A hydraulic gelling material and its preparation device and method

A technology for hydraulic cementation and raw materials, which is applied in the field of gypsum-based hydraulic cementitious materials, hydraulic cementitious materials and their preparation devices, can solve the problems of insufficient toughness, high energy consumption and high heat loss, and achieves reduction of greenhouse gases Emissions, stable production, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0261] Embodiment 1: prepare hydraulic cementitious material I

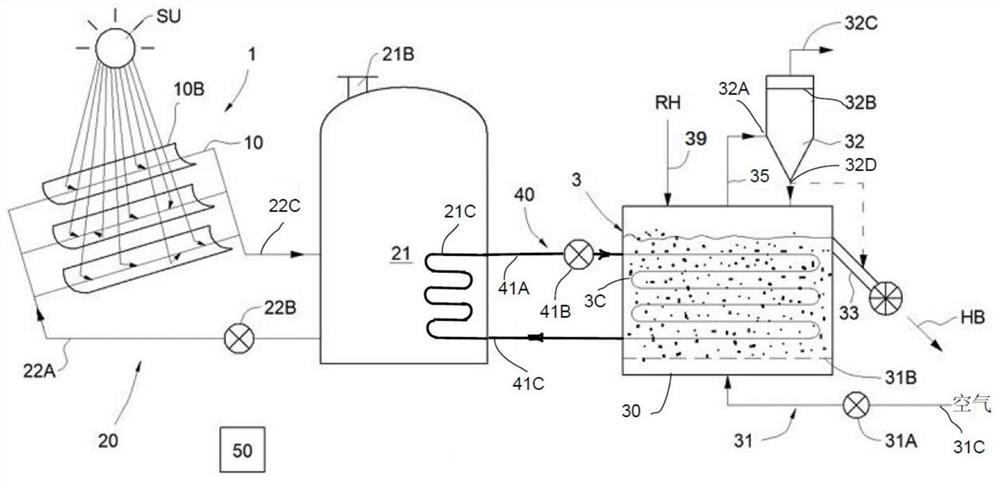

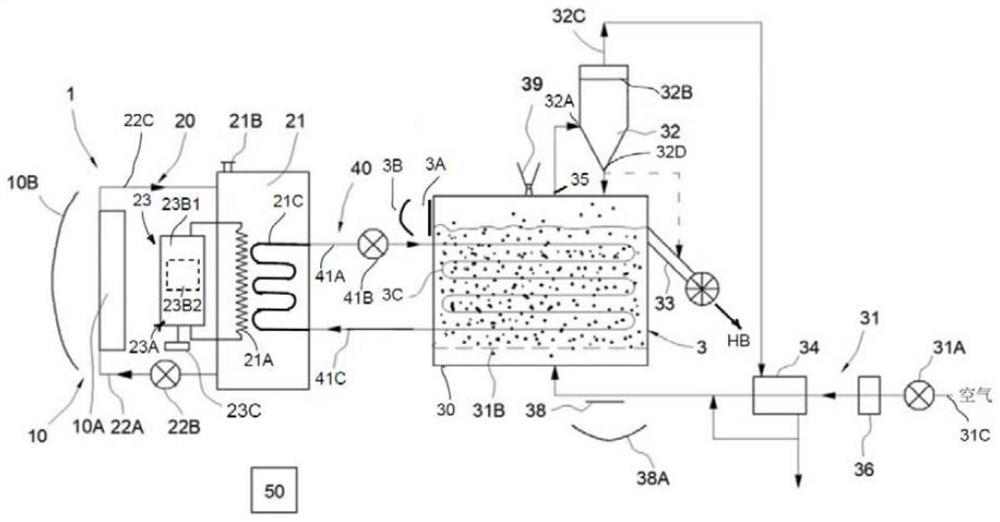

[0262] The heat transfer oil (such as Dow Corning Dimethicone PMX-200) in the heat transfer oil storage tank 21 (the storage tank equipped with a drying device is preferred to deal with the moisture that may exist) passes through the upstream solar heat collection system 1 (for example, Trough solar heat collection system) is heated to 235°C by solar energy. The volume of the heat transfer oil storage tank 21 is designed according to the energy consumption of at least 24 hours of continuous production of the gypsum-based hydraulic cementitious material (that is, greater than the average daily output of 2.4 tons) (calculated according to the solar radiation conditions of the installation site and the composition of raw materials).

[0263] The mixed material that fluidized bed reactor 30 fills comprises: (1) about 120kg / h phosphogypsum (the by-product during phosphoric acid industrial production), and described ph...

Embodiment 2

[0275] Embodiment 2: Preparation of hydraulic gelling material II

[0276] Embodiment 2 is different from Embodiment 1: (1) the raw material that fluidized-bed reactor 30 fills in is by the natural gypsum of 120kg / h (containing free water mass fraction is 5%) and 10kg / h through pulverized powdery Quicklime composition; (2) During the entire residence time (20 minutes) of the reaction mixture in the fluidized bed reactor 30, the temperature is maintained at 160°C (±2°C). All the other conditions are the same as in Example 1.

[0277] The hydraulic gelling material II contains the following components (mass fraction): calcium sulfate hemihydrate (CaSO 4 1 / 2H 2 O) 80.7%, anhydrous calcium sulfate (CaSO 4 )7.3%, calcium hydroxide (Ca(OH) 2 ) 12.0%.

[0278] The hydraulic gelling material II has the following properties:

[0279] - Setting time (DIN 1168): initial setting time 75 minutes, final setting time 95 minutes;

[0280] - Yield (DIN 1164): 86 l / 100 kg dry material; ...

Embodiment 3

[0285] Embodiment 3: Preparation of hydraulic gelling material III

[0286] The difference between embodiment 3 and embodiment 2 is: (1) the raw material that the reactor fills is the desulfurization gypsum (flue gas desulfurization product of 130kg / h, and above-mentioned desulfurization gypsum contains the free water of mass fraction 18% and mass fraction 7-8 % unreacted calcium hydroxide); (2) the temperature of the reaction mixture was maintained at 165° C. (± 2° C.) throughout the residence time (40 minutes) of the reactor. All the other conditions are the same as in Example 2.

[0287] The hydraulic gelling material III contains the following components (mass fraction): calcium sulfate hemihydrate (CaSO 4 1 / 2H 2 O) 78.2%, anhydrous calcium sulfate (CaSO 4 )12.1%, calcium hydroxide (Ca(OH) 2 ) 10.0%.

[0288] The hydraulic gelling material III has the following properties:

[0289] - Hardening time (DIN 1168): initial setting time 110 minutes, final setting time 160 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com