Dual-purpose limiting device for cake discharge and filtering cloth washing by grouping and pulling filtering plates of efficient filter press

A filter press filter plate and limit device technology, which is applied in the fields of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problem of not being able to control the filter plate to wash cloth in one step, and shorten the pulling time, pulling the plate, etc. Efficient and accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

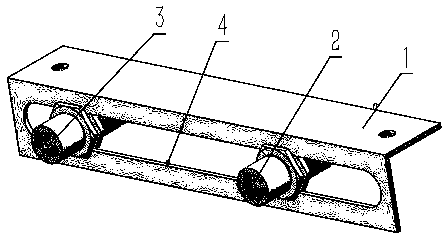

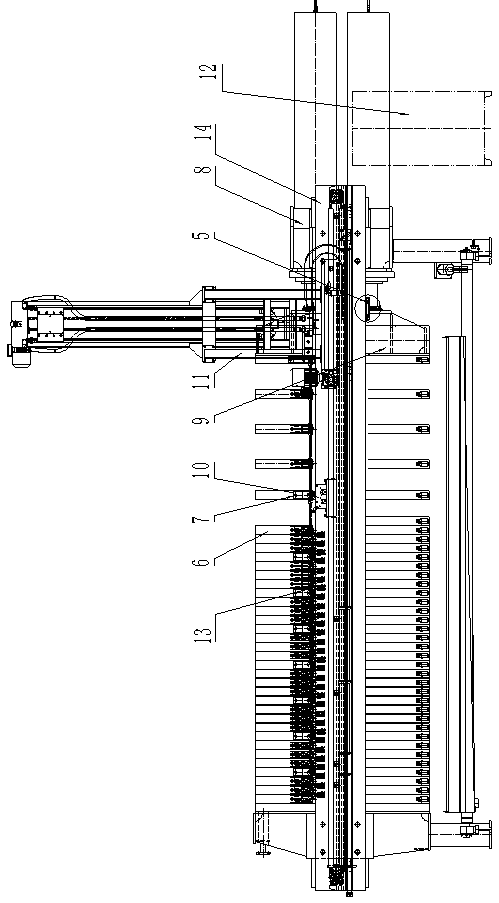

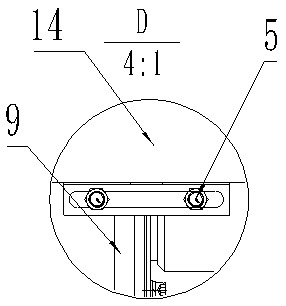

[0017] A dual-purpose limiting device for cake unloading and cloth washing by grouping the filter plates of a high-efficiency filter press. It is composed of components such as positioner 3, and has a simple structure; its outstanding substantive feature is that it innovates the operating procedure, and on the basis of the original cake unloading limiter, a cloth washing limiter 2 is added, and it is connected with the PLC program control cabinet 12 ; Both limiters are fixed on the L-shaped limit adjustment plate 1 (position adjustable), the cake unloading limiter 3 is close to the side of the push plate 9, and the cloth washing limiter 2 is close to the side of the machine base 8 (from the The push plate 9 is far away), keep a certain distance (100mm to 200mm) from each other, and the limit adjustment plate is installed on the filter press beam 14 behind the push plate 9; the two limiters are interlocked to control the cake unloading and cloth washing respectively Pull the fi...

Embodiment 2

[0021] The filter plates are grouped to pull apart the dual-purpose limit device for cake unloading and cloth washing and the corresponding operating procedure for cake unloading of the high-efficiency filter press: the PLC program control system of the high-efficiency filter press defaults to the cake unloading limiter 3 (NBN25-30GM65-E2 The sensor) is in the "normally open" state. When the filter press completes the filtration and only needs to unload the cake (most of the cycle operations do not need to clean the filter cloth), the pull plate trolley 10 automatically groups and pulls the filter plate 6 to realize the gravity unloading of the cake; The process of pulling plate unloading cake is: the pulling plate trolley 10 pulls the head plate 7 of the first group of filter plates (the first filter plate of each group, the first set of head plate is the push plate) to drive the whole set of filter plates 6 to move forward, when The cake unloading limiter 3 senses the head pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com