 places a packaging box 6 corresponding to each subpackage column 3 .

[0018] The number of the packing column 3 can be designed according to actual needs. Limiting pieces 5 are provided at both ends of the slide rail 4 . The conveyor belts 1 can be arranged in multiples, and carry out the delivery of products at the same time. The assembly line can work in a clean roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com