A construction method of aluminum alloy formwork roof end plate for pipe gallery

A technology of aluminum alloy formwork and construction method, which is applied in the direction of formwork/formwork/work frame, artificial island, water conservancy projects, etc., can solve the problems of difficulty in roof installation and construction, and smaller construction size of shaped formwork, achieving good combination effect, Increased safety factor, cost and time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below, but it should be noted that the implementation of the present invention is not limited to the following embodiments.

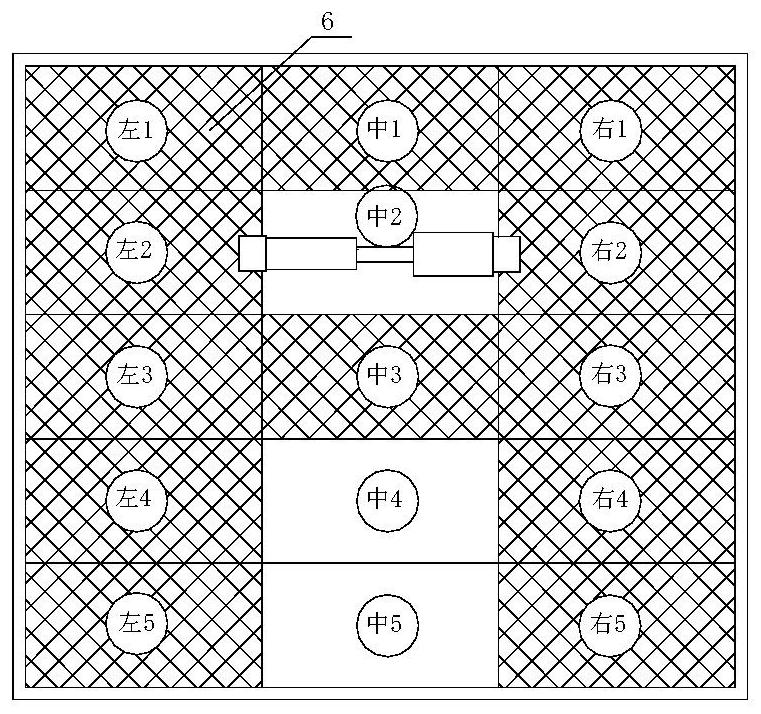

[0028] See Figure 1-Figure 6 , a construction method of the aluminum alloy formwork roof end plate of a pipe gallery, comprising the following methods:

[0029] 1) Make a jack tensioning tool. In order to compensate the length of the jack and adapt to the length of the template, weld the length compensation block 4 at the end of the piston of the jack 5, weld the positioning frame 1 at the end of the length compensation block 4, and weld the positioning frame 1 at the other end of the jack 5 Also welding positioning frame 1, described positioning frame 1 is L type, and laser emitter 2 is installed on the positioning frame 1 upper end, and laser emitter 2 can adopt laser pointer.

[0030] 2) After installing the bottom plate and side wall formwork of the pipe gallery, install the roof formwork 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com