Precoated sand shell mold casting technology

A technology of shell casting and coated sand, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of time-consuming and labor-intensive, low efficiency of mold taking, etc., and achieve the goal of increasing adaptability, increasing efficiency, and increasing friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

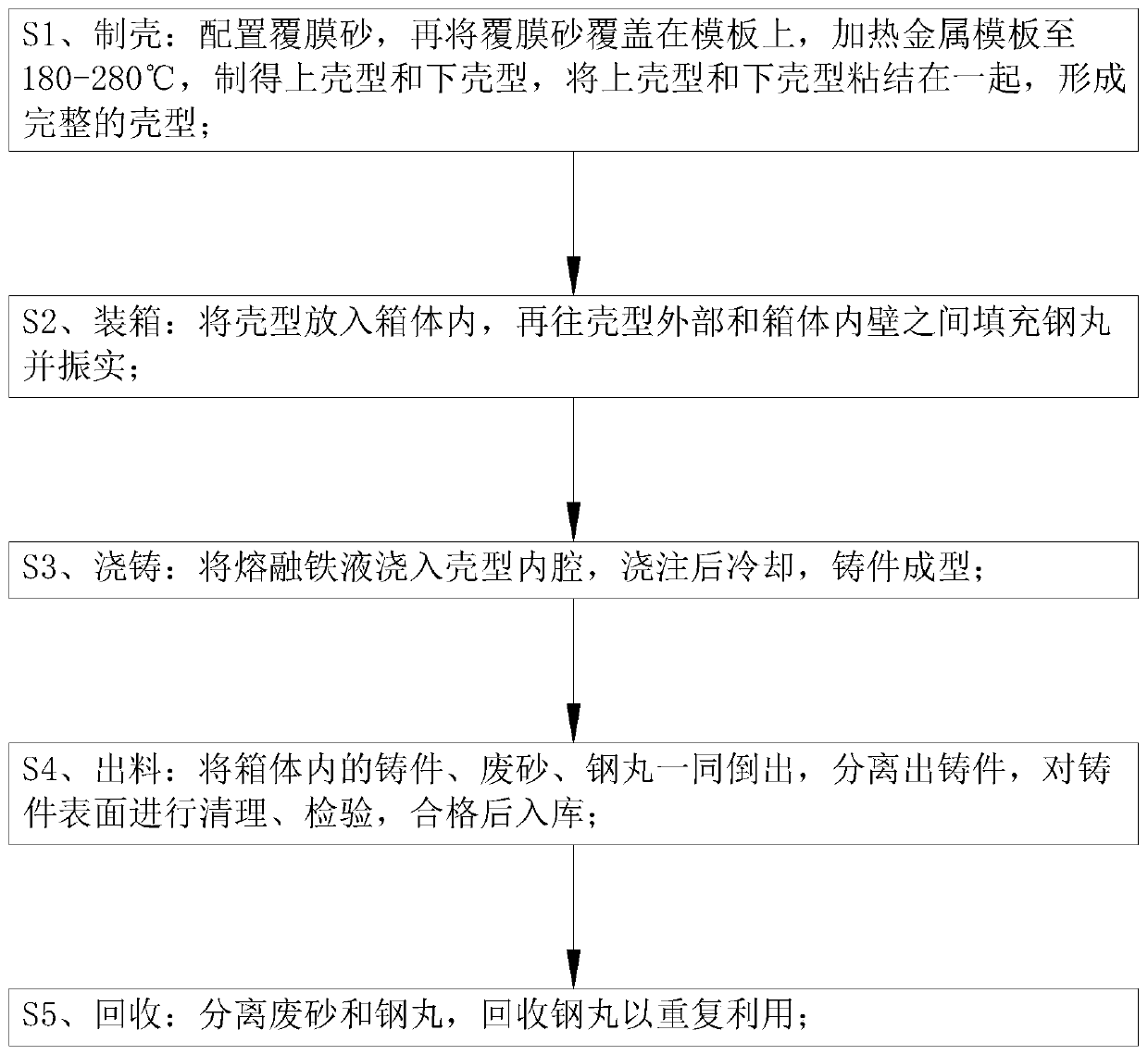

Method used

Image

Examples

Embodiment approach

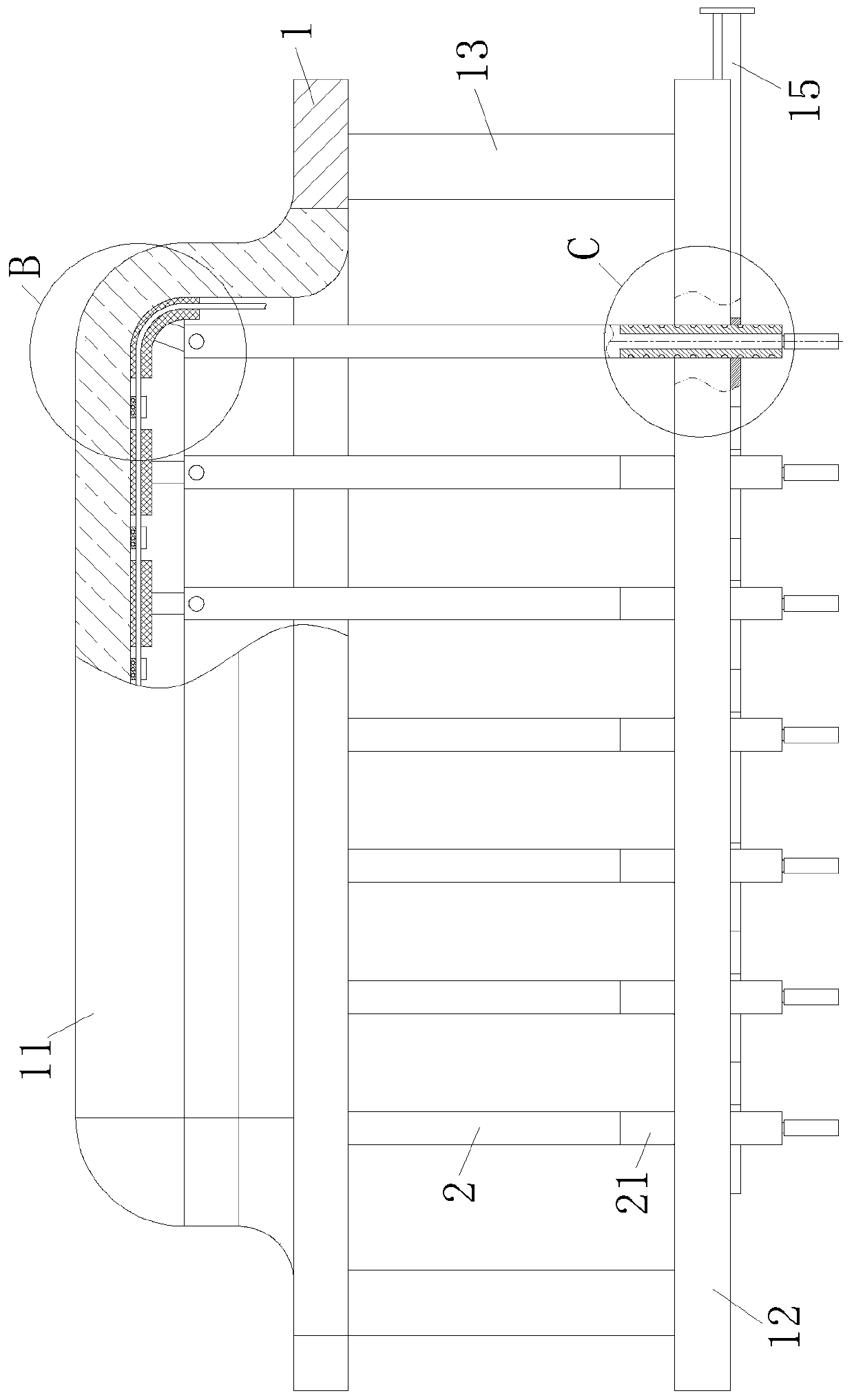

[0039] As an embodiment of the present invention, the clamping block 16 is provided with a rubber layer 17 on the side close to the sliding column 2. The rubber layer 17 is used to increase the friction between the clamping block 16 and the sliding column 2 and reduce the friction between the sliding column 2 and the sliding column. 2 Loosening; the clamping block 16 is provided with an arc-shaped groove 18, and the groove 18 cooperates with the rubber layer 17 to reduce the loosening of the clamping block 16 and further increase the efficiency of template taking; through the rubber layer 17, the clamping block can be increased 16 and the sliding column 2, so as to further prevent the sliding column 2 from loosening and ensure the accuracy of the mold taking of the elastic film 11. When the sliding column 2 slides relative to the block 16 and slides to the corresponding position of the groove 18, the sliding After the column 2 squeezes the rubber layer 17, the rubber layer 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com