A rapid drilling and piling equipment for highway protection construction on expansive soil sections

A technology for piling equipment and dirt roads, which is applied to drilling equipment and methods, drilling equipment, and earth-moving drilling and mining, etc., can solve the problems of low operation efficiency, poor versatility and adaptability, and high working noise, so as to reduce the difficulty of drilling. , the effect of prolonging service life and reducing stiffness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

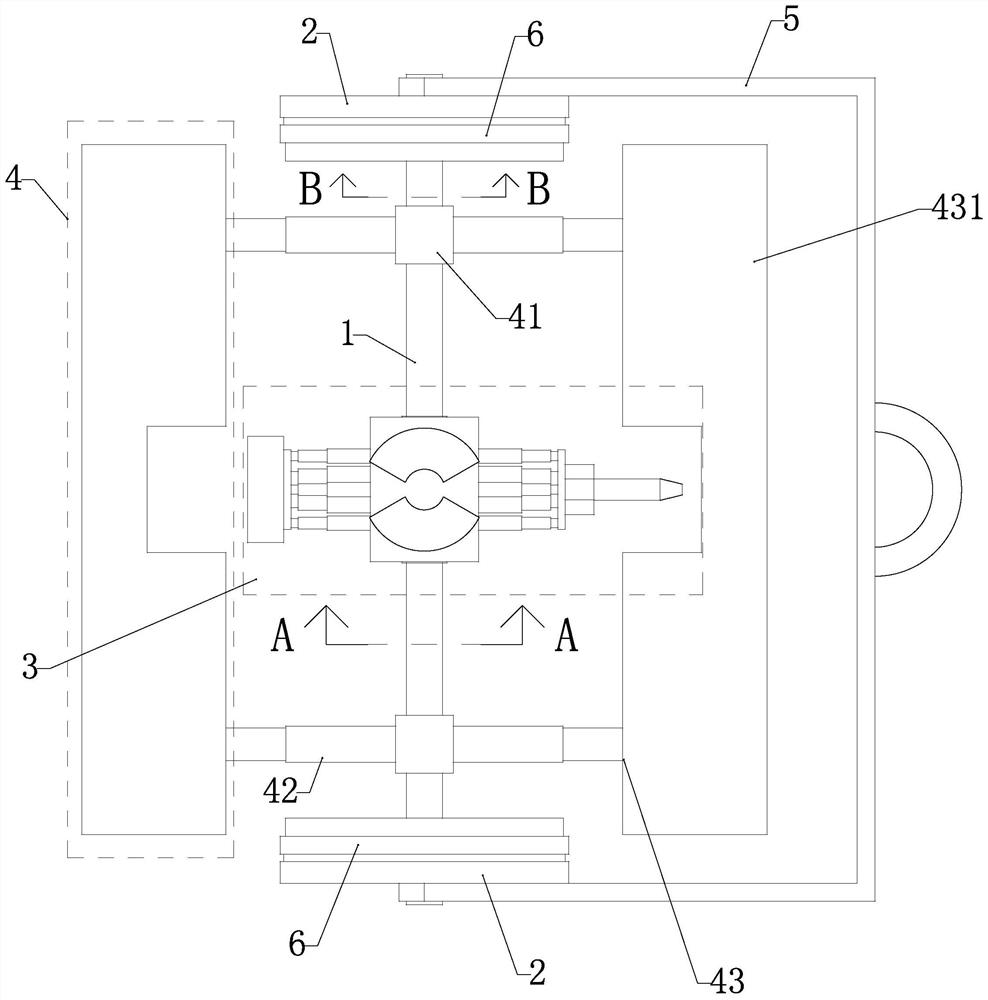

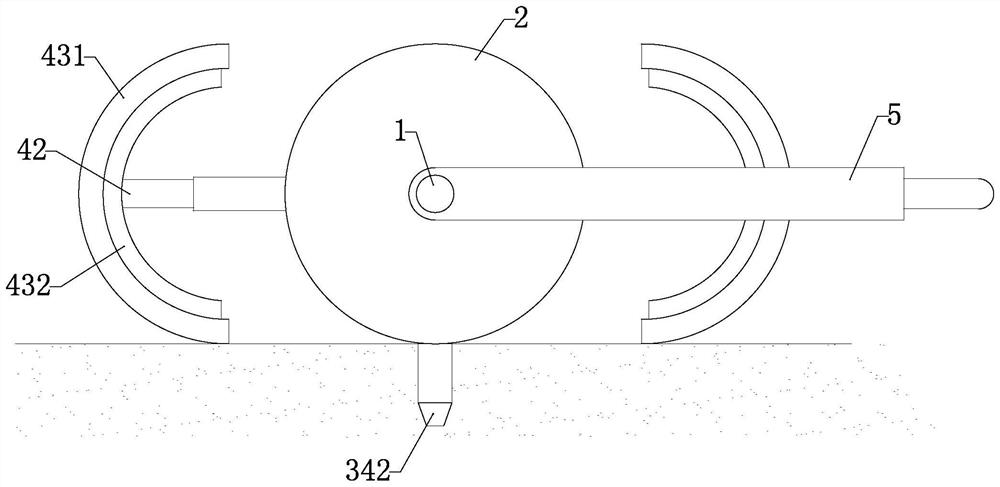

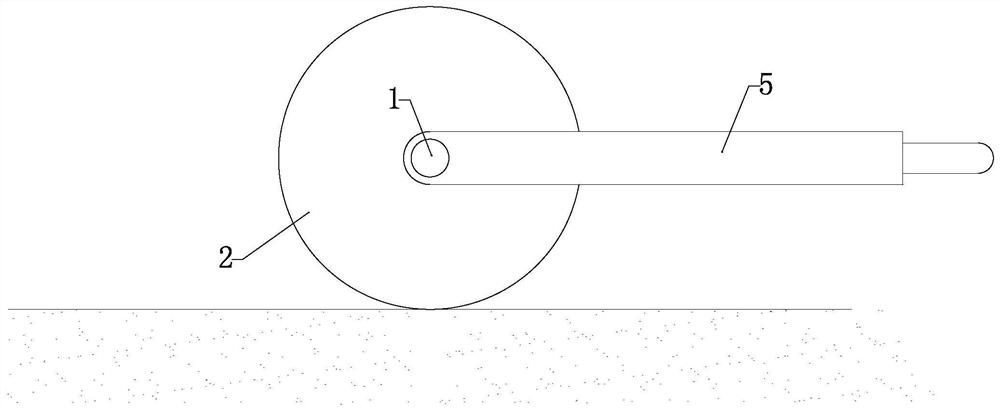

[0035] Such as Figure 1-11 As shown in , a rapid drilling and piling equipment for highway protection construction on expansive soil road sections includes a horizontally arranged main shaft 1, and the two ends of the main shaft 1 are respectively movably inserted in the middle of each supporting wheel body 2 at its two ends. In the bearing hole of the main shaft 1, a rapidly switchable drilling and piling mechanism 3 is provided in the middle of the main shaft 1. The drilling and piling mechanism 3 is used to realize drilling and piling on the road surface. The inner and outer sides of the main shaft 1 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com