Constant-voltage driven COB light source

A light source and low-voltage technology, which is applied in the field of constant voltage driving COB light sources, can solve the problems of no light, overcurrent of other LED light sources, etc., achieve installation and cost reduction, facilitate large-scale automatic production, and reduce thermal resistance of heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

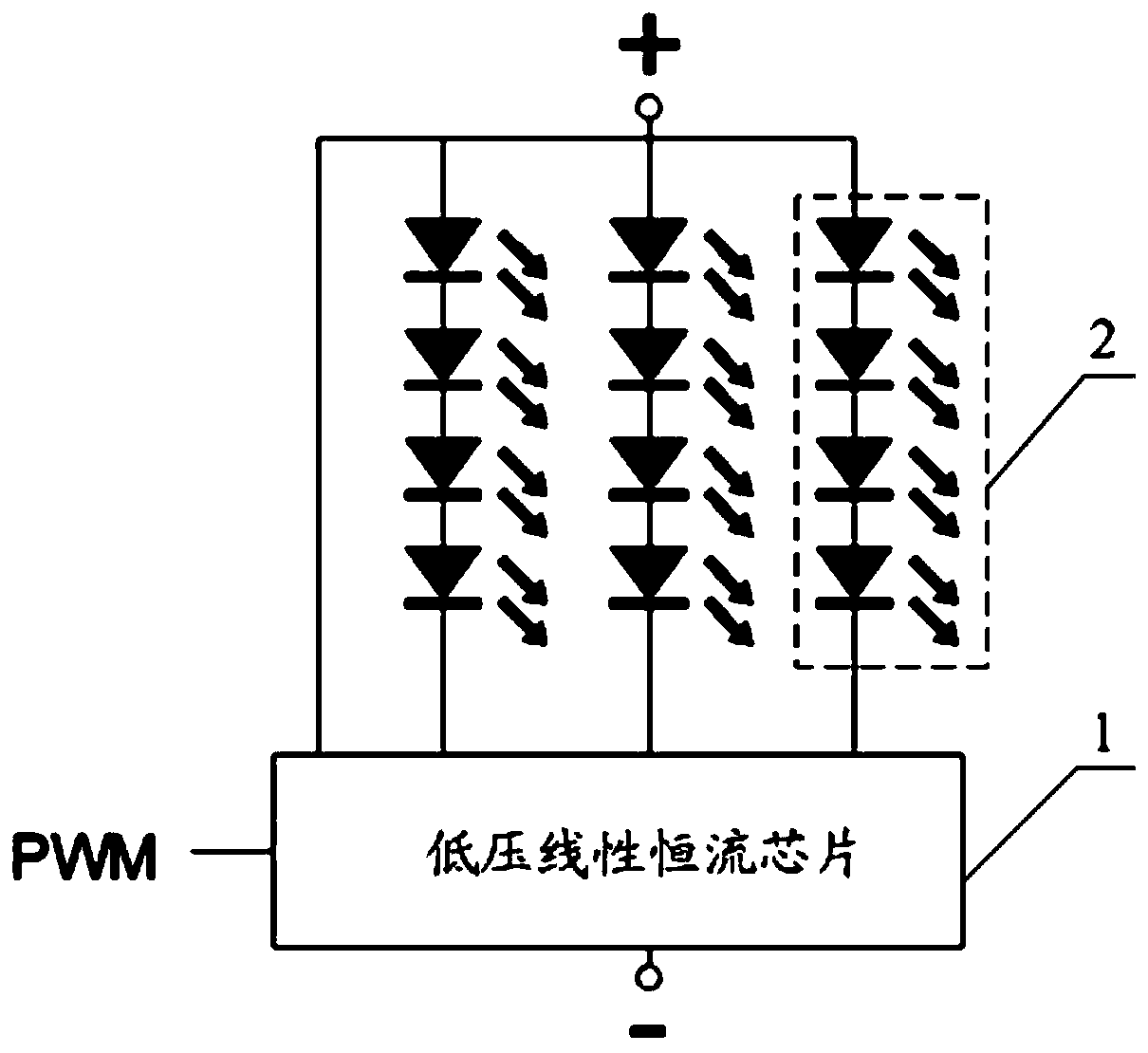

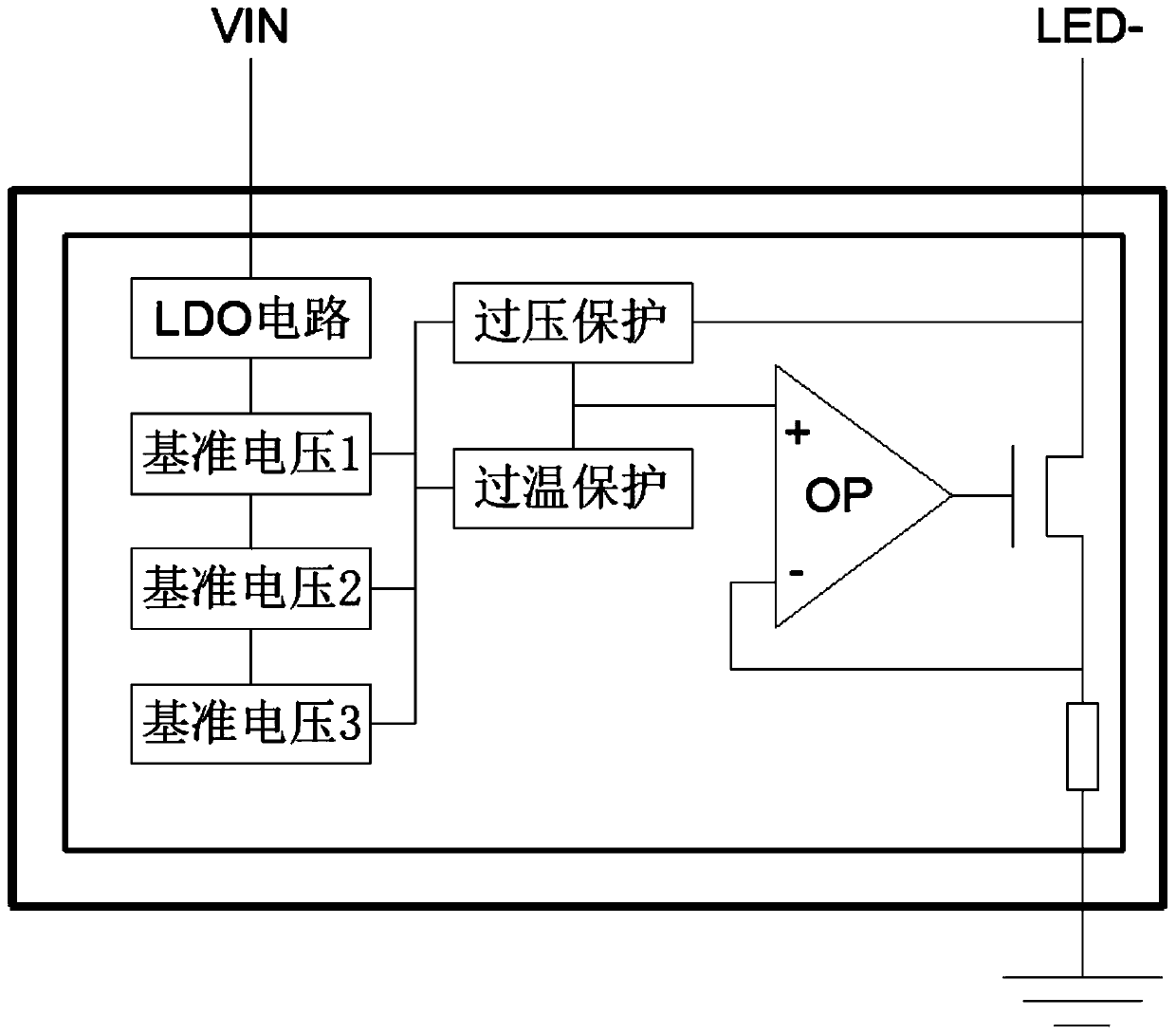

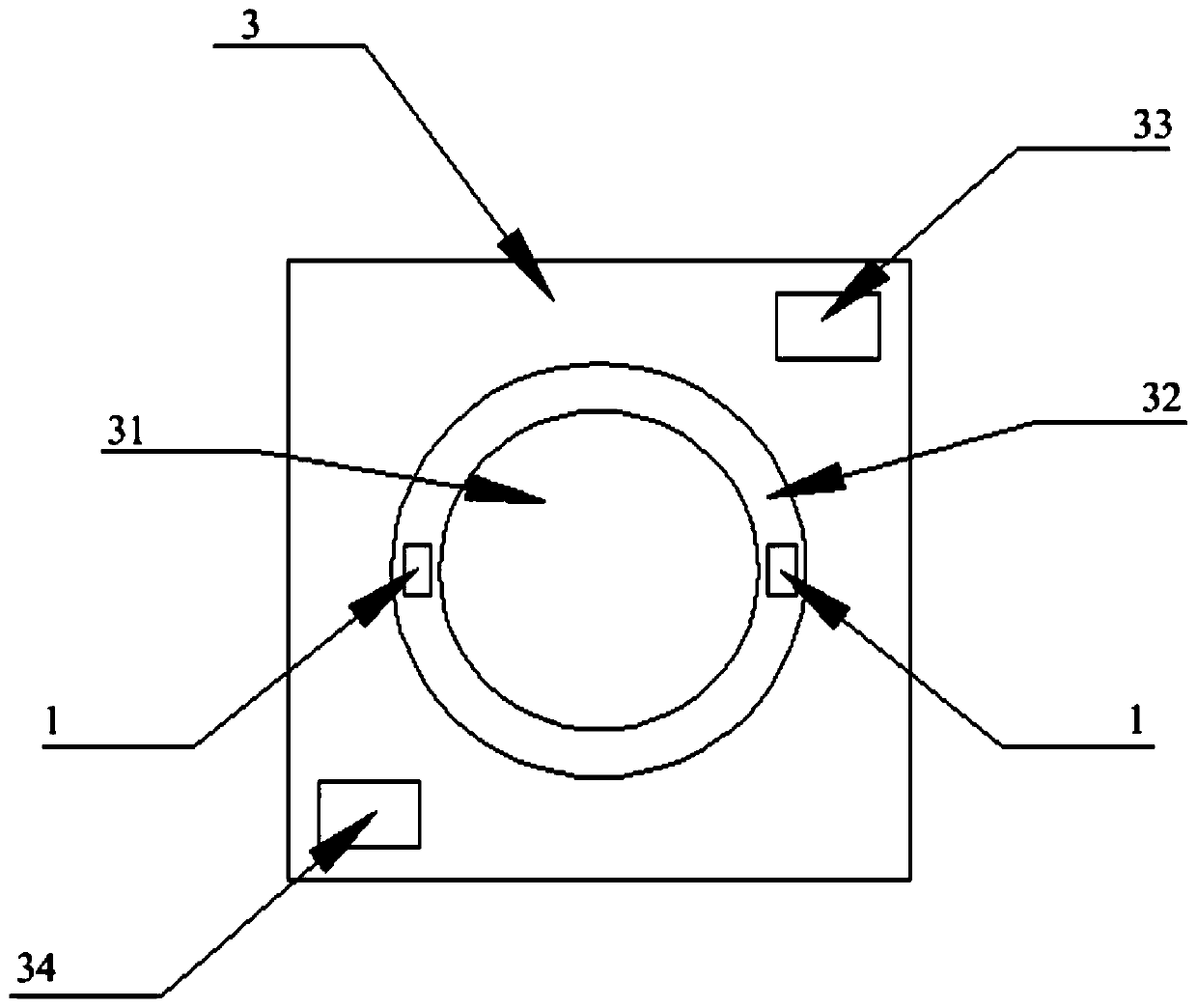

[0023] see figure 1 , figure 1 It shows the specific structure of the constant voltage driving COB light source of the present invention, which includes a COB substrate and at least one set of light-emitting modules packaged on the COB substrate, each light-emitting module includes a one-to-one corresponding LED module 2 and a low-voltage A linear constant current chip 1; the LED module 2 includes at least one LED chip, and the LED chip and the low-voltage linear constant current chip 1 are integrally packaged on the COB substrate in a bare crystal manner; the LED module 2 The positive pole is connected to an external power supply, and the external power supply is used to provide a low-voltage DC power supply of 12-42V for the LED chip; the negative pole of the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com