Soil sampling device for metal detection

A soil sampling and metal detection technology, applied in sampling devices and other directions, can solve the problems of inability to meet batch sampling, cumbersome operations, and low soil sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

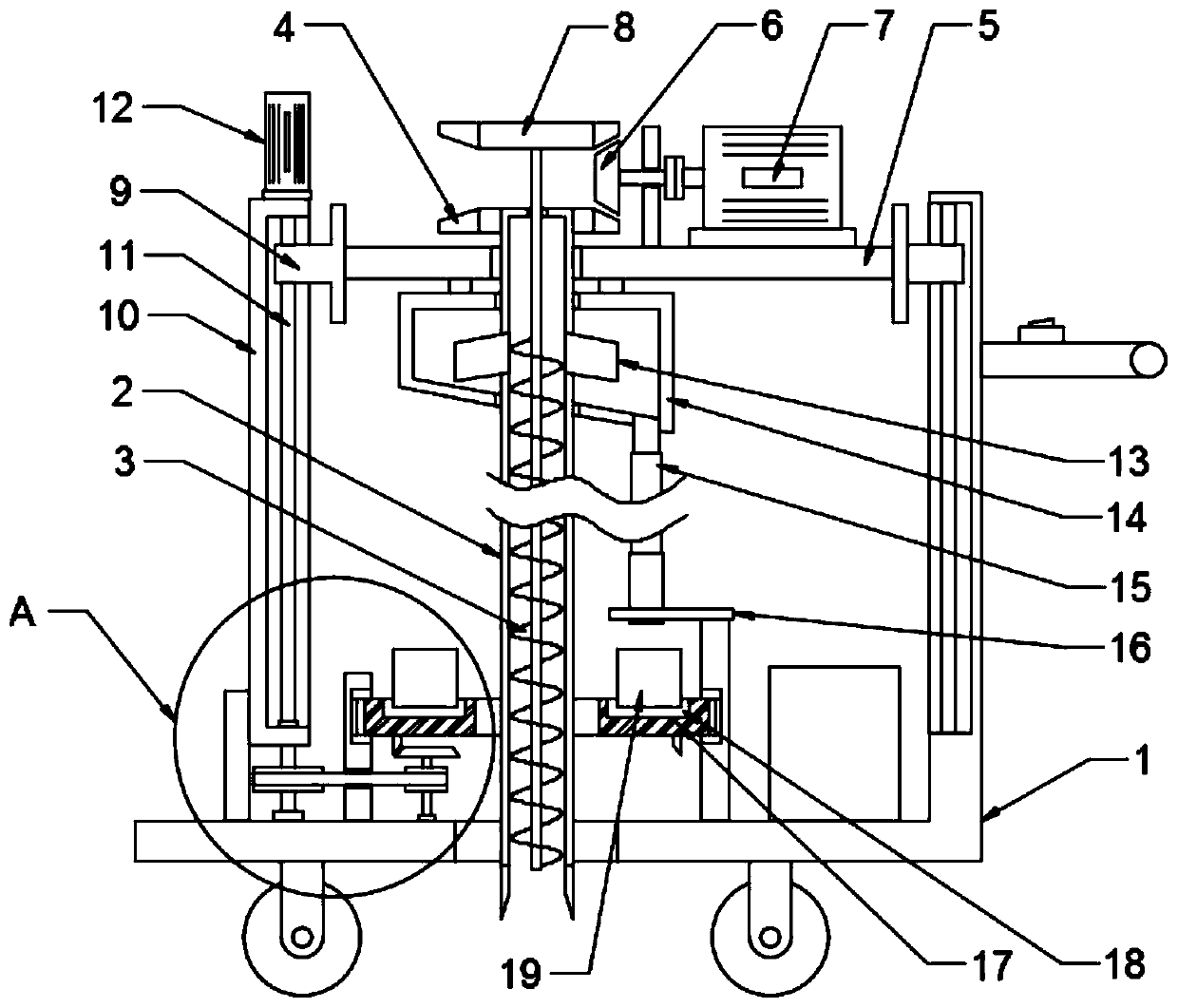

[0022] see Figure 1-4 , in an embodiment of the present invention, a soil sampling device for metal detection includes a cart 1 and a soil fetching mechanism; the soil fetching mechanism includes a drill barrel 2 that can move up and down, and a helical blade roller 3 is arranged in the drill barrel 2, The spiral blade roller 3 lifts the soil sample entering the drill tube 2; the upper end of the drill tube 2 is nested with a lifting frame 5, and the drill tube 2 is rotatably connected to the lifting frame 5 through a bearing; the outer side of the drill tube 2 is sleeved and fixed There is a first bevel gear 4, the first bevel gear 4 is engaged with a drive gear 6, the drive gear 6 is connected to the output shaft of the drive motor 7, the drive motor 7 is electrically connected to the vehicle power supply, and a switch panel is arranged on the cart 1 , to facilitate starting the drive motor 7; the helical blade roller 3 extends to the top of the drill cylinder 2 and is fixe...

Embodiment 2

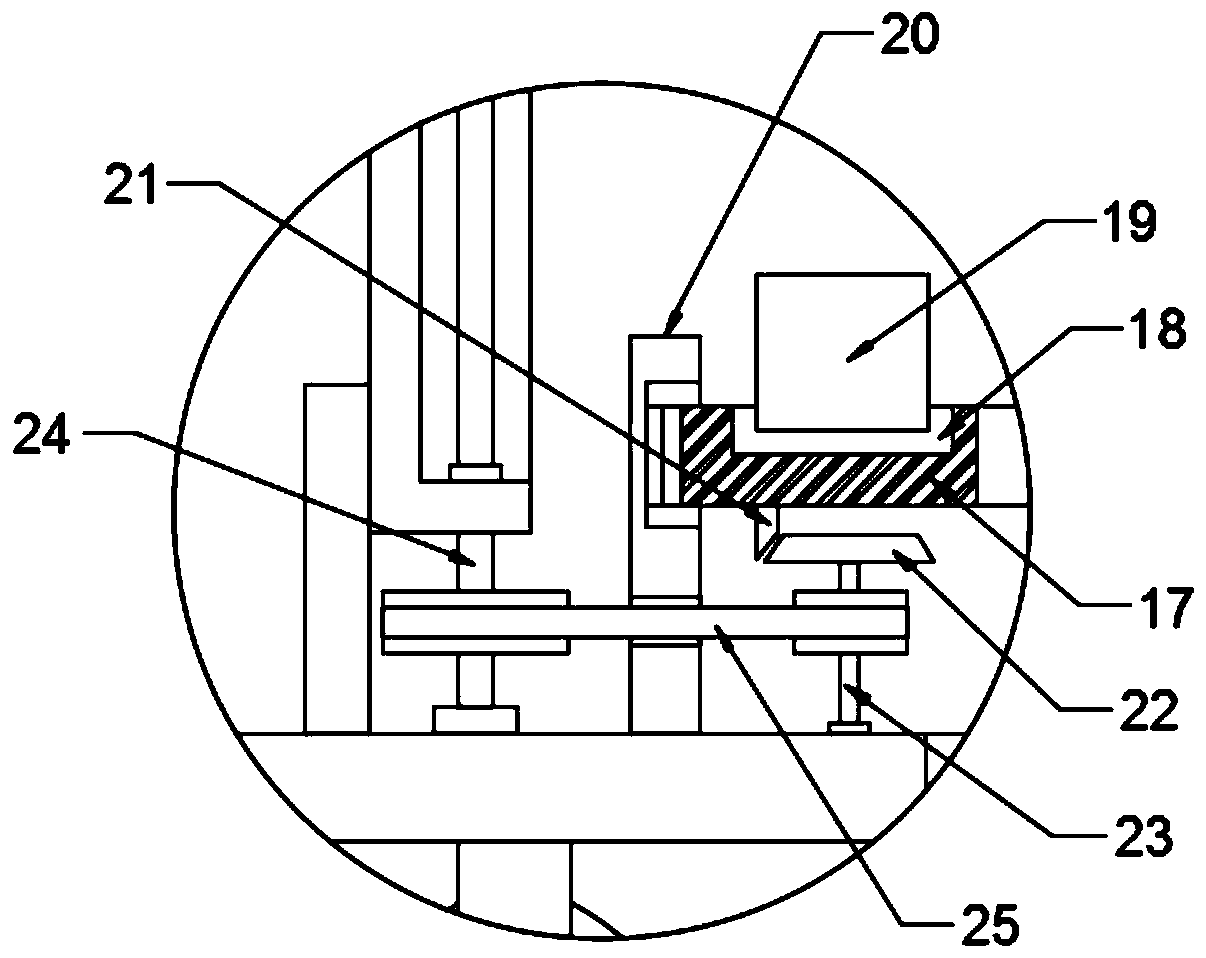

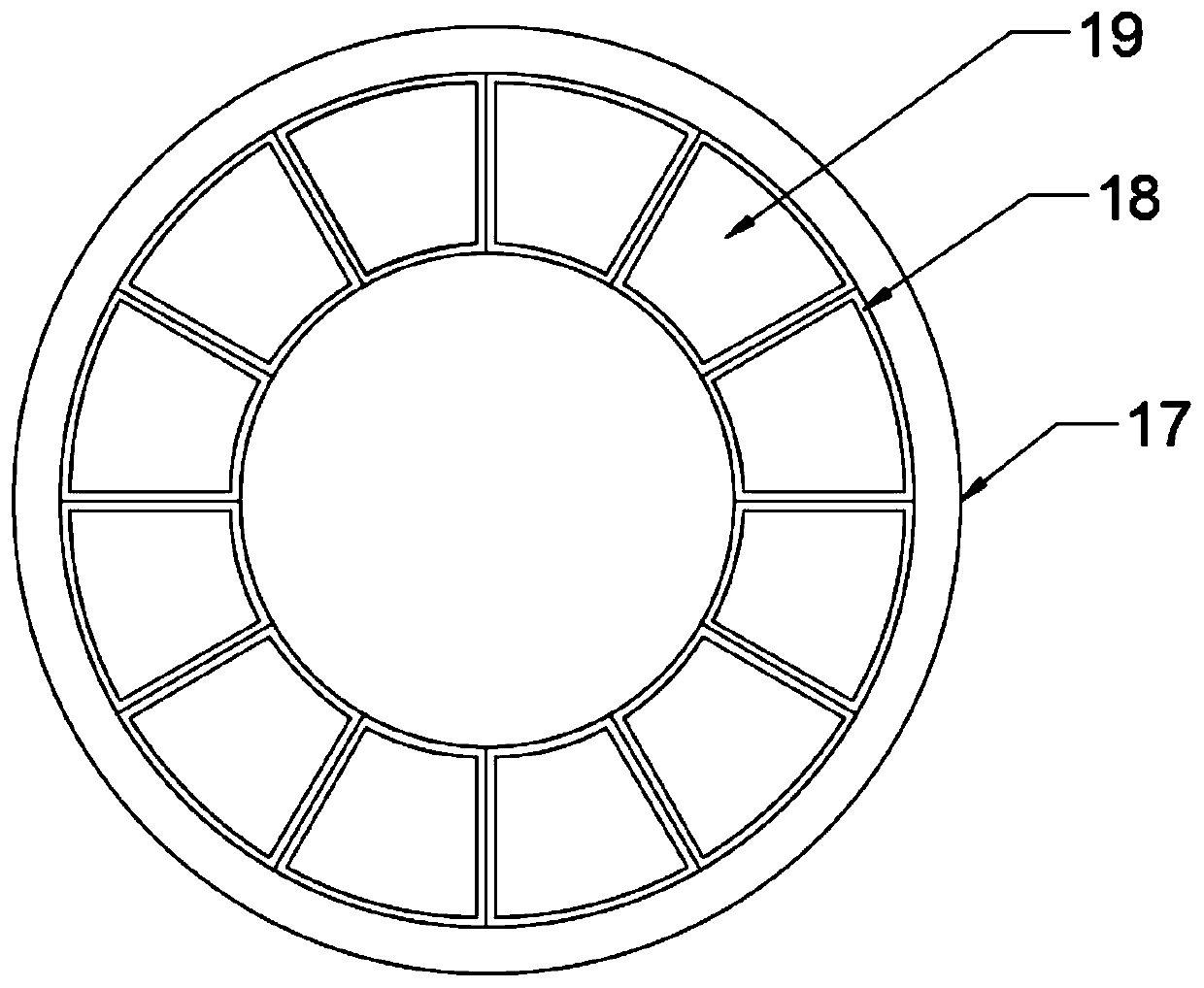

[0026] The difference between this embodiment and Embodiment 1 is that: the outside of the drill barrel 2 is provided with a material receiving mechanism, the material receiving mechanism includes a material receiving barrel 14 sleeved on the outside of the drill barrel 2, and the material receiving barrel 14 is fixedly connected with the lifting frame 5 And it is rotatably connected with the drill barrel 2; the lower end of the receiving barrel 14 is connected with a feeding pipe 15, and the feeding pipe 15 is a telescoping tube; the lower part of the feeding pipe 15 is provided with a bearing plate 17, and the bearing plate 17 is An annular disc set on the outside of the drill barrel 2, the bearing disc 17 is rotatably connected with a ring frame 20, and the ring frame 20 is fixedly connected with the trolley 1; the upper end surface of the bearing disc 17 is provided with fan-shaped grooves 18 distributed in a circle and connected end to end , the fan-shaped groove 18 is nes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com