Round bamboo joint runthrough treatment equipment and joint runthrough treatment process

A technology for processing equipment and round bamboo, which is applied in mechanical equipment, sugarcane machining, etc., can solve the problems of not being able to meet industrialization, industrialization, excessive labor dependence, and low efficiency, so as to reduce manual operations, realize automation, and communicate The effect of high energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

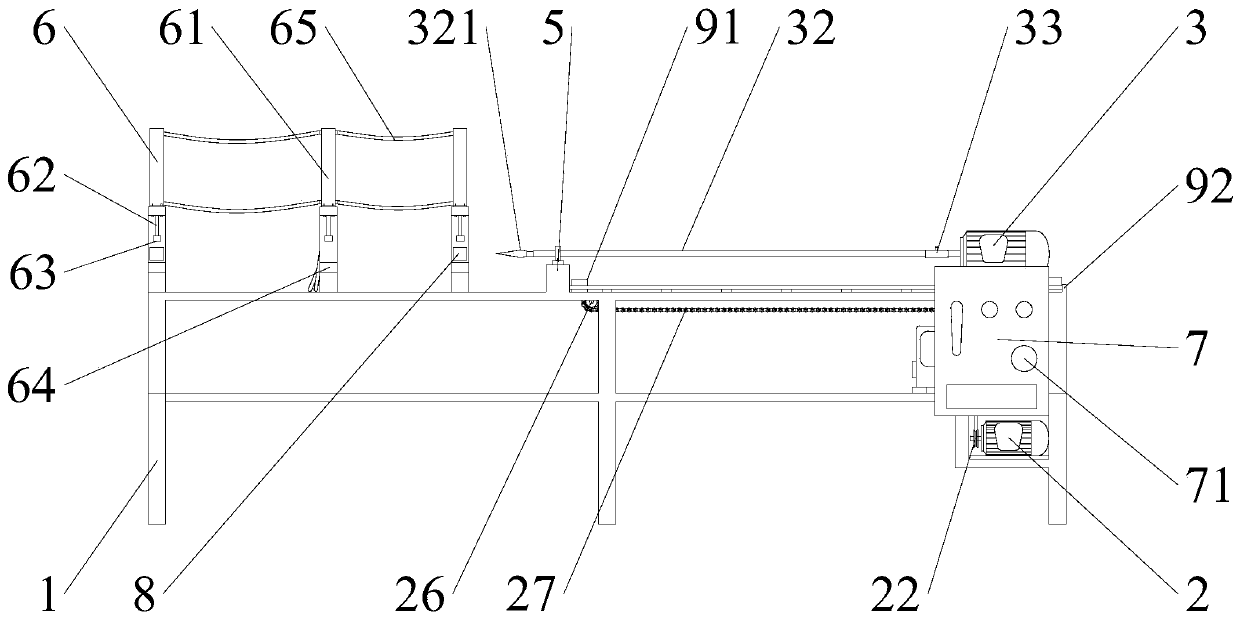

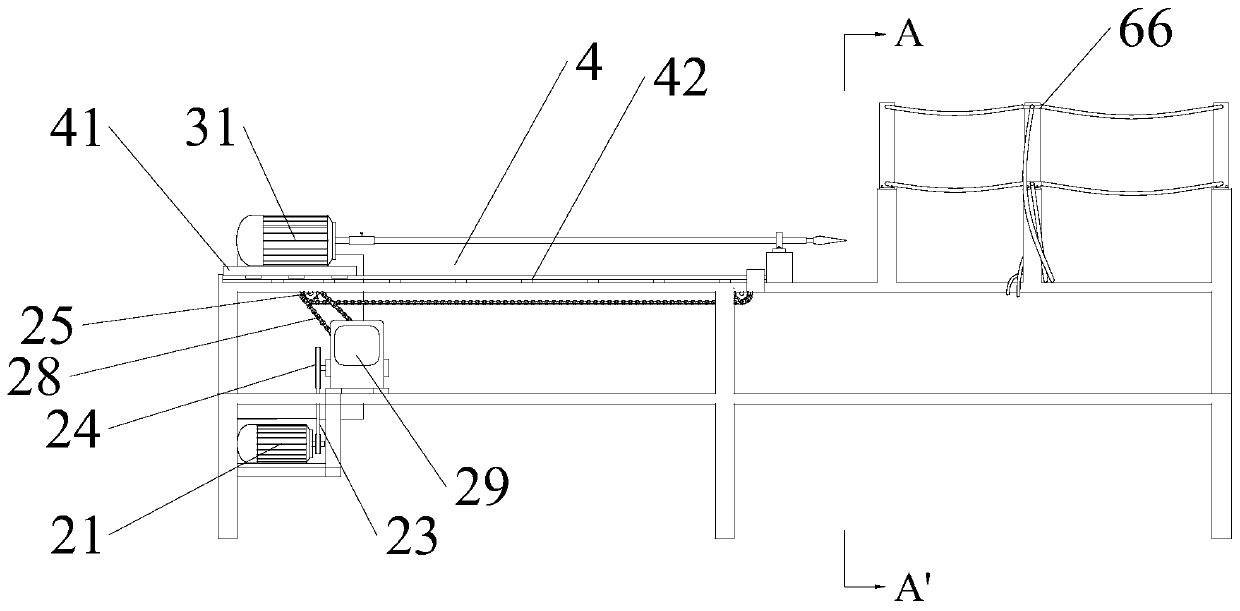

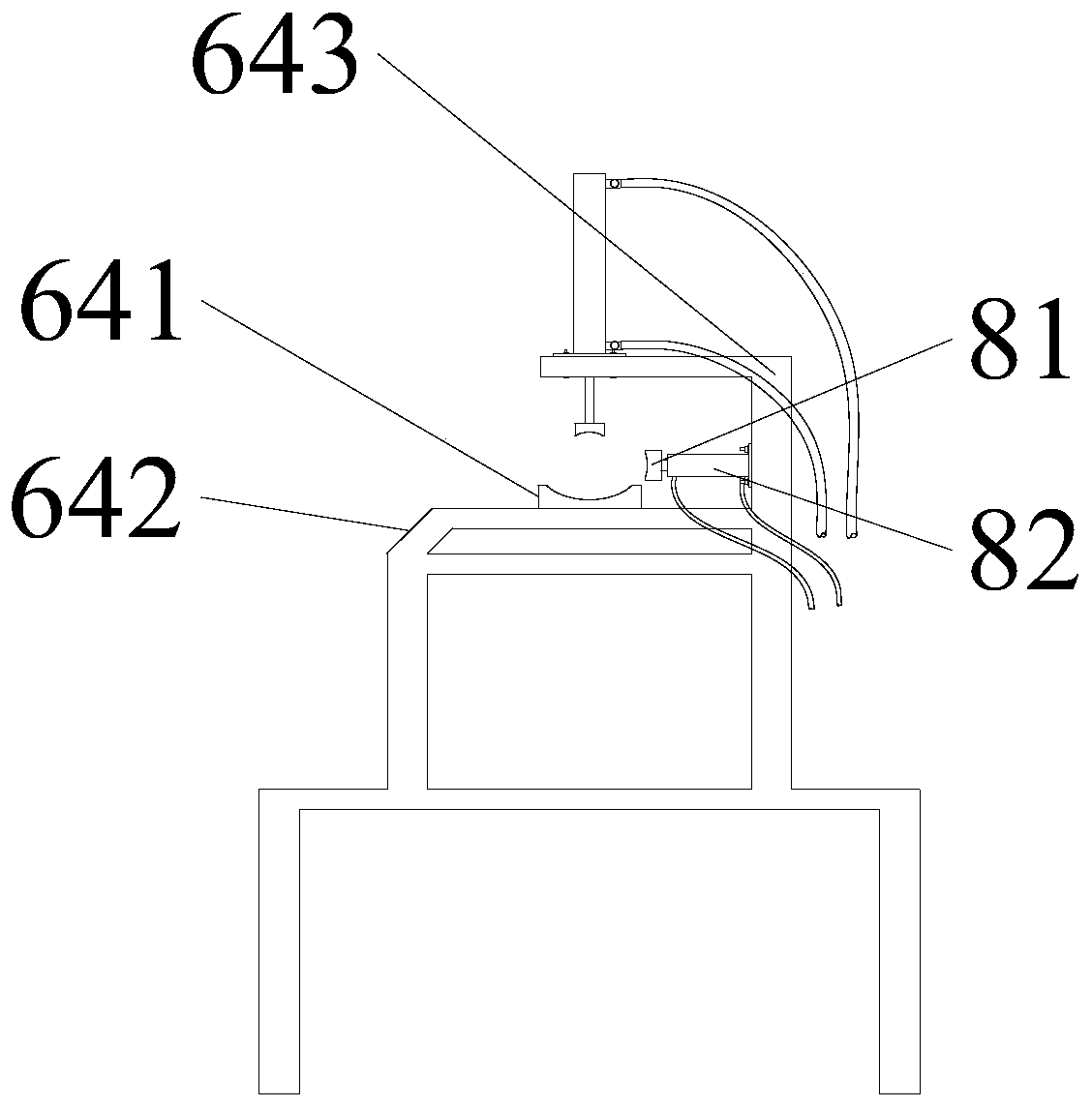

[0038] combine Figure 1 to Figure 3 , a round bamboo joint processing equipment, comprising a main body 1, a transmission device 2 is provided on one side of the main body 1, a moving device 4 is provided on the transmission device 2, and a joint device 3 is provided on the mobile device 4. The other side of the main body 1 is provided with a feeding device (not shown in the figure), and a pressing device 6 for fixing round bamboo is also arranged between the feeding device and the joint device 3, and the pressing device 6 is arranged on the main body 1 .

[0039] The transmission device 2 is installed on one side of the main body 1 and includes a first motor 2 , and a driving wheel 22 is sheathed on a rotating shaft of the first motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com