Curved surface cover plate, processing method of curved surface cover plate and terminal

A processing method and cover plate technology, which is applied to the structure of telephone sets, telephone communications, electrical components, etc., can solve the problems of difficulty in forming a smooth transition surface, easy generation of bubbles, and difficult processing, so as to improve the hand feel and appearance effect, The effect of avoiding bending operations and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

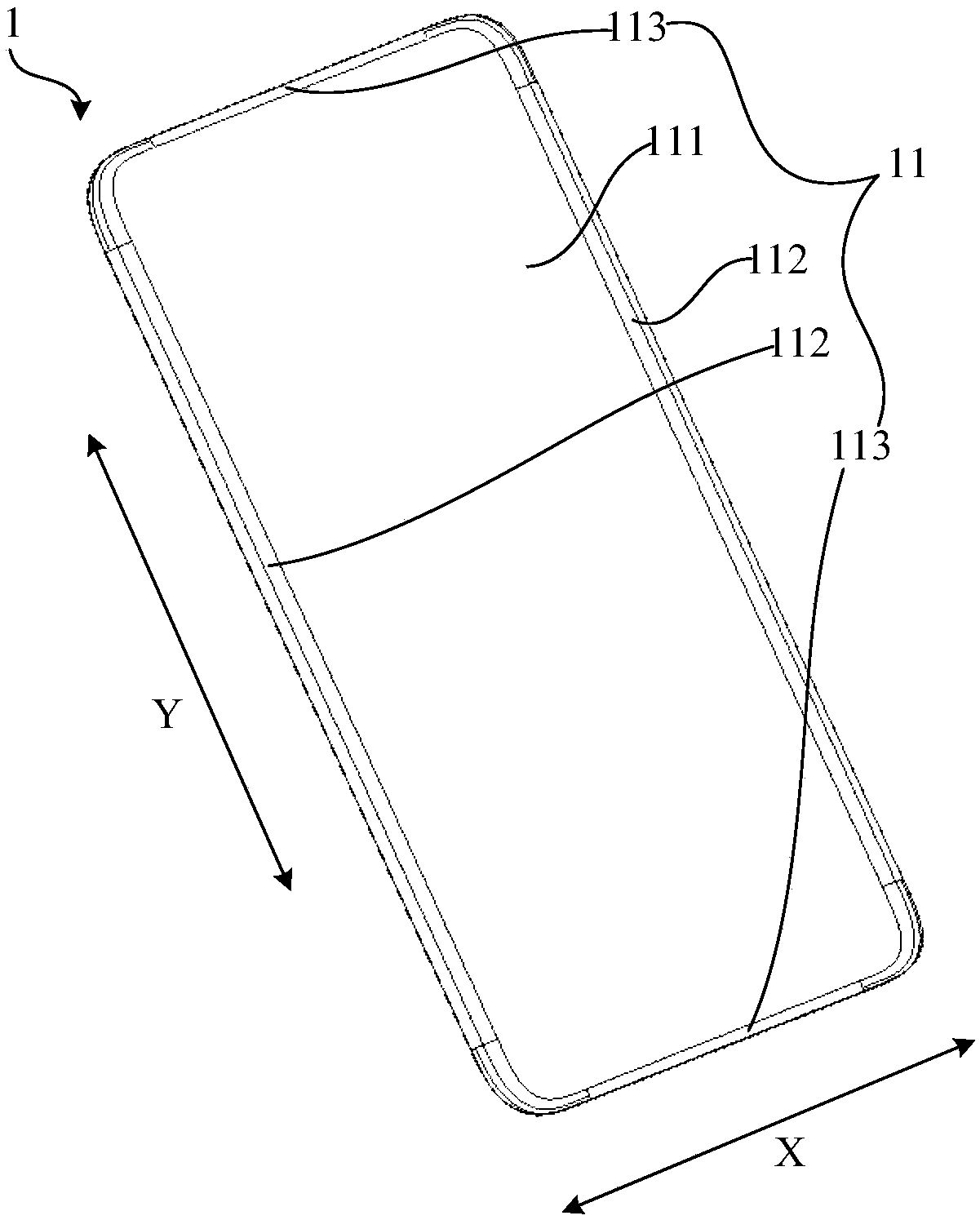

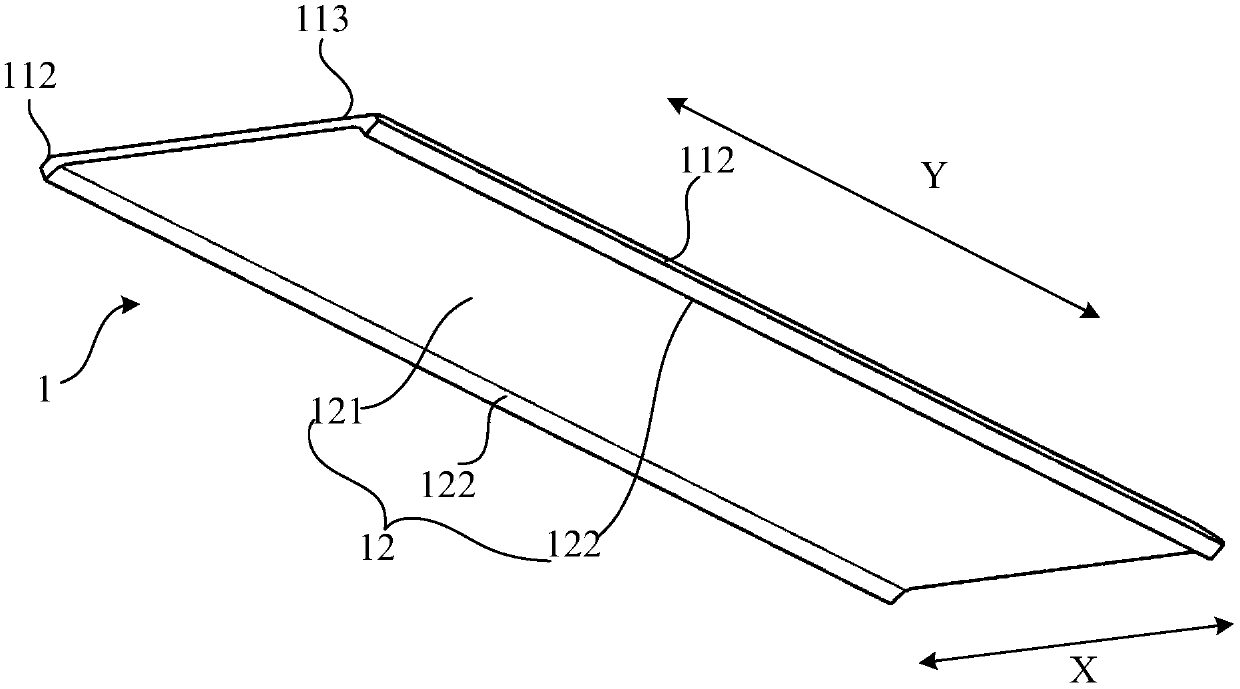

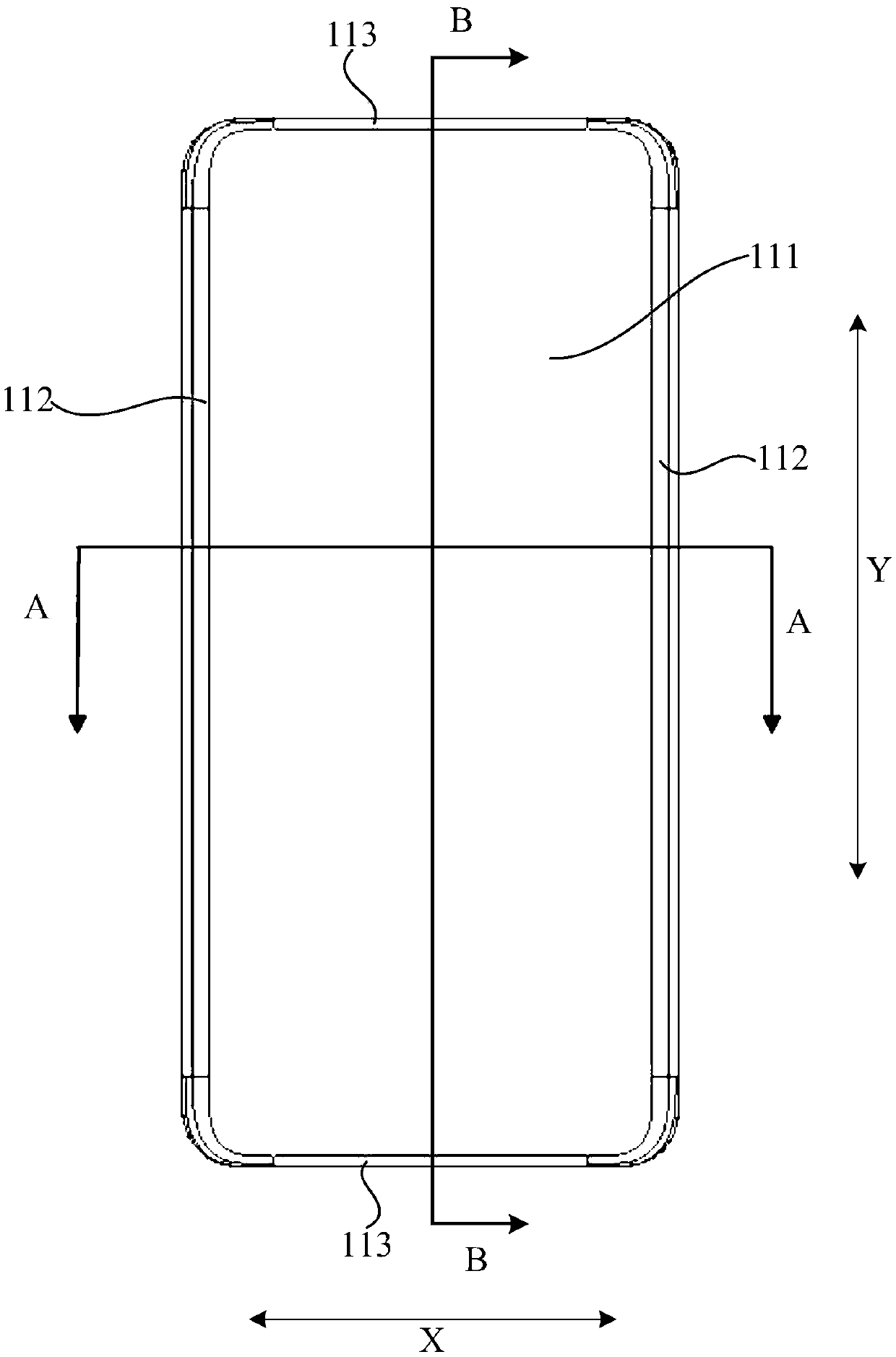

[0038] see figure 1 and figure 2 , the embodiment of the present application provides a curved cover plate, the curved cover plate 1 in the embodiment of the present application includes a front side 11 and a back side 12 oppositely arranged, wherein, as figure 1 As shown, the front side 11 includes a first middle area 111, two first edge areas 112 and two second edge areas 113, and the two first edge areas 112 are respectively located at both ends of the first middle area 111 along the first direction X , the two second edge regions 113 are respectively located at both ends of the first middle region 111 along the second direction Y, the first direction X is perpendicular to the second direction Y, and both the first direction X and the second direction Y are connected to the first middle The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com