One-cavity multi-type automobile decoration injection mold

An injection mold, multi-style technology, applied in the field of one-cavity multi-style auto accessories injection molds, can solve the problems of high stability requirements, installation stability defects, difficulty in effectively exhausting air, etc., to achieve stable and safe installation process, improve The effect of high work efficiency and demolding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

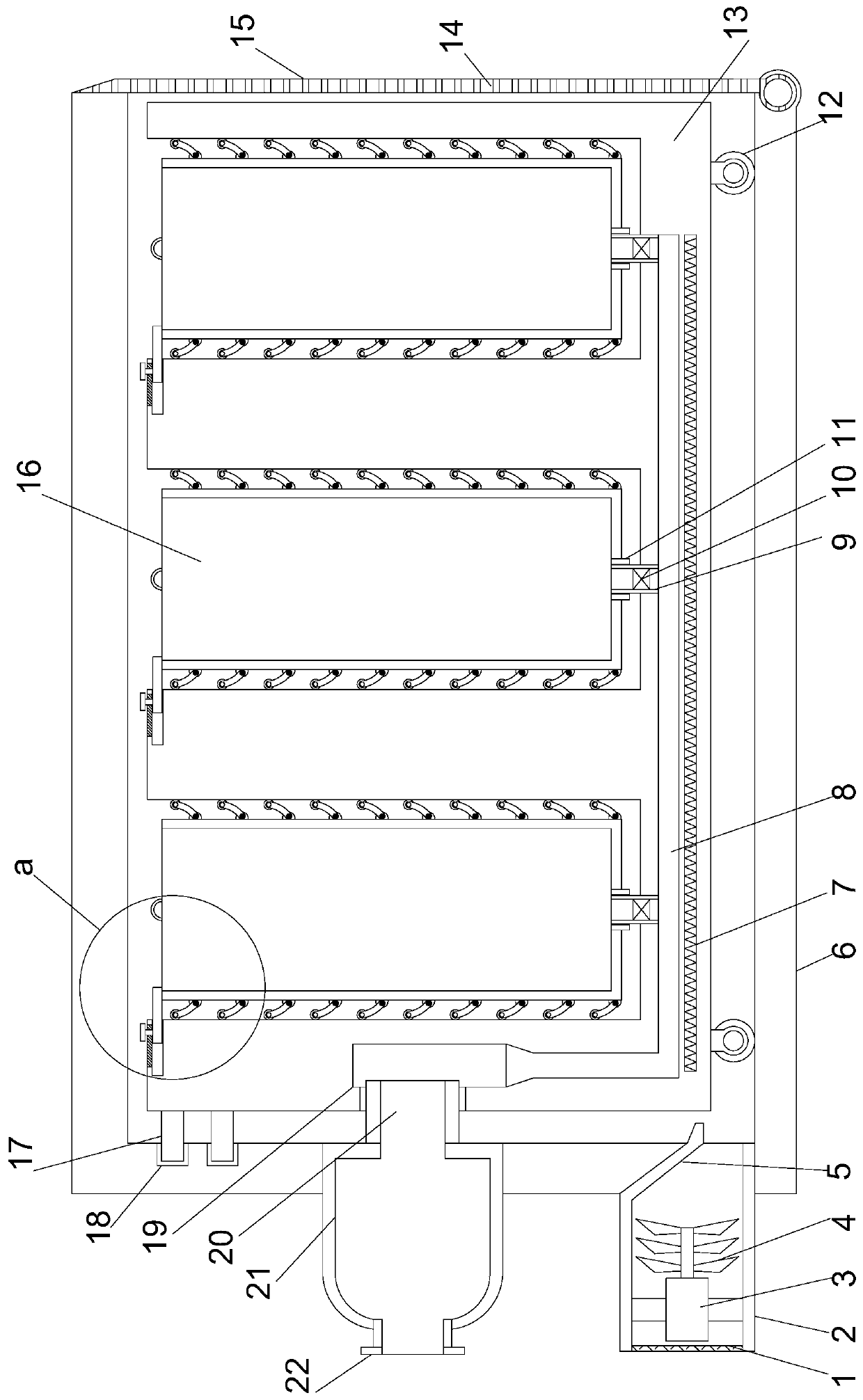

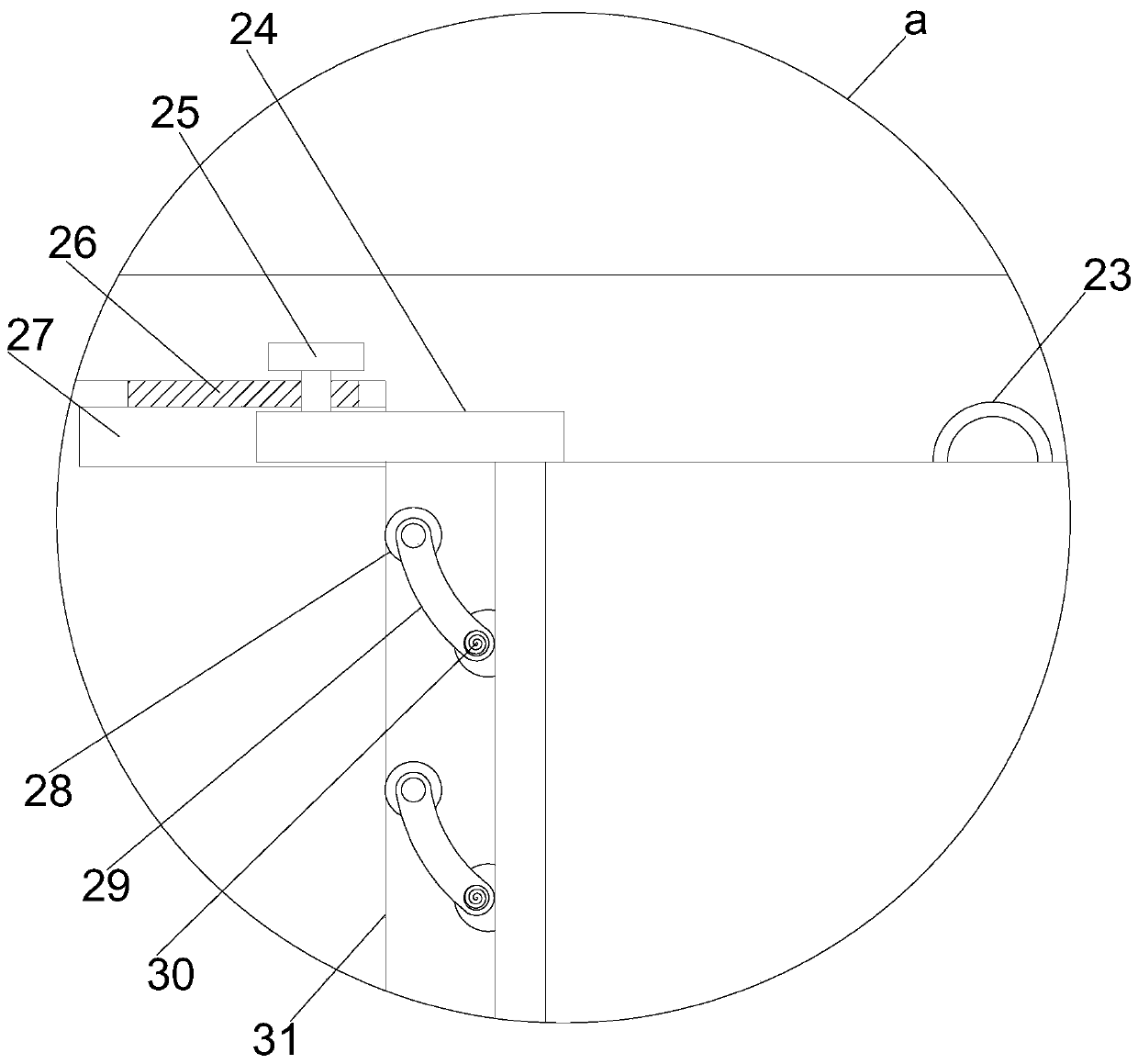

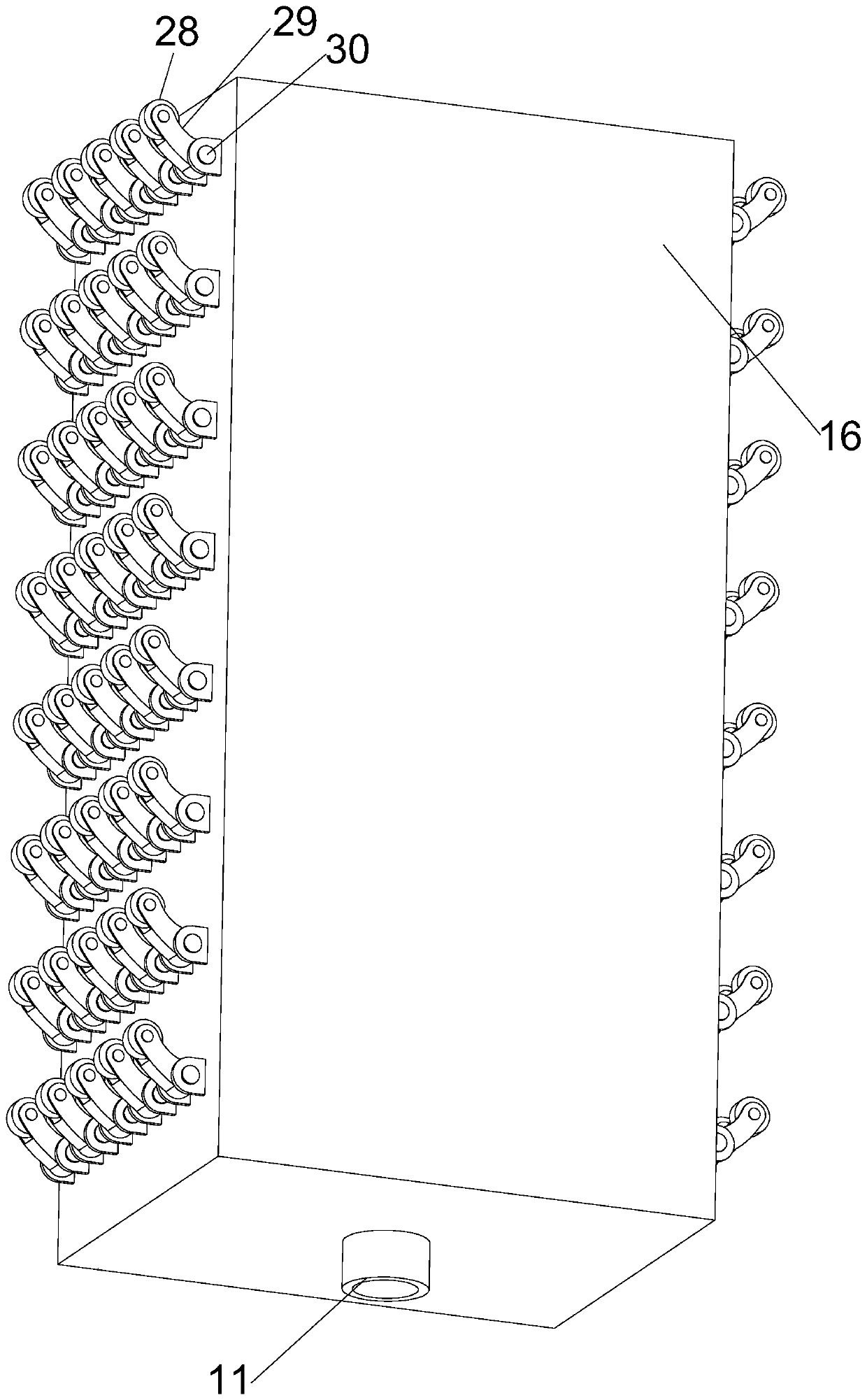

[0024] see Figure 1~3 , in an embodiment of the present invention, a one-cavity multi-style automotive accessories injection mold, including a horizontal support installation cover 6, the inside of the support installation cover 6 is horizontally provided with a mobile installation frame 13, and the four corners of the lower end of the mobile installation frame 13 are all provided with Move the guide wheel 12, the right end of the supporting mounting cover 6 is provided with a rotating gate 15, the lower end of the rotating gate 15 is connected with the supporting mounting cover 6 through a rotating shaft, and several ventilation holes 14 are evenly arranged on the rotating gate 15, and the moving mounting frame The upper left end of 13 is provided with two groups of conductive pillars 17, and the inside of the supporting installation cover 6 cooperates with the conductive pillars 17 to be provided with conductive grooves 18, and three groups of guide installation grooves 31 a...

Embodiment 2

[0027] On the basis of Embodiment 1, after the injection mold is installed in the guide installation groove 31, the upper end of the mold installation frame 16 is limited by operating the sliding block 25 to push the sliding guide column, which ensures the stability of the mold during the injection molding process and avoids the injection molding process. The problem of overflow, and the cooperation of the conductive column 17 and the conductive groove 18, enables the electric heating coil 7 at the bottom to be activated to ensure that the imported materials can always maintain fluidity and avoid blockage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com