Hydraulic oil tank and engineering machine

A hydraulic oil tank and oil tank technology, applied in the hydraulic field, can solve problems such as abnormal noise, oil pump cavitation, and hydraulic system paralysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

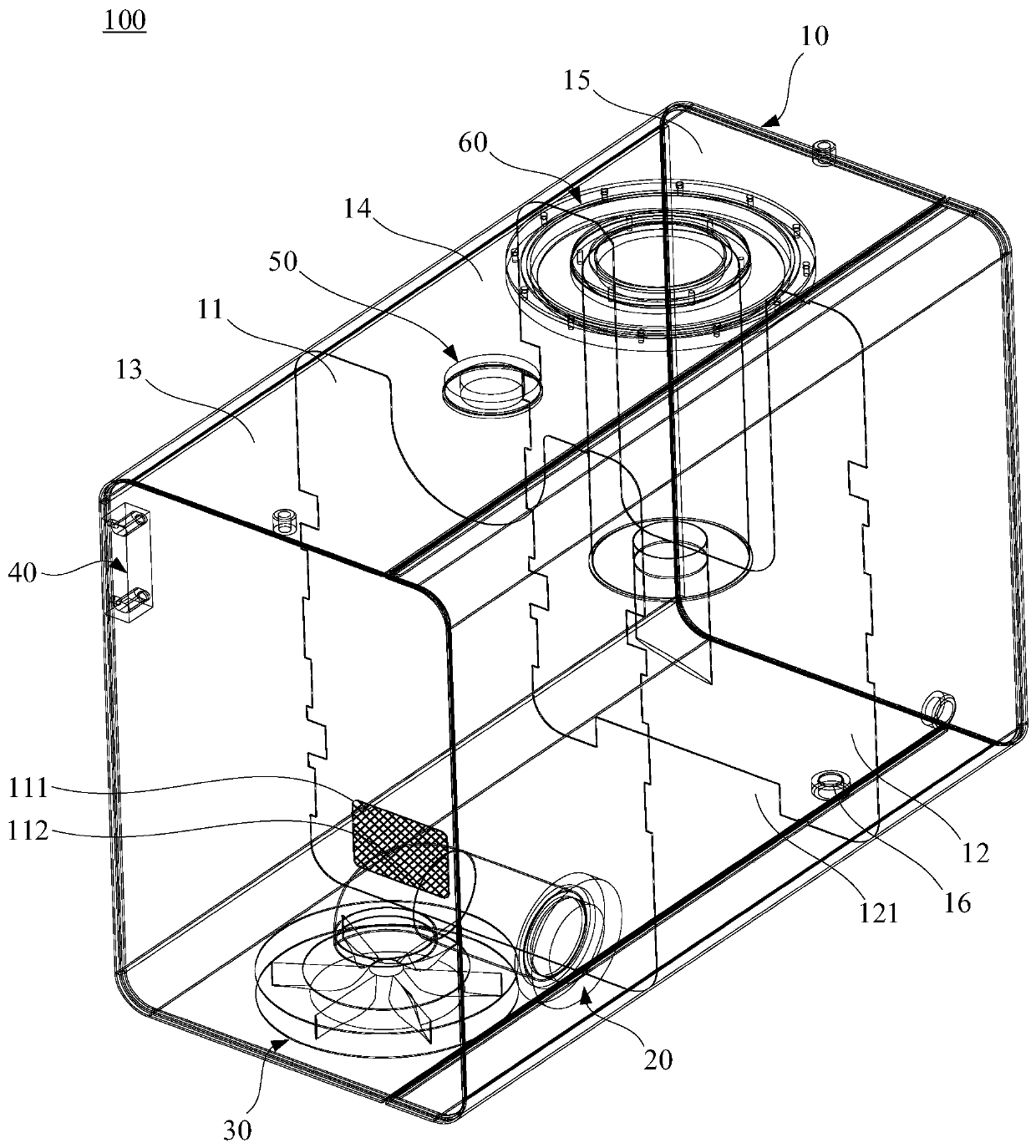

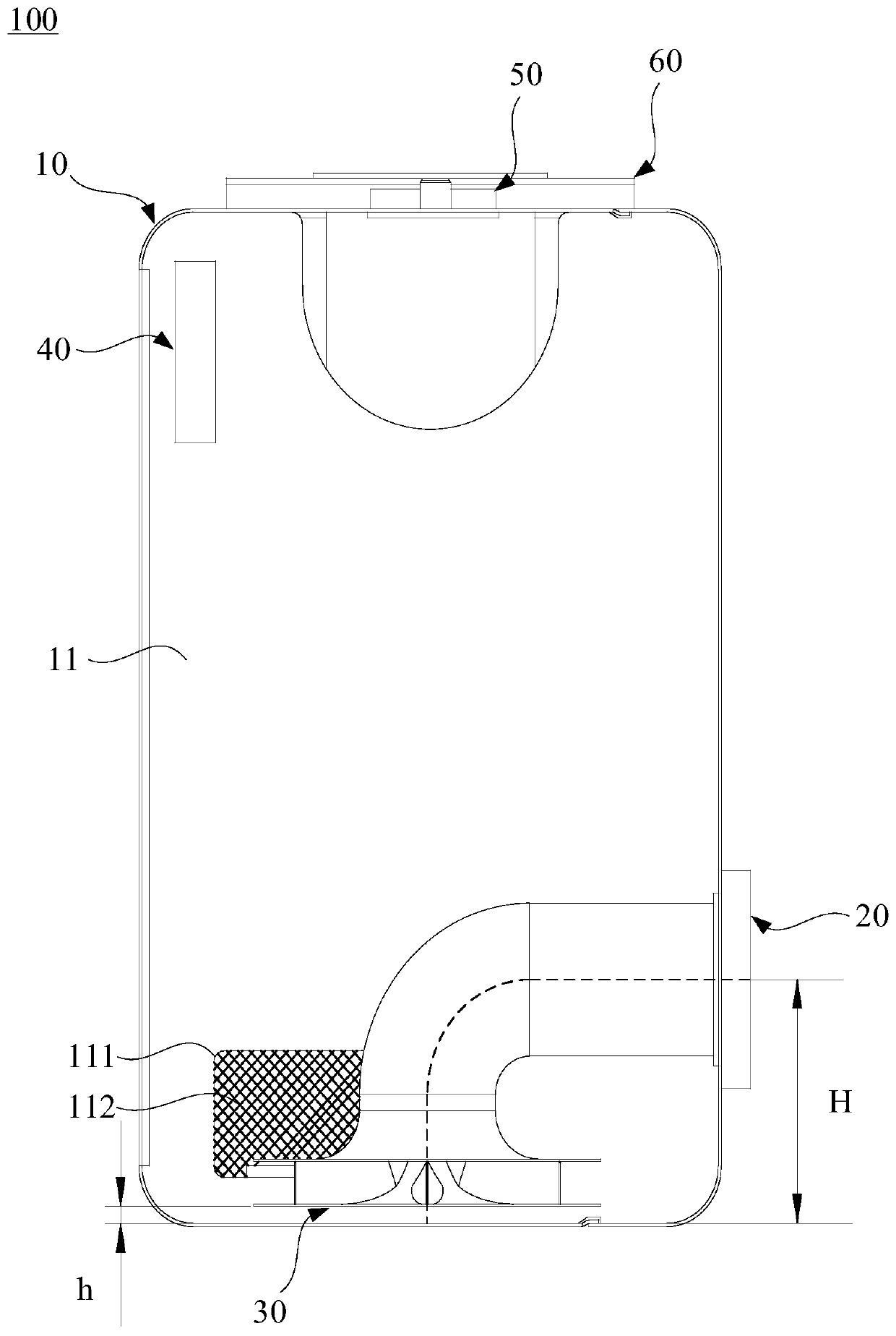

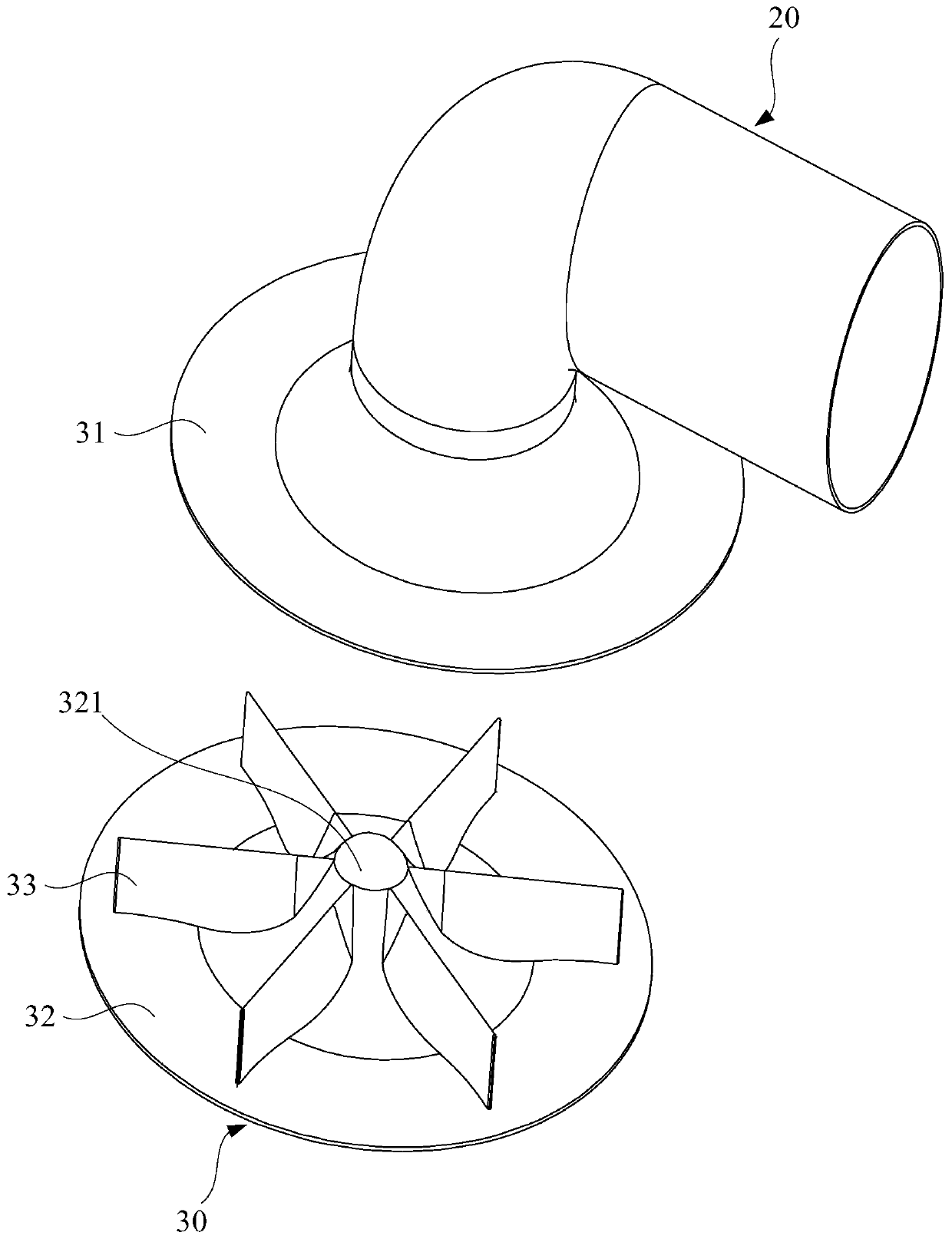

[0030] Please refer to Figure 1 to Figure 3 , the present embodiment provides a hydraulic oil tank 100, which includes a main body 10 of the oil tank, an oil suction pipe 20 and a swirl preventer 30. The main body of the oil tank 10 is a hollow structure with a housing chamber, and the oil suction pipe 20 extends into the housing chamber, and the oil suction pipe 20 The oil suction port of the oil tank is facing the bottom wall of the oil tank main body 10. The swirl preventer 30 includes a top plate 31 and a bottom plate 32 which are opposite and arranged at intervals. The top plate 31 has a circular structure. At one end, the swirl preventer 30 further includes a plurality of deflectors 33 arranged between the top plate 31 and the bottom plate 32 , and a gap is formed between two adjacent deflectors 33 . The hydraulic oil tank 100 can avoid the swirl phenomenon at the oil suction port inside the oil tank, thereby avoiding the cavitation phenomenon of the oil pump.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com