Light extending type lifting device and implementation method

A light, hanger technology, applied in the direction of safety devices, transportation and packaging, load hanging components, etc., can solve the problems of fast installation of steel structure rods, low construction efficiency, affecting the progress of the project, etc., to ensure the safety of hoisting and stability, improve installation and construction efficiency, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

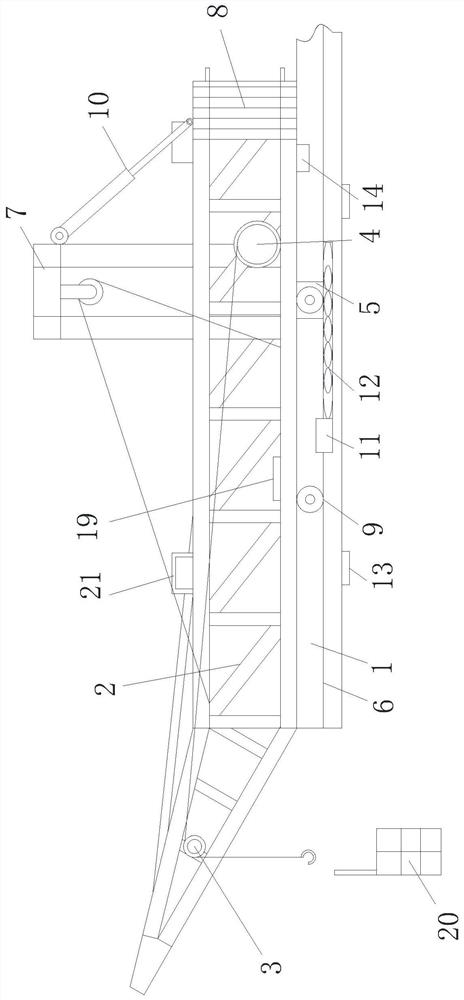

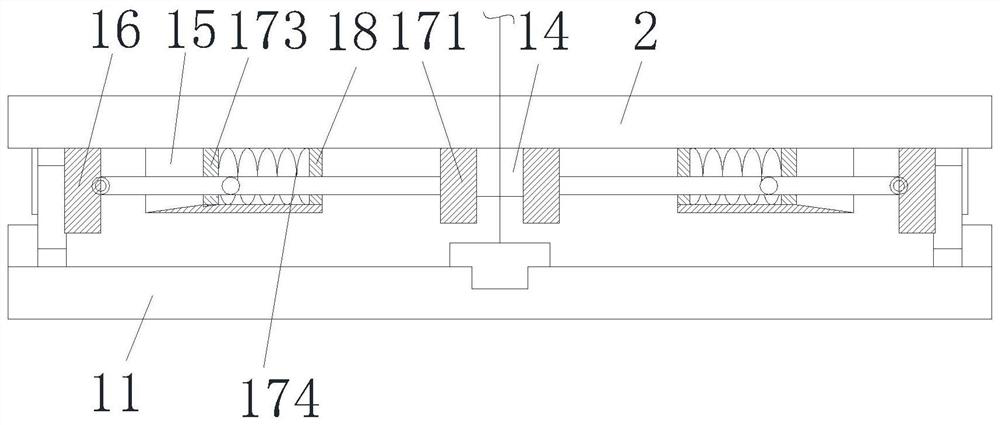

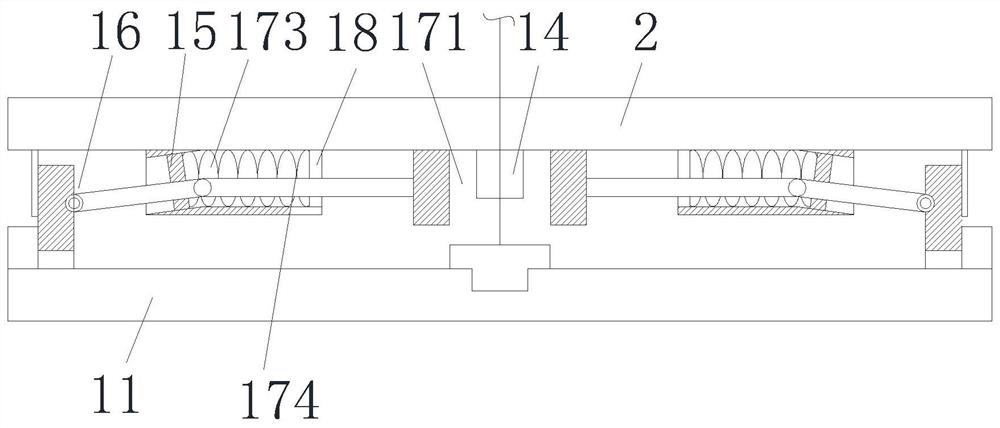

[0031] Such as Figure 1 to Figure 3 As shown, a light-duty protruding lifting device includes a base 1 and a hanger 2 that moves relative to the base 1. The base 1 is provided with a guide rail 6 and a support frame 7, and the hanger 2 is provided with a fixed pulley. 3. Hoist 4, driver 5 and counterweight 8, the fixed pulley 3 is arranged on the front side of the hanger 2, the wire rope on the hoist 4 is connected to a hook through the fixed pulley 3, and the driver The output end of 5 is connected with a transmission member 9 and the transmission member 9 forms a transmission fit with the guide rail 6. The counterweight 8 is arranged at the tail of the hanger 2, and a support member 10 is rotatably installed on the support frame 7. The support The end of the member 10 away from the support frame 7 is rotatably connected to the tail of the hanger 2 , and the support member 10 gradually increases pressure on the rear of the hanger 2 as the hanger 2 moves forward. The driving...

Embodiment approach

[0041] An implementation method of a light-duty protruding lifting device, comprising the following steps:

[0042] Step 1: First, hang the hanger 2 above the base 1 by lifting equipment to ensure that the gear assembly and the rack on the guide rail 6 are meshed and matched, and then rotate the end of the support 10 on the support frame 7 away from the support frame 7 and install it on the At the afterbody of the hanger 2, one end of the connecting rope is fixedly installed on the slide block one 11, and the other end is fixed around the fixed pulley 32 and the front end of the hanger 2, and finally the slide block two 13 is first installed on the base 1 and connected with The hanger 2 is fixedly installed;

[0043] Step 2: Control the driving part 5 through the remote control handle 20 to drive the gear assembly to move forward along the rack, the counterweight 8 moves forward with the hanger 2, and at the same time the support part 10 exerts pressure on the counterweight 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com