Surrounding type paint spraying device for outer layer of power distribution cabinet

A power distribution cabinet and wrap-around technology, which is applied to the field of wrap-around paint spraying devices on the outer layer of power distribution cabinets, can solve the problem of uneven paint spraying on the outer layer of power distribution cabinets, easy diffusion of paint beads, and dripping into the environment, etc. problems, to achieve uniform painting effect, avoid damage, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

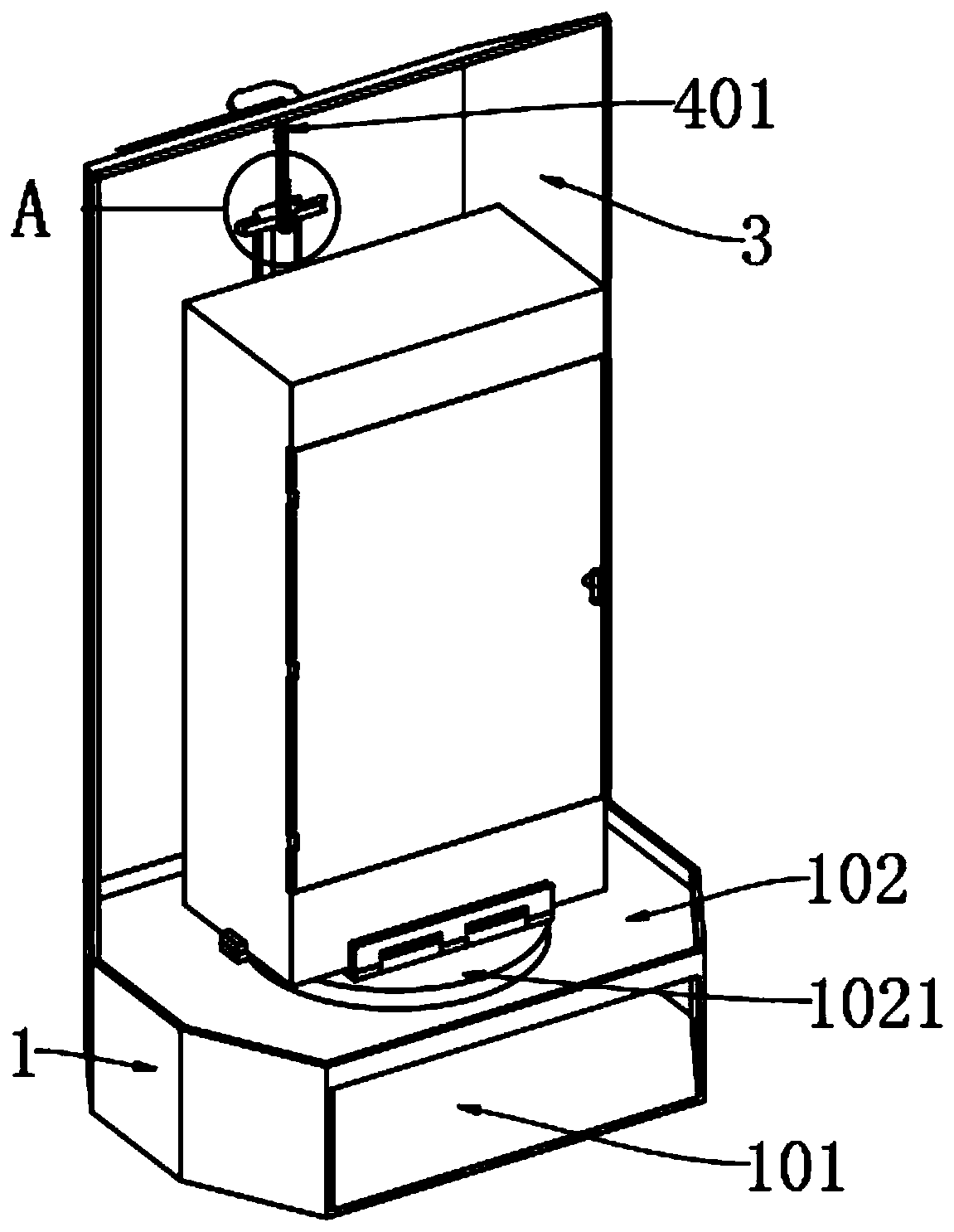

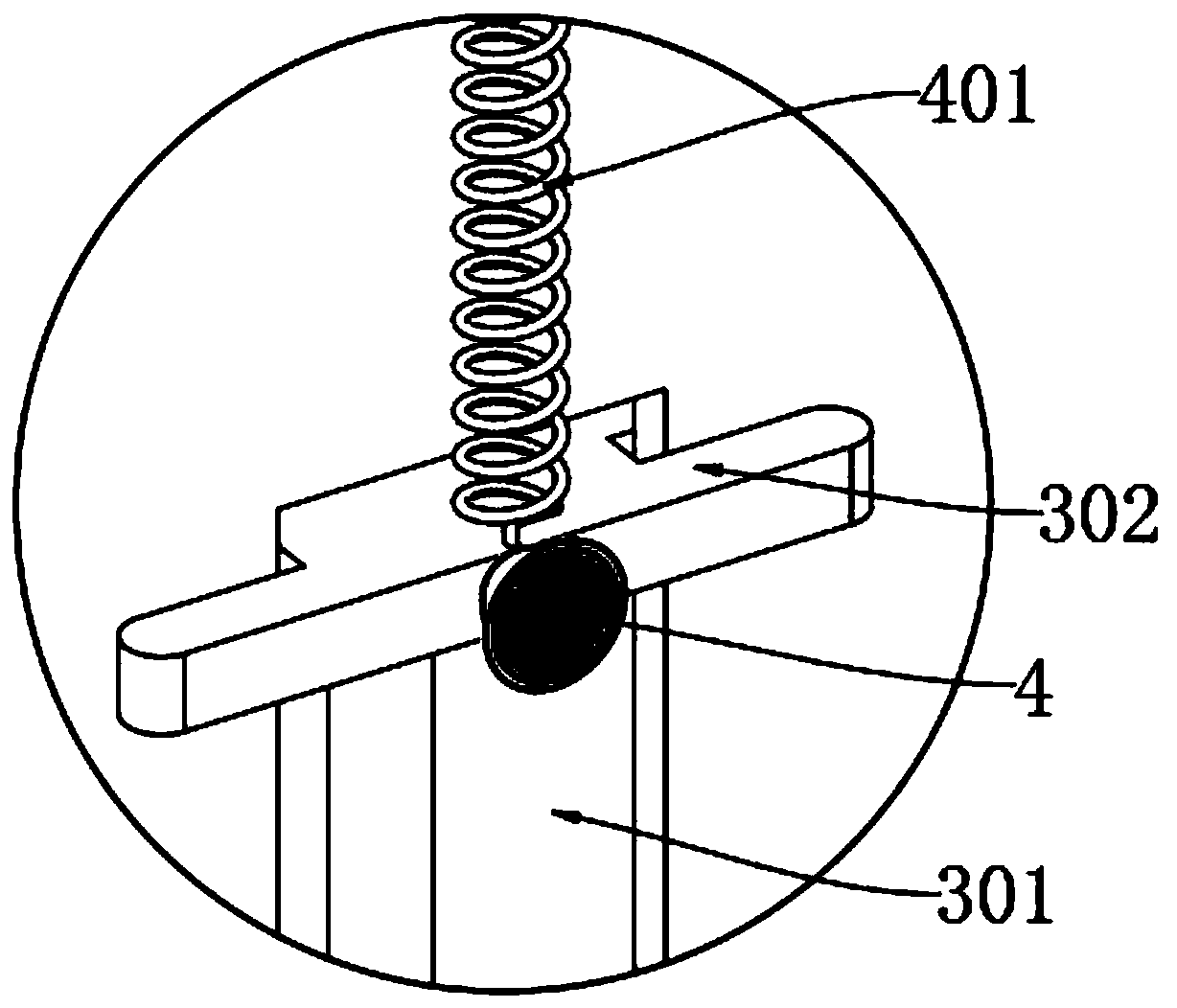

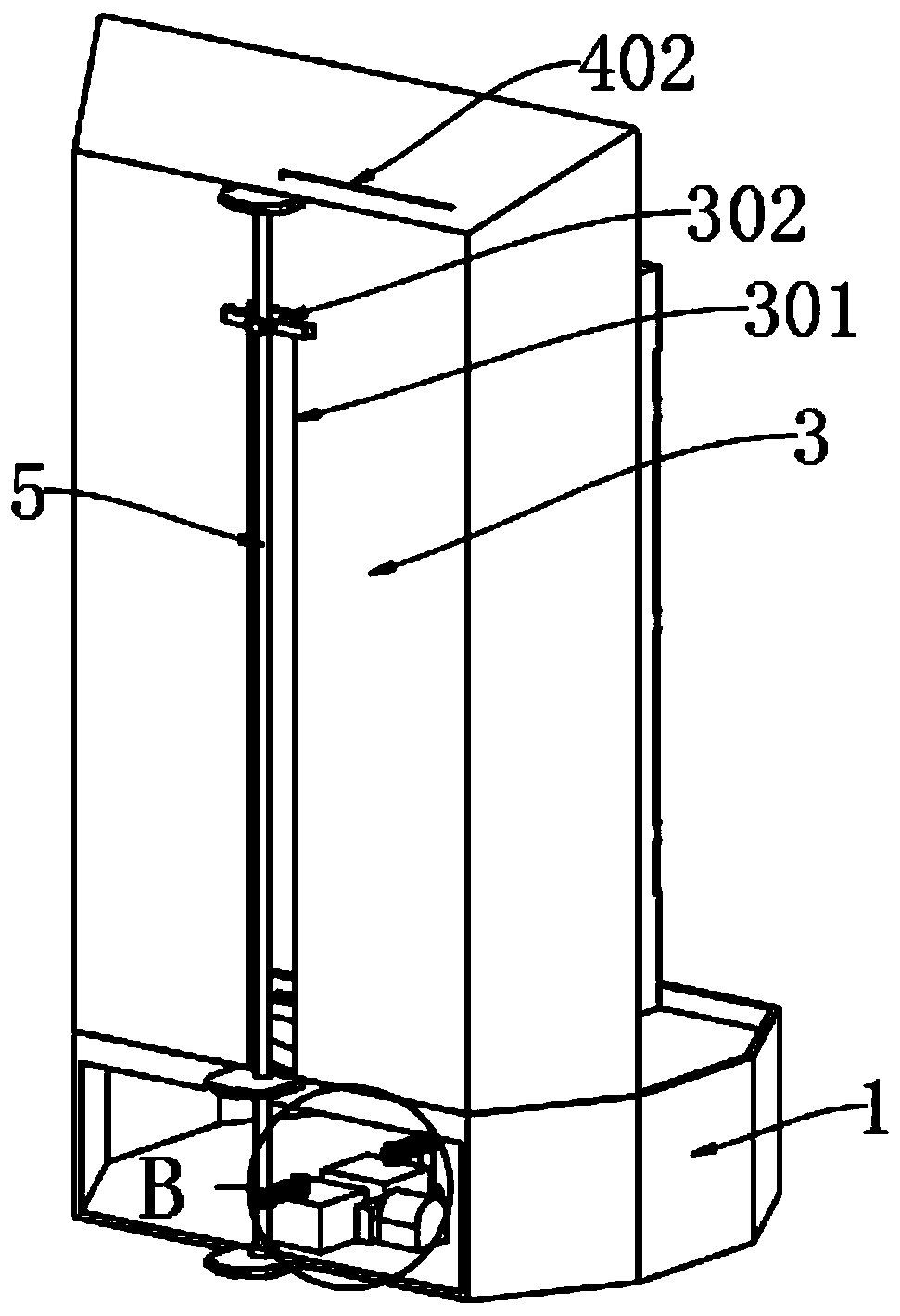

[0033] as attached figure 1 to the attached Figure 8 shown:

[0034] The present invention provides a wrap-around paint spraying device for the outer layer of a power distribution cabinet, which includes a base 1 and a clamping and rotating mechanism 2 for the power distribution cabinet; There is a groove 102, and a fixed backing plate 1021 with a circular structure is also arranged in the middle position of the groove 102. The bottom side is also connected with a rotating shaft 6, the rotating shaft 6 penetrates down into the cavity 101 and is embedded in the bearing seat, and the rotating shaft 6 is connected with the output end of the transmission gearbox B601 through a V-belt, and the rear end side of the base 1 is also connected There is a blocking cover 3, and the blocking cover 3 is provided with a lifting card hole 301, an I-shaped blocking block 302 is slidably clamped on the lifting blocking hole 301, and the front end of the I-shaped blocking block 302 is fixed w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap