Novel multifunctional bonding machine

A laminating machine, multi-functional technology, applied in the direction of material gluing, mechanical equipment, devices for coating liquid on the surface, etc., can solve the problems of inapplicable production plan, complicated operation, single function, etc., to improve the lamination accuracy, Simple operation and novel layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

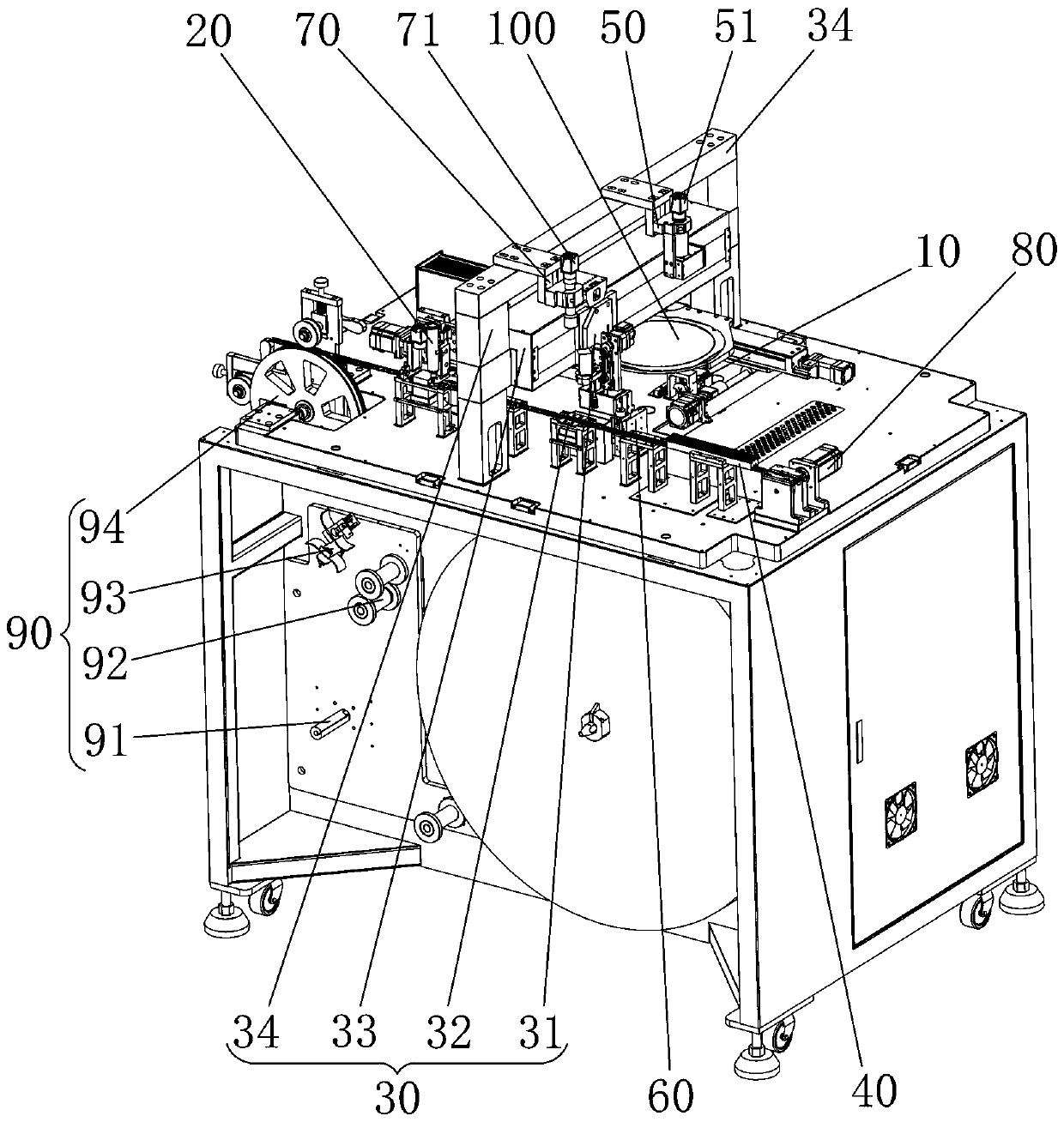

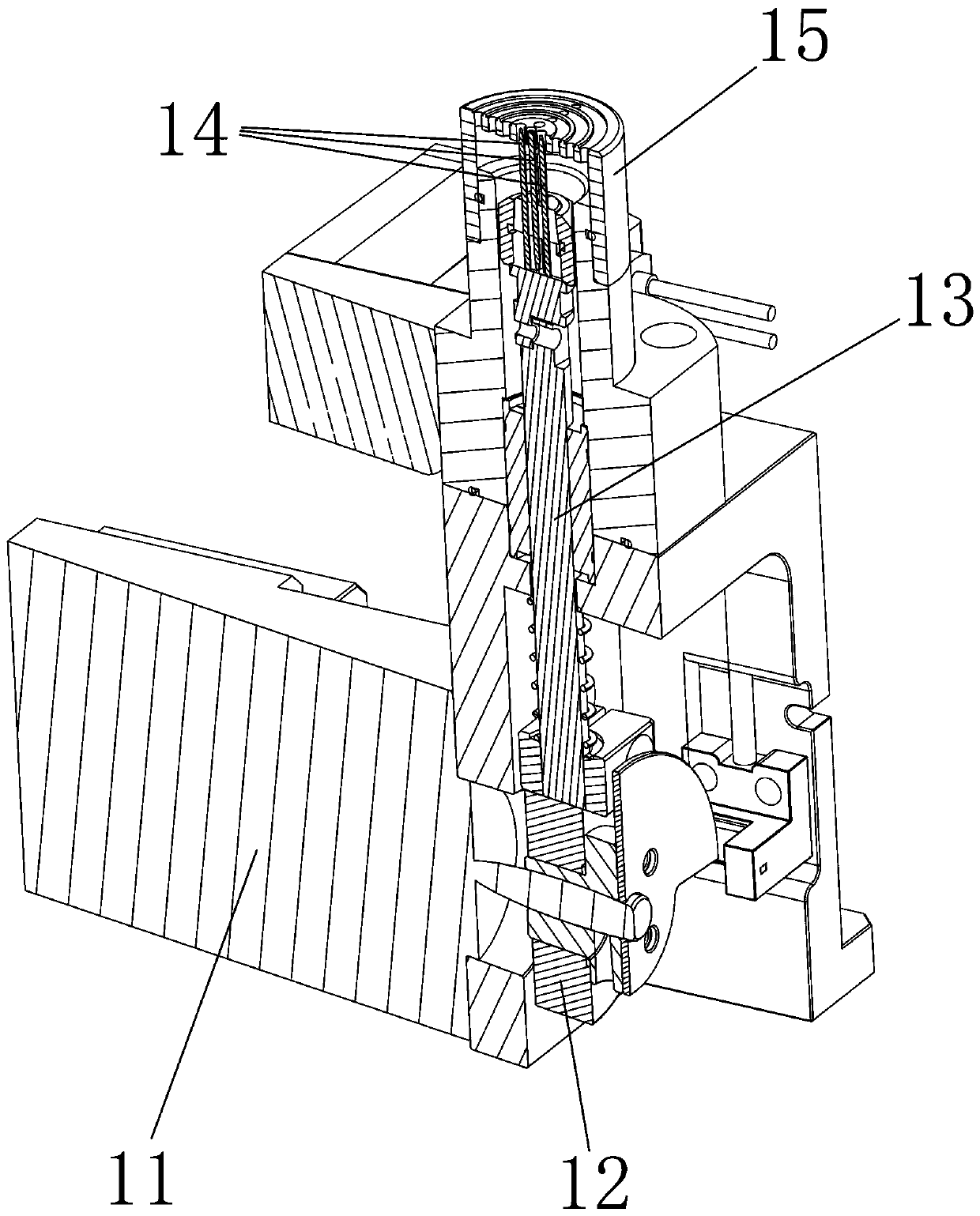

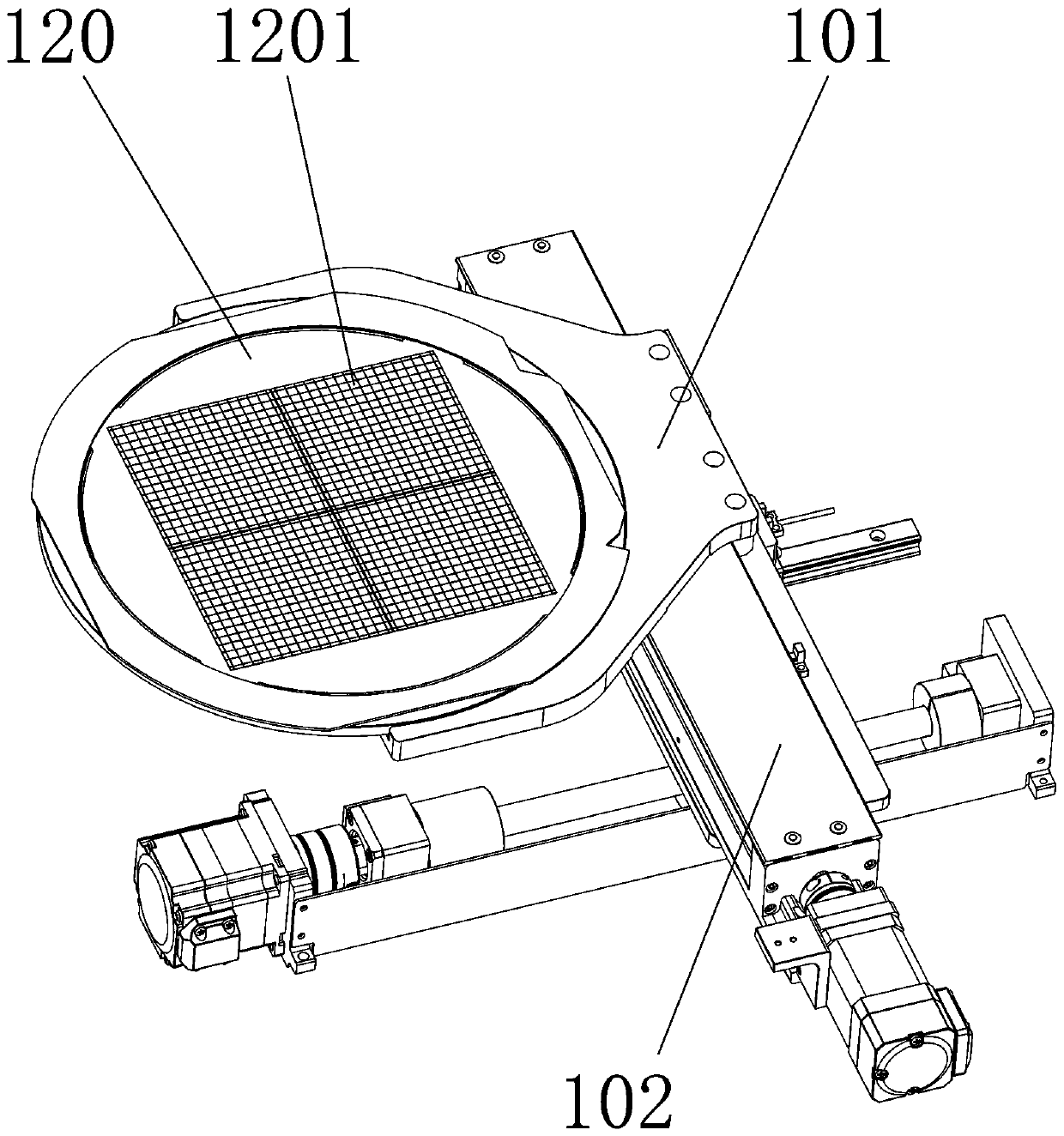

[0029] combined with figure 1 to attach Image 6 As shown, a new type of multifunctional laminating machine is used to attach a filter to the metal bracket of the camera module holder, as shown in the attached image 3 As shown, several filters 1201 are distributed in rows and columns on the filter tray 120, with Figure 5 As shown, a number of metal brackets 1101 arrays are distributed at the strip 110, including a thimble module 10, a glue dispensing module 20, a bonding module 30, a UV curing module 40, a visual screening module 50, a flying shot positioning module 60, a bonding positioning Module 70, material tape pulling module 80, first feeding module 90 for supplying material tape 110, and second feeding module 100 for supplying optical filters, material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com