Bottom sill structure for force elimination pool

A stilling pool bottom plate and stilling pool technology, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., and can solve problems such as cavitation, impact damage, and insufficient water flow energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

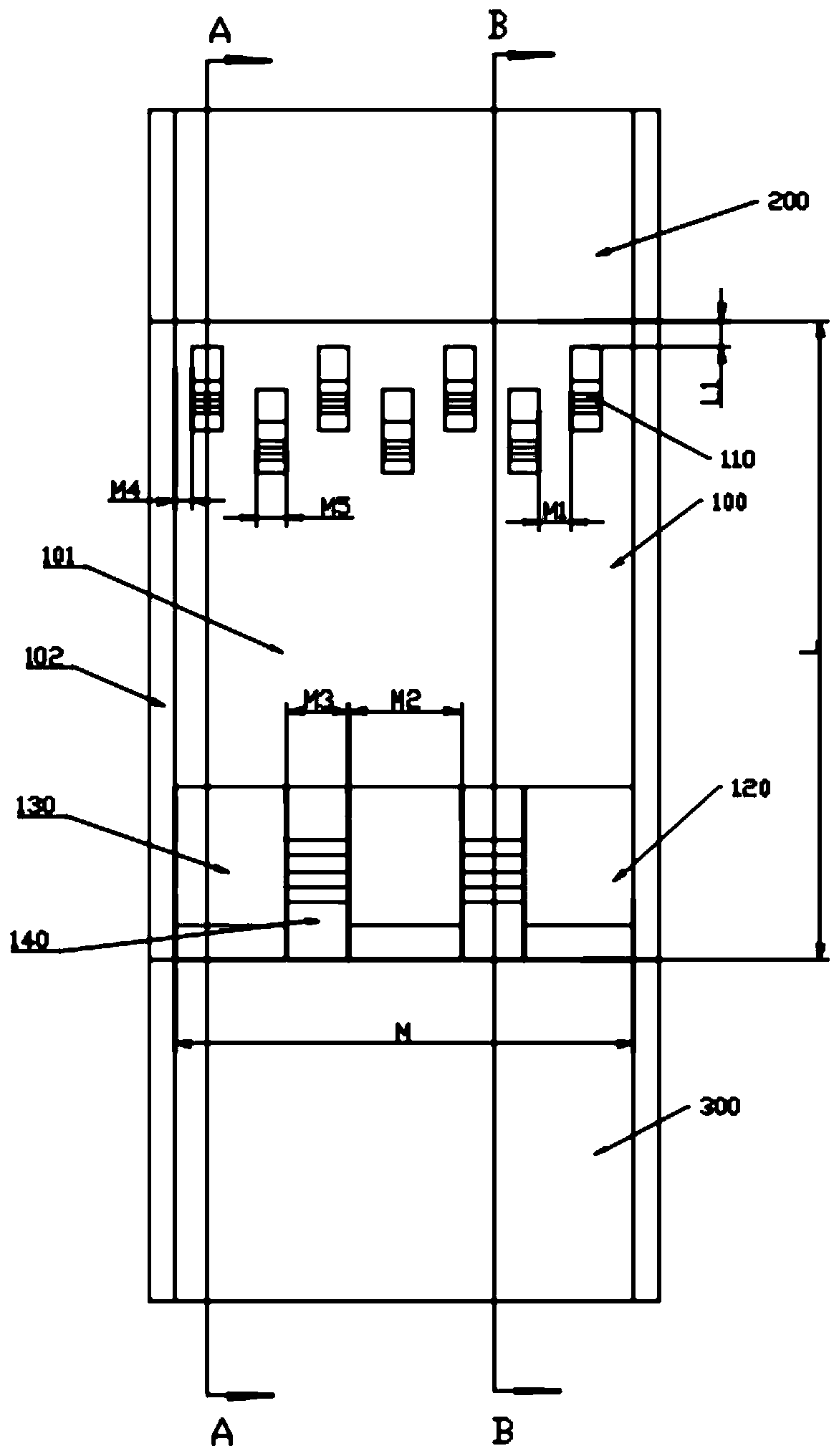

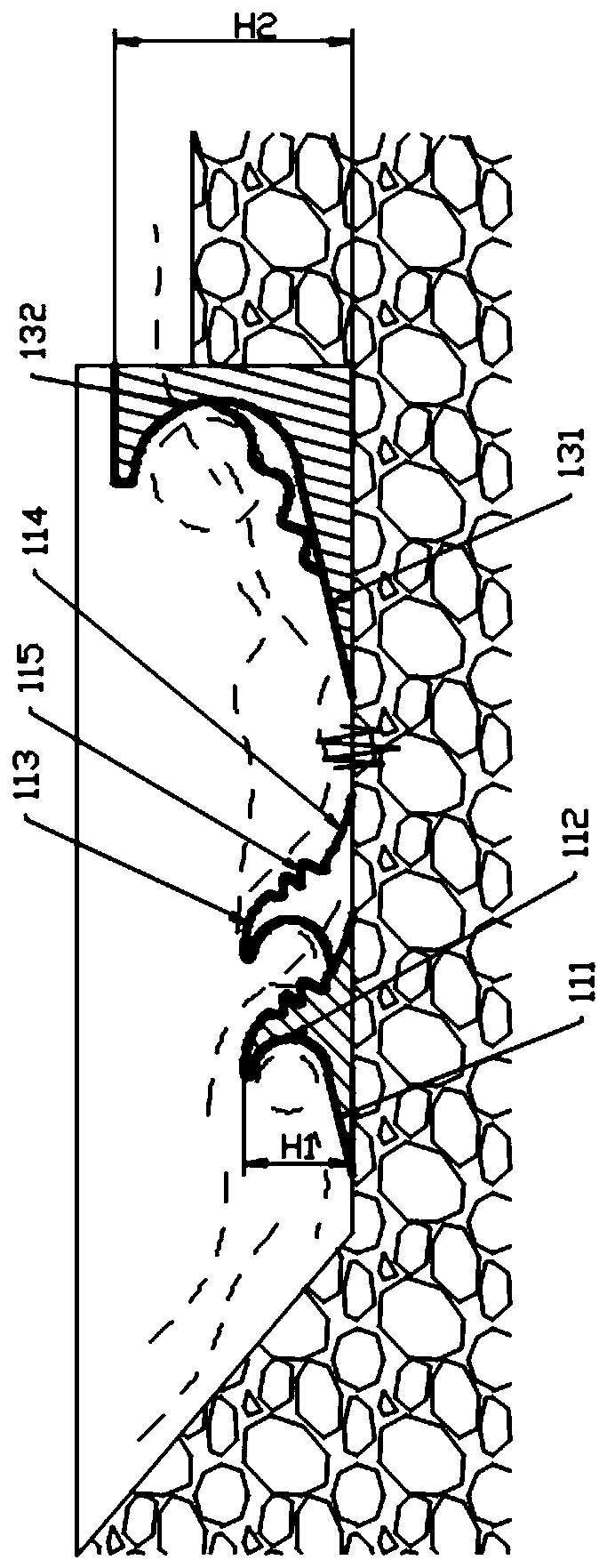

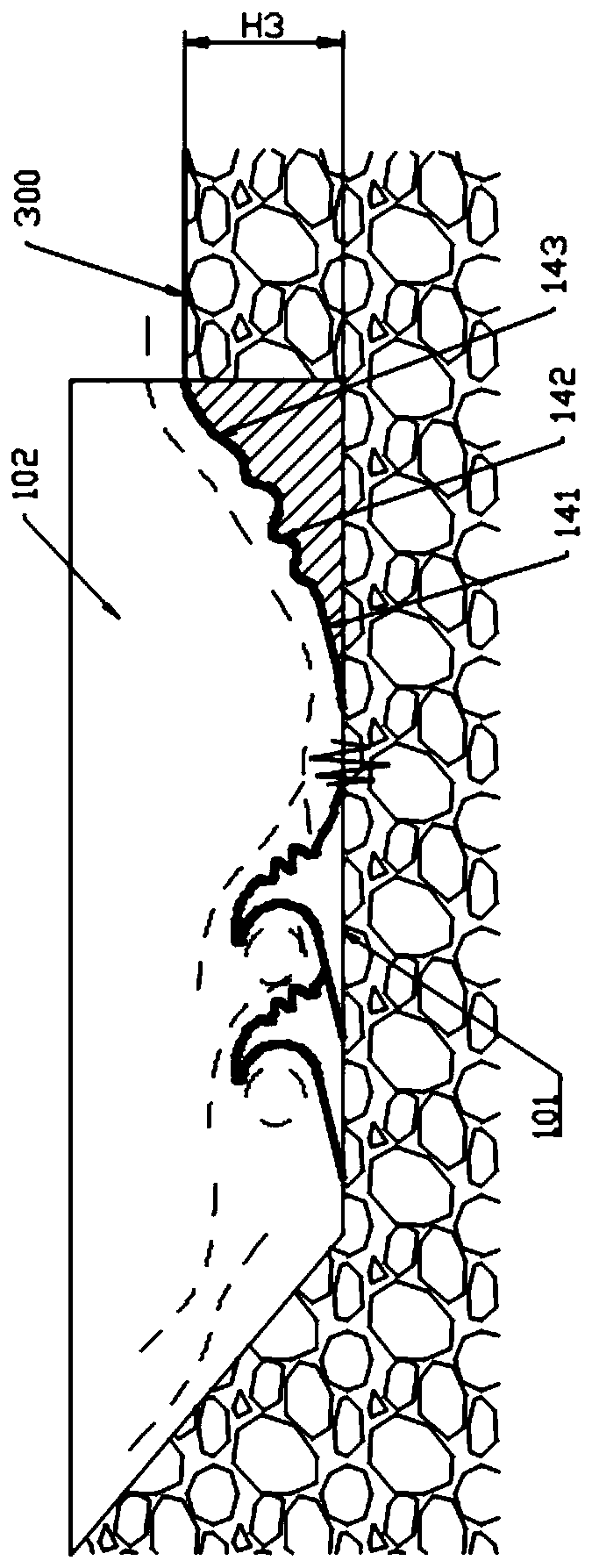

[0024] Example: such as Figure 1-3 As shown, a stilling basin 100 includes a stilling basin bottom plate 101 and a stilling basin side plate 102 . The upstream part of the stilling basin is connected to the overflow tank 200, the downstream part of the stilling basin is connected to the apron 300, and the depth of the stilling basin is greater than that of the apron. A front bottom sill 110 at the upstream part and a rear bottom sill 120 at the downstream part are arranged on the floor of the stilling basin. The front bottom sill is opposite to the overflow tank, and is used to reduce the kinetic energy of the water flowing down from the overflow tank. The tail sill is arranged between the stilling basin and the apron, and is used to further dissipate the energy of the water flow downstream of the stilling basin and make it flow into the apron smoothly, reducing the length of the apron.

[0025] In this embodiment, the front bottom sills 110 are divided into two rows along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com