Riveting pressure tool

A tooling and riveting technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as high safety risks, unsightly appearance of parts, and high requirements for operators, so as to improve the pass rate, reduce weight, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

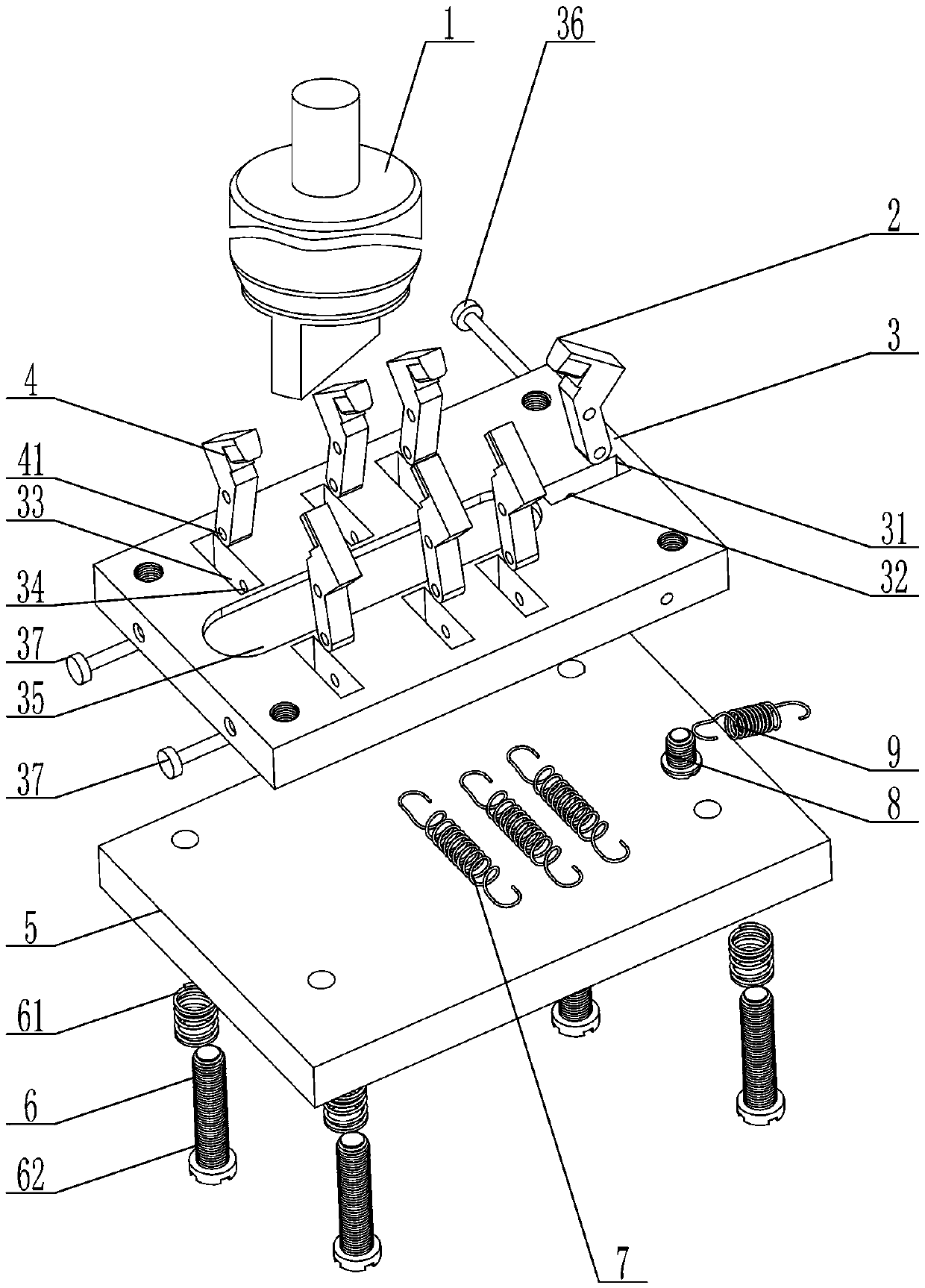

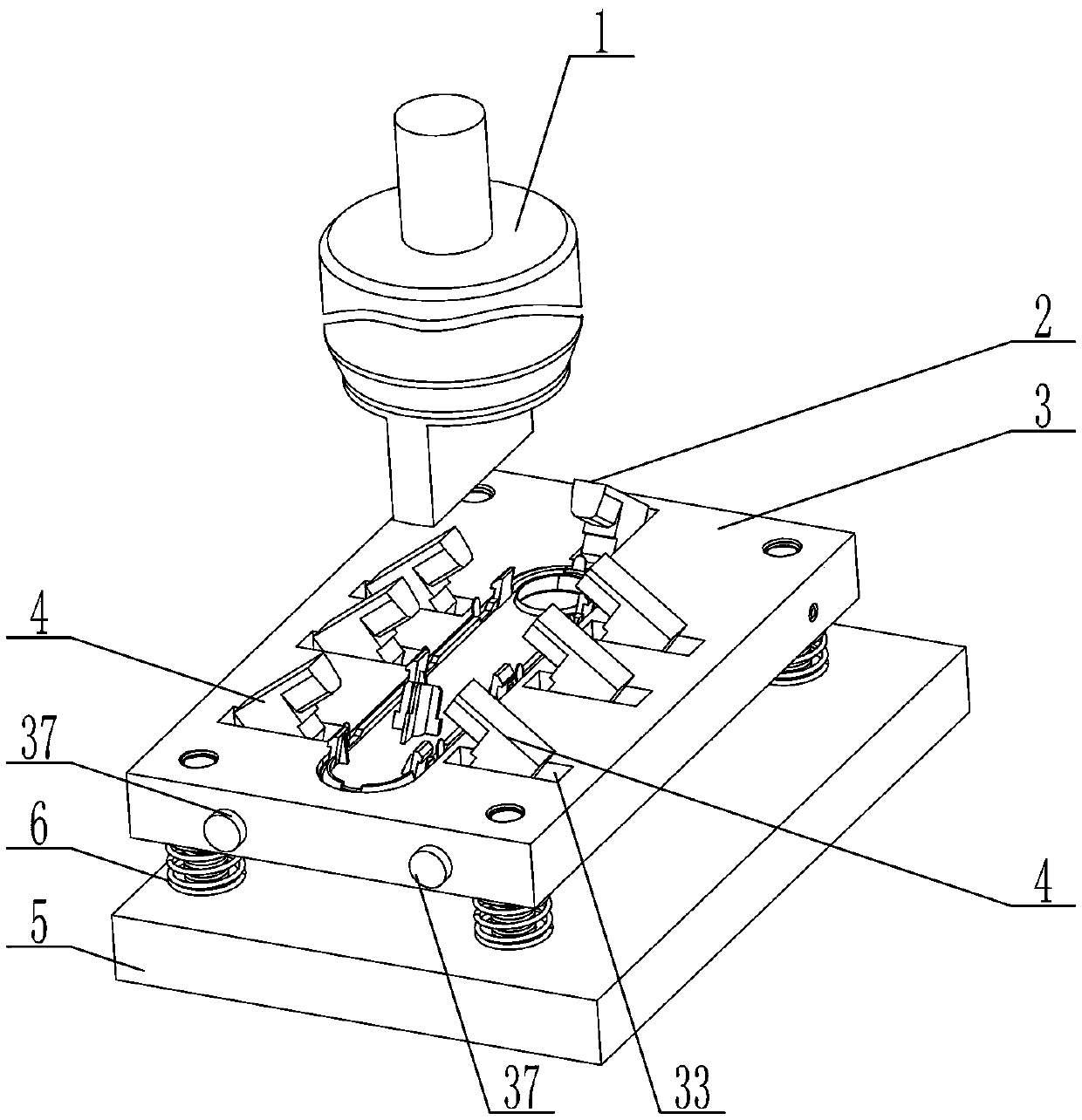

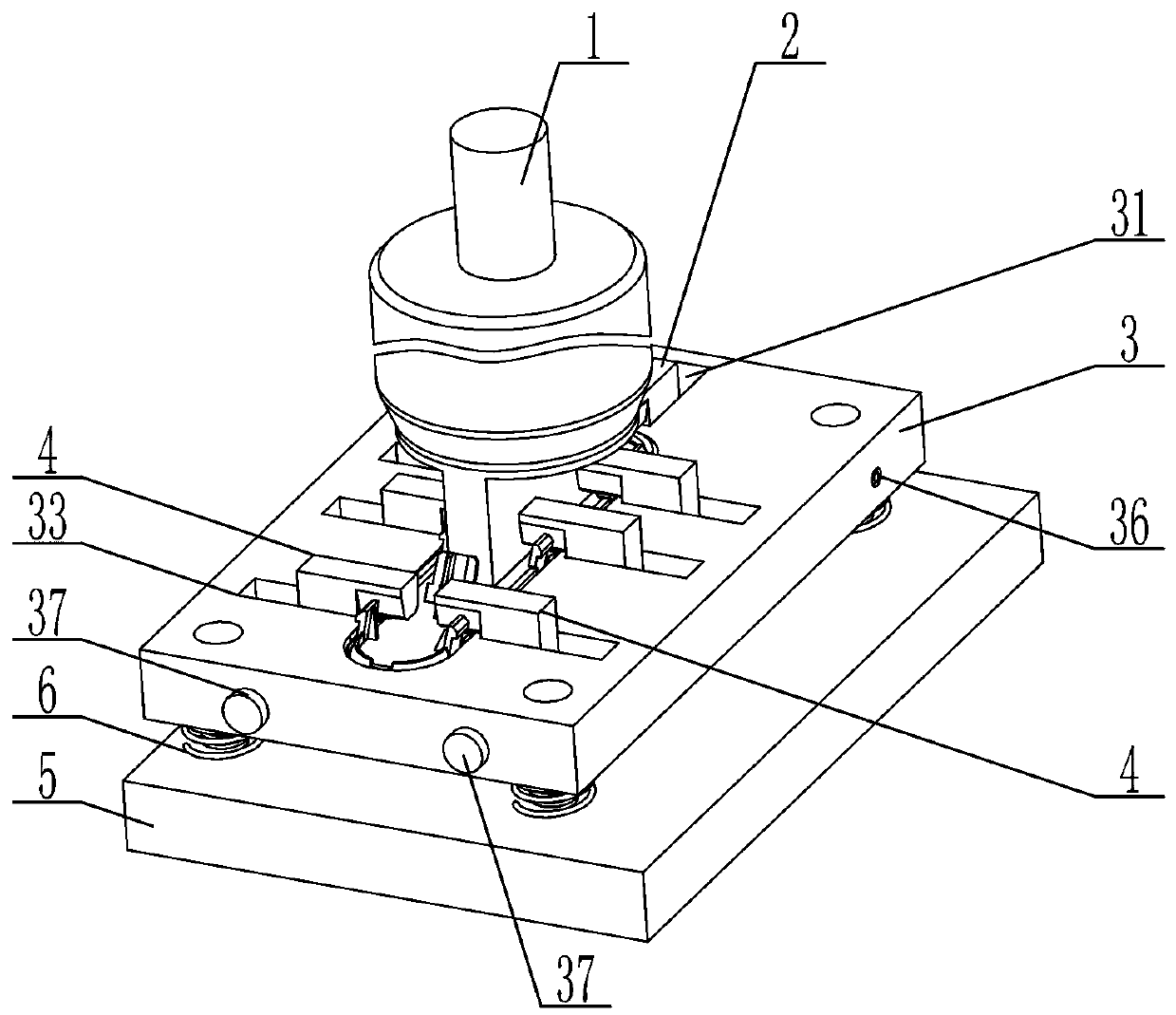

[0035] Such as Figure 1 to Figure 8 As shown, a riveting tooling includes an upper mold 1, a first pressure block 2, a lower mold 3, a fixed plate 5, and a guide and positioning member 6, and the lower mold 3 is provided with a first fixed shaft 36, and the The upper mold 1 fits with the lower mold 3 and drives the lower mold 3 to move downward, the guide positioning member 6 passes through the fixed plate 5 and is connected with the lower mold 3, and also includes Extension spring fixed shaft 8, the first extension spring 9, the first extension spring hole 22 is arranged on the first pressure block 2, the extension spring fixed shaft 8 is connected with the lower mold 3, the described One end of the first extension spring 9 is connected with the extension spring fixed shaft 8, and the other end of the first extension spring 9 is connected with the first extension spring hole 22 on the first pressure block 2, and the The bottom of the first pressing block 2 is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com